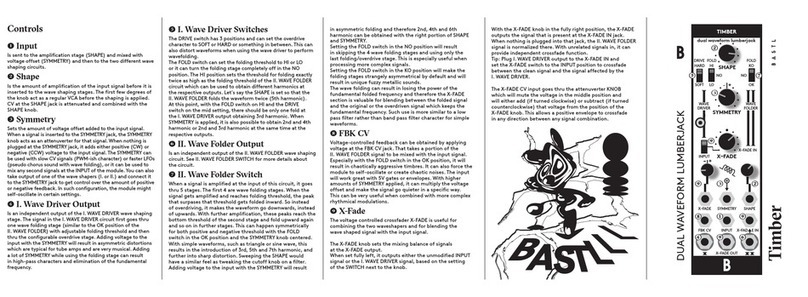

Bastl Instruments POPCORN v1.1 User manual

last update: 19. 7. 2018

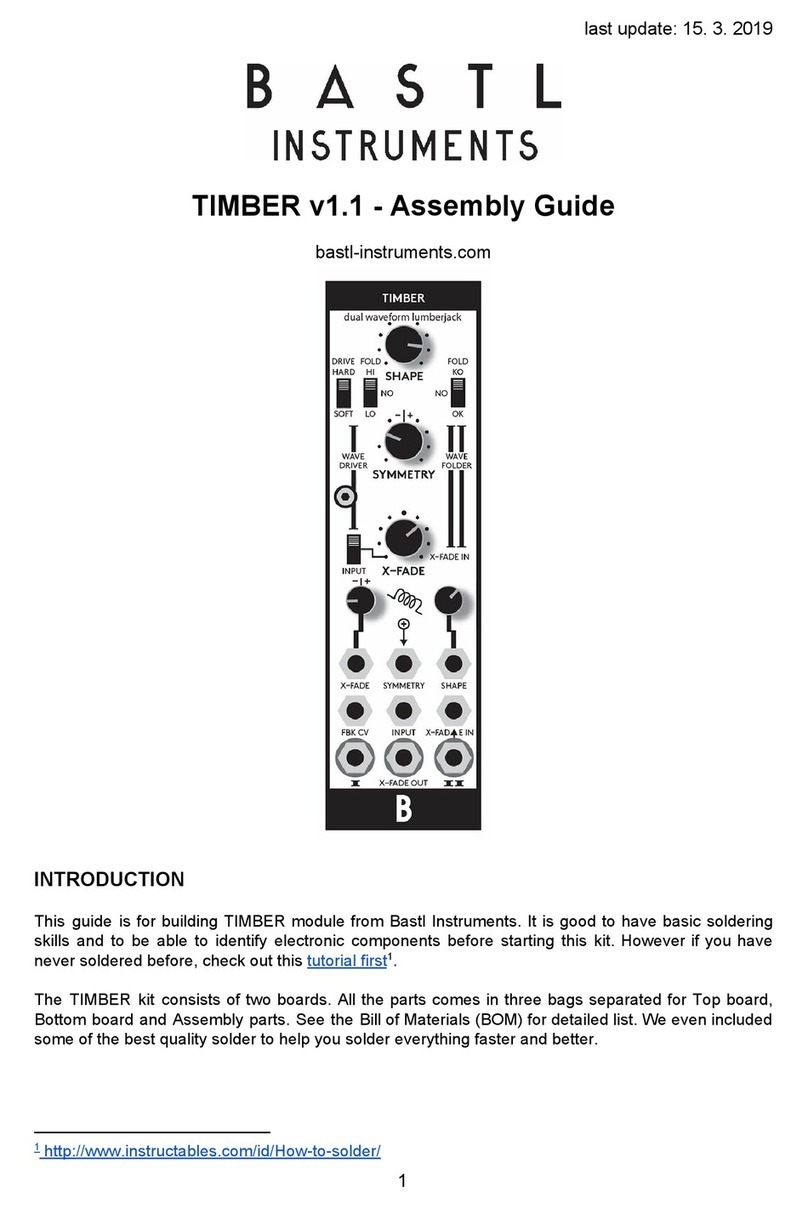

POPCORN v1.1 - Assembly Guide

bastl-instruments.com

INTRODUCTION

This guide is for building Popcorn module from Bastl Instruments. It is good to have basic soldering

skills and to be able to identify electronic components before starting this kit. However if you have

never soldered before, check out this tutorial first .

1

The Popcorn kit consists of two boards. All the parts comes in three bags separated for Top board,

Bottom board and Assembly parts. See Bill of Materials (BOM) for detailed list. We even included

some of the best quality solder to help you solder everything faster and better.

1 http://www.instructables.com/id/How-to-solder/

1

BILL OF MATERIALS

POPCORN v1.1

TOP BOARD

qty

value

part

6

220R

R-EU_0204/5

9

1k

R-EU_0204/5

9

17mm

long small button

6

PJ-301BMB

jack connector

9

green

LED 3 mm

6

bipolar R/G

LED 3 mm

8

B100K 25mm

linear potentiometer

2

B100K 25mm

linear potentiometer - central detent

1

2x4 pin

Male pinheader

1

19 pin

Male pinheader

4

6 pin

Male pinheader

BOTTOM BOARD

1

220R

R-EU_0204/5

1

1k

R-EU_0204/5

2

1

10k

R-EU_0204/5

8

100k

R-EU_0204/5

1

33k

R-EU_0204/5

1

47k

R-EU_0204/5

1

330k

R-EU_0204/5

1

4M7

R-EU_0207/5

2

1N4007

DIODE-D-7.5

17

100nF

ceramic capacitor

4

10uF

electrolytic capacitor

3

2N3904

transistor

1

7805

voltage regulator

1

L79L05

voltage regulator

1

16MHz

resonator

2

100mA

fuse

1

ATMEGA328-PU-ND

4

74HC595

IC in foam

3

CD4051BE

IC in foam

1

MCP6002

IC in foam

1

MCP4921

IC in foam

1

TL072

IC in foam

3

8 pin DIL

DIL socket - in foam

7

16 pin DIL

DIL socket - in foam

1

28 pin DIL

DIL socket - in foam

2

40 pin

Female pinheader

1

2x4 pin

Double female pinheader

1

6 pin

Male pinheader

1

8 pin

Male pinheader

3

2x5 pin

Double male pinheader

ASSEMBLY

1

M3 x 11mm

spacer nut x nut

1

M3 x 11,5mm

spacer screw x nut

3

M3 x 6mm_Imbus

screw

1

M3

nut

4

M3 x 8mm_cross

panel screw + washers

6

jack washers

6

jack nuts

1

allen key

1

bottom

PCB

1

top

PCB

1

power cable 10-10pin

1

power cable 10-16pin

1

front panel / w DIY sign

3

BEFORE STARTING THE KIT...

Before starting this kit, prepare the following tools:

● Soldering iron

● Multi-meter

● Flush cutters

● Smaller pliers

● n2. hex screwdriver or allen key (enclosed with kit)

● Phillips screwdriver

● Wrench No. 8

● Protective eyewear

● Isopropyl alcohol + smaller and clean brush (optional)

We suggest that you work in a clean and a well lit and ventilated environment to avoid accidents or

losing any of the small components. Also briefly go through this guide and make sure that you

understand all the steps before you start soldering.

When you are done with soldering, you would probably like to calibrate your Popcorn. It is pretty

simple. Please check the info about firmware v1.1 and calibration guide here .

