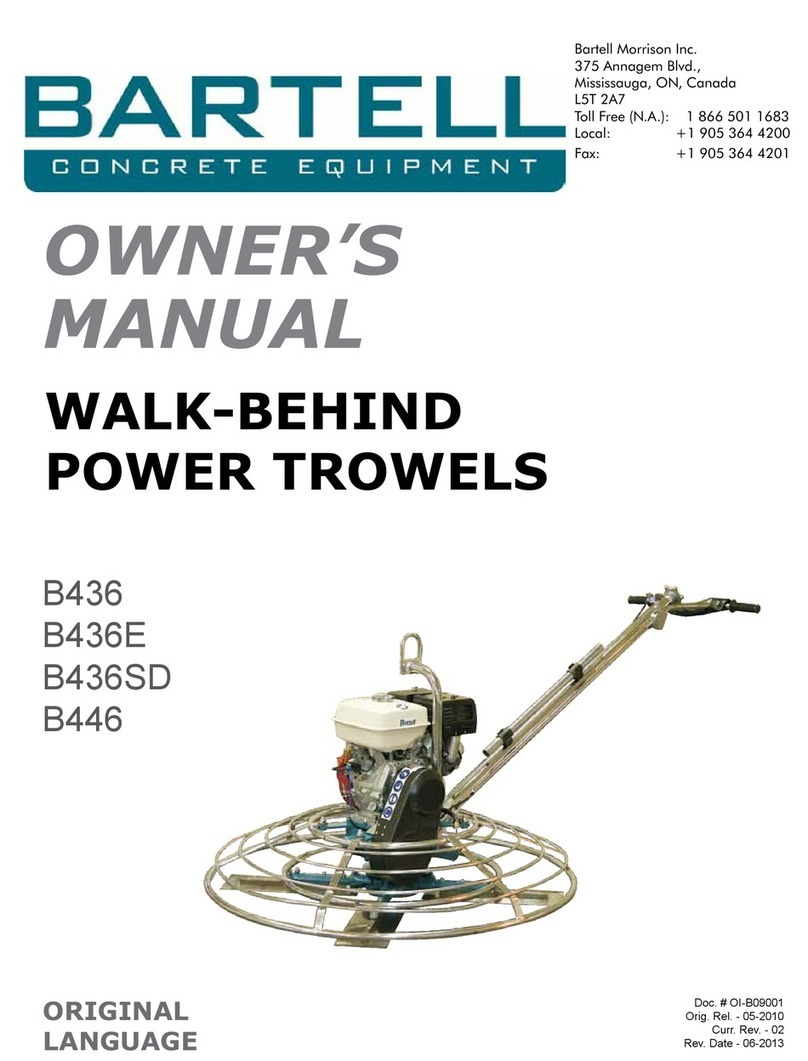

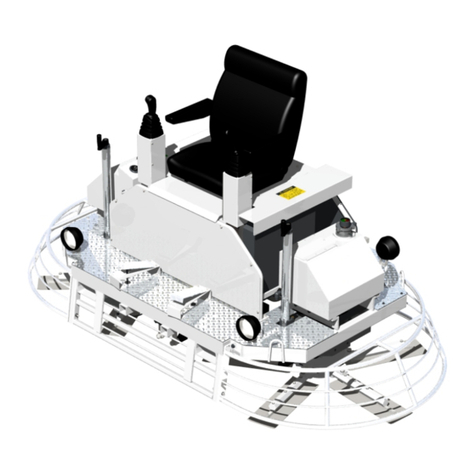

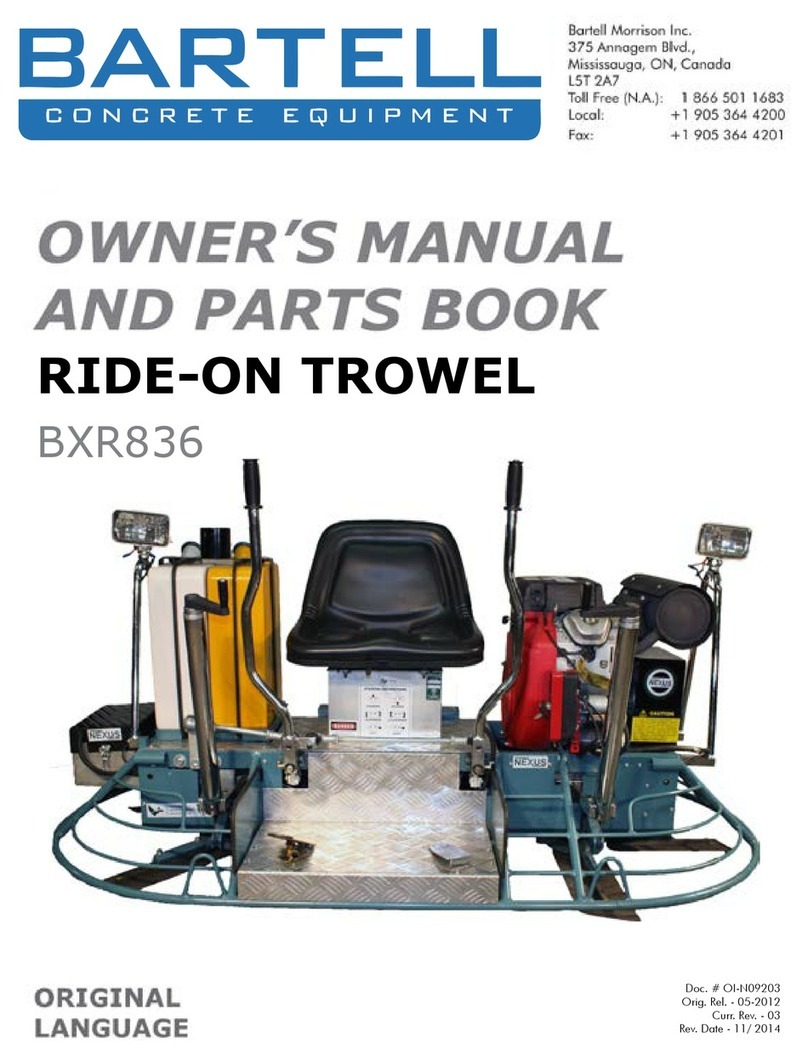

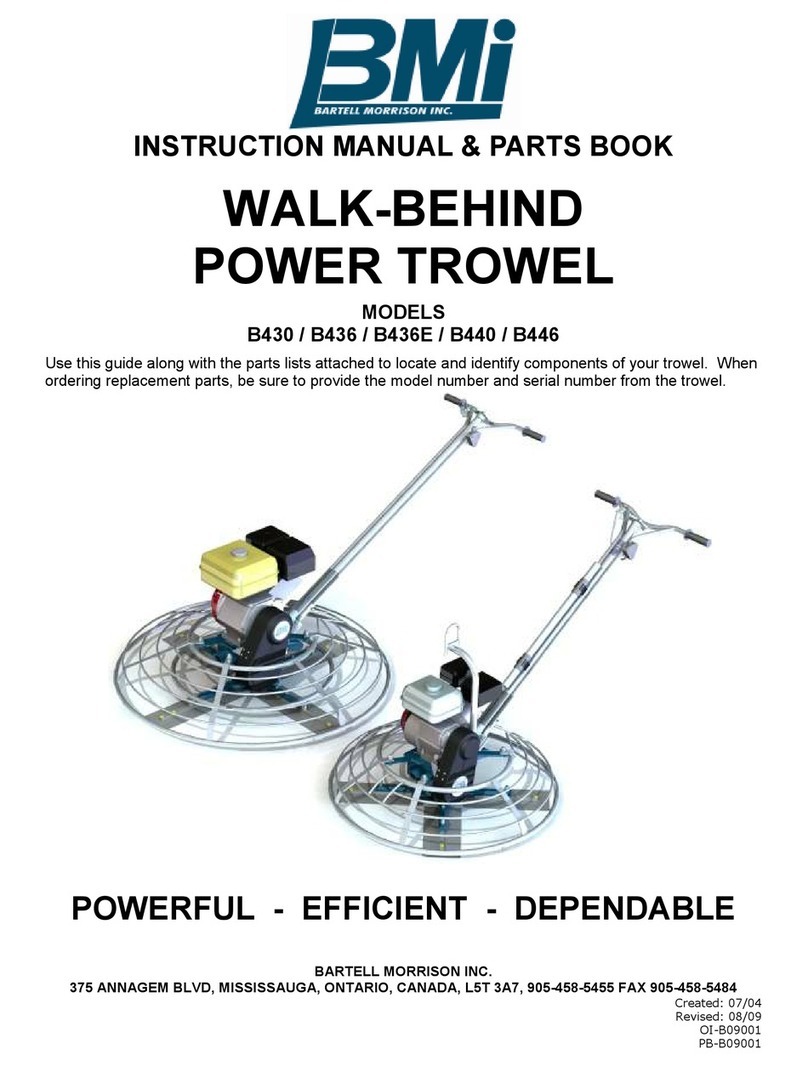

TS74 RIDE-ON TROWEL INSTRUCTION MANUAL

BARTELL MORRISON INC. BARTELL MORRISON (USA) LLC

375 ANNAGEM BLVD, MISSISSAUGA, ONTARIO, CANADA, L5T 3A7, 905-364-4200 FAX 905-364-4201

200 COMMERCE DRIVE, FREEHOLD, NEW JERSEY, USA, 07728, 732-566-5400 FAX 732-566-5444

Created: 04/08

Revised: 06/14

- 3 -

TABLE OF CONTENTS

QUALITY ASSURANCE/MACHINE BREAK-IN ........................................................................................4

