Baso 120-2 User manual

RED

WHITE

RED A-GREEN

BLACK

BLACK

SD

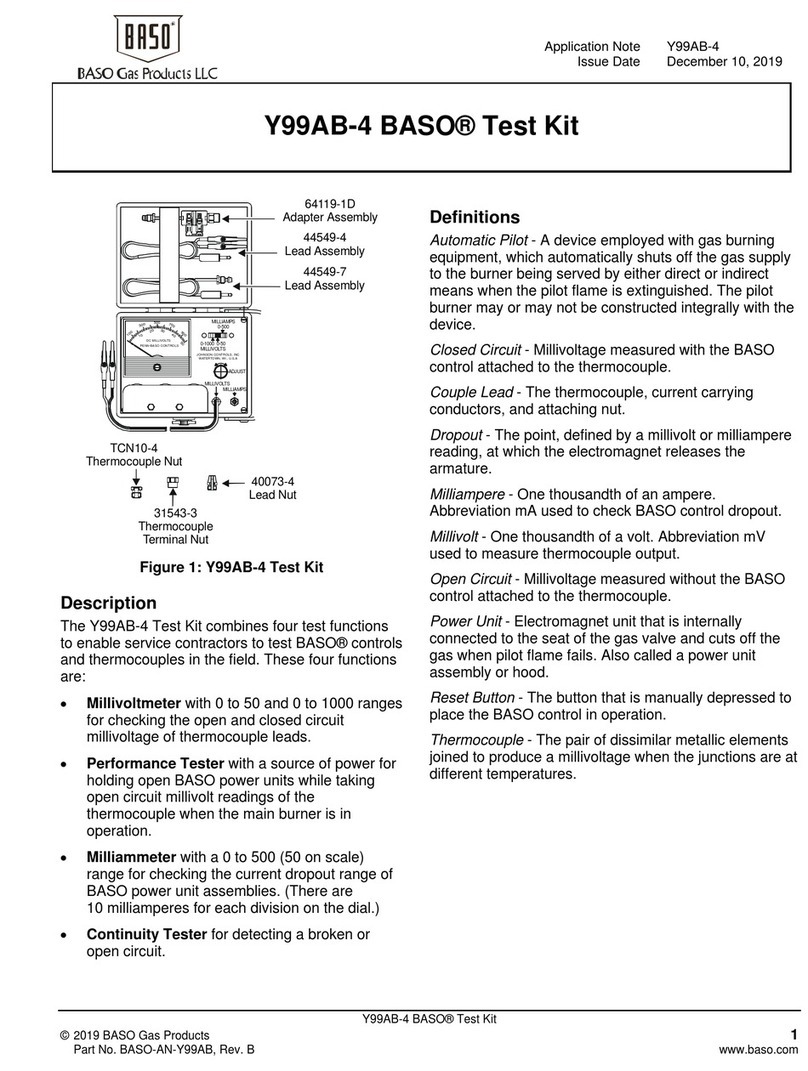

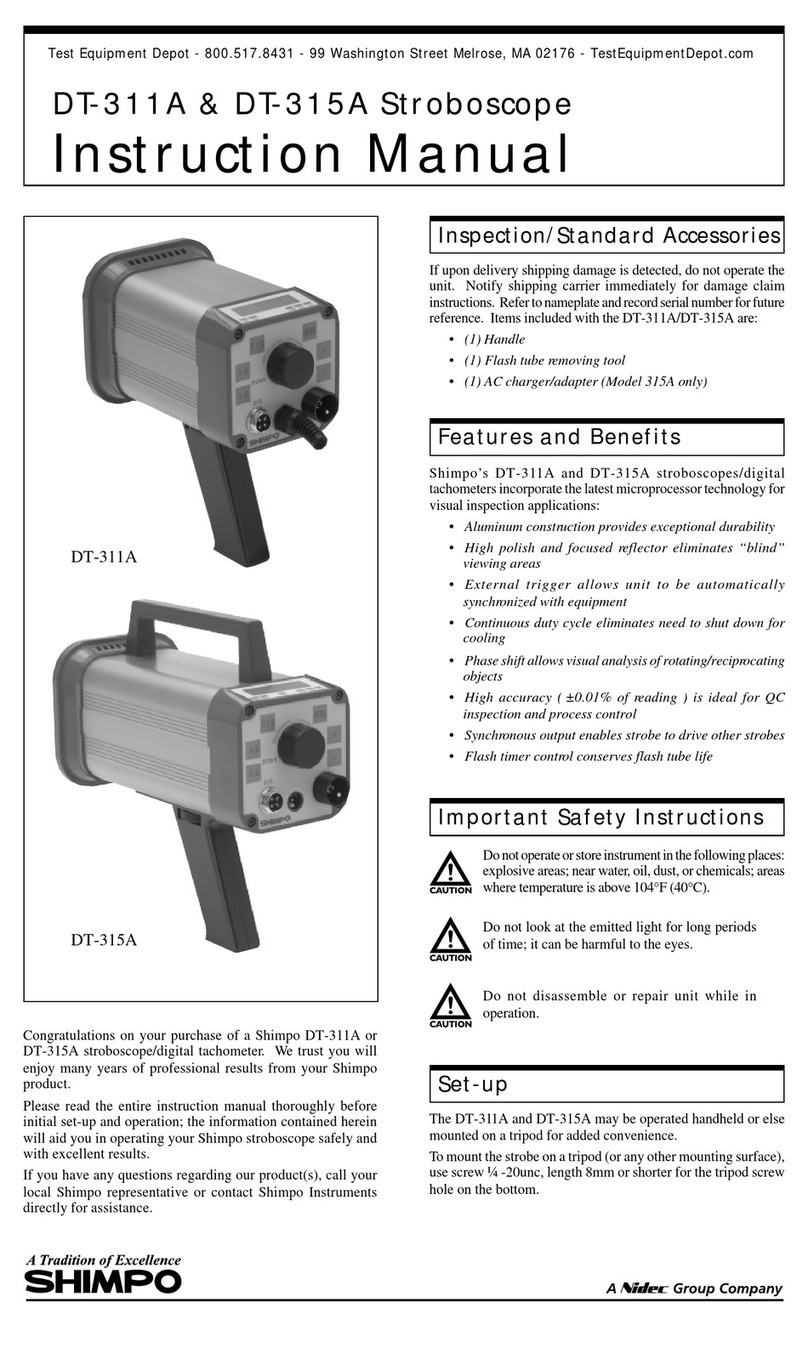

THIS TEST KIT COMBINES THE FOLLOWING FUNCTIONS:

A MILLIVOITMETER with 3 direct reading scales for checking open

circuit millivoltage of Thermocouple Leads and Pilot Generators.

