6

PART 4: PRETESTING CHECKLIST

The pretesting checklist should always be completed prior to using the

SMART MUTT®X.

Unit Placement

• Place the tester on a at, level surface.

Maintain Connectors

Dielectric grease should be used on all connections to avoid corrosion. If a bad

connection exists at the terminal junction, you may get an erroneous reading and the

MUTT®will not work properly.

• Make sure you have a solid connection in the socket.

• Be certain the 7 pins in each plug are clean and spread to the proper size.

• Always check the MUTT® connector pins at the side of the MUTT®for proper

expansion. Over time, the pins may bend in slightly resulting in a poor connection

between the connector and the cable ends. A at head screwdriver can be used

to expand the pins until a tight connection is made.

TrailerCongurationSet-up

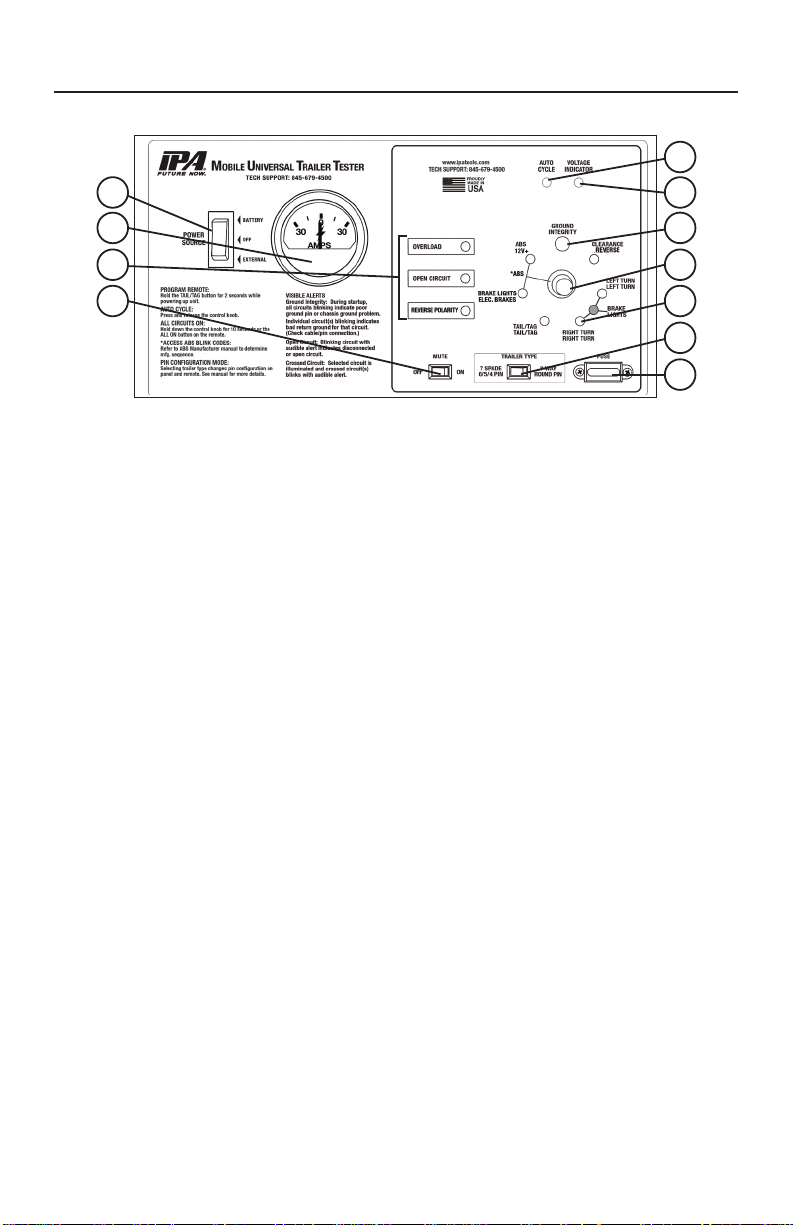

The SMART MUTT® X is a microprocessor controlled, diagnostic trailer tester

specically designed for testing lights and electric brakes on trailers with 4, 5, 6, 7

round pin and 7 spade pin type connections. Every time you power up the tester with

the Trailer Type switch in the 7-WAY SPADE 6/5/4 PIN position, the internal computer

wants to know which of these types of trailer connections you are testing. Note, this

phase is known as Trailer Conguration Set-Up and is indicated by a high speed

ickering of the LEDs surrounding the control knob only when in 7-WAY SPADE 6/5/4

PIN mode. If left untouched after 15 seconds, the tester will always default to a 7

spade pin conguration. However, if the user is testing a 4, 5 or 6 round pin type trailer

connection, this setting can be adjusted by rotating the control knob counterclockwise

to select the desired number of circuits. Trailer Conguration Set-Up is not initiated

when the unit is powered up in 7-WAY ROUND PIN mode.

Testing 4, 5, and 6 Round Pin Type Trailer Connections

The SMART MUTT® X is hard wired to a 7 spade pin connector, located on the side of

the tester. Each unit is supplied with a plug-in adapter, which will adapt the tester to 4,

5 and 6 round pin type connections. To test trailers with these types of connections,

the adapter must be plugged in line between the tester and the trailer. The instructions

above for Trailer Conguration Set-Up should be used for more efcient and accurate

testing.

Call 888-786-7899 with any technical questions.