11.Presser foot lifting set mechanism(Option parts) 44

12.Driver copmponents 45

13.Accessories for model WF3955-45DD,WF3955-45AUT 46

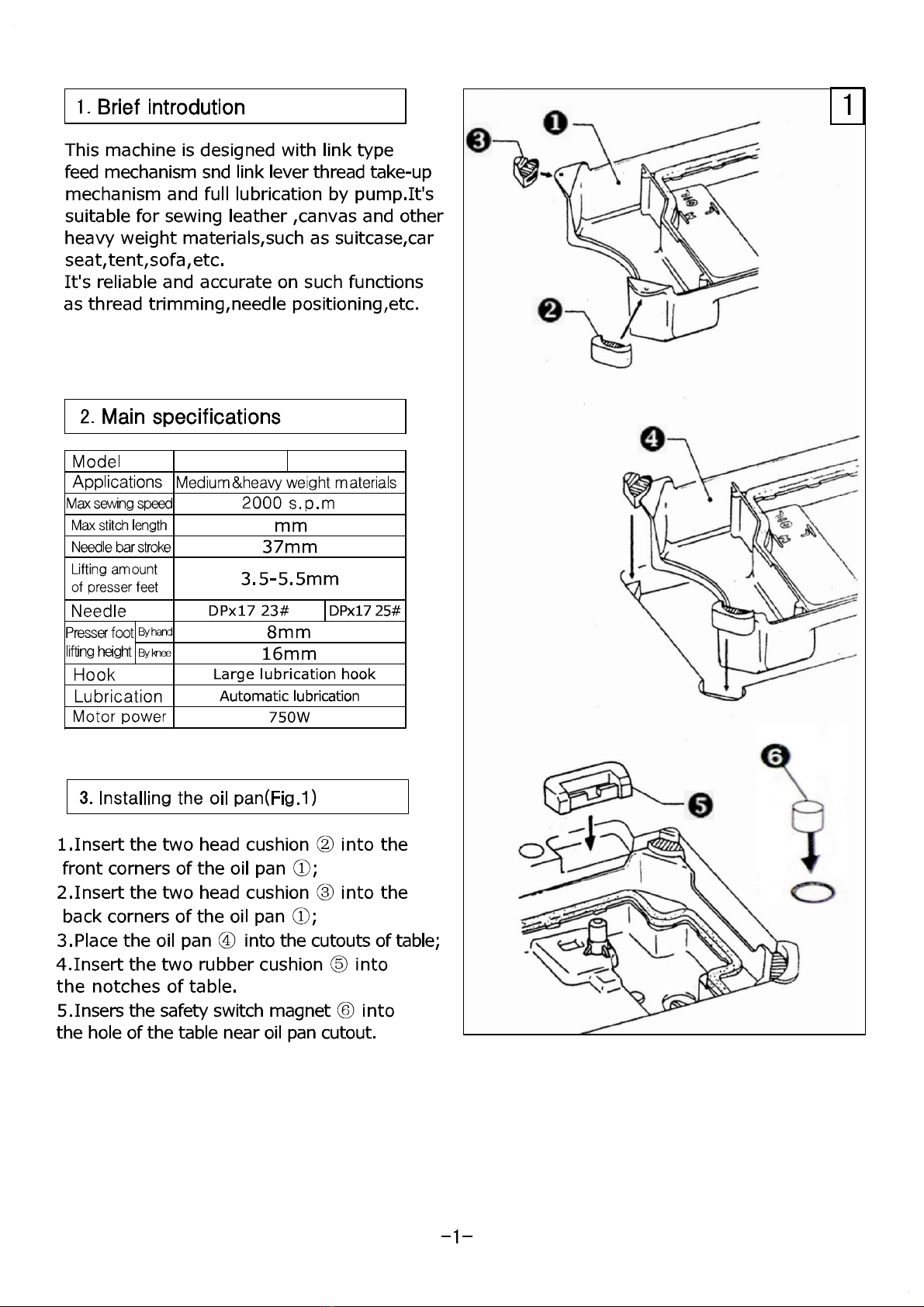

CONTENTS

Operation

instruction

1.Brief introduction

...........................................................................................

1

2.Machine specification

......................................................................................

1

3.Installing

the

oil pan

.................................................................