2

BOTTOM BOARD

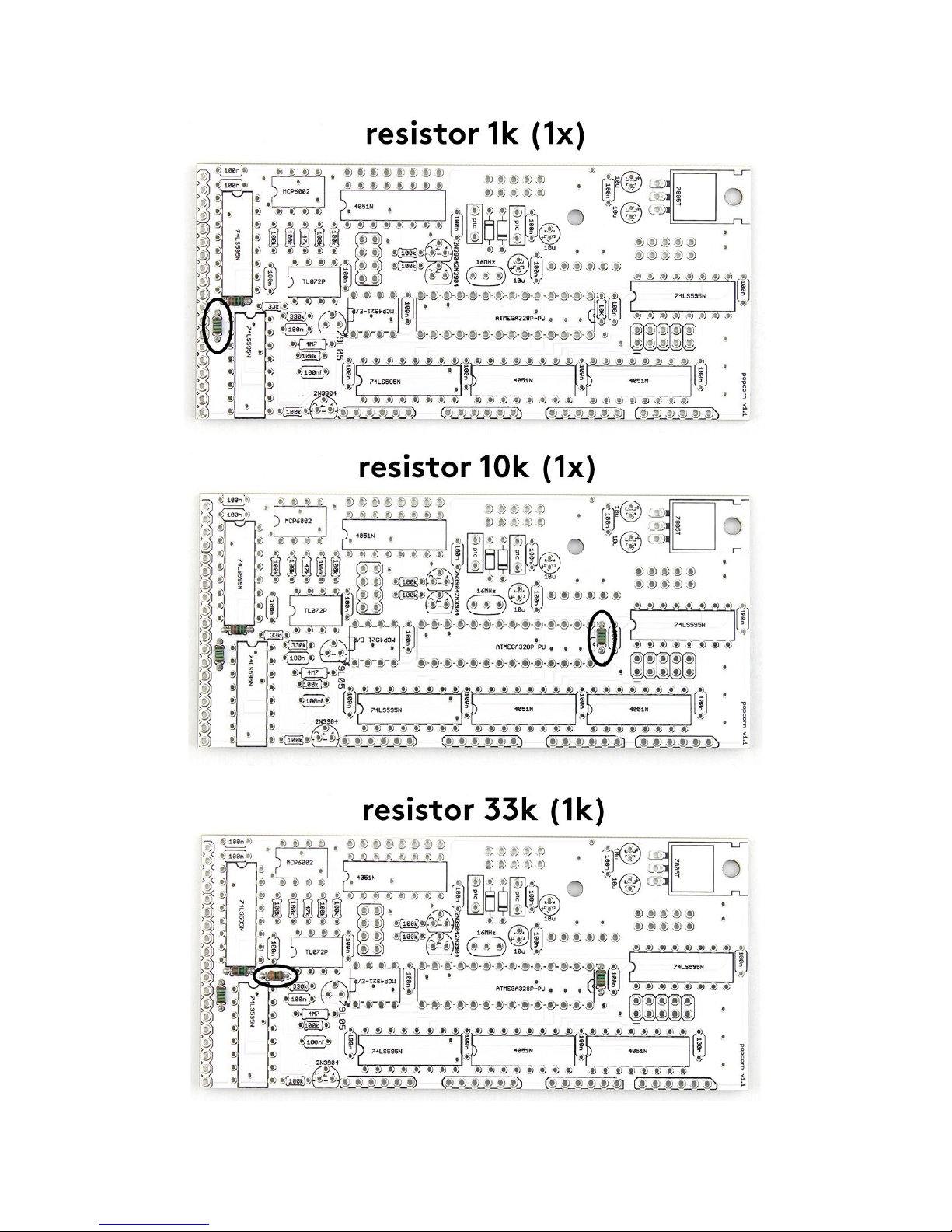

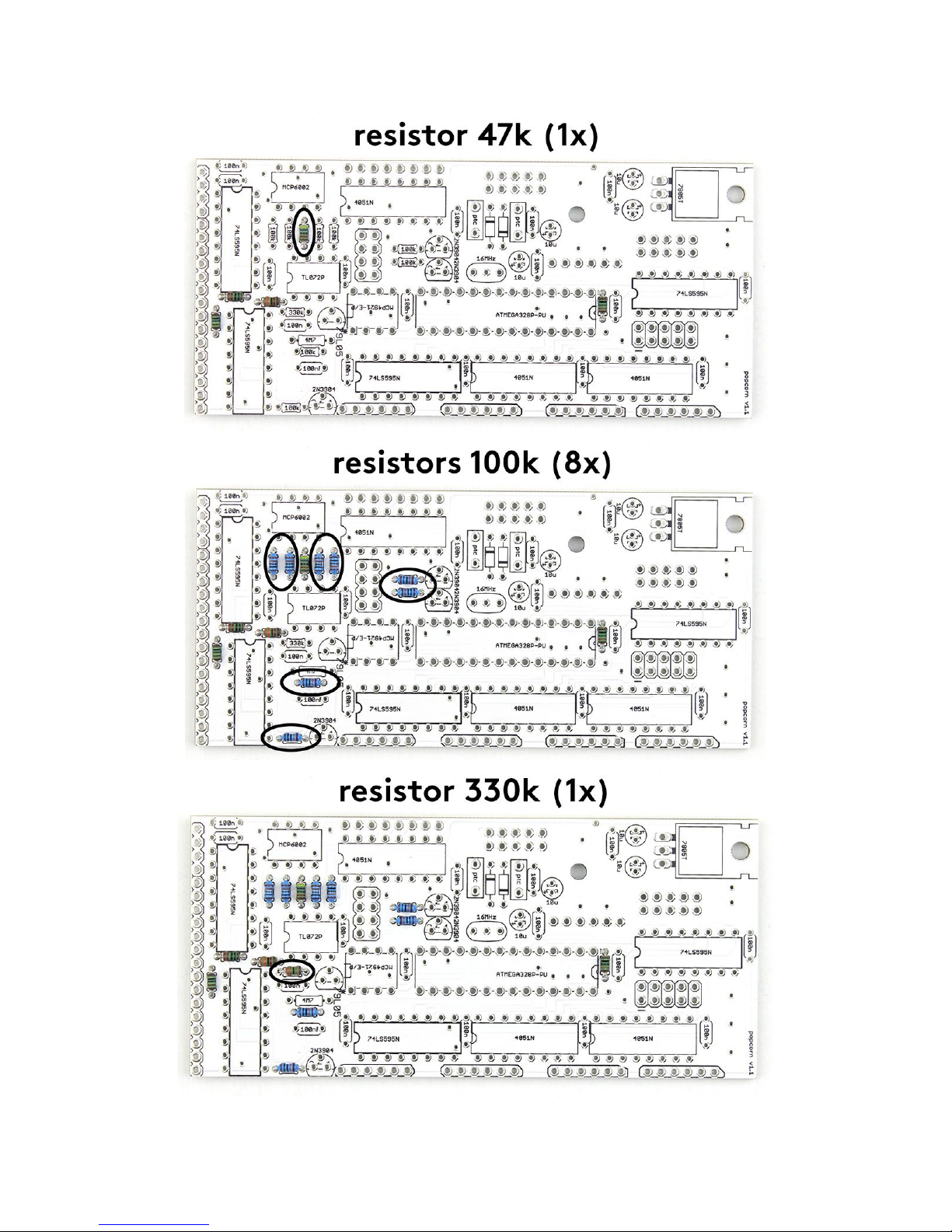

RESISTORS

Start with the bottom board parts. First of all, take your time and check the values of all resistors

using a multimeter (or you can check the color codes if you are seasoned enough):

3

-220R (1x), 1k (1x), 10k (1x), 33k (1x), 47k (1x), 100k (8x), 330k (1x), 4M7 (1x).

Then solder them on the bottom PCB and snip the leads close to the PCB (be sure to make this step

on all remaining leads in the course of this guide).

2 http://www.bastl-instruments.com/wp-content/uploads/2018/06/popcorn-v1.1-update.pdf

3 https://learn.sparkfun.com/tutorials/how-to-use-a-multimeter/measuring-resistance