A PERFORMANCE TESTER with a source of power for holding Baso

controls open for taking open circuit millivolt readings of the Thermo-

couple while the main burner is in operation.

A MILLIAMMETER with 3 direct reading scales for checking current

dropout range of Baso Power Unit Assemblies.

A CONTINUITY TESTER for detecting a broken or open circuit.

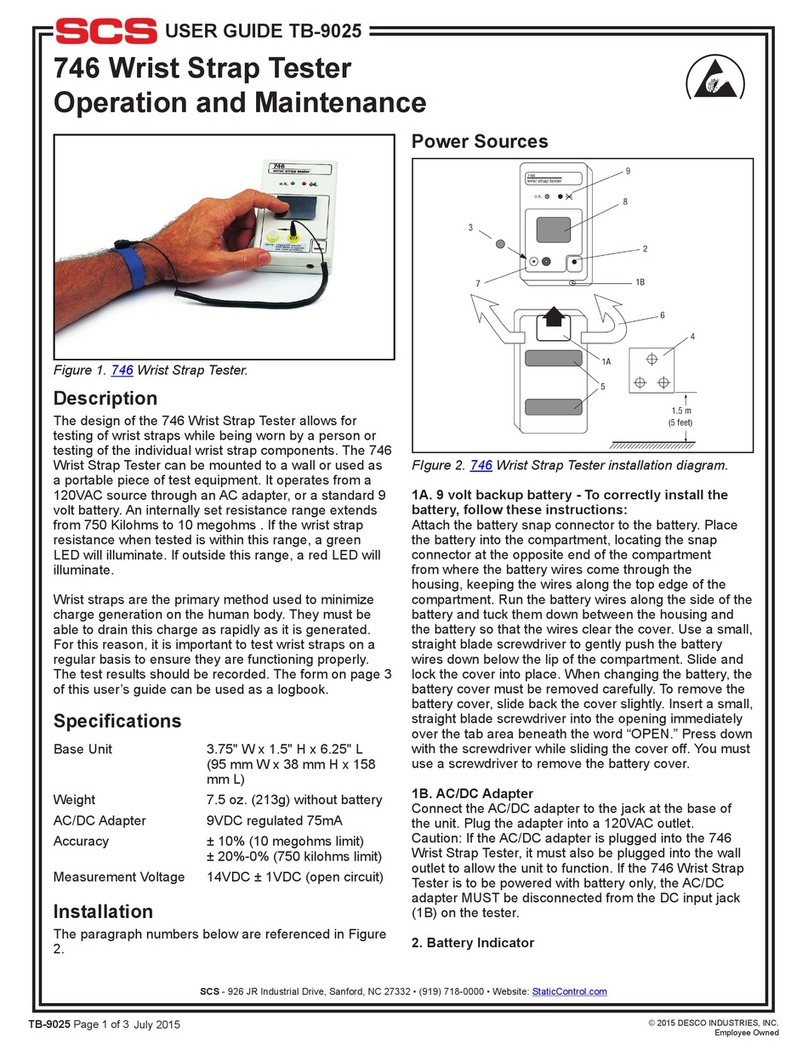

MODEL 120 BASO TEST KIT GENERAL INSTRUCTIONS

When using meter, plugs must be inserted into jacks firmly and squarely. Adapters

and nuts of thermocouples must be clean and tight. Any meter fluctuation caused by

the movement of these parts shows loose connections. Poor connections will cause

false readings. Replace batteries with positive or center terminals up.

WARNING Do not use this meter to measure any outside current.

Do not use this meter to measure AC voltages.

This meter is designed and calibrated far DC voltages up to 900

MILLIVOLTS only. Any attempt to measure AC current or DC current

over 900 MILLIVOLTS will damage the meter.

Do not operate meter so as to cause needle to swing violently to right

to limit of travel. To prevent violent needle swing, set selector switch

to proper range before attaching test cables.

Please check this instrument for damage immediately upon arrival

of shipment.

.12O-2

BASOiiB-YEL[OW

I. Procedure for taking open circuit MILLIVOLT READINGS of the Thermocouple.

Disconnect Thermocouple from Baso Control and attach proper cable to

Thermocouple.

Turn selector switch to the MV range scale needed for the type of Thermocouple

being tested. Pilot Generators are tested on the 300 or 900 MV scale, as

needed. Insert plug end of cable in millivolts jack of test kit.

Millivolt readings should agree with those given in Table I, with a normal

pilot flame.

II. Procedure for taking fixed load millivolt readings of the thermocouple.

Note:

CABLES AND

THERMOCOUPLE

ADAPTERS FOR

MILLIVOLT

TESTING

Red

Red

THERMOCOUPLE LEAD

A-GREEN

Black

TRANSFORMER

Lc

PtLOT BURNER GAS LINE

Fits series 17 and 50 Thermocouples.

With Adapter 1, Fits 80 Series Thermocouples.

With Adapter 2, Fits B30 and B20 Series Thermbcouples.

With Adapter 4, Fits 97 and 107 Series Thermocouples.

Fits other makes of Thermocouples or Pilot Generators

and Basofron valves.

- Fixed Load Adapter

- Closed Circuit Adapter

2

Disconnect thermocouple from Baso control and attach fixed load adapter A

to thermocouple using proper fitting.

Attach alligator clip cable to terminals of fixed load adapter A. Bent

terminal indicates negative polarity.

Turn selector switch to MV range scale needed for the type of therrnocoupJe

being tested. Insert plug end of clip cable in millivolts jack of test kit.

Millivolt readings should agree with those given in Table I, with a normal

pilot flame.

Procedure Iand Procedure II are to be used for testing Baso Thermocouple

Leads and Procedure IV for drop-out testing of Baso Power Units.

Do not use the closed circuit adapter for testing Baso Automatic

Pilot Control Systems.

POWER SOJRCE I HE RMOS IA

bent terminal

III. Procedure for PERFORMANCE TESTING.

Attach proper cables to Thermocouple Lead and Baso Power Unit.

Loosen thermostat or control wire from transformer, or shut off manual cock

in gas line.

With the selector switch turned to the proper milliamp range, turn the adjuster

knob to get a full scale reading, and reset the Baso control. Caution: The

control will now remain open for further tests until the power unit connection

is broken or until the milliamp jack is removed from test kit.