MAINTENANCE RECORD.........................................................................................................................5

ROUTINE SERVICE INTERVALS..............................................................................................................6

FOREWORD..............................................................................................................................................8

SAFETY PRECAUTIONS ..........................................................................................................................8

ASSEMBLY INSTRUCTIONS....................................................................................................................8

1. BATTERY...............................................................................................................................................8

2. STEERING HANDLE ASSEMBLY..........................................................................................................8

3. PITCH CONTROL ASSEMBLY (FIGURE 1)...........................................................................................8

4. SEAT ASSEMBLY..................................................................................................................................9

5. TRANSPORTER ASSEMBLY ................................................................................................................9

OPERATING INSTRUCTIONS...................................................................................................................9

1. STARTING PROCEDURES - WARM TEMPERATURES.......................................................................9

2. STARTING PROCEDURES - COLD TEMPERATURES ........................................................................9

3. STOPPING PROCEDURES...................................................................................................................9

4. STEERING (FIGURE 2) .........................................................................................................................9

5. FLOAT/TROWEL PITCH SETTING......................................................................................................10

6. BLADE SYNCHRONIZATION (FIGURE 3)...........................................................................................10

7. TRANSPORTER USE..........................................................................................................................10

MAINTENANCE INSTRUCTIONS ...........................................................................................................10

1. GENERAL............................................................................................................................................10

2. AIR CLEANER......................................................................................................................................10

3. SPARK PLUG.......................................................................................................................................10

4. BELT CHANGE PROCEDURE.............................................................................................................11

5. BELT TENSIONING SPECIFICATION (FIGURE 4)..............................................................................11

LUBRICATION.........................................................................................................................................11

1. ENGINE OIL.........................................................................................................................................11

2. SPIDER PLATE....................................................................................................................................11

3. GEARBOX............................................................................................................................................11

4. GEARBOX OIL CHANGE.....................................................................................................................11

5. GREASE FITTINGS .............................................................................................................................11

TROWEL ARM ADJUSTMENT FIXTURE ...............................................................................................12

ASSEMBLY DRAWINGS AND PARTS LIST...........................................................................................13

1. CHASSIS ASSEMBLY (FIGURE 1).....................................................................................................14

CHASSIS PARTS LIST.......................................................................................................................15

2. POWERPLANT ASSEMBLY (FIGURE 2) / POWERPLANT PARTS LIST...........................................16

3. DRIVE TRAIN ASSEMBLY (FIGURE 3)...........................................................................18

DRIVE TRAIN PARTS LIST................................................................................................................19

4. STEERING ASSEMBLY (FIGURE 4) ..................................................................................................20

STEERING PARTS LIST ....................................................................................................................21

5. GEARBOX ASSEMBLY-LH (FIGURE 5).............................................................................................22

GEARBOX PARTS LIST.....................................................................................................................23

6. GEARBOX ASSEMBLY-RH (FIGURE 6).............................................................................................24

GEARBOX PARTS LIST.....................................................................................................................25

7. PITCH CONTROL ASSEMBLY (FIGURE 7)........................................................................................26

PITCH CONTROL PARTS LIST..........................................................................................................27

8. SPIDER PLATE ASSEMBLY (FIGURE 8) / PRESSURE PLATE ASSEMBLY (FIGURE 9).................28

SPIDER PLATE ASSEMBLY / PRESSURE PLATE ASSEMBLY PARTS LIST ..................................29

9. TROWEL BLADE ASSEMBLY (FIGURE 10).......................................................................................30

TROWEL BLADE PARTS LIST...........................................................................................................31

10. TRANSPORTER ASSEMBLY (FIGURE 11).......................................................................................32

TRANSPORTER PARTS LIST............................................................................................................33

TROUBLESHOOTING.............................................................................................................................34

SPECIFICATIONS ...................................................................................................................................35

COMPANY INFORMATION.....................................................................................................................36

NOTES.....................................................................................................................................................37

RIDE-ON POWER TROWEL WARRANTY……………………………………………………………………....38

SAMPLE OF CE CERTIFICATE…………………………………………………………………………………..40