4

5

6

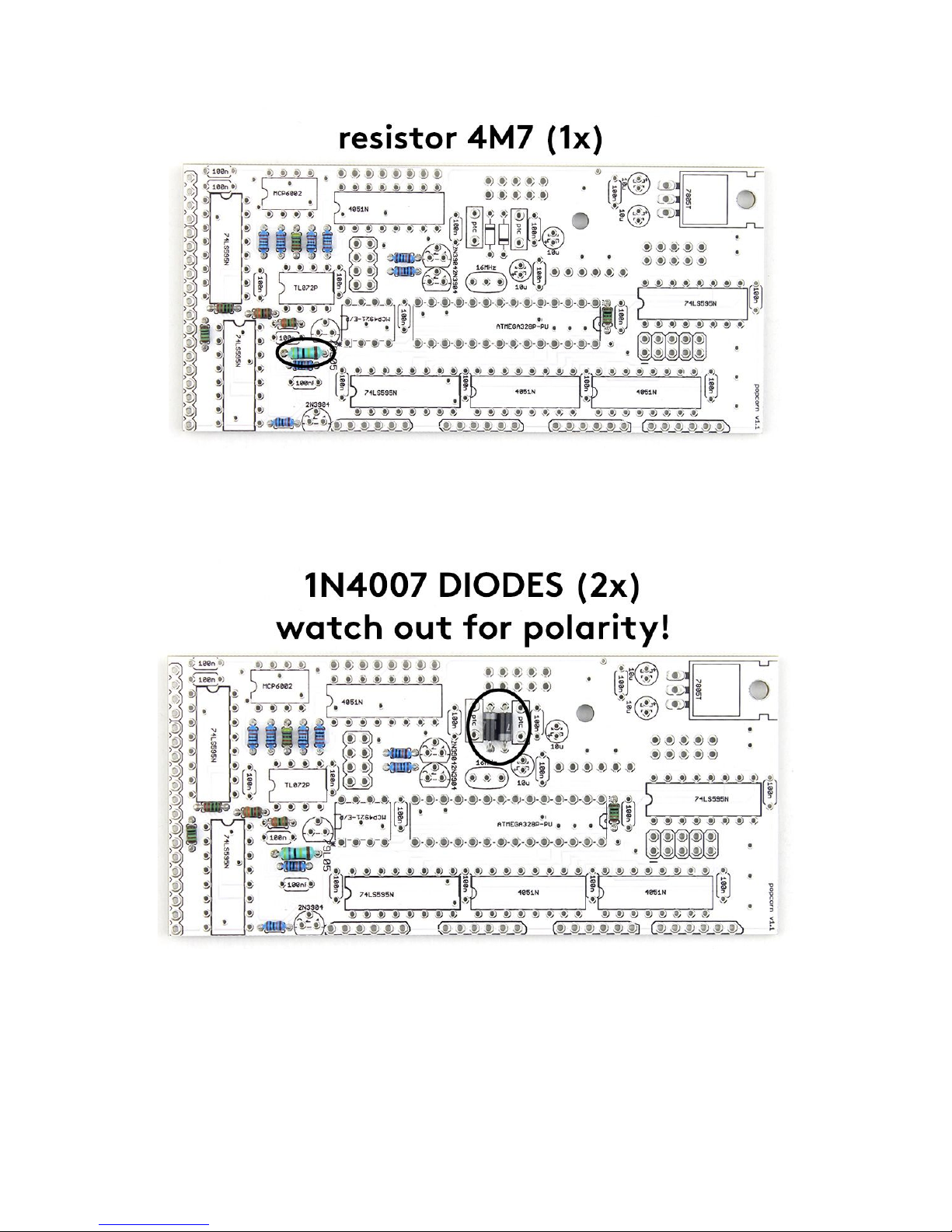

DIODES

Solder also the diodes (1N4007 - 2x). Be careful, diodes are polarized! Make sure that the marking

ring on the diode body matches the marking on the circuit board. Check the photo below.

7

MALE HEADERS

Solder the male pinheaders now (1x 6 pins, 1x 8 pins and 3x double 5x pins). Be careful to solder

them straight. You may first solder just one of the pin, take the board in your hand and re-heat that pin

while pressing down on the header to align it (be careful, you don’t want to touch the pin you are

heating up). Wait for it to cool and solder the rest of the pins.

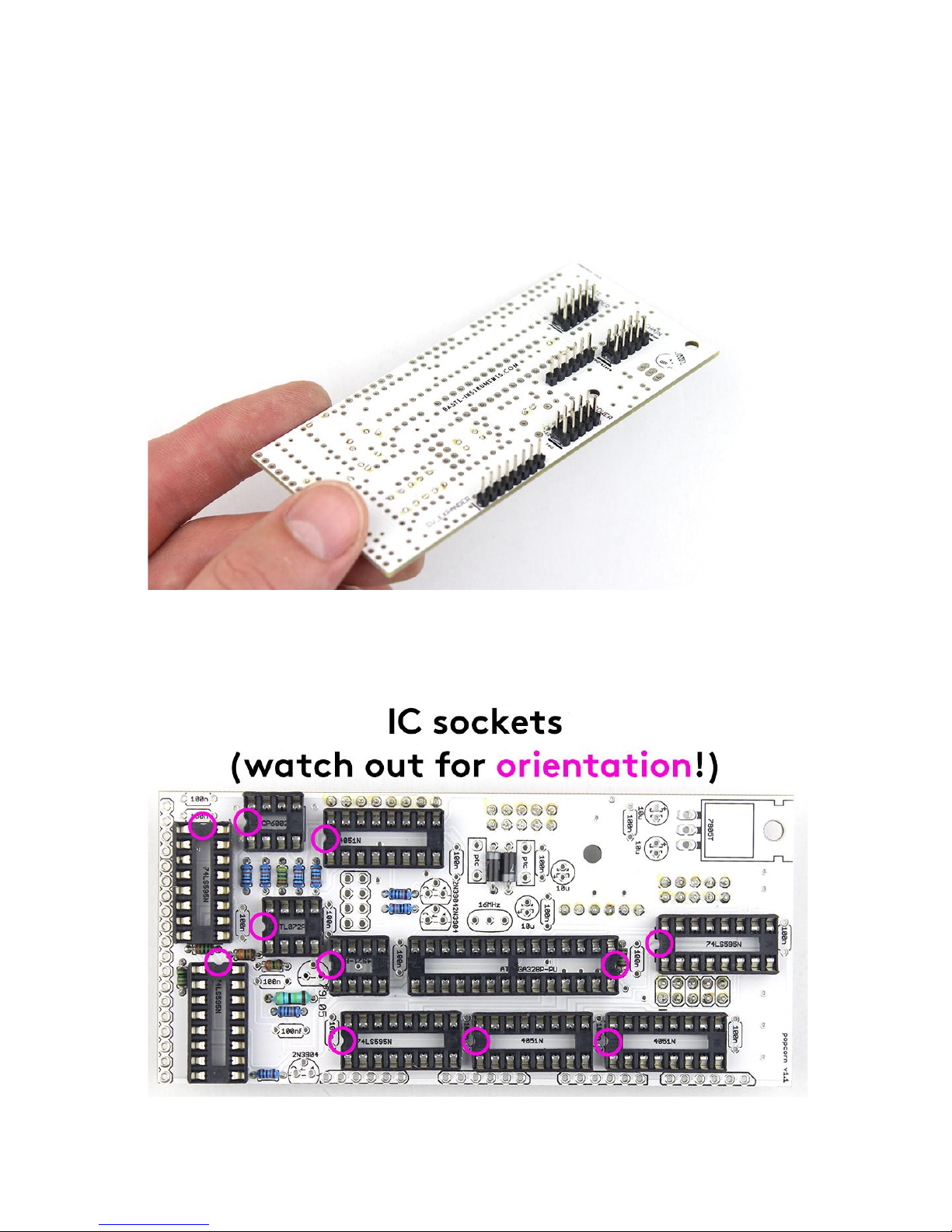

IC SOCKETS

Solder all the IC sockets (3x 8 pin, 7x 16 pin and 1x 28 pin). Make sure that the notch on the

socket matches the print on the board.