Turn the selector switch to the proper millivolt scale and take a reading with

the main burner off.

Connect loosened control wire, or turn on manual valve to bring main burner

on. Observe millivolt readings throughout normal cycle of operation, watching

for millivolt decreases due to operational conditions.

CABLES FOR

PERFORMANCE

TESTING

Use Proper

Millivolt

Test & Dropout

Test Cables

ABLE I. THERMOCOUPLE

LEAD TYPE

OUTPU.

TURN DOWN

urtr LIKI..UII

MV RANGE Minimum Voltage

Using Adapter "A's

NORMAL NOT LESS THAN

17D 4 MV 30-35 16 12

B20 5 MV 25-35 17 9

B30 30 MV 115-135 100 30

50,58D 4 MV 17-20 11 9

80, 88D 4 MV 20-25 15 9

87D 4 MV 30-35 17 9

88E, 88H with H Pilot 4 MV 14-17 12 7

88E 4 MV 25-30 17 9

97D 4 MV 30-35 21 13

107D 4 MV 30-35 21 13

in Combination For all 800, 300, 500 Baso Controls, Basoid, Actrol, or Basotrol,

Automatic Pilot installations.

light pilot burner

In the turn-down test, the pilot flame is reduced to the point that

the TC open-circuit output is at the turn-down level. The pilot must

be able to light the main burner within 4 seconds in this condition.

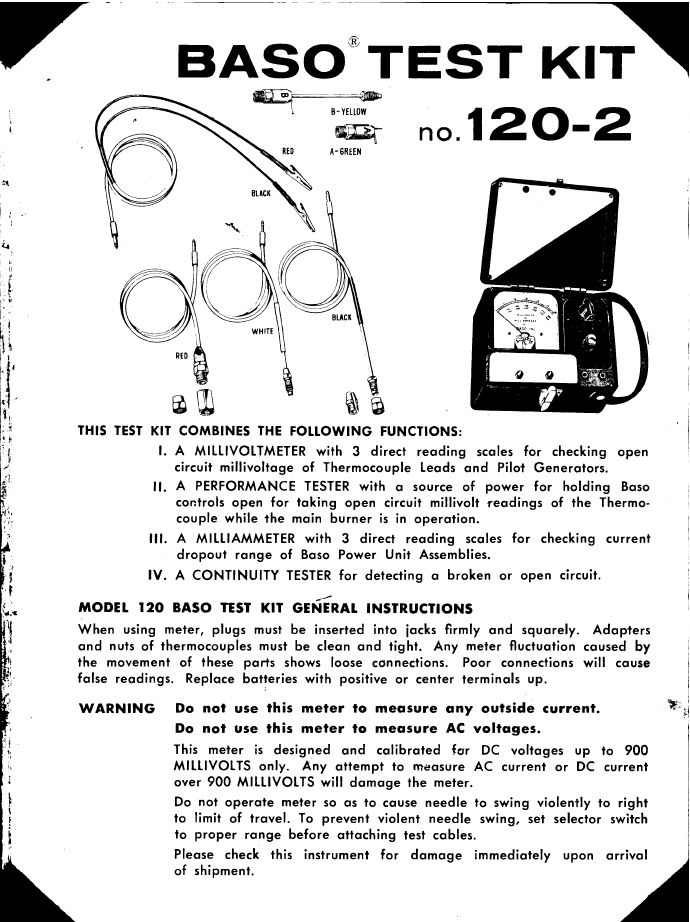

IV. Procedure for using Milliammeter for DROPOUT TESTING.

Attach proper cables and set meter selector switch as designated by chart.

Turn adjuster knob to get a full scale reading and reset control by pressing

in reset button firmly.

Turn adjuster knob slowly to left until Baso Power Unit releases. The Mliii-

ampere reading at the moment of release is the dropout point of the Baso

Power Unit. Take two more readings by the same process, and average out

readings. Milliampere dropout point must lie within the high and low range

given in Table II.

CABLES AND

ADAPTERS FOR

DROPOUT

TESTING

Black

White

Fits 800 Series Baso, Basotrol, Actrol, and Basoid Controls.

With Adapter 3, Fits 960 Series.

With Adapter 1, Fits 300 and 500 Series, B Series Basoid.

Fits Basotron Series.

4

5

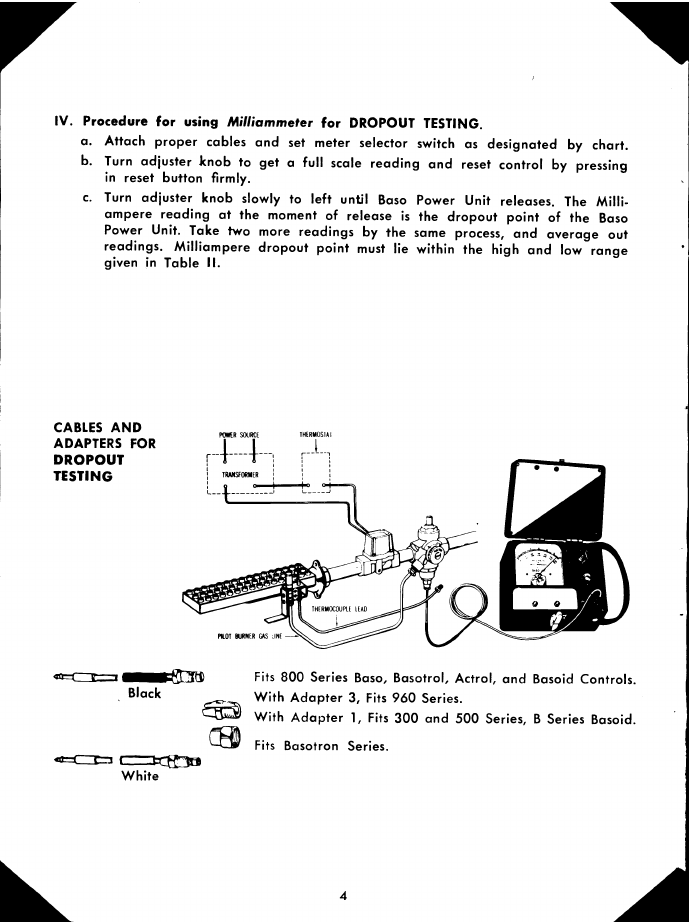

BASO MODEL SET

SWITCH MA RANGE OF

POWER UNIT ASSY. E0LE TYP

TH AND E

All 300 and 500 Series

Baso Valves and

B Series Basoid Valves

900MA 250 600 No. 50 or No. 58 Up

to 54" mcI. No. 17D

55" to 72" md.