•·····················

1

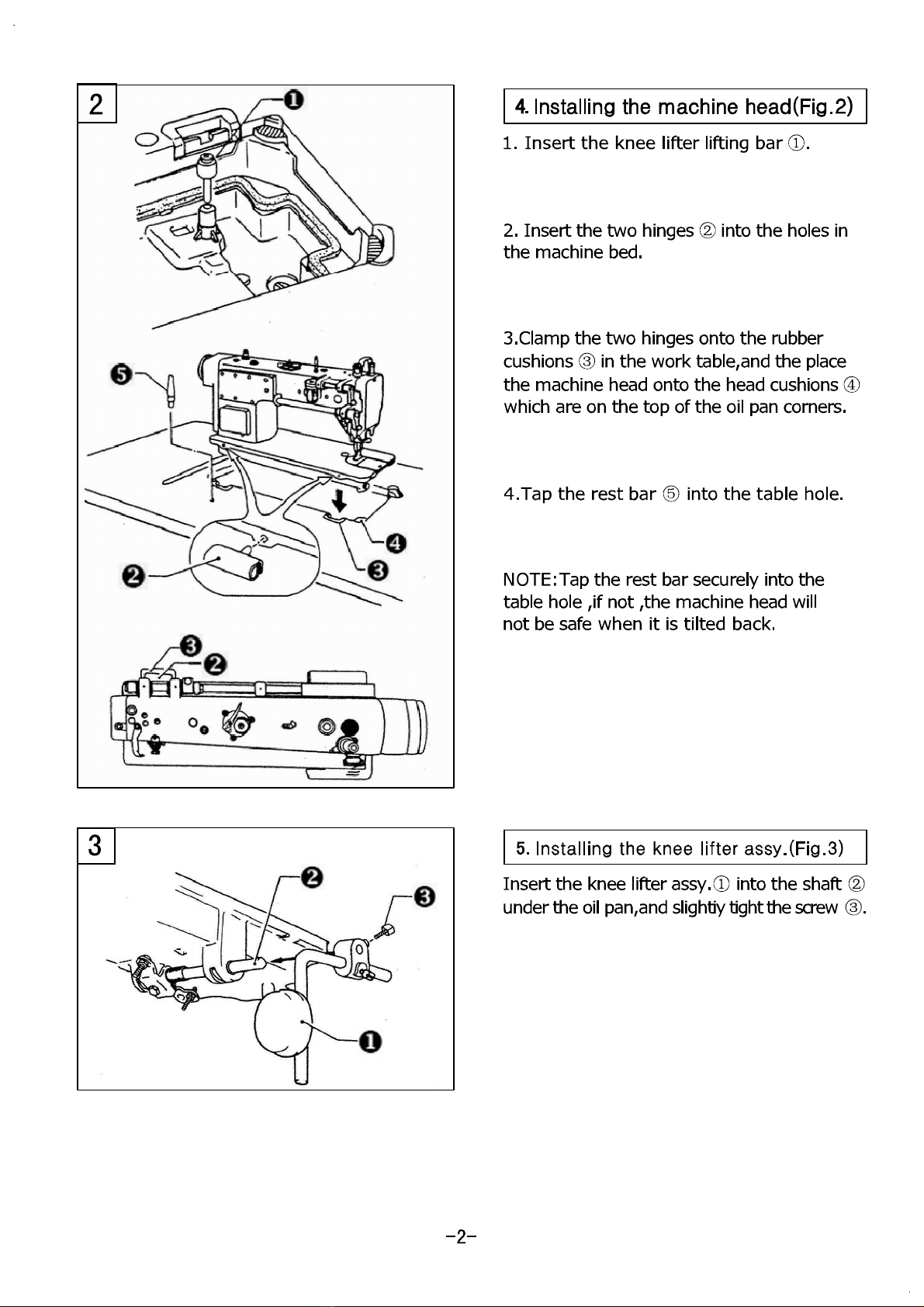

4.Installing

the

machine head

............................................................................

2

5.Installing

the

knee lifter assy

...........................................................................