8

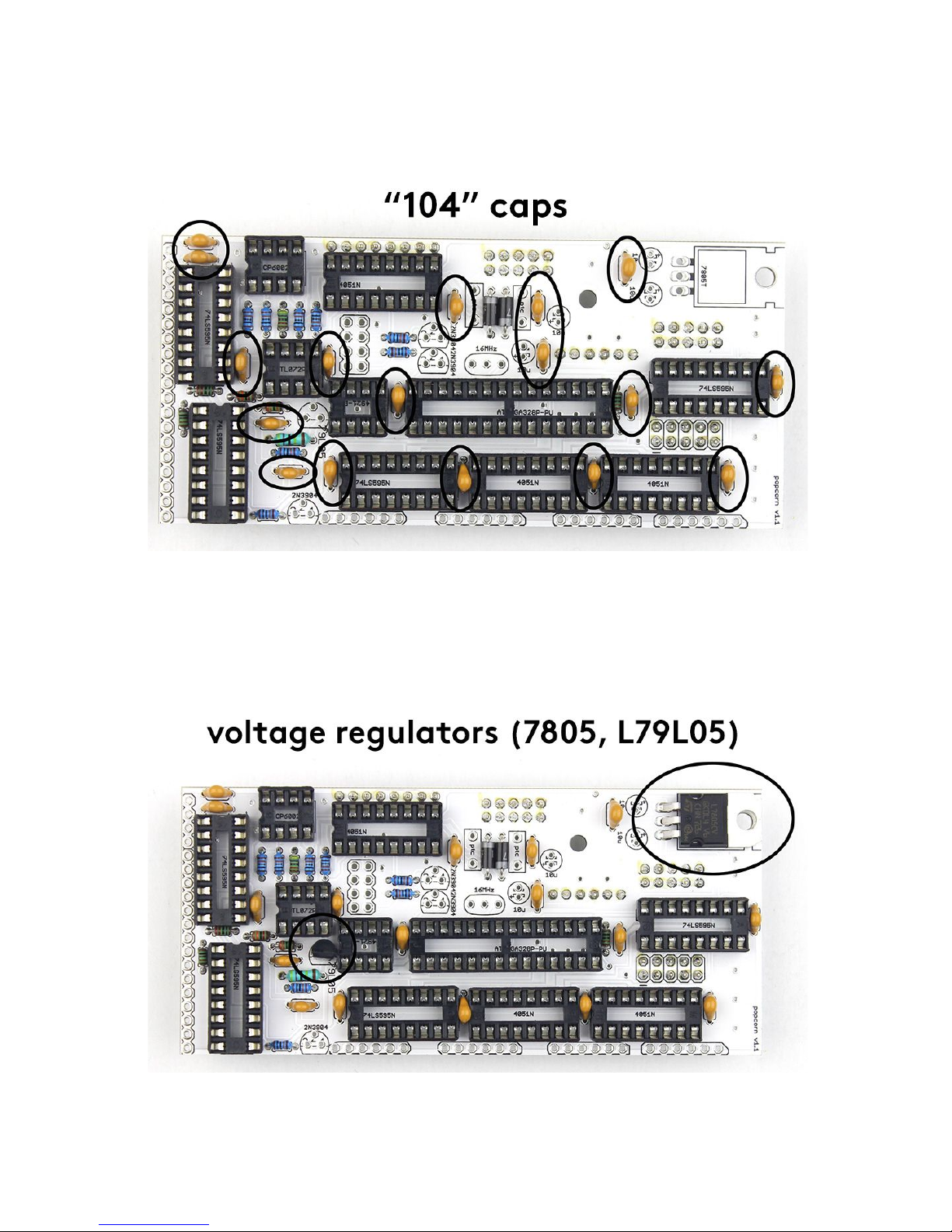

CAPACITORS

Let’s do the 100nF ceramic capacitors now. There are seventeen of them (marked “104” on itself).

VOLTAGE REGULATOR

Proceed to the 7805 voltage regulator. Bend its legs close to the body first. Insert it then to the spot

and make it lay on the PCB.

There is also another voltage regulator (L95L05). Add it to the right spot and be aware of the

orientation. It has to match the outline on the PCB.

9

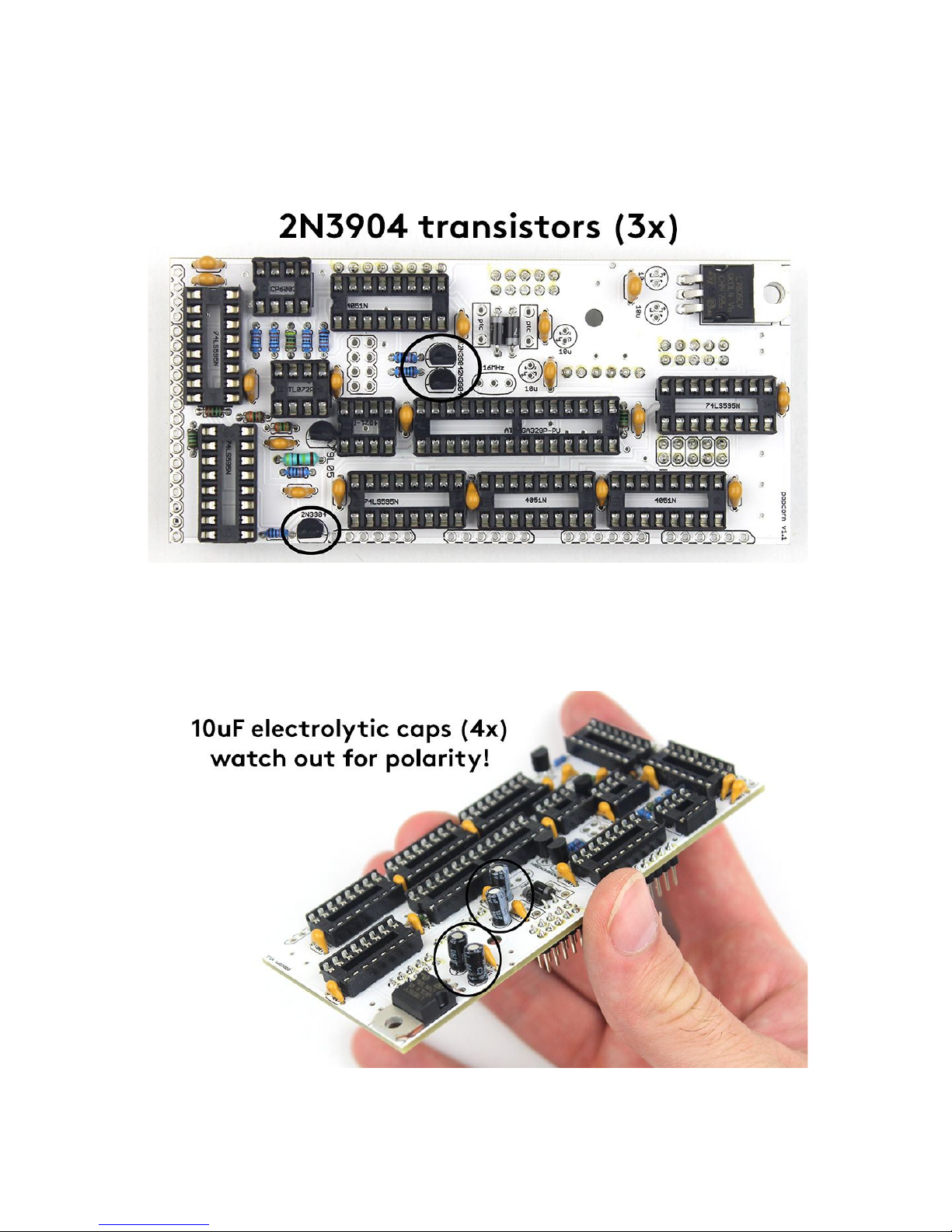

TRANSISTORS

Add three transistors (2N3904). Just be aware of the right orientation again!

ELECTROLYTIC CAPACITORS

Let’s do the electrolytic caps (4x 10μF). These ones are polarized! There is a plus (+) sign on the

PCB that has to match the longer lead of the electrolytic capacitor (actually the minus (–) side is also

marked on the body of the capacitor with a white strip).

10

FUSES

Solder the two fuses right on the rectangular spot signed “PTC”. These parts look quite similar to

capacitors so don’t let it confuse you.

RESONATOR

Insert also the resonator (the orange component with 3 leads). This part is not polarized so you can

insert it in any direction.

