BASI BPT50-A User manual

BASI Instrument AB, P.O.Box 53, SE-275 06VOLLSJÖ, SWEDEN

tel: +46 (0)40 88009, fax: +46 (0)40 929877, e-mail: info@basi.se

BPT50-A

OPERATION MANUAL

Please read this Operation Manual before mounting and operating!

Save the Manual for future references!

PRESSURE TRANSMITTER WITH DISPLAY

v1-2-03.13

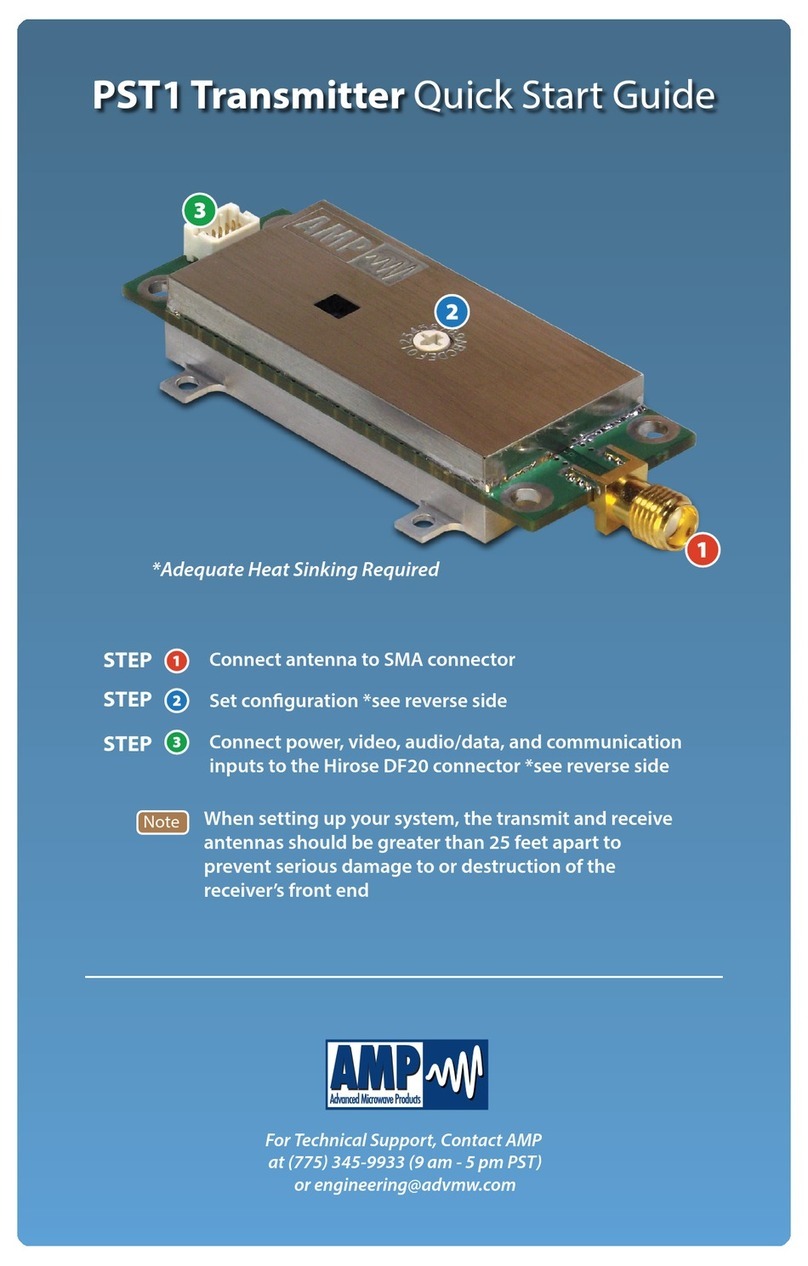

Overview

2

BPT50-A is a combination of a pressure

sensor and a programmable loop-

powered 5-digit LCD display that allows

visualization of the measured pressure

from -9999 to 9999 units. BPT50-A is also

equipped with a programmable pressure

alarm driving a low-power electronic relay

output which can also be used to activate

various electric actuators for ON/OFF

pressure control.

