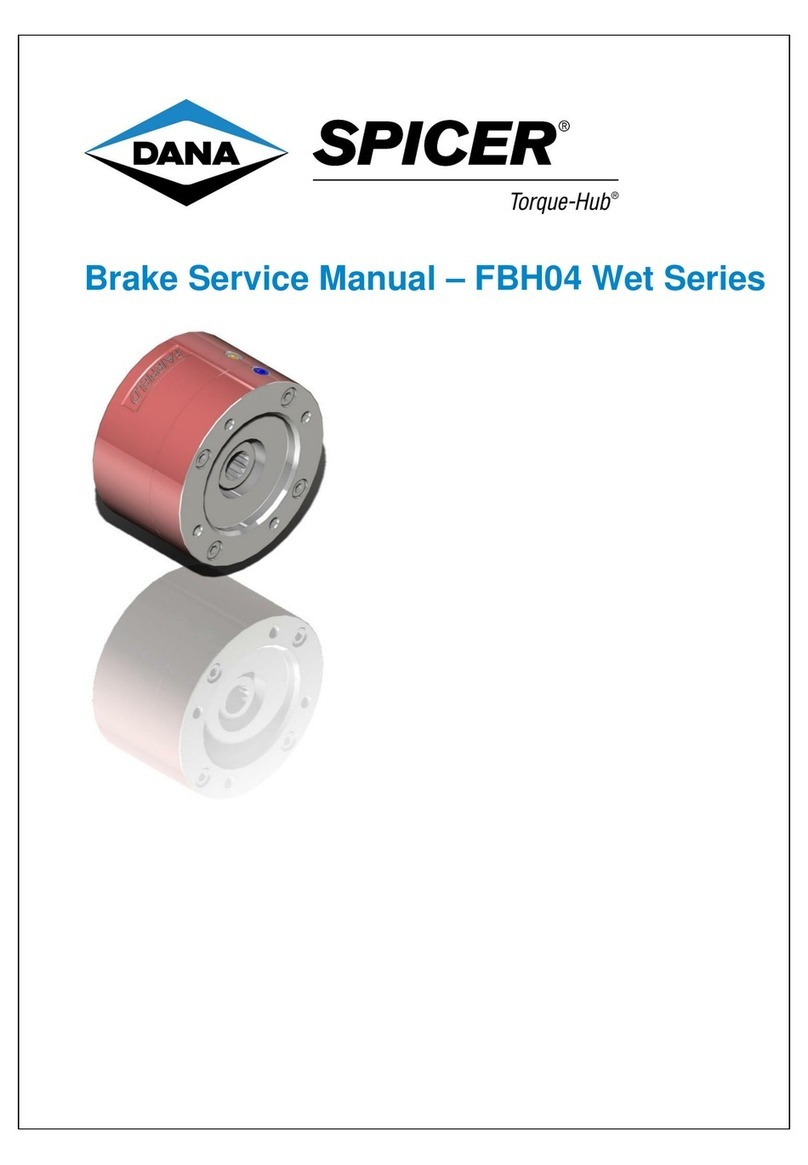

Installation

Position 1-off gasket (5) over male pilot on brake housing

(4). Locate brake shaft (1) and secure brake in position

using 2-off ½” UNC mounting bolts in the through mounting

(fixing) holes provided. Connect hydraulic pressure supply

to brake pressure inlet port. Ensure that the hydraulic

pressure is set to the required level up to a maximum of

3000 psi (200 bar) and check that the brake disengages

and re-engages correctly.

Maintenance

The brake is required to be kept in good working order and

must be included in the planned maintenance program for

the equipment to which the brake is installed. This must

include torque testing together with inspection and replace-

ment of the working parts such as friction plates (3 & 6)

and, springs (22 & 23). The frequency of inspection

depends on the duty demanded of the brake.

Dismantling (and Dis-assembly)

To remove brake from its installed position, reverse

procedure previously described in the Installation instruc-

tions. Place the complete brake assembly on a clean, dry

workbench.

Remove external gaskets (5) as necessary.

REFER TO DIAGRAMS FOR THE FOLLOWING:

1)

Supporting brake on face ‘A’, remove the six socket

head cap screws (SHCS) and washers (items 13 & 14) in

equal increments to ensure the spring pressure within

the brake is reduced gradually and evenly. Alterna-

tively, if a press is available, the cylinder housing (8) can

be restrained on face ‘B’ while removing the six SHCS

and washers (13 & 14). The brake assembly can nowbe

fully dismantled and the partsexamined.

2)

Remove cylinder housing (8) and piston (9) sub-assem-

bly and dismantle if required, removing ‘O’ ring seals (15

& 17) and backing rings (16 & 18) as necessary.

3)

Remove gasket (7) from housing(2).

4)

Remove friction plates (3 & 6) and pressure plate (4).

Important: Friction faces must not come into contact

with oil or grease as this will seriously reduce the brake

torque capacity.

5)

Remove 2-off dowel pins(19).

6)

Remove springs (22 & 23).

Note: See chart on page 5 for spring arrangement and

quantities for the particular brake model used.

7)

Should it be necessary to replace ball bearing (10) or

shaft seal (12), reverse remainder of brakesub-assem-

bly, supporting on face ‘C’ of housing (2).

8)

Remove internal retaining ring(11).

9)

Using arbor press or similar to break ‘Loctite’ seal,

remove brake shaft (1) from housing (2) and layaside.

10)

Reverse housing (2) and press out ball bearing(10).

Shaft seal (12) can also be removed ifnecessary.

Examination

All components can now be examined and inspected,

paying particular attention to the following:

1)

Inspect friction plates (3 & 6) and friction surfaceon

pressure plate (4) for wear ordamage.

2)

Examine friction plates (3) and brake shaft (1) forwear

or damage to thesplines.

3)

Examine input and output splines of brake shaft (1)for

wear ordamage.

4)

Examine compression springs (22 & 23) for damageor

fatigue.

5)

Check ball bearing (10) for axial float or wear.

6)

Examine ‘O’ ring seals (15 & 17) and backing rings (16

& 18) for damage.

OBTAIN REPLACEMENT PARTS AS REQUIRED.

Assembly

Clean all parts thoroughly. Reverse procedure previously

outlined in Dismantling instructions taking particular care

with:

a)

Assembly of shaft seal (12).

b)

Assembly of bearing (10).

c)

Quantity and orientation of springs (22 &23).

Note: See chart on page 5 for spring quantities and

arrangement for the particular brake model used.

d)

Assembly sequence of friction plates (3 & 6). - See

diagram.

1)

Lightly lubricate rotary shaft seal (12) and assembleto

housing (2) taking care not to damage seallip.

2)

Apply ring of Loctite 641 or equivalent adhesive to full

circumference of housing (2) bearing recess adjacent to

shoulder. Apply complete coverage of Loctite 641 to

outside diameter of bearing (10) and assemble fully in

housing (2), retaining with internal retaining ring (11).

Remove excess adhesive with a clean cloth. Press shaft

(1)

through bearing (10), ensuring bearing inner ringis

adequately supported.

3)

Assemble correct quantity of springs (22 & 23) in

orientation required.