11

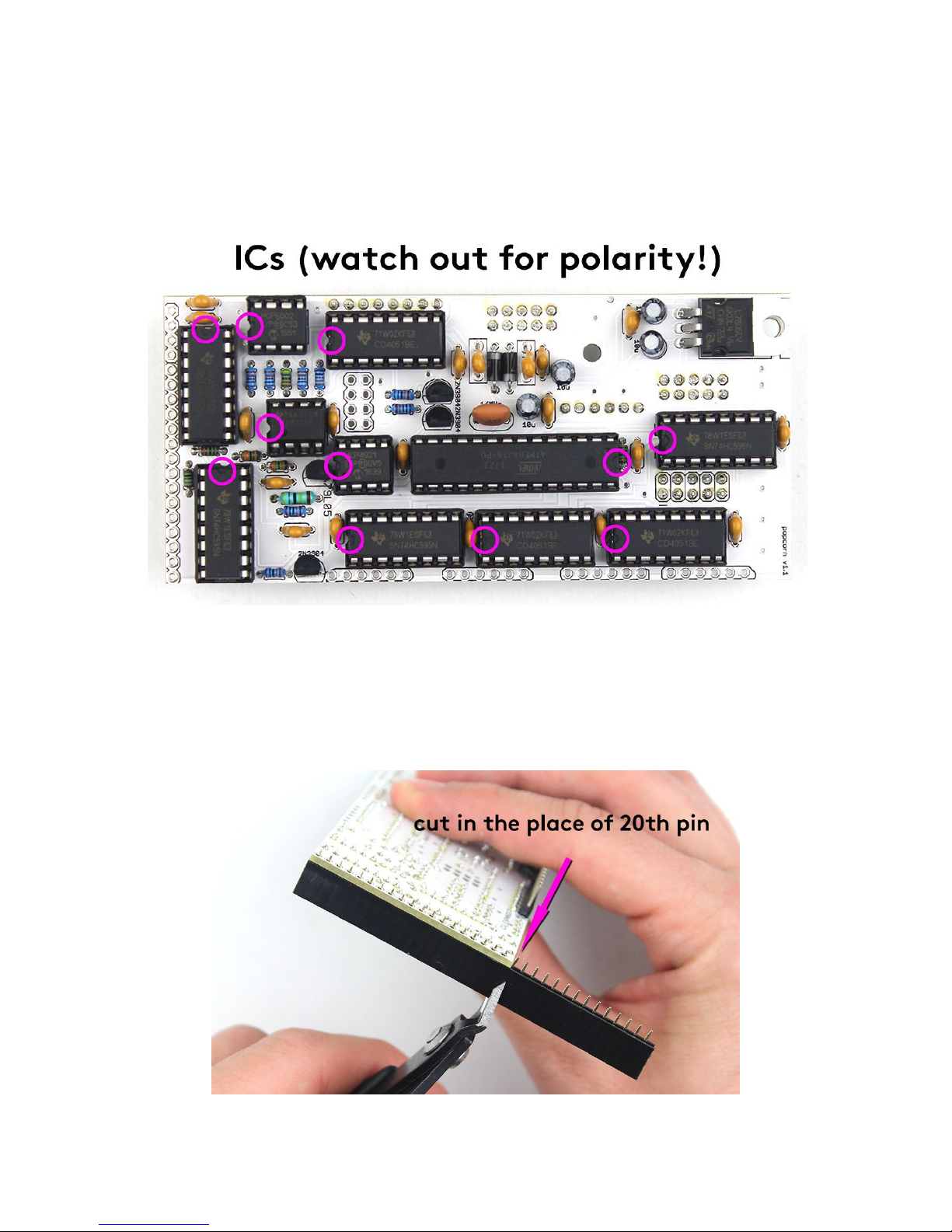

INSERTING ICs

Next don’t forget to place ICs into the sockets (1x TL072, 1x MCP4921, 1x MCP6002, 3x CD4051BE,

4x 74HC595, 1x Atmega). There is a notch on each IC that should match with the notch on the

socket (for TL072 is relevant the dot on it). Installing ICs can be also a little tricky. You should bend

the IC leads in slightly with your fingers. Then press all the leads into the sockets in one shot.

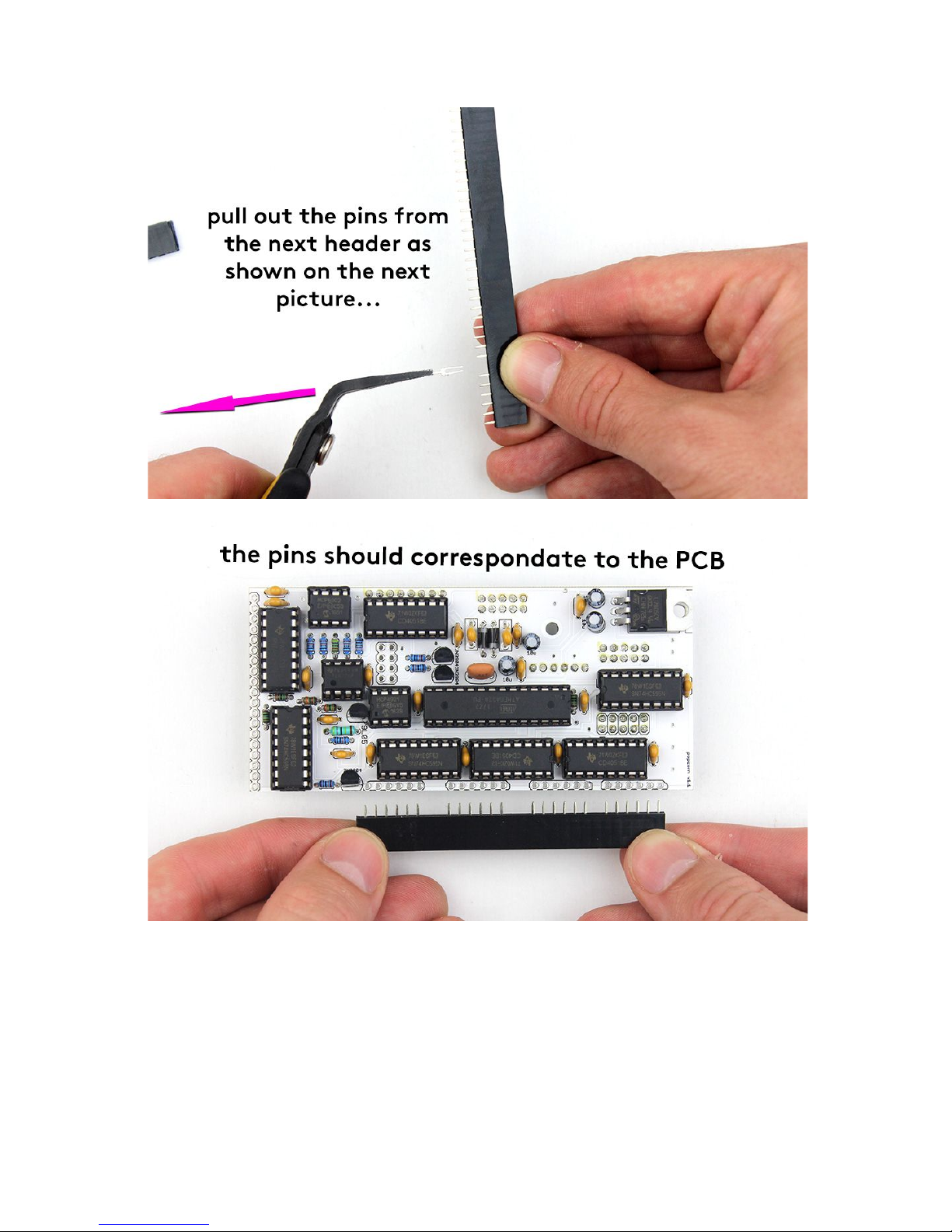

PREPARING FEMALE HEADERS

As you can see two female pinheaders left. You can prepare them now. Use your flush cutters to

get the lengths of 19 and 29 pins. You will always lose one pin when cutting the female headers, so

be sure to cut it always after the last required pin - see the picture to check where to cut to get 19 pin.

Then you have to adjust the 29 pin one by pulling out some pins. See the photos again. Hold on with

these parts then. You will use them in later steps

12

For now you are finally done with the bottom board. Make the last check that all parts are on the right

place and everything is properly soldered.