X3* Power Units for 300

and 500 Series Baso Valves

and B Series Basoid Valves

900 and

300MA

180 315 No. 17D

73" to 144" mcI.

X4" Power Units for 300

and 500 Series Baso Valves

and B Series Basoid Valves

300MA 110 220 No. 17D

145" to 240" mcI.

808, A809, 811, t815,

A817F, t818, 819, 820,

821, 825, A828, 829,

Any 830, 831, t832, D833,

Any 840, 841, Any 842,

t843, 845, 846, 850, 852,

853, 1815, 1825

854, 856, 8815, B1815, 8844,

GAV, GHV, GKV, GRV, GSV,

GTV, GXV, NDV

Basoid Valve AF, AG, AJ,

AK, Al-I

Basoid Valve AF, AG, AJ, AK

Basstat Valve CA

Basotrol Valve GFV, NBV, NCV

Actrol Valve MAS, MCS, MCV,

MCVR

300MA 100 300 No. 80 or No. 88

Up to 54" mcI.

No. 87

55" to 72" mcI.

W850, W853 300MA 20 50 No. B2OD

24" to 60" mcI.

X5* Power Units for

above Baso Valves 300MA 60 200 No. 87

73" to 144" mcI.

X6* Power Units for

above Baso Valves 300MA 50 145 No. 87

145" to 240" md.

TABLE II. DROPOUT RANGE

For Baso Controls or their Power Units

Controls ore in satisfactory condition if the point of dropout falls within the specified

range

* "X" Range applies anly to controls or power units identified by this suffix after the

part number. All controls used with Thermocouple longer than 72" must be of the

proper "X" dropout range. Do not use "X' controls with Thermocouples less than

72" in length.

6

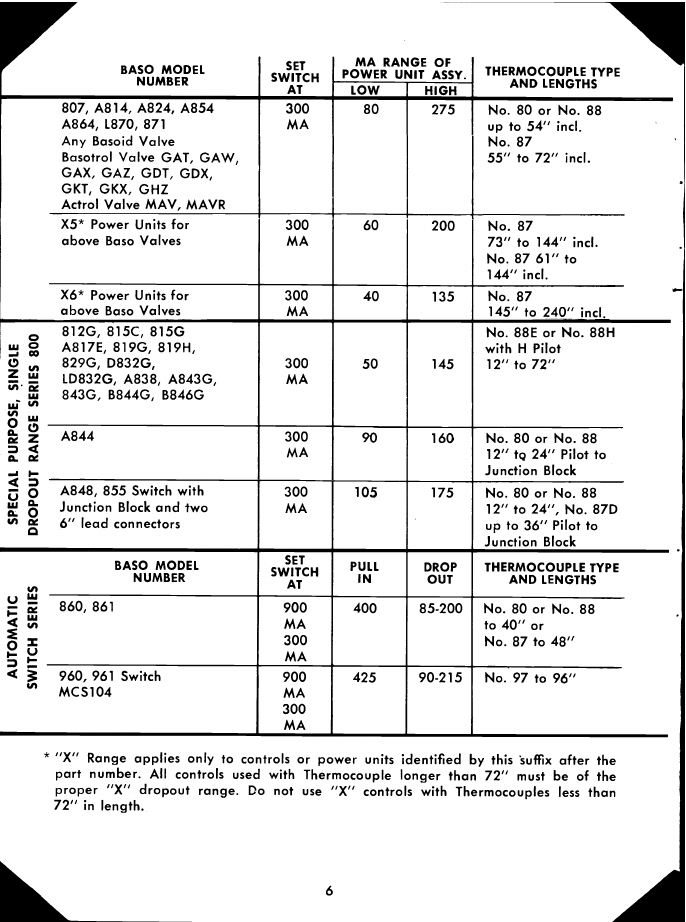

VBASO MODEL

NUMBER SET

SWITCH

AT

MA RANGE OF

POWER UNIT ASSY. THERMOCOUPLE TYPE

AND LENGTHS

LOW HIGH

807, A814, A824, A854

A864, 1870, 871

Any Basoid Valve

Basotral Valve GAl, GAW,

GAX, GAZ, GDT, GDX,

GKT, GKX, GHZ

Actrol Valve MAY, MAVR

300MA 80 275 No. 80 or Na. 88

up to 54" mcI.

No. 87

55" to 72" mcI.

X5* Power Units for

above Baso Valves 300MA 60 200 No. 87

73" to 144" mcI.

No. 87 61" to

144" mcI.

X6* Power Units for

above Baso Valves 300MA 40 135 No. 87

145" to 240" mcI.

812G. 815C, 815G

A817E, 819G, 819H,

0829G, D832G,

1D832Q, A838, A843G,

ui 843G. B844G, B846G

300MA 50 145

No. 88E or No. 88H

with H Pilot

12" to 72"

A844

Q.

300MA 90 160 No. 80 or No. 88

12" tg 24" Pilot to

Junction Black

A848, 855 Switch with

Junction Black and two

SI 6" lead connectors

300MA 105 175 No. 80 or No. 88

12" to 24", No. 87D

up to 36" Pilot to

Junction Block

BASO MODEL

NUMBER SET

SWITCH

AT PULLIN DROP

OUT THERMOCOUPLE TYPE

AND LENGTHS

860, 861 900MA300MA

400 85-200 No. 80 or No. 88

to4O"or

No. 87 to 48"

4960, 961 Switch

'MCS1O4 900MA300MA

425 90-215 No. 97 to 96"

Procedures for CONTINUITY TESTING.

Use proper cable and set selector switch to 300 MA scale.

With plug end of clip cable inserted in millivolt Jack, touch the alligator clips

together and turn the adjuster knob until you get a full scale (300 MA)

reading. If you are unable to get a full scale reading the connections are

poor or the batteries should be replaced.

Test for open circuit by touching or clamping the alligator clips to the terminal

or points in a circuit to be checked. DO NOT ATTEMPT THIS CHECK BEFORE

CUTTING OFF THE LINE POWER TO THE APPLIANCE.

If the circuit has very low resistance, you will get a full scale reading, but if a

coil or other resistance is in the circuit being tested this added resistance will

give a reading less than full scale. Any reading at all indicates a complete

circuit.

(Note: In effect this meter is being used as an ohmmeter when checking con-

tin u I ty.)

