BASI PR 800 User manual

Door Bar

PR 800/900

PR 900 = application

for door leaf widths from 900 to 1,050 mm

PR 800 = application

for door leaf widths from 800 to 950 mm

burglary protection for inwards opening doors

INSTALLATION INSTRUCTIONS

facebook.com/BASIGmbH @basi_gmbh www.basi.eu

General notes

Intended use

The PR 800/900 ZA reinforced bolt lock

provides additional protection against

unauthorised entry into rooms. It is suit-

able for inwards opening wooden, metal

and plastic doors with a width of 800 to

950 mm

(PR 800 ZA), or 900 to 1,050

mm

(PR 900 ZA).

Please follow the instructions in this man-

ual to assemble the reinforced bolt lock

correctly. The ideal level of protection can

only be achieved if you follow these as-

sembly and operating instructions appro-

priately. Keep the assembly instructions

safe in case you need to remove the lock

or replace the cylinder.

Warnings: No hazards are to be

expected if the device is used in

accordance with the instructions

and in a professional manner.

Small parts and packaging materials can

be swallowed by children and lead to

choking! Make sure that small parts and

packaging materials do not get into the

hands of children. Dispose of the pack-

aging material immediately.

These installation instructions cannot

cover all application cases. If you have

any further questions, please contact

your dealer or subcontractor.

The manufacturer expressly reserves the

right to make technical changes.

Disclaimer

The manufacturer accepts no liability for

damage and/or injury resulting from im-

proper handling and/or assembly of the

product or use of the required tools. If you

use power tools (e.g. drill), follow all safety

instructions of the tool manufacturer.

Scope of delivery

Check that the delivery is complete:

•

1x reinforced bolt lock (1)

•

1x BM double profile cylinder

30/55mm for TS 40 mm (22)

• 2x side parts, plastic (6)

•

1x inner rosette ZA, stainless steel (16)

•

1x inner rosette, plastic (15)

• 2x spring washers (23)

• 2x screw M5x35 (17)

• 4x screw M5x15 (20)

• 4x screw M4x10 (cylinder head) (19)

• 4x screw M6x75 (10)

Türblattstärke

door thickness

• 4x dowel 8x40 (8)

• 2x expansion dowel 10x112 (9)

• 2x strike plate (13) with covers (14)

• 12x spacer plate 2 mm (11)

• 2x spacer plate 12 mm (12)

• 3x keys

Required tools

• various screwdrivers

• drill

• metal drill: Ø 13,0mm (also use for

wood),

Ø13.5mm, Ø15.0mm, Ø18.5mm,

Ø10.0mm

• stone drill: Ø 10.0mm

(min. 180mm)

• hole cutter/saw: Ø 35 mm

• spirit level, tape measure

General installation tips

Preface to installation: Before

installation, make sure that the

reinforced bolt lock is suitable for the

structural conditions. Depending on

the door thickness, order a suitable

double profile cylinder. Tighten the

fastening screws by hand with a suitable

screwdriver to avoid overtwisting.

Designed for double profile cylinders:

Installation steps

1. Remove the housing cover (7) from the

reinforced bolt lock and place it centrally

on the door leaf from the interior side,

so that the distances to the edges of the

door leaf are equal.

2. Mark the hole for the cylinder and drill

a hole with a diameter of 35 mm at the

desired height in the door leaf. Note: the

distance up to the middle of the double

profile cylinder is 387 mm.

*appropriate double profile cylinder

door thickness model design

40 mm 30/55 mm

45 mm 30/60 mm

50 mm 30/65 mm

55 mm 30/70 mm

60 mm 30/75 mm

65 mm 30/80 mm

70 mm 30/85 mm

75 mm 30/90 mm

min. 12 + door thickness

If the double profile cylinder

is already installed, continue

with Step 10. Otherwise, install

the double profile cylinder as

follows:

3. Remove the screws and spring

washers (19) from the cylinder plate (18).

4. Take the cylinder plate out and remove

the plastic insert.

5. Remove the gear inserted under the

cylinder plate (4, 5)

6. Slide one part (4) of the gear onto the

double profile cylinder from the left, and

the other part (5) from the right. The wider

segment of the gear parts is placed on

the lock pin (21) of the double profile

cylinder. Both parts form an interlocking

connection with the locking nose.