13

TOP BOARD

RESISTORS

Let's move to the top PCB now. Again, start with the resistors:

-220R (6x), 1k (9x)

14

PINHEADERS

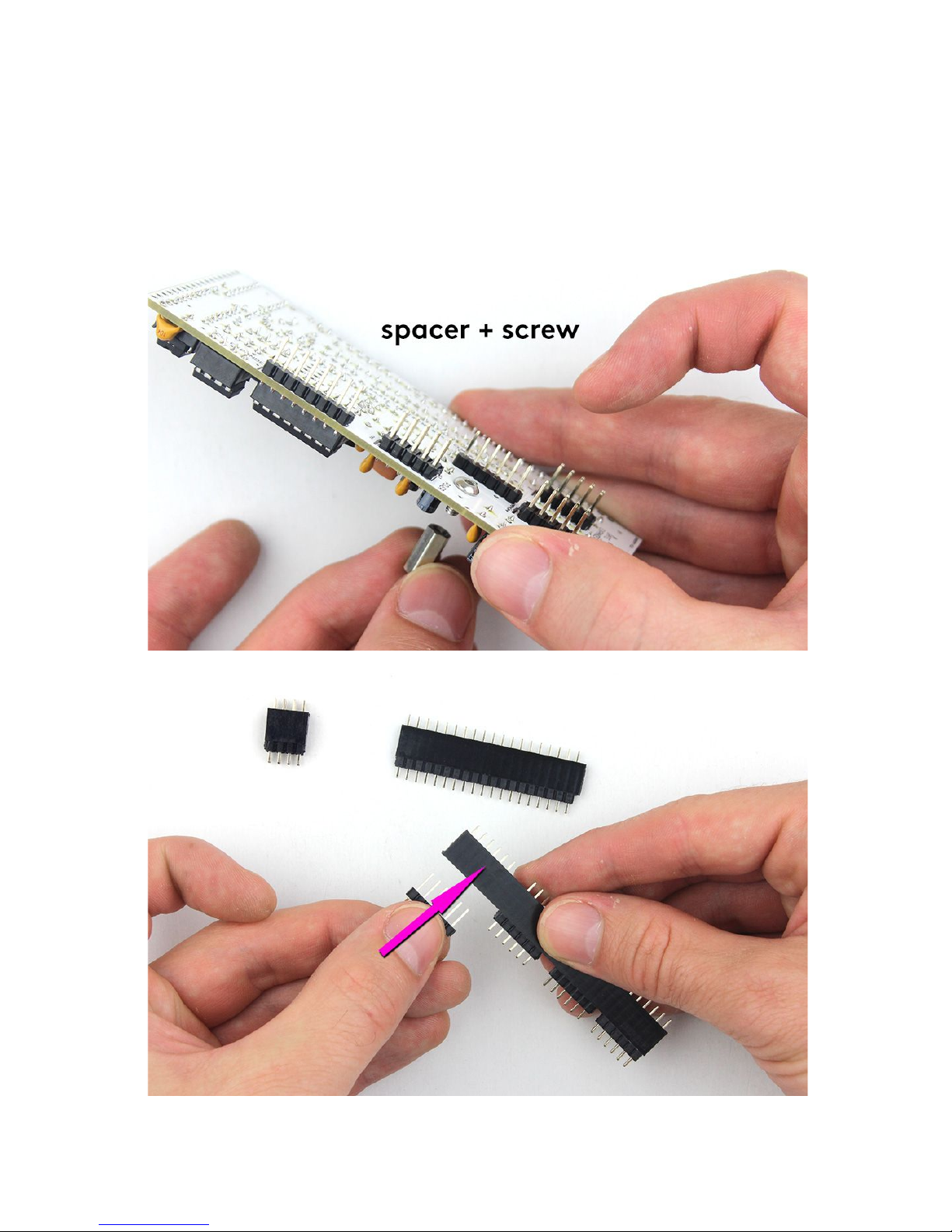

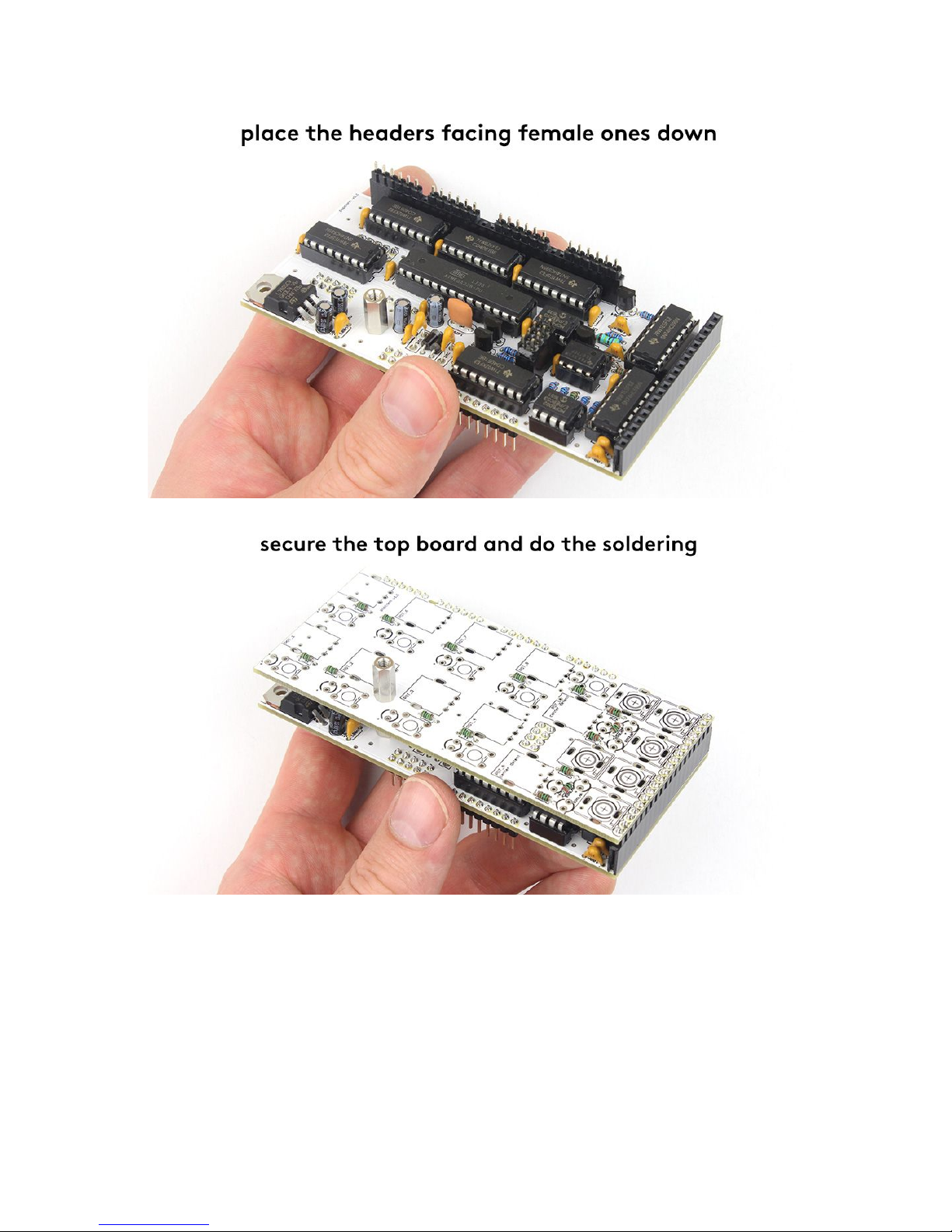

Now it’s time to connect the boards with pinheaders.

1) Mount the spacer with the screw to the bottom board first.

2) Insert male headers into the female ones.

3) Put the headers on the bottom board facing the female ones down.

4) Place the top board on and secure it with the other spacer. Check the position and do the

soldering of headers finally.