CABLE FOR

CONTINUITY

TESTING

R souc IHRMOAI

PIlOT BURMR GAS LIN( TRMOCOUE LEAD

Clip to Terminal Posts or Wire ends, or use as probes.

(Polarity not important for continuity testing.)

7

Plug into mA jack, not mV jack.

milliamp

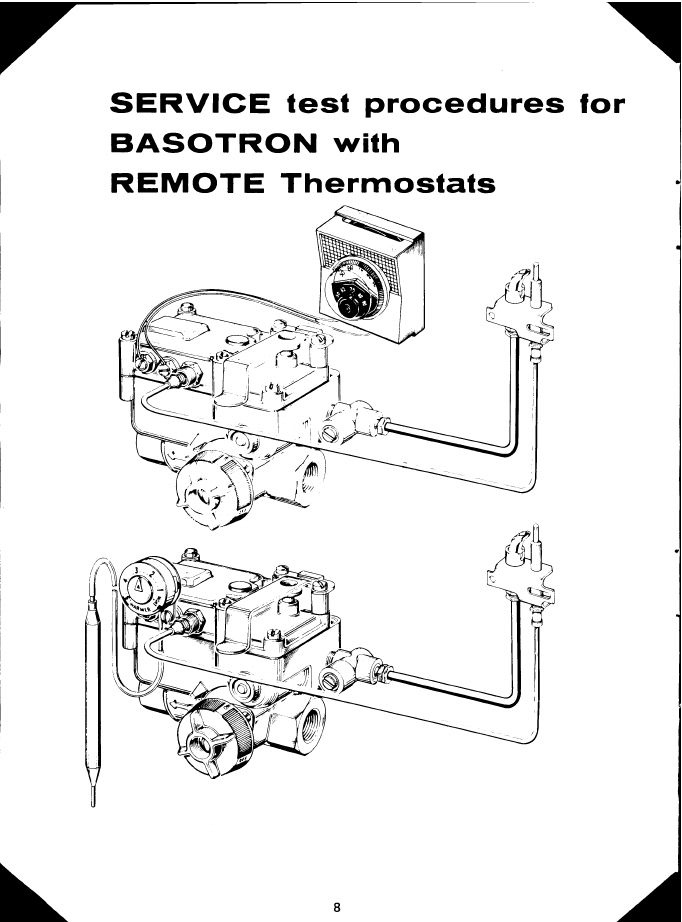

SERVICE test procedures for

BASOTRON with

REMOTE Thermostats

Poor MV output.

Excessive draft.

Recirculation of flue

products.

Excessive tempera.

ture.

Improper pilot flame

size or characteristic.

Defective thermocouple.

Weak holding BASO

power unit.

insufficient MV output.

Weak or defective ther.

mocou pie.

High resistance in con-

trol circuit.

Loose thermostat wiring

or defective thermostat.

Defective actuator.

Use Test Procedure lB.

Baffle secondary air or

shield pilot burner.

Check venting and main

burner orifice sizing and

correct where necessary.

Check main burner in-

put and correct if nec-

essary.

Check gas pressure,

clean pilot burner, and

adjust flame.

Test thermocouple under

Test Procedures Iand II

on page 2.

Test under Procedure lll.A.

Use Test Procedure lB.

(Check and correct as in

(a) through (d) above).

Use Test Procedure Iand

Replace thermocouple if

necessary.

Use Test Procedure Il-Ill.

Isolate source of resistance

and correct or replace as

indicated.

Use Test Procedure IV. Cor-

rect or replace as indicated.

Use Test Procedure lilB or

Replace if necessary.

A

CONDITION

Pilot burner outage or

varying performance.

Pilot burner burning, plug

valve knob turned to ON

position, thermostat call-

ing for heat. Main burner

does not come on.

Thermostat not calling for

heat, or turned way

down, plug valve knob

in ON position - main

burner will not shut off.

SERVICE SUGGESTIONS

POSSIBLE CAUSE

Shorted thermostat cir-

cuit.

Foreign particles lodged

between valve seat.

9

REMEDY

Check thermostat wires for

shorts.

Remove top of control and

clean valve seat.

10

BA SOT RON

ACTUATOR

BASO POWER UNIT

DIAGRAM I

- 030 DTN ER MOCOVPI.(

kTE5T KIT

7JUMPER

2

THERMOSTAT

White cable plugged into MA lack and attached to IC terminal post. Red cable plugged

into MV jack and attached with adapter 2 to IC. Jumper clip across thermostat

term in a Is.

PROCEDURE No. I (See Diagram I)

Isolated Open Circuit MV Test of Thermocouple

Step A. - With Main Burner Off

Turn plug valve to PILOT position.

Attach cables as shown.

Turn meter adjustment knob to right to full setting to provide holding power

for BASO unit, push reset and light the pilot burner, and allow time enough

for the thermocouple to reach its maximum reading.

AT THIS POINT THE NORMAL READING SHOULD BE 125 TO 150 MILLIVOLTS.

If the reading is less: Check thermocouple under procedure I and II on page 2.

Check the pilot under service suggestions (Page 9) for "Pilot outage" under (d).

Step B. - With Main Burner On

1. Cycle main burner on and off, simulating normal operating conditions, by

turning the red plug valve from PILOT to ON positions. IF MILLIVOLT READING

DROPS BELOW 85 MV AT ANY POINT DURING THE OPERATION OF THE

APPLIANCE, THE CAUSE OF THIS DROP SHOULD BE DETERMINED AND

CORRECTED. (See service suggestions under "Poor MV output" (a) thru (d).)

1

I

milliamps

)DIAGRAM II

_- B300THERUOCQIjPL(

THERMOSTAT

Thermostat wire disconnected from Terminal 1. Selector switch turned to 300 MV. Clip

cable plugged into MV jack. Red clip attached to Terminal 1. Black clip attached to

Terminal 2.

PROCEDURE No. II (See Diagram II)

Closed Circuit MV Test of Entire Circuit

Attach Millivoltmeter cable as shown.

Set thermostat to highest setting.

Turn plug valve knob to PILOT position, push down r&set button and Ight

pilot. Allow thermocouple to become fully heated, and note maximum reading.

AT THIS POINT, THE METER WILL INDICATE AN OPEN CIRCUIT MV READING

OF THE THERMOCOUPLE AS IN PROCEDURE IA.