2

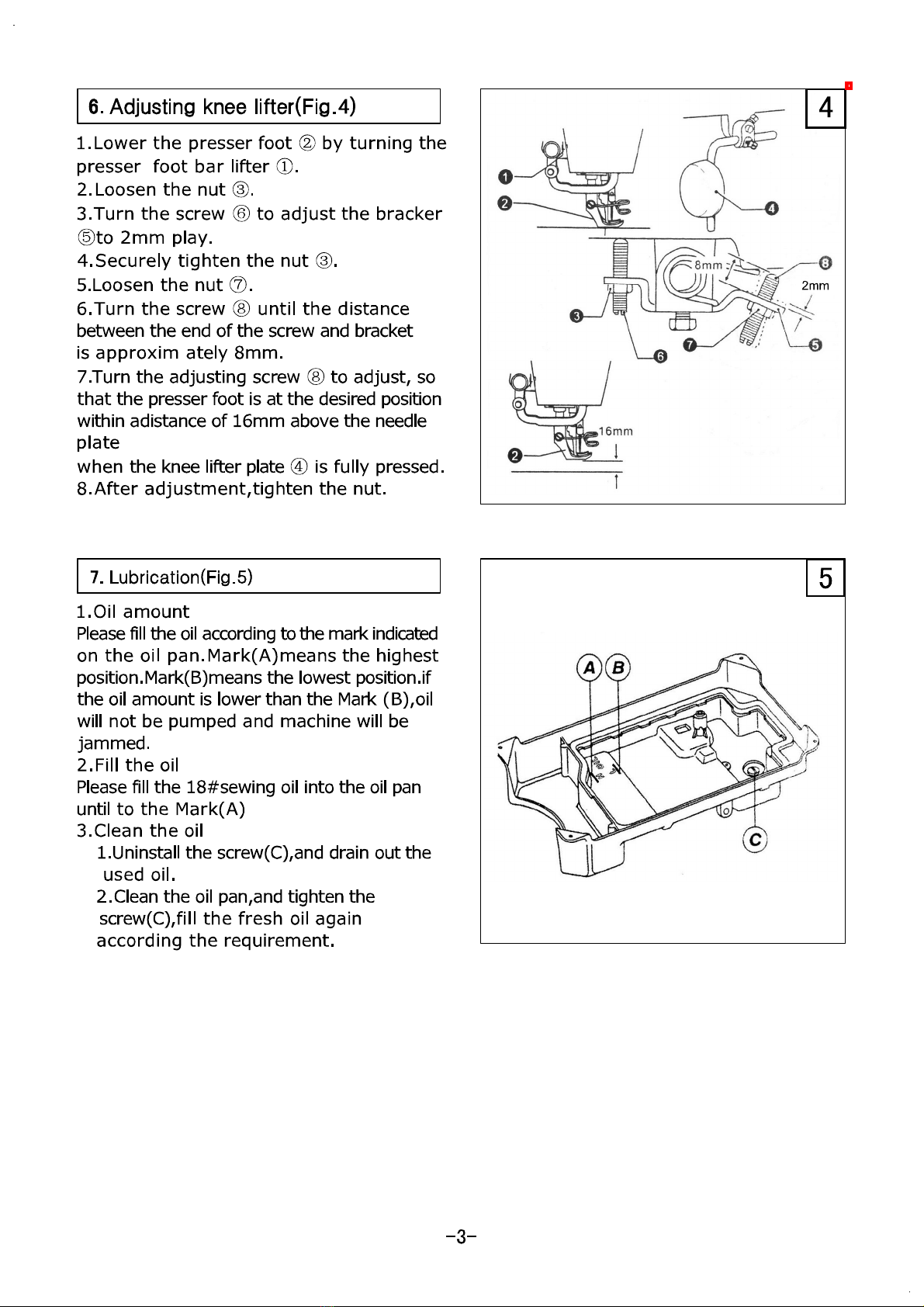

6.Adjusting

the

knee lifter

..................................................................................

3

7.Lubrication

....................................................................................................

3

8.Test operation

...............................................................................................

4

9.Installing

the

needle

.......................................................................................

s

10.Removing

the

bobbin case

.............................................................................

5

11.Winding

the

bobbin thread

............................................................................