7. Insert the double profile cylinder into

the cylinder plate (18) and fasten the

cylinder with the M5x15 screws (20) and

spring washers (23).

8. Slide the gear racks (2, 3) onto the

stop, so that the crossbar is in what will

later become the opening position. The

locking bit must fit into the wide recess

on the gear rack.

9. Now insert the assembled cylinder into

the reinforced bolt lock with the cylinder

plate and fasten the plate with the screws

and spring washers (19).

Now fasten the reinforced bolt lock to

the door:

10. Place the reinforced bolt lock with the

inserted double profile cylinder, so that

the cylinder is in the drill hole in the door.

11. Align the crossbar with the spirit level

and mark both fastening holes for the ZA

outer rosette (16).

12. Drill the holes with a 12 mm Ø drill bit.

13. Reinsert the reinforced bolt lock, slide

the ZA outer rosette (16) over the locking

cylinder on the outer side of the door and

fasten the rosette with the spring washers

and M4x10 screws (19) (cylinder head).

14. Check the alignment with the spirit

level, mark the holes at the ends (24).

15. Drill the holes and fasten the

reinforced bolt lock to the door leaf with

the M5x35 screws (17).

16. Put the cover (7) back on and press

the side parts (6) and the plastic inner

rosette (15) in.

(covert)

X = bolt adjustable three times on both sides

Assembling the strike plates:

17. Place the strike plates (13) at the

height of the crossbar on the door frame

or on the wall on both sides.

Tip: When you have finished the

reinforced bolt lock, you can slide the

strike plate over the extended crossbar.

This makes alignment easier.

18. Mark the drill holes.

19. Remove the strike plates, unlock the

lock, drill holes for the dowels and insert

the wall dowels (8).

20. Place enough spacer plates (11, 12)

between the wall and the strike plate for

the crossbar to glide easily into the strike

plate without tension. Make sure that

the ‘noses’ of the spacer plates lock into

the corresponding recesses on the next

spacer plate.

21. Attach the strike plates with the

M6x75 screws (10).

22. Now drill the holes for the expansion

dowel (9). Insert the expansion dowel and

tighten it.

23. Press to close the covers (14) on the

strike plates (13).

Cleaning/maintenance

NEVER use any pray oils etc. Clean

the crossbar regularly with a cloth. The

mechanics inside have been adequately

greased ex-works.

Disposal

Help to protect the

environment and dispose of

the product and the packaging materials

in accordance with the local regulations.

© Copyright

Reproduction or duplication (even

excerpts thereof) is forbidden without

approval of:

BASI GmbH Konstantinstraße 387

41238 Mönchengladbach

Germany

2023

This publication, including all its parts, is

protected by copyright.

Any use outside the narrow limits of

copyright law without the consent of

BASI GmbH is not allowed and liable to

prosecution.

This applies in particular to duplications,

translations, microfilming and the

feeding and processing in electronic

systems.

BASI GmbH

Konstantinstraße 387

41238 Mönchengladbach

Germany

X = bolt adjustable three times on both sides

(optionally available)

N

o

t

i

n

c

l

u

d

e

d

i

n

t

h

e

d

e

l

i

v

e

r

y

!

X = bolt adjustable three times on both sides

(covert)

