3

IP2395EN

General safety precautions

ATTENTION! Important safety instructions.

Follow these instructions carefully. Failing to follow the

instructions contained in this manual may result in serious

personal injury or damage to the equipment.

Keep these instructions for future reference.

This manual and the manuals for any accessories can be

downloaded at www.ditecautomations.com

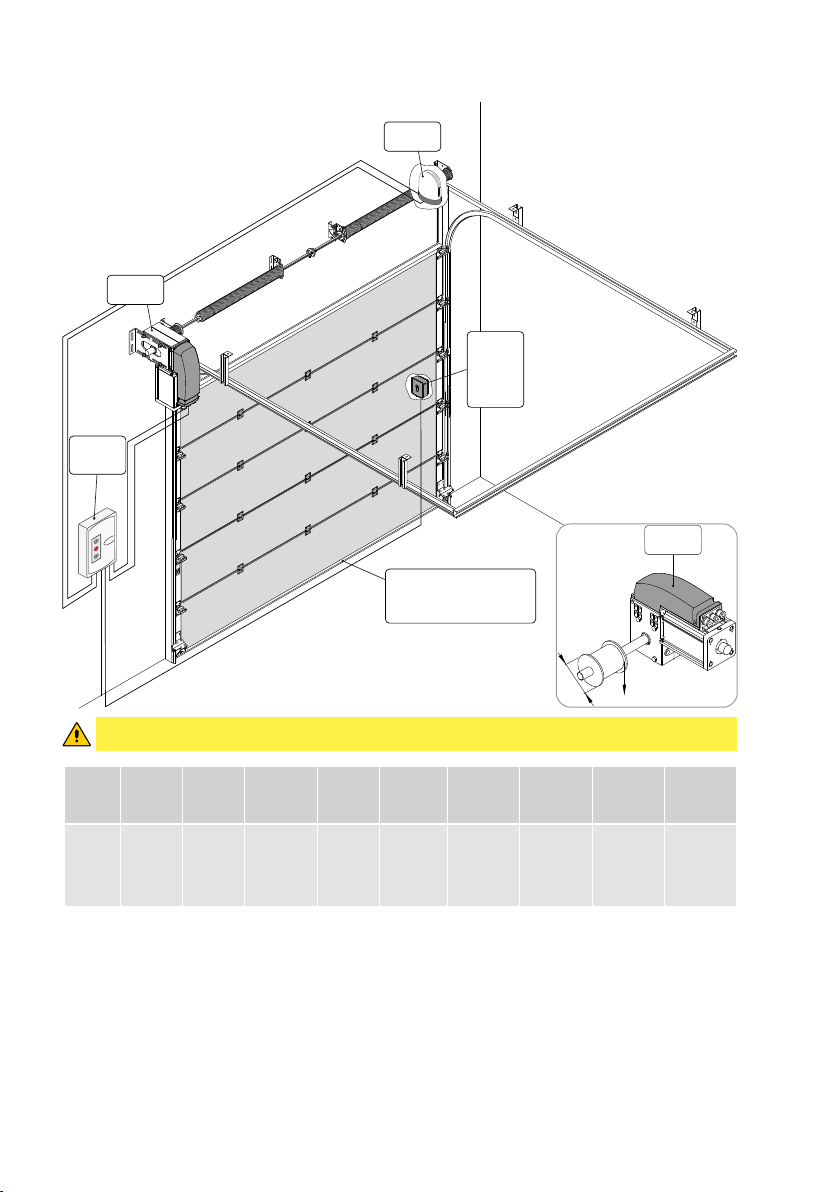

This installation manual is intended for qualified personnel only •

Installation, electrical connections and adjustments must be car-

ried out by qualified personnel in accordance with Good Engineering

Practice and in compliance with the regulations in force • Read the

instructions carefully before starting to install the product. Incorrect

installation could cause dangerous situations • Check the integrity

of the product before starting installation

Packaging materials (plastic, polystyrene, etc.) should not be

discarded into the environment or left within the reach of

children, as they are potentially dangerous • Do not install the

product in an explosive environment or atmosphere. The presence

of flammable gases or fumes is a serious safety hazard • Ensure

that the operating temperature range indicated in the technical

data is compatible with the place of use • Before installing the

motorisation, check that the existing structure and the support

and guide components have the required strength and stability.

Check the stability and smoothness of the guided part and ensure

that there is no risk of derailment or falling. Make all structural

modifications necessary to create safety barriers and protect or

segregate all crushing, shearing, conveyance and danger zones

in general. The manufacturer of the motorisation system is not

liable for non-compliance with Good Engineering Practice in build-

ing the door or gate to be motorised or for any deformation that

may occur during use • The safety devices (photocells, sensitive

edges, emergency stops, etc.) should be installed in consideration

of the standards and directives in force, Good Engineering Practice,

the installation environment, the operating logic of the system and

the forces created by the motorised door or gate • The safety