15

16

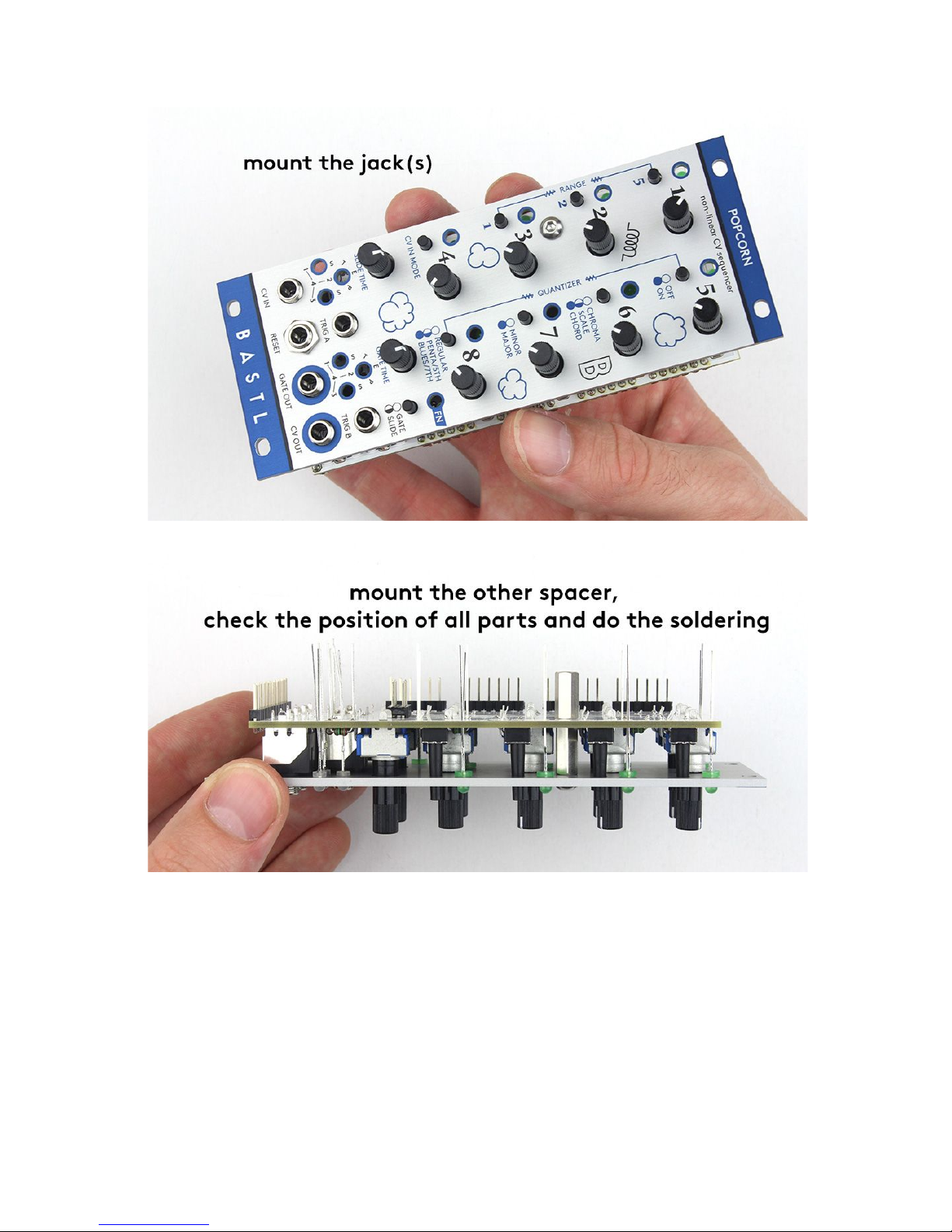

JACKS, POTENTIOMETERS, BUTTONS & LEDS

You are almost done. Let's do the rest of the components by just putting them in first (no soldering

yet! It starts at point 8!):

1) Unmount the top board.

2) Insert green LEDs (9x) -watch out for orientation! (the longer lead has to go into the plus

(+) hole signed on PCB). Insert also the transparent ones (6x) - watch out for orientation

again!

3) Insert buttons (9x) - be sure they’re at the right angle and right on the board.

4) Try the center detent potentiometers (2x) and place them at their spot - be sure they’re

placed in the right angle and they’re right on the board. Then do also the rest of

potentiometers (8x).

5) Insert jack connectors (6x).

6) Mount the spacer to the front panel.

7) Place the front panel on and mount the jacks (you don’t have to mount them all as you have

to unmount them in the next step).

8) Mount the spacer with the other one. Check the position of all the parts if they are flat on the

board and at the right angle, push the LEDs to the panel and do the soldering (SOLDERING

TIP: you can start by soldering just one of the leg at each component so you can make

adjustments easier by reheating)

17

18

19

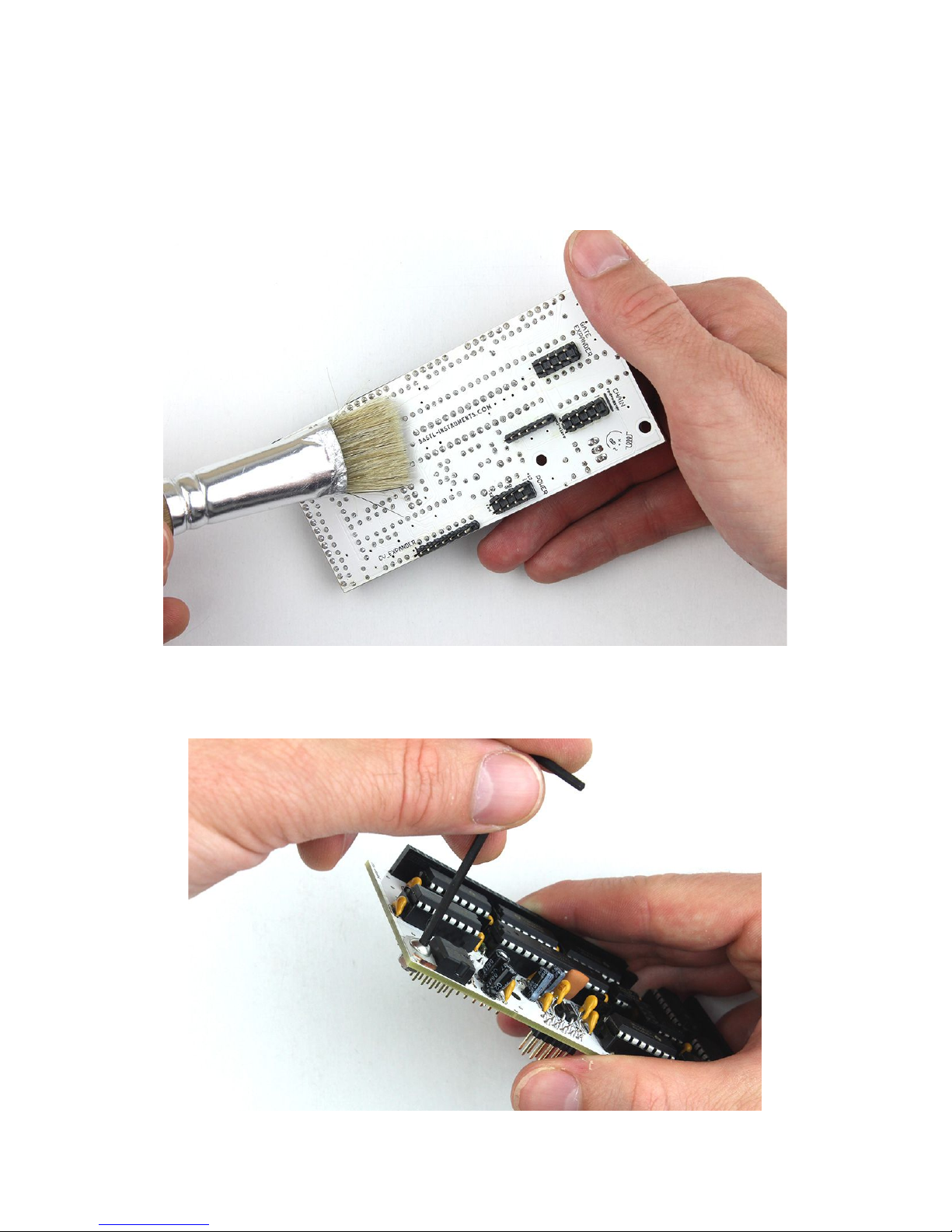

CLEANING (OPTIONAL)

After the soldering is done you might want to clean your PCB. You can use e.g. isopropyl alcohol. Put

some of the liquid all over the PCB using the brush (be aware to not let it flow into the pots), let it act

for a while and sweep it off. Then just let it dry. You can repeat these steps until you are satisfied with

the result.

SCREW + NUT

You can also mount the screw and nut to the voltage regulator now.

