TS100 RIDE-ON TROWEL INSTRUCTION MANUAL

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

200 COMMERCE DRIVE, FREEHOLD, NEW JERSEY, USA, 07728, 732-566-5400 FAX 732-566-5444

Created: 06/05

Revised: 06/14

- 3 -

TABLE OF CONTENTS

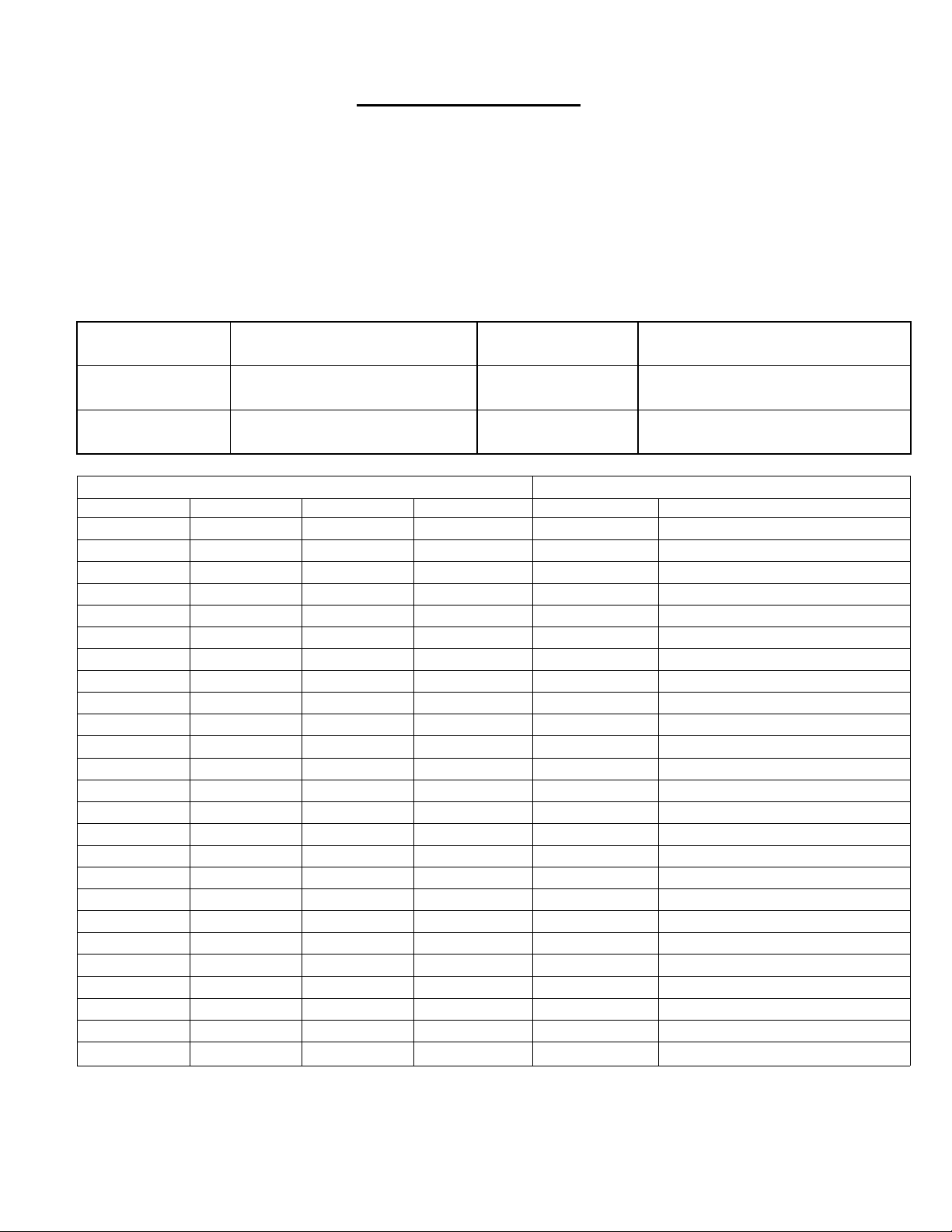

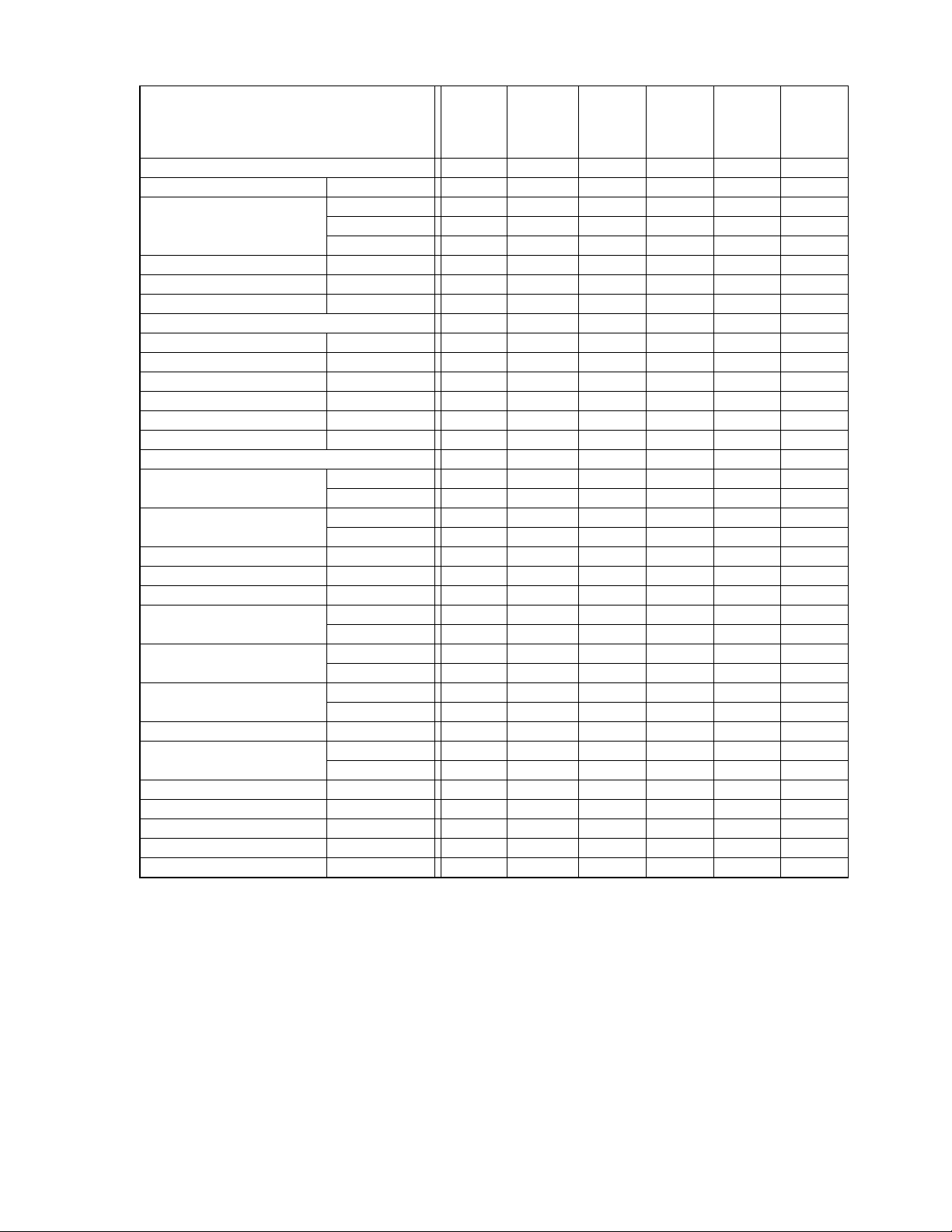

QUALITY ASSURANCE/MACHINE BREAK-IN................................ 4

RIDE-ON POWER TROWEL WARRANTY........................................ 5

MAINTENANCE RECORD................................................................. 6

ROUTINE SERVICE INTERVALS...................................................... 7

FOREWORD....................................................................................... 9

SAFETY PRECAUTIONS................................................................... 9

ASSEMBLY INSTRUCTIONS............................................................ 9

1. BATTERY........................................................................................ 9

2. PITCH CONTROL SYSTEM (FIGURE 1)....................................... 9

3. SEAT ASSEMBLY ........................................................................ 10

4. TRANSPORTER ASSEMBLY....................................................... 10

OPERATING INSTRUCTIONS......................................................... 10