s

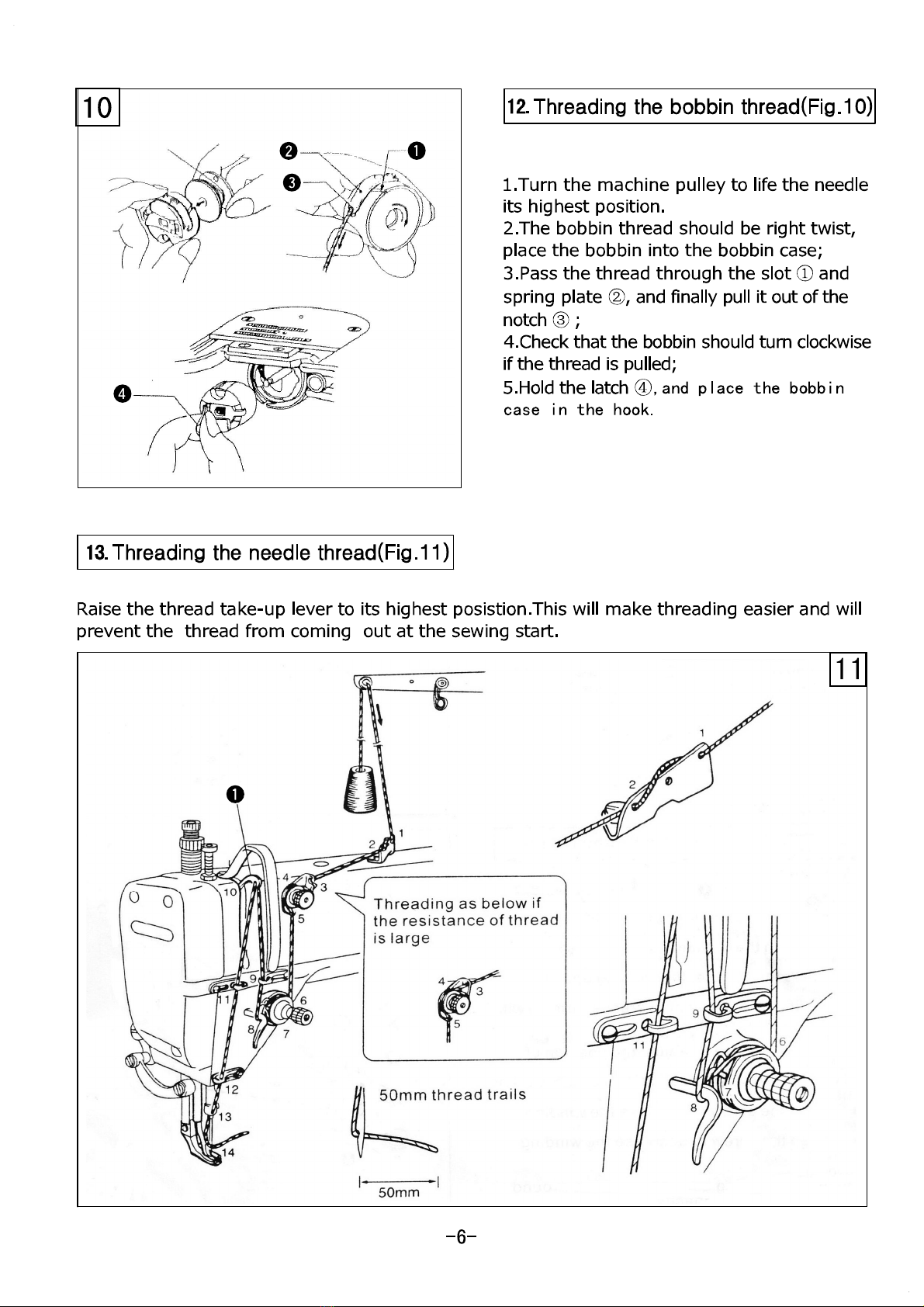

12.Threading

the

bobbin thread

..........................................................................

6

13.Threading

the

needle thread

..........................................................................