This manual suits for next models

13

Table of contents

Popular Door Opening System manuals by other brands

argenta

argenta INVISIDOOR SDX-125 manual

Eco

Eco FSA ECO SR-EFR BG Assembly instruction

Dorma

Dorma PT 51 Installation instruction

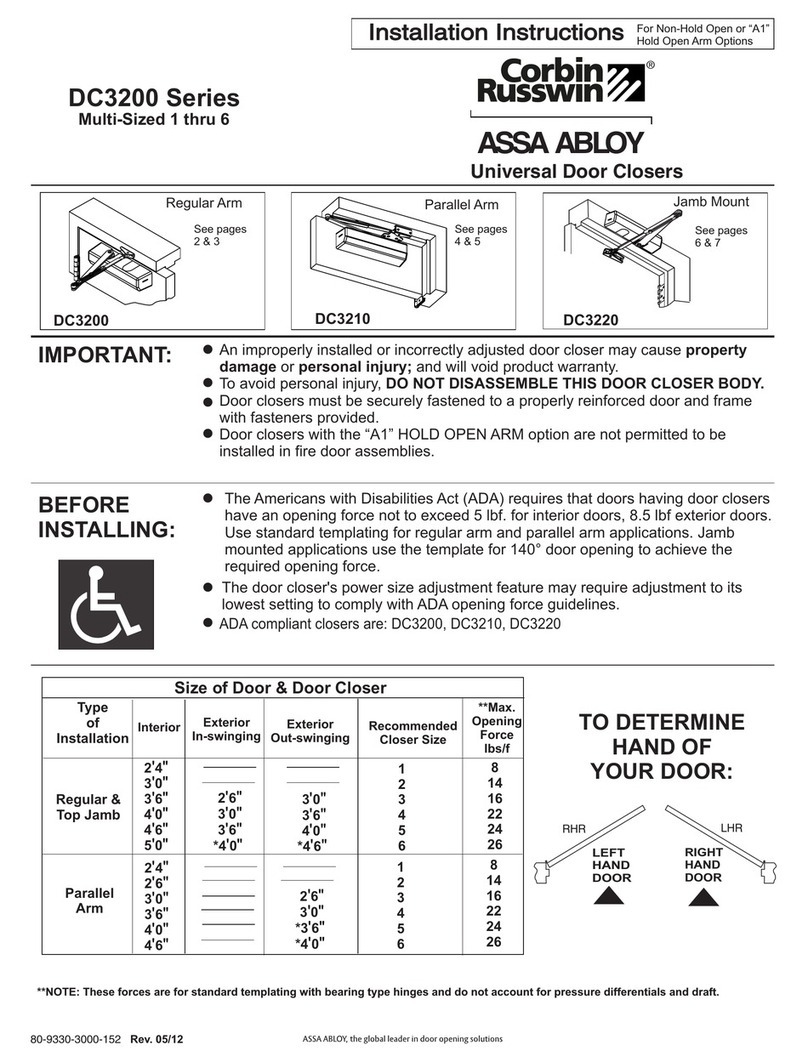

Assa Abloy

Assa Abloy DC3210 installation instructions

Dormakaba

Dormakaba HSW EASY SAFE installation instructions

MANTION SMT

MANTION SMT WIBAT APPLIQUE installation instructions

FritsJurgens

FritsJurgens Top pivot Reversed Mounting manual

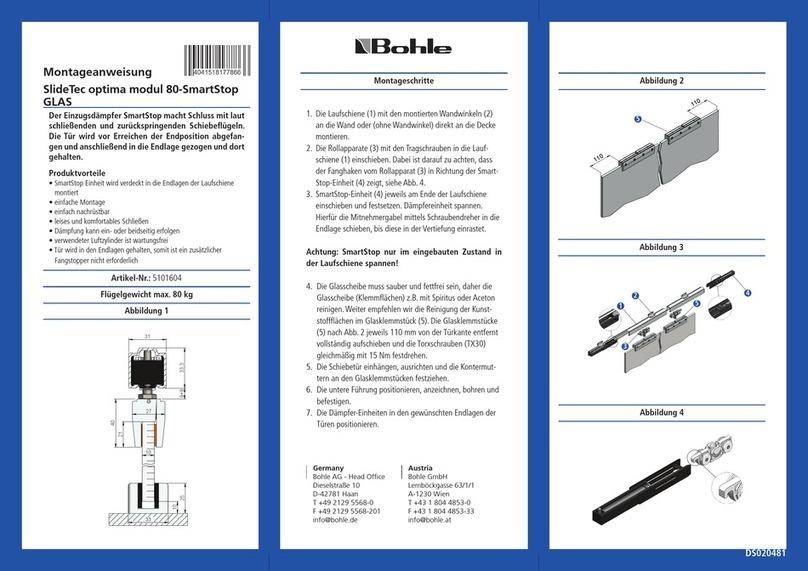

Bohle

Bohle SmartStop GLASS installation instructions

Automatic Technology

Automatic Technology Syncro ATS-3 Quick operation guide

Criminalistics

Criminalistics Premier Canine System Plus manual

DITEC

DITEC DOD Technical manual

Von Duprin

Von Duprin XP98 installation instructions