1. STARTING PROCEDURES - WARM TEMPERATURES ............ 10

2. STARTING PROCEDURES - COLD TEMPERATURES.............. 10

3. STOPPING PROCEDURES.........................................................10

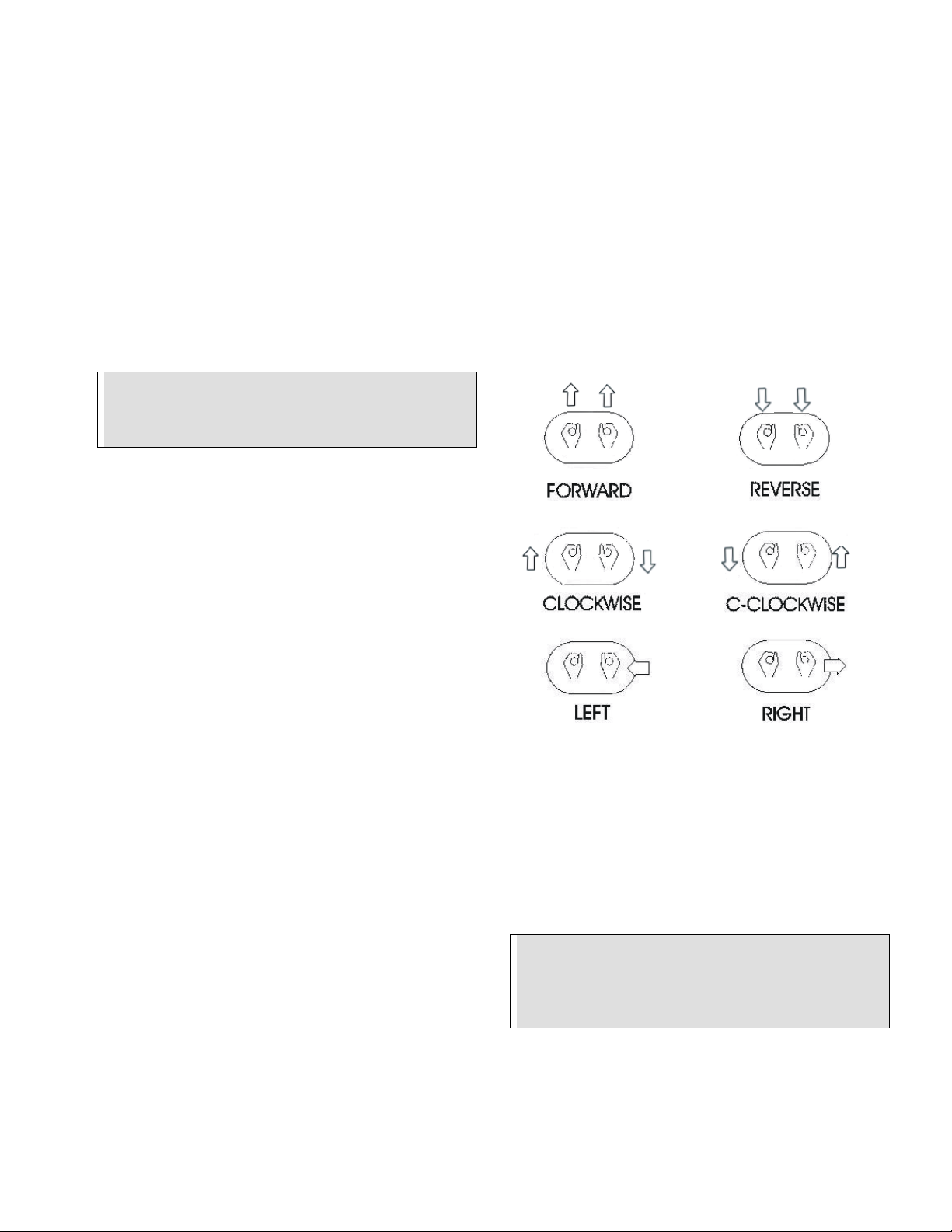

4. STEERING (FIGURE 2)................................................................ 10

5. FLOAT/TROWEL PITCH SETTING.............................................. 11

6. BLADE SYNCHRONIZATION (FIGURE 3)................................... 11

7. TRANSPORTER USE................................................................... 11

MAINTENANCE INSTRUCTIONS.................................................... 11

1. GENERAL..................................................................................... 11

2. AIR CLEANER.............................................................................. 11

3. SPARK PLUG............................................................................... 11

4. BELT CHANGE PROCEDURE..................................................... 12

5. BELT TENSIONING SPECIFICATION (FIGURE 4)..................... 12

LUBRICATION ................................................................................. 12

1. ENGINE OIL.................................................................................. 12

2. SPIDER PLATE ............................................................................ 12