6

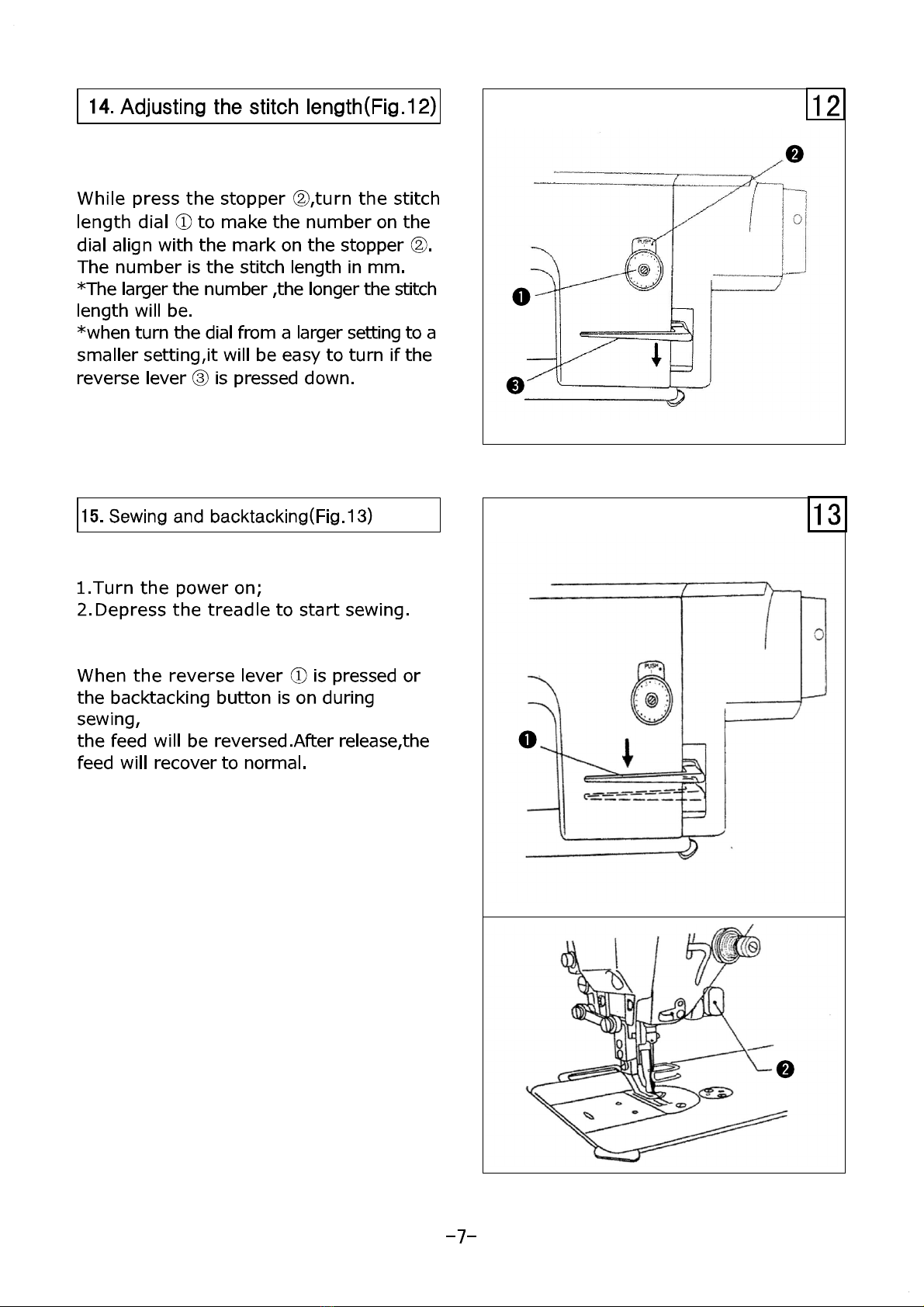

14.Adjusting

the

stitch length

.............................................................................

7

15.Sewing and backtacking

................................................................................

7

16.Adjusting

the

thread tension

..........................................................................

8

17.Adjusting

the

presser

foot

pressure

................................................................

8

18.Adjusting

the

trailing length

after

thread

trimming

...........................................

g

19.Adjusting

the

thread tension spring

................................................................

g

20.Adjusting

the

upper thread guide

..................................................................

10

21.Adjusting

the

presser

foot

height

..................................................................

10

22.Adjusting

the

feed dog height

......................................................................

10

23.Adjusting

the

feed dog angle

.......................................................................

11

24.Adjusting

the

difference

of

stitch length between the forward

and

backtacking

............

11

25.Adjusting

the

tension release

.......................................................................

11

26.Adjusting

the

timing

of

needle and feed mechanism

........................................

12

27.Adjusting

the

rotary

hook lubrication

amount

.................................................

12

28.Adjusting

the

height

of

needle

of

needle bar and the timing with hook

..................

13

29.Adjusting

the

oil pump

................................................................................

13

30.Adjusting

the

lifting

amount

of

presser feet

....................................................

14

31.Adjusting

the

trimming

mechanism

..........................................................

15-16

32.Clean

........................................................................................................

17

Parts

Manual

1.Casting mechanism

..................................................................................

18-21

2.Needle

bar

and thread

take-up

mechanism

..................................................

22-23

3.Presser foot mechanism

............................................................................

24-25

4.Feed mechanism

......................................................................................

26-29

5.Upper feed mechanism

.............................................................................

30-31

6.Hook mechanism

.....................................................................................

32-33

7.Lubrication mechanism

..............................................................................

34-35

8.Thtead

trimming

mechanism

......................................................................

36-39

9.Reverse stitching mechanism

.....................................................................

40-41

10.Accessories

for

model

.............................................................................

42-43

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com