Assuming the open circuit MV read-

ing is within range, touch the dis- OPEN CIRCUIT CLOSED CIRCUIT

connected thermostat wire to its MV READING MV READING

terminal. AT THIS POINT, THE

METER WILL INDICATE A CLOSED 150 45 or less

CIRCUIT READING, AND SHOULD 145 43½ or less

BE .3 OR LESS OF THE OPEN 140 42 or less

CIRCUIT READING AS TABULATED. 135 40½ or less

130 39 or less

If the closed circuit reading is 125 37½ or less

greater than indicated - 120 36 or less

Test the thermostat circuit under 115 341/2 or less

Procedure IV. 110 33 or less

Test the actuator under Procedure 105 31½ or less

IIIB. 100 30 or less

If both of these check out satis- 95 28½ or less

factorily, replacement of the 90 27 or less

thermocouple is indicated. 85 25½ or less

5. With thermostat wire connected, turn plug valve knob to ON to light main

burner. UNDER OPERATING CONDITIONS THIS READING SHOULD REMAIN

FAIRLY CONSTANT. A considerable decrease in millivoltage would indicate

adverse conditions in the combustion chamber affecting the pilot flame. Check

suggestions listed under PILOT BURNER OUTAGE.

I1

DIAGRAM III

Thermostat wires disconnected, or integral thermostat removed. Jumper clip across

thermostat terminals. White cable plugged into MA lack and attached to thermocouple

post. Selector switch set at 0-300 MA scale.

PROCEDURE No. III (See Diagram III) (For testing with a millivoltmeter

Isolated Test of Actuator and Safety Shutoff only, use Procedure V)

Step A. - BASO Safety Power Unit Test

Before attaching meter cables, set plug valve knob to PILOT position.

Attach proper cables as shown.

With plug valve in PILOT position, turn meter adjustment knob right to highest

reading position, push reset button and light the pilot. (The meter will hold

the BASO power unit open.)

Slowly turn meter adjustment knob to left until BASO power unit drops out,

shutting off the pilot flame. THIS SHOULD OCCUR BETWEEN 45 MA AND

90 MA. A dropout point higher than 90 MA indicates a weak holding unit and

requires replacement.

Step B. - Actuator Test - For Valves with Pilot Line Baso

With plug valve knob in PILOT position, turn meter adjustment knob to right

to highest setting.

Push reset button down and light pilot.

Turn plug valve knob to ON, lighting main burner.

Push down on reset button, holding it down while turning the meter adjustment

knob slowly to the left to the point where the main burner goes off, and to the

right to the point where the main burner comes on. THE CLOSING POINT

SHOULD BE AT 35 MA OR BELOW. THE OPENING POINT SHOULD BE AT

ANY POINT UP TO 110 MA. Repeat two or more times and take an average

reading. A higher opening or closing point indicates replacement.

Actuator Test - For Valves with Main Line Baso

Turn meter adjusting knob to the left as far as possible. Attach thermocouple

to Baso.

With plug valve knob in pilot position, push reset button down and light pilot.

Turn plug valve knob to on.

Turn meter adjusting knob slowly to the right until main burner comes on. The

point at which this occurs would be any point up to 110 MA. Turn meter

adjusting knob slowly to left until main burner goes off. (If adjustment does

not reduce low enough, remove plug from Test Kit jack to accomplish closing.)

Any closing point below 35 MA is satisfactory.

13

BASO POWER UNIT

BA SOT RON

ACTUATOR

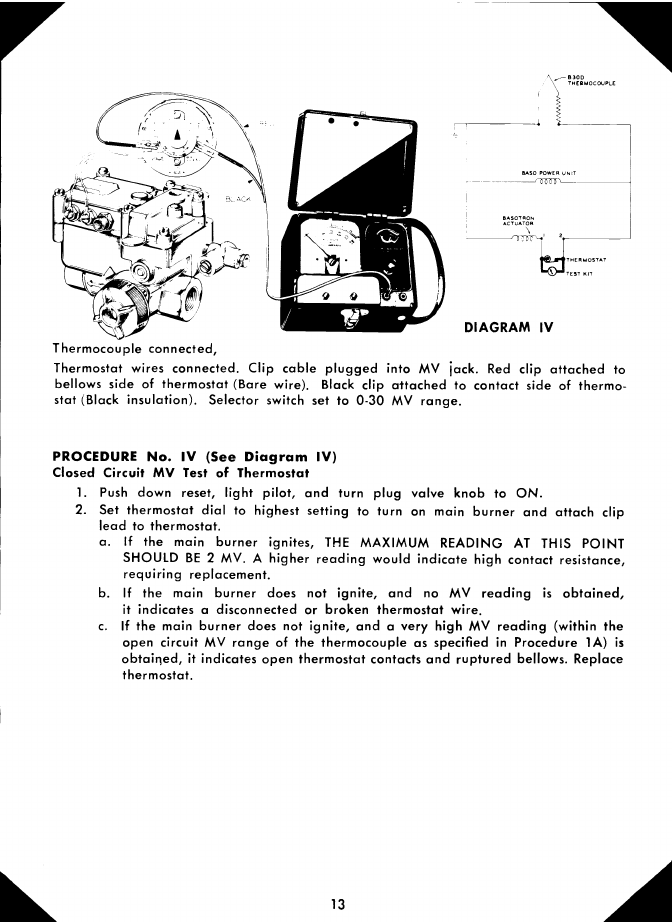

DIAGRAM IV

_- B300THERMOCOUPLE

THERMOSTAT

TEST RIT

Thermocouple connected,

Thermostat wires connected. Clip cable plugged into MV jack. Red clip attached to

bellows side of thermostat (Bare wire). Black clip attached to contact side of thermo-

stat (Black insulation). Selector switch set to 0-30 MV range.

PROCEDURE No. IV (See Diagram IV)

Closed Circuit MV Test of Thermostat

Push down reset, light pilot, and turn plug valve knob to ON.

Set thermostat dial to highest setting to turn on main burner and attach clip

lead to thermostat.

If the main burner ignites, THE MAXIMUM READING AT THIS POINT

SHOULD BE 2 MV. A higher reading would indicate high contact resistance,

requiring replacement.

If the main burner does not ignite, and no MV reading is obtained,

it indicates a disconnected or broken thermostat wire.

If the main burner does not ignite, and a very high MV reading (within the

open circuit MV range of the thermocouple as specified in Procedure 1A) is

obtained, it indicates open thermostat contacts and ruptured bellows. Replace

thermostat.