20

Table of contents

Other Bastl Instruments Recording Equipment manuals

Bastl Instruments

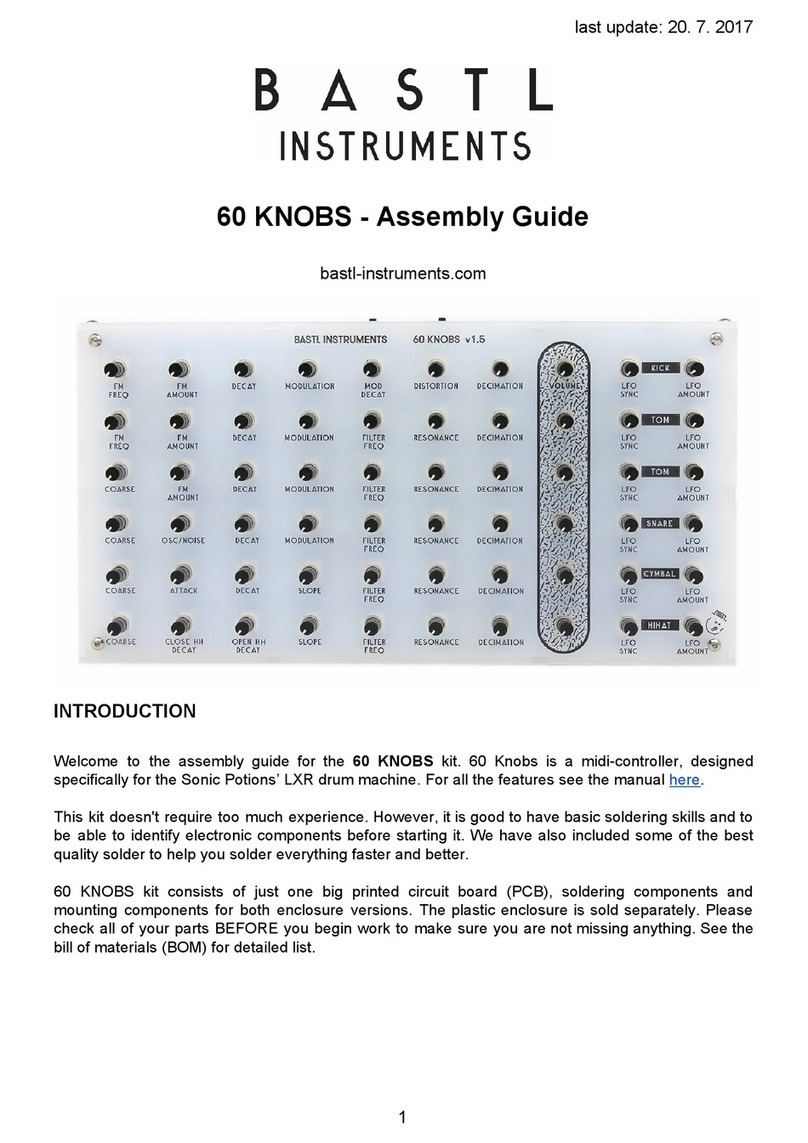

Bastl Instruments 60 KNOBS User manual

Bastl Instruments

Bastl Instruments SoftPop User manual

Bastl Instruments

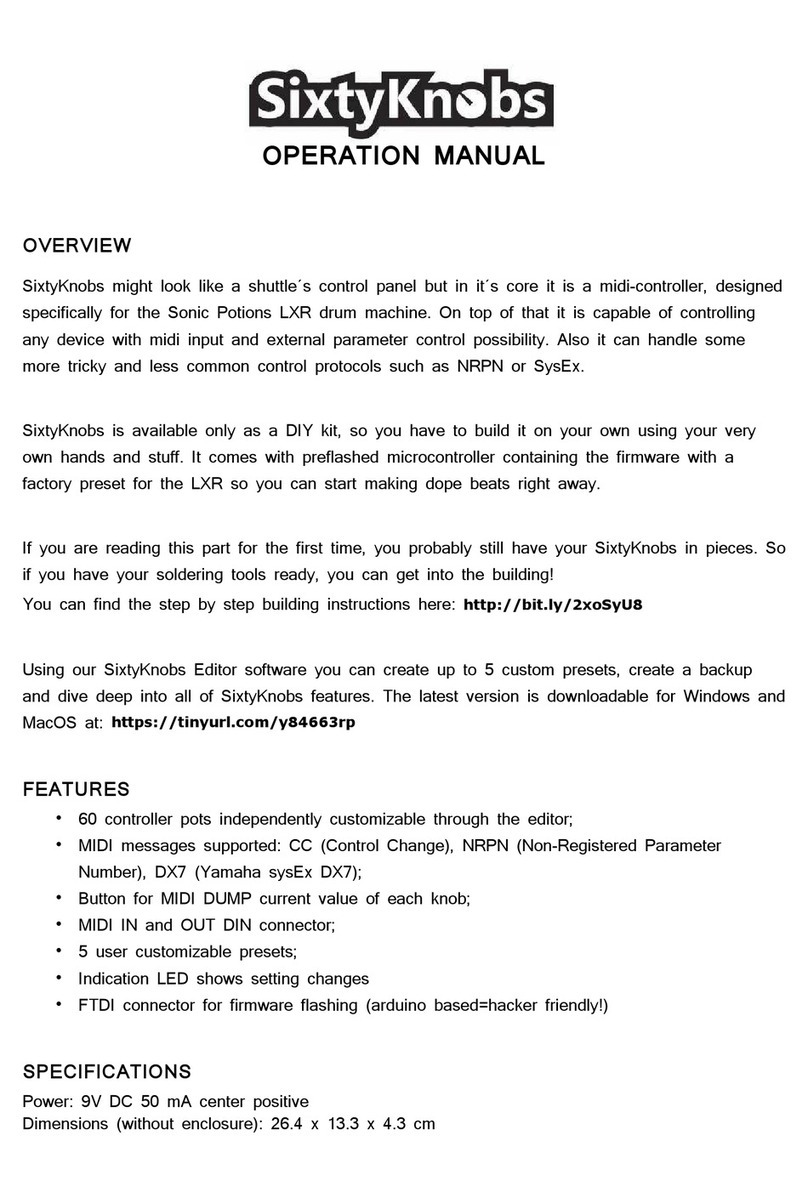

Bastl Instruments SixtyKnobs User manual

Bastl Instruments

Bastl Instruments KOMPAS User manual

Bastl Instruments

Bastl Instruments Knit Rider User manual

Bastl Instruments

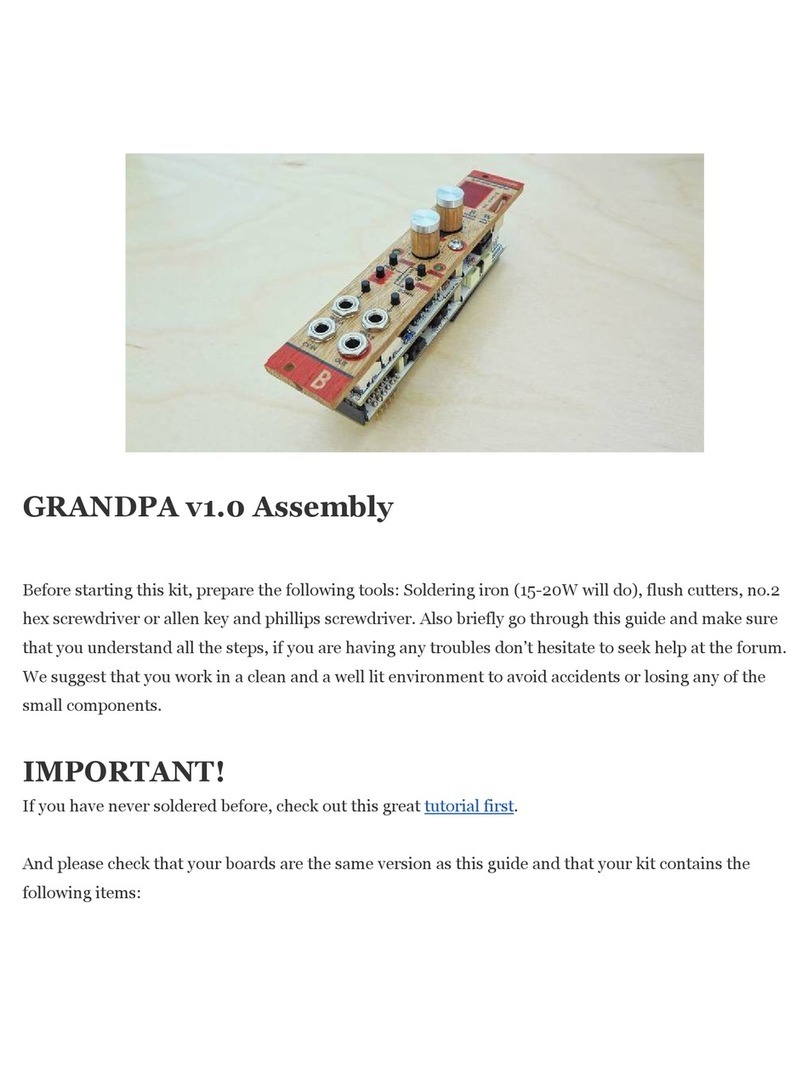

Bastl Instruments GRANDPA v1.0 User manual

Bastl Instruments