3. GEARBOX ....................................................................................12

4. GEARBOX OIL CHANGE.............................................................12

5. GREASE FITTINGS...................................................................... 12

ASSEMBLY DRAWINGS AND PARTS LIST...................................13

1. CHASSIS ASSEMBLY (FIGURE 1) ..............................................14

CHASSIS PARTS LIST.................................................................16

2. POWERPLANT ASSEMBLY (FIGURE 2).....................................18

POWERPANT PARTS LIST..........................................................19

3. DRIVE TRAIN ASSEMBLY (FIGURE 3) .......................................20

DRIVE TRAIN PARTS LIST..........................................................21

4. STEERING ASSEMBLY (FIGURE 4)............................................22

STEERING PARTS LIST...............................................................23

5. GEARBOX ASSEMBLY (FIGURE 5) ............................................24

GEARBOX PARTS LIST...............................................................25

6. PITCH CONTROL ASSEMBLY (FIGURE 6).................................26

PITCH CONTROL ASSEMBLY PARTS LIST...............................27

7. SPIDER PLATE ASSEMBLY (FIGURE 7)/ PRESSURE

PLATE ASSEMBLY (FIGURE 8)...................................................28

SPIDER PLATE ASSEMBLY / PRESSURE PLATE

ASSEMBLY PARTS LIST..............................................................29

8. TROWEL BLADE ASSEMBLY (FIGURE 9)..................................30

TROWEL BLADE PARTS LIST.....................................................31

9. RETARDANT SPRAY SYSTEM (FIGURE 10)..............................32

RETARDANT SPRAY SYSTEM PARTS LIST..............................33

10. TRANSPORTER ASSEMBLY (FIGURE 11) ..............................34

TRANSPORTER PARTS LIST......................................................35

11. TRANSPORTER DOLLY ASSEMBLY (FIGURE 12) .................36

TRANSPORTER DOLLY PARTS LIST.........................................37

12. TRANSPORTER HANDLE ASSEMBLY (FIGURE 13) ..............38

TRANSPORTER HANDLE PARTS LIST......................................39

13. ELECTRICAL SCHEMATIC (FIGURE 14) .................................40

TROUBLESHOOTING......................................................................41

SPECIFICATIONS ............................................................................42

COMPANY INFORMATION..............................................................43

NOTES ..............................................................................................44