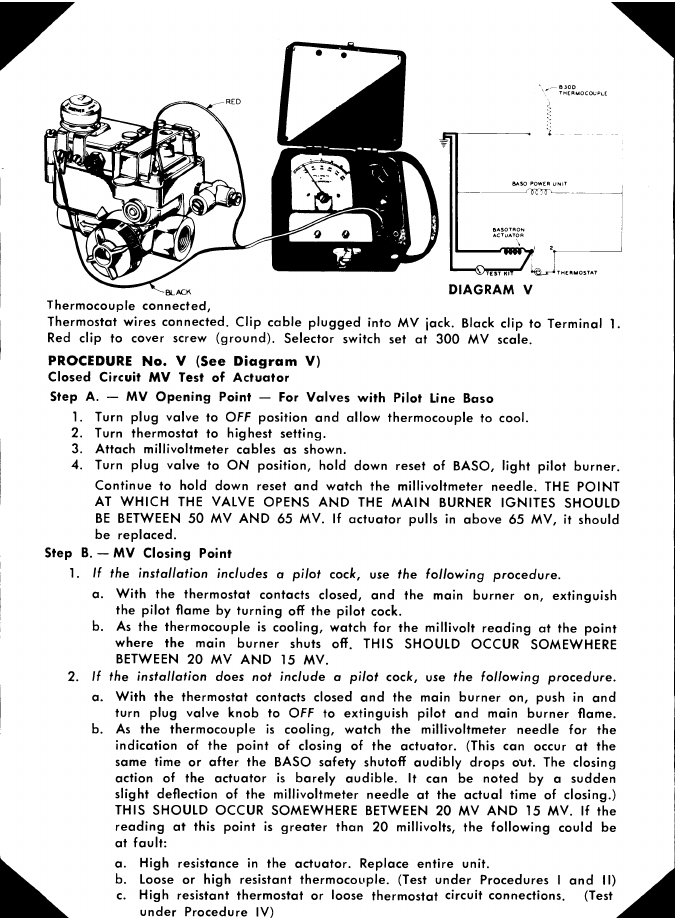

BASO POWER UNIT

0 C 0

BA S 01 RON

ACTUATOR

- B300THE RhIOCOUPLE

TEST KU THERMOSTAT

DIAGRAM V

BLftCK

Thermocouple connected,

Thermostat wires connected. Clip cable plugged into MV lack. Black clip to Terminal 1.

Red clip to cover screw (ground). Selector switch set at 300 MV scale.

PROCEDURE No. V (See Diagram V)

Closed Circuit MV Test of Actuator

Step A. - MV Opening Point - For Valves with Pilot Line Baso

Turn plug valve to OFF position and allow thermocouple to cool.

Turn thermostat to highest setting.

Attach millivoltmeter cables as shown.

Turn plug valve to ON position, hold down reset of BASO, light pilot burner.

Continue to hold down reset and watch the millivoltmeter needle. THE POINT

AT WHICH THE VALVE OPENS AND THE MAIN BURNER IGNITES SHOULD

BE BETWEEN 50 MV AND 65 MV. If actuator pulls in above 65 MV, it should

be replaced.

Step B. - MV Closing Point

1. If the installation includes a pilot cock, use the following procedure.

With the thermostat contacts closed, and the main burner on, extinguish

the pilot flame by turning off the pilot cock.

As the thermocouple is cooling, watch for the millivolt reading at the point

where the main burner shuts off. THIS SHOULD OCCUR SOMEWHERE

BETWEEN 20 MV AND 15 MV.

2. If the installation does not include a pilot cock, use the following procedure.

With the thermostat contacts closed and the main burner on, push in and

turn plug valve knob to OFF to extinguish pilot and main burner flame.

As the thermocouple is cooling, watch the millivoltmeter needle for the

indication of the point of closing of the actuator. (This can occur at the

same time or after the BASO safety shutoff audibly drops out. The closing

action of the actuator is barely audible. It can be noted by a sudden

slight deflection of the millivoitmeter needle at the actual time of closing.)

THIS SHOULD OCCUR SOMEWHERE BETWEEN 20 MV AND 15 MV. If the

reading at this point is greater than 20 millivolts, the following could be

at fault:High resistance in the actuator. Replace entire unit.

Loose or high resistant thermocouple. (Test under Procedures I and II)

High resistant thermostat or loose thermostat circuit connections. (Test

under Procedure IV) .4

SERVICE test procedures for

BASOTRON with

INTEGRAL Thermostats

15

Pr

Poor MV output.

Excessive draft.

Recirculation of flue

prod ucts.

Excessive tempera-

tu re.

Improper pilot

flame size or char-

acteristic.

Defective thermocouple.

Weak holding BASO

power unit.

Insufficient MV output.

Weak or defective ther-

mocouple.

Defective thermostat.

Defective actuator.

Use Test Procedure I.

Baffle secondary air or

shield pilot burner.

Check venting and main

burner orifice sizing

and correct where nec-

essary.

Check main burner in-

put and correct if nec-

essa ry.

Check gas pressure,

clean pilot burner, and

adjust flame.

Test thermocouple under

Test Procedures I and II on

page 2.

Test under Procedure 2.

Use Test Procedure lB.

(Check and correct as in

(a) through (d) above.)

Use Test Procedure Iand

II on page 2. Replace

thermocouple if necessary.

Use Test Procedure Ill.

Replace as indicated.

Use Test Procedure Ill.

Replace if necessary.

CONDITION

Pilot burner outage or

varying performance.

Pilot burner burning, plug

valve knob turned to ON

position, thermostat call-

ing for heat. Main burner

does not come on.

Thermostat not calling for

heat, or turned way

down, plug valve knob in

ON position - main

burner will not shut off.

SERVICE SUGGESTIONS

POSSIBLE CAUSE

Shorted thermostat cir-

Cu it.

Foreign particles

lodged between valve

seat.

16

REMEDY

Use Test Procedure Ill.

Remove actuator and clean

valve seat.