Mounting and Wiring

Important note:

If the medium temperature

is higher than the maximum,

specified for your transmitter,

mount an additional

cooling spiral tube between

the object and the transmitter

in order to decrease

the medium temperature

at the transmitter input.

Mounting

Screw the BPT50-A transmitter to its

exact place using a preinstalled bush

with a female thread matching

the transmitter's one (¼", ½", etc.).

To ensure hermetical mounting,

use a proper gasket (e.g. DIN16258).

The right tightening torque depends

on the gasket material and shape

as well as on the mounting thread.

For mounting, use ONLY a proper

hexagonal wrench applying the torque

ONLYto the hexahedral transmitterhead!

The installation site must be

protected from deep-freezing

and high-temperature sources, and

all environmental conditions must be

within those, specified for your

transmitter type (see 'Specifications').

Wiring

Connect the transmitter via detachable

connector Mini-HIRSCHMAN by following

the markings as shown on the left.

Important note:

The supply voltage must be

greater than the required minimum

(marked on the label) plus

the load voltage drop at 20 mA!

Parameter Programming

3

Some parameters

are accessible only

when the respective

functionality is installed.

(see 'Specifications').

-Changing

Point Position value

reflects on the real value

of all parameters

with ISU!

E.g.: changing

Point Position value

from (0) to (0.0)

would change

a Set-point value

of 100 to 10.0!!!

Device parameters

BPT50-A is a programmable device whose

service behavior is determined by a set

of parameters. All the parameters, along

with their names, symbols, and value ranges,

are given in Table 1.

Setting numerical parameter value

Enter parameter value adjustment mode

(see 'Program Levels').

The whole part of the value together with

the left zeroes appears on the display,

and the rightmost digit blinks.

To select another digit, press .

The 4 rightmost digits can accept values

from 0to9, and the leftmost digit

can accept the value -or none.

To increase or decrease the blinking digit

value, use respectively or .

Confirm the adjusted value by pressing

simultaneously + .

If the new value has not been confirmed

and no key has been pressed for a certain

period of time, value adjustment

automatically ceases, and the parameter

retains its initial value.

Setting symbolic parameter value

Enter parameter value adjustment mode

(see 'Program Levels').

Read the blinking parameter value.

To change the value, use or ,

and to confirm, press + .

If the new value has not been confirmed

and no key has been pressed for a certain

period of time, value adjustment

automatically ceases, and the parameter

retains its initial value.

Table 1

Notes

Configuration Parameters

when indicating values

with the input-signal measurement unit (ISU)

display offset value

higher value for better filtration

For authorized personnel ONLY!

DO NOT SET to YES!

++L_ - activates under set point,

_V++- activates over set point

Keyboard Locking Parameter (parameter of Hidden level)

d"EY (keyboard disabled),

ESP (only set-point adjustment enabled),

E"EY (keyboard enabled)

Unit

-

ISU

ISU

ISU

-

-

-

ISU

-

-

Value

0, 0.0, 0.00, 0.000

-9999 ... 9999

-9999 ... 9999

-9999 ... 9999

0…255

0…3000

no, YES

-9999 ... 9999

++L_, _V++

d"EY,

ESP,

E"EY

Description

Display decimal point position

Display value at low limit of the input range

Display value at high limit of the input range

Constant to be added to the measured input value

Relative time constant of the input filter

Zone around the measured value,

within which the filter is active

Enables / disables calibration mode.

Set-point value of the alarm output

Control action direction of the alarm output

Keyboard locking mode

Symbol

Pnt

ILo

IHi

oFFS

\t

\b

cALE

SP1

dir1

Loc"

Parameter

Point Position

Display Low

Display High

Display Offset

Filter Time

Filter Band

Calibration

Set Point

Direction

Lock

Keyboard

Program Levels

5

Programming order

Unlock the keyboard.

Adjust the configuration parameters.

If needed, restrict the access again

by adjusting the Lock Keyboard parameter.

Access control (Hidden level)

Hold depressed while turning

the power supply on and until

Loc" appears.

Set keyboard locking mode

according to Table 1.

Basic level

At power-on, BPT50-A enters Basic level.

At this level, the device indicates

the measured pressure with a resolution,

according to the Point Position parameter.

If the measured value is greater than

Display High + 10, the display shows

blinking error message {++}.

When the measured value is less than

Display Low - 10, L__V is displayed.

Either error message may appear

on the display also as a result

of a damaged sensor.

Configuration level

Enter from Basic level by pressing

and holding until conF appears

on the display.

Choose a parameter using or .

To enter parameter value

adjustment mode, press .

If no key has been pressed for a while,

the device automatically returns

to Basic level, storing all confirmed

changes.

For quick exiting and saving,

use key combination +or

select rtn and press .

Output Control

6

Alarm output operation

The alarm output operates

according to the control

algorithm parameters.

The sign in the upper left

display corner indicates

activated alarm output.

ON/OFF control algorithm

The static characteristic

of an alarm relay controlled

by an ON/OFF algorithm

is shown on the left drawing.

Input Filtration

Low-pass filter

This first-order filter acts

ONLY within a certain band

around filter output value.

This has been designed

to cut periodic noises

outside the communication

signal spectrum.

Filter operation is defined

by two parameters:

Filter Time (defines filter time

constant) and Filter Band

(defines filter active band

around filter output value).

If the newly measured value

differs from the filter output

by more than Filter Band,

the filter resets with a new

initial output value

(newly measured value).

Waste Disposal

7

Do not dispose of

electronic devices

together with

household waste

material!

If disposed of within European Union,

this product should be treated

and recycled in accordance with the laws

of your jurisdiction implementing

the WEEE Directive 2002/96

on the Waste Electrical and Electronic

Equipment.

Specifications

8

Pressure Range

Output Signal

Alarm Output

Power Supply UB

Voltage Deviation

Loop Voltage Drop

Maximum Line Load

Medium Temperature

Ambient Temperature

Sensor Accuracy

Display Error

Sensor Temperature Drift

Display Temperature Drift

Response Time

Overload

Process Connection

Protection Class: sensor / display

.......................... bar

4…20 mA, 2-wire

SSR 0.12A/240V, MOS gate 0.1A/60V

16…32 VDC, ...............................

2% at 50/60 Hz

max. 6 V

RA[] = (UB[V] - 14 V) / 0.02 A

-30…85 °C

-20…70 °C

1.0% (at medium temperature 10...40 °C)

0.1% from span

0.02% from span for 1 °C

0.01% from span for 1 °C

10 ms (0...99% of span)

1.5 x full span

G¼", G½", ¼" NPT, ½" NPT,

....................................

IP65 / IP44

Warranty and Support

………………………….

serial number

………………………….

manufacturing date

QC check mark …….……(passed)

(stamp)

BASI Instrument AB

p.o.box 53

SE-275 06 VOLLSJÖ, SWEDEN

tel: +46 (0)40 88009

fax: +46 (0)40 929877

e-mail: sales@basi.se

QD-8.2.4-WC

Warranty

BASI Instrument AB warrants this product

to be free from defects in materials

and workmanship for 2 years. If your unit

is found to be defective within that time,

we will promptly repair or replace it.

This warranty does not cover accidental

damage, wear or tear, or consequential

or incidental loss. This warranty

does not cover any defects caused

by wrong transportation, storage, installation,

or operating (see 'Specifications').

Technical support

In the unlikely event that you encounter

a problem with your BASI device,

please call your local dealer or contact

directly our support team.

Table of contents

Other BASI Transmitter manuals