Basler BE1-59N User manual

Other Basler Relay manuals

Basler

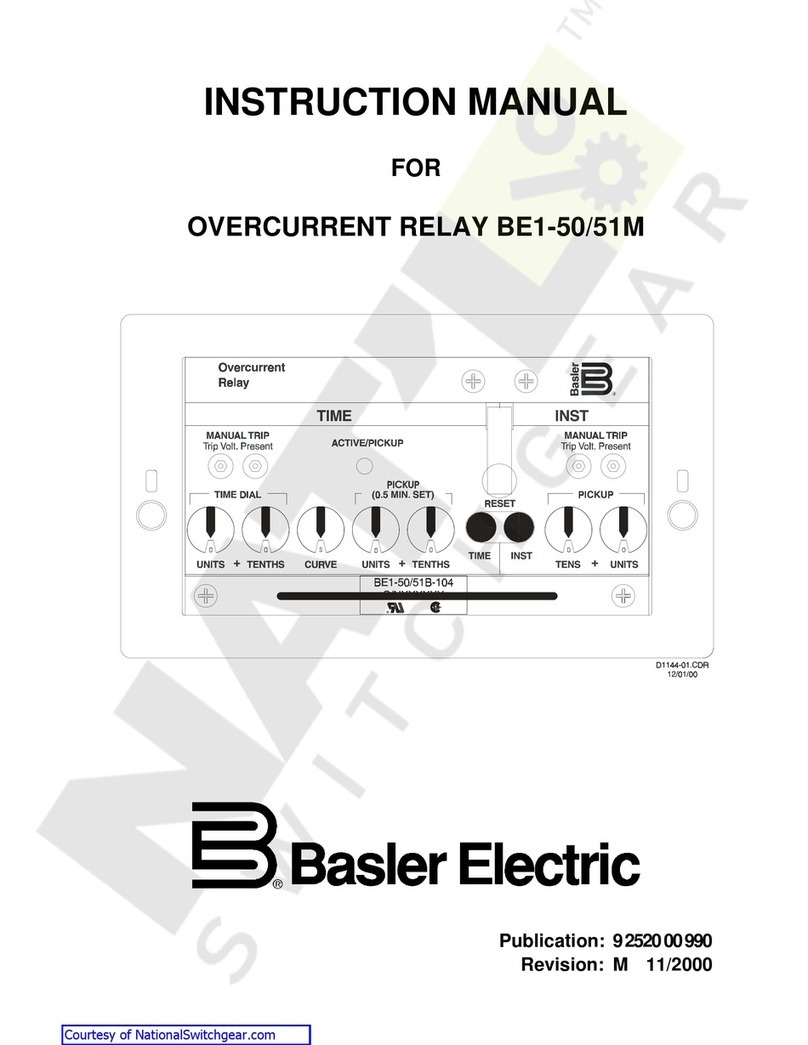

Basler BE1-50/51M-100 Series User manual

Basler

Basler BE1-50/51M-222 User manual

Basler

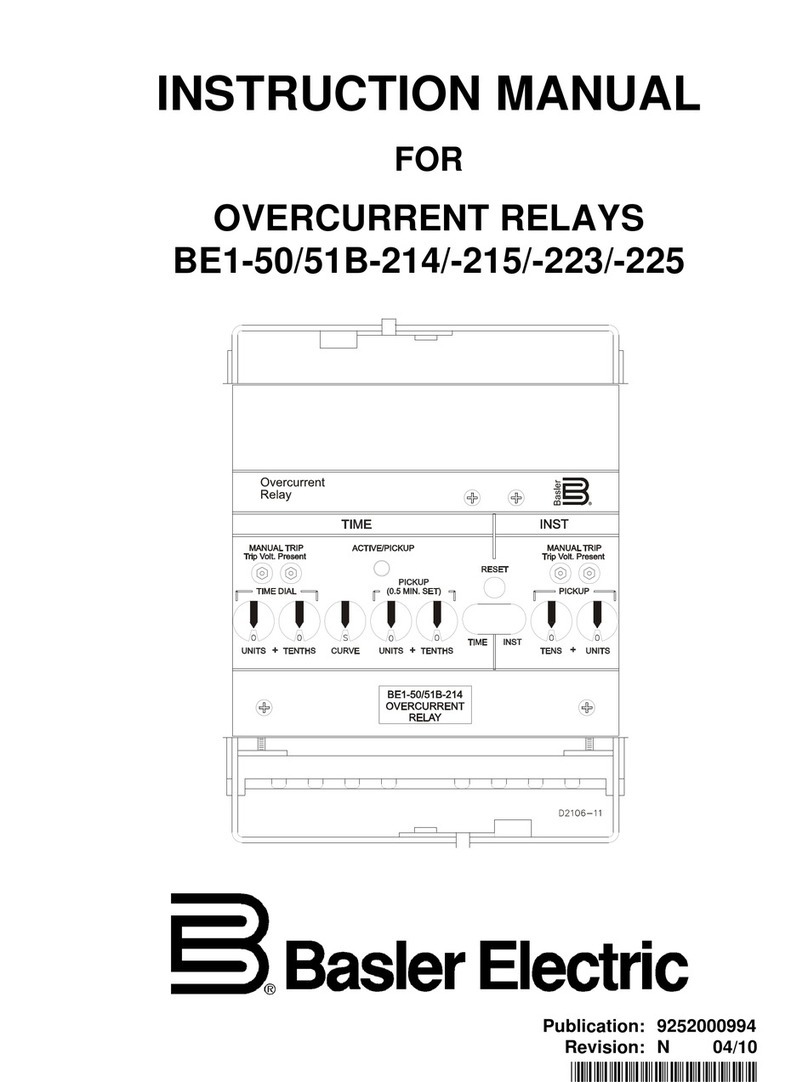