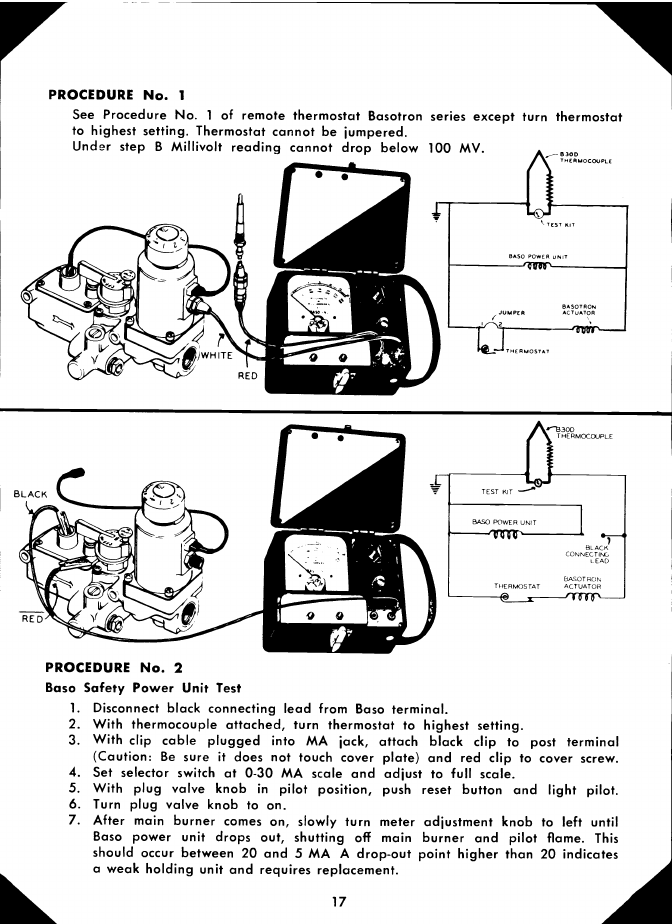

PROCEDURE No. 1

See Procedure No. 1of remote thermostat Basotron series except turn thermostat

to highest setting. Thermostat cannot be jumpered.

Under step B Millivolt reading cannot drop below 100 MV. A.-83ODTHERMOCOUPLE

17

3OD

T HERMOCcXJPLE

PROCEDURE No. 2

Baso Safety Power Unit Test

Disconnect black connecting lead from Baso terminal.

With thermocouple attached, turn thermostat to highest setting.

With clip cable plugged into MA jack, attach black clip to post terminal

(Caution: Be sure it does not touch cover plate) and red clip to cover screw.

Set selector switch at 0-30 MA scale and adjust to full scale.

With plug valve knob in pilot position, push reset button and light pilot.

Turn plug valve knob to on.

After main burner comes on, slowly turn meter adjustment knob to left until

Baso power unit drops out, shutting off main burner and pilot flame. This

should occur between 20 and 5 MA A drop-out point higher than 20 indicates

a weak holding unit and requires replacement.

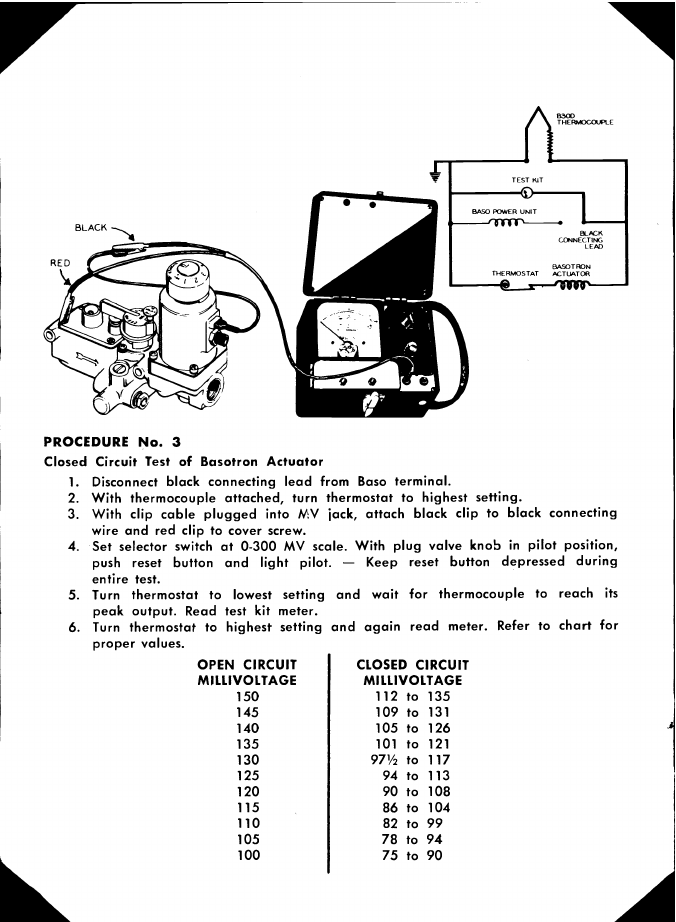

PROCEDURE No. 3

Closed Circuit Test of Basotron Actuator

Disconnect black connecting lead from Baso terminal.

With thermocouple attached, turn thermostat to highest setting.

With clip cable plugged into MV jack, attach black clip to black connecting

wire and red clip to cover screw.

Set selector switch at 0-300 MV scale. With plug valve knob in pilot position,

push reset button and light pilot. - Keep reset button depressed during

entire test.

Turn thermostat to lowest setting and wait for thermocouple to reach its

peak output. Read test kit meter.

Turn thermostat to highest setting and again read meter. Refer to chart for

proper values. OPEN CIRCUIT

MILLI VOLTAGE

150145140135130125120115110105100

CLOSED CIRCUIT

MI LLIVOLTAGE

112 to 135

109 to 131

105 to 126

101 to 121

97½ to 117

94 to 113

90 to 108

86 to 104

82 to 99

78 to 94

75 to 90

If the closed circuit millivoltage reading is greater than the maximum value

given in the chart, it indicates high resistance thermostat contacts or a faulty

internal connection. A reading equal to the open circuit reading indicates a

loss of fill in the thermostat or an open circuit in the actuator coil. If the

closed circuit millivoltage reading is less than the minimum value given in the

chart, it indicates a shorted actuator coil or a defective thermocouple. The

thermocouple should be checked according to procedure No. 1. The rest of

the indicated faults require replacement of the Basotron actuator.

REPLACEMENT PARTS LIST

REPLACEMENT ITEM

Adapter Nut - No. 1

Adapter Nut - No. 2

Lead Adapter - No. 4

Split Nut Adapter - No. 3

Red Cable

White Cable

Black Cable

Clip Cable

Adiusting Knob

Selector Knob

Fixed Load Adapter "A"

Closed Circuit Adapter "B"

19

PART No.

31543-1

31543.2

4248 3-1

40073-3

44549.3

44549-6

44549-7

44549.4

44589.1

90409.6

903 89-6

90379-6

Order

byPart Number

Shown

BA S 0 Milwaukee 1, Wiscdnsin

INC.

"Pioneers in thermoelectric gas controls"

Litho in U.S.A. 20007-603 REV. 1-61

t

January 1961

Table of contents

Other Baso Test Equipment manuals