Basler BE1-50/51B-214 User manual

Basler

Basler BE1-46N User manual

Basler

Basler BE1-50BF User manual

Basler

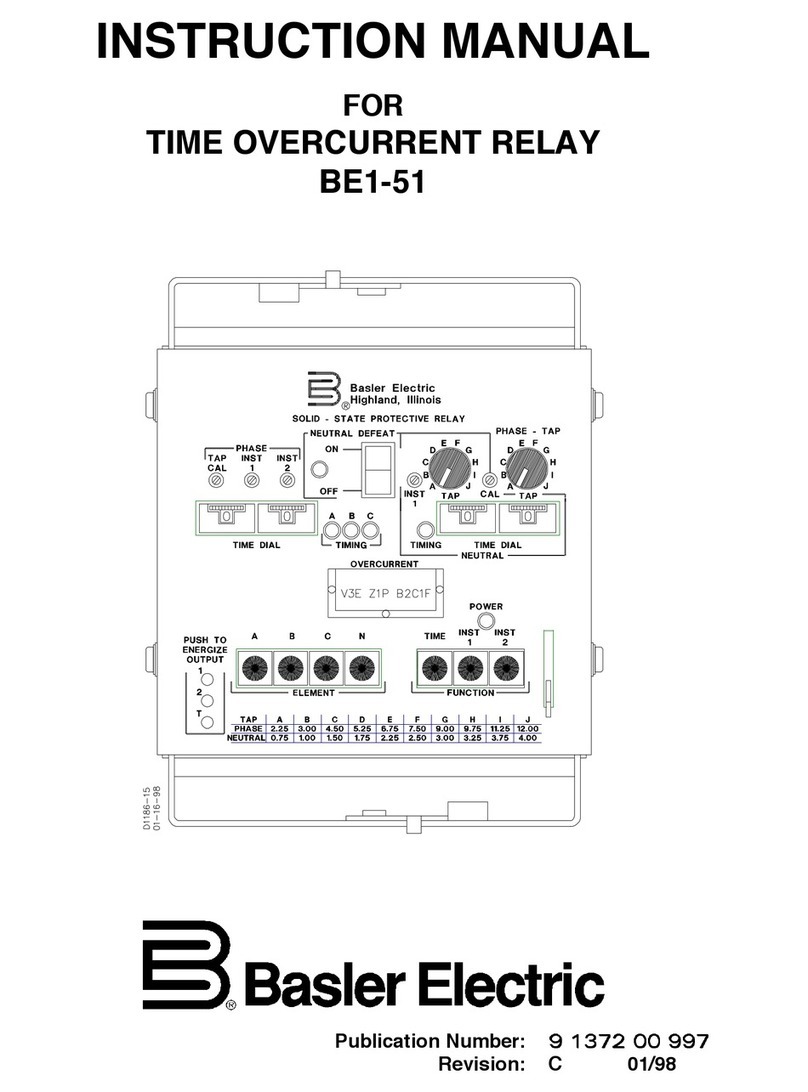

Basler BE1-51 User manual

Basler

Basler BE1-67N User manual

Basler

Basler BE1-951 User manual

Basler

Basler BE1-67 User manual

Basler

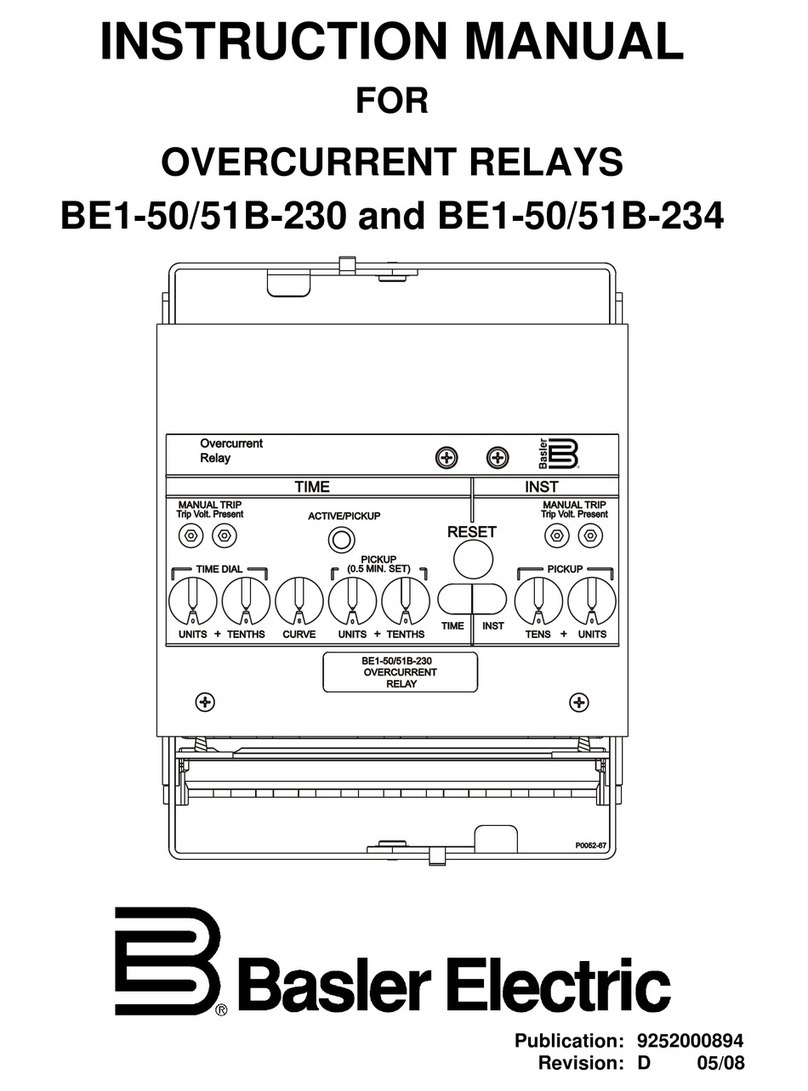

Basler BE1-50B-230 User manual

Basler

Basler BE1-27 User manual

Basler

Basler BE1-87T User manual

Basler

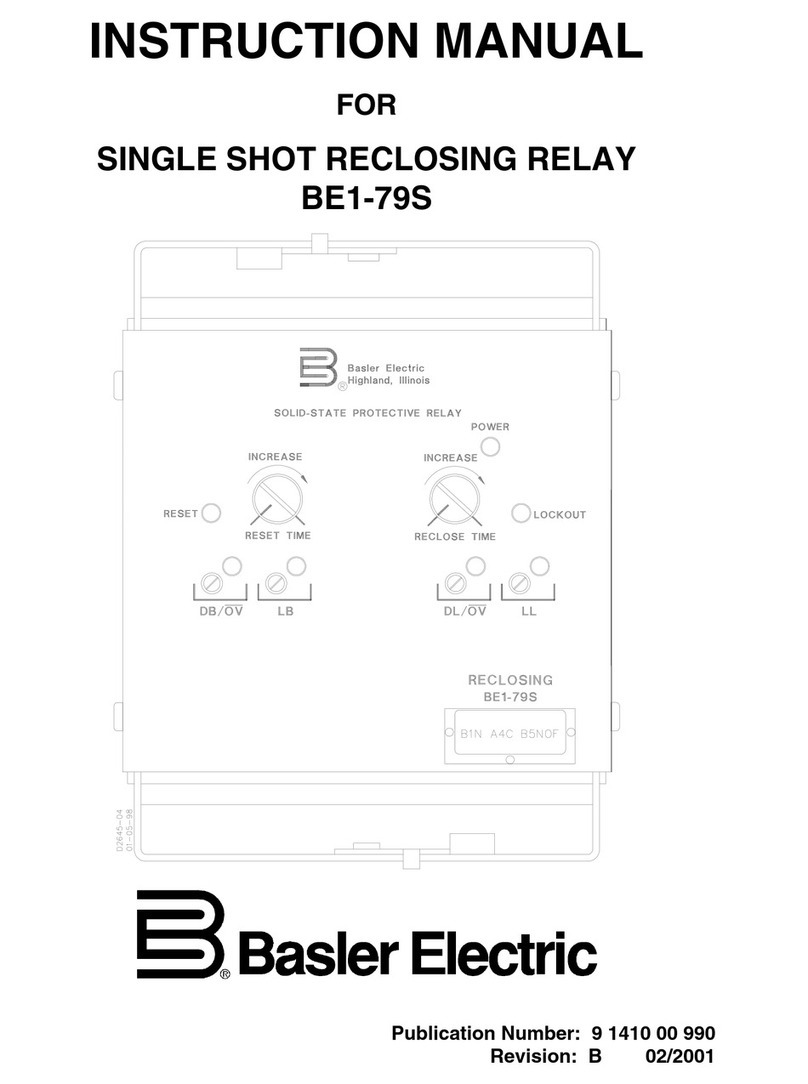

Basler BE1-79S User manual

Basler

Basler BE1-81 User manual

Basler

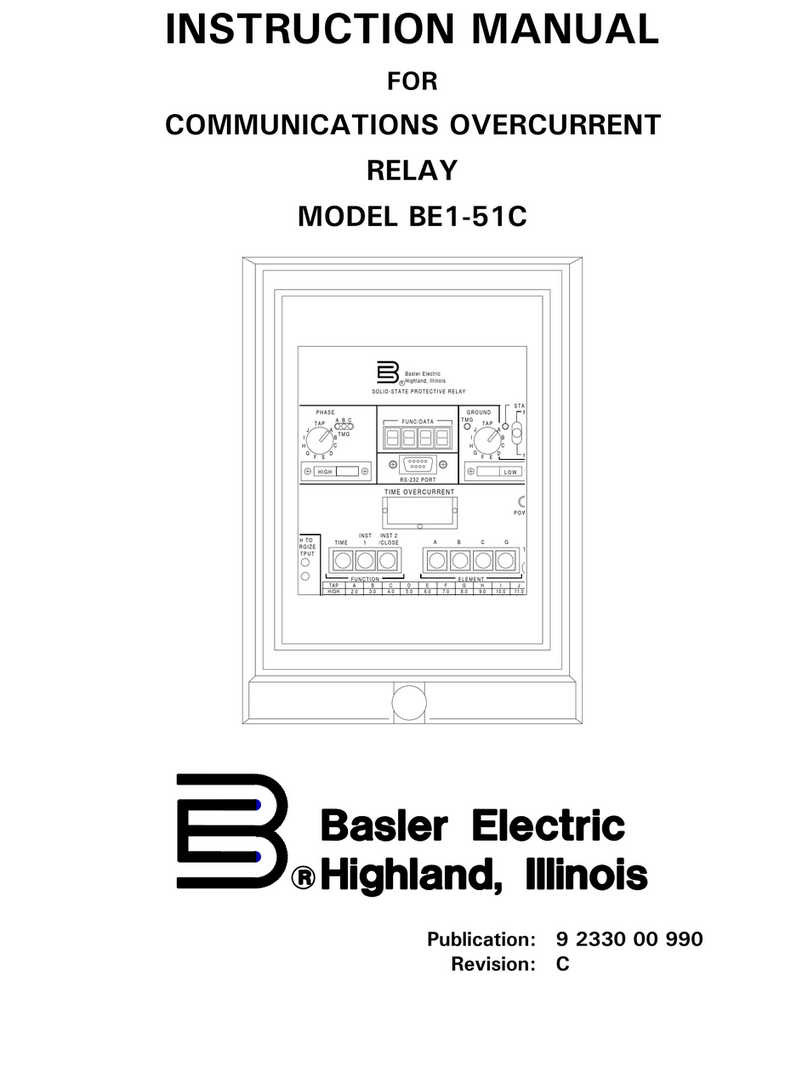

Basler BE1-51C User manual

Basler

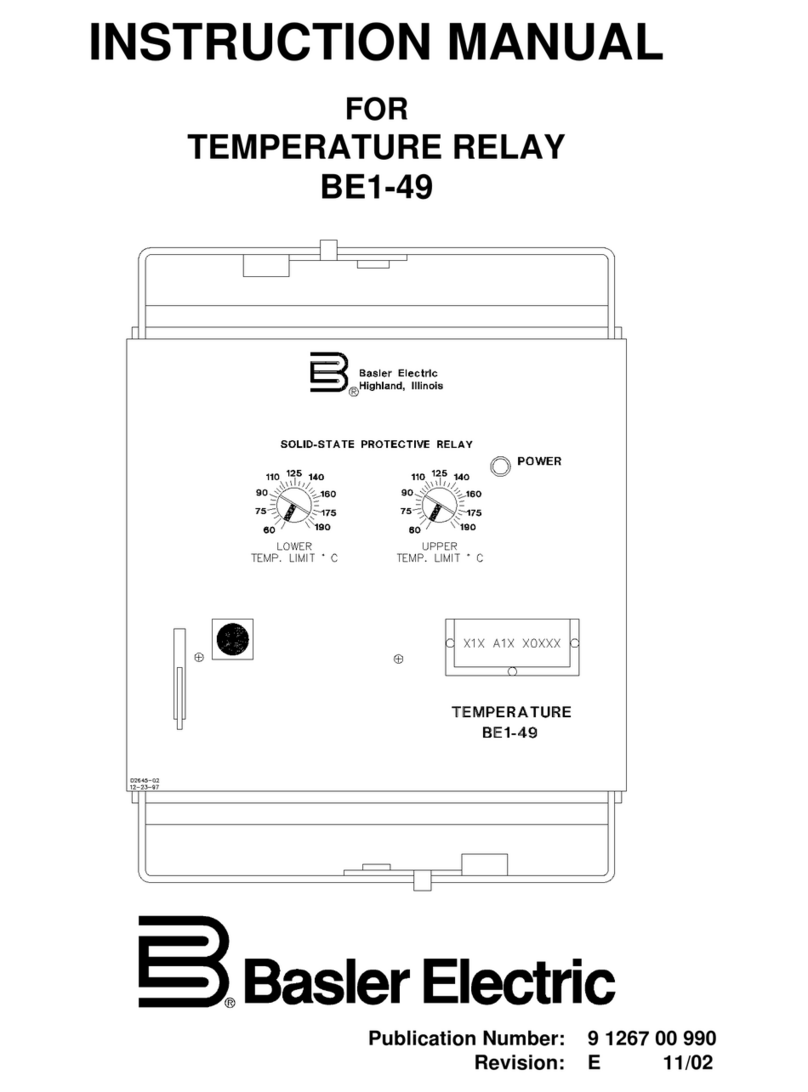

Basler BE1-49 User manual

Basler

Basler BE1-59NC User manual

Basler

Basler BE1-50/51B-217 User manual

Basler

Basler BE1-50B User manual

Basler

Basler BE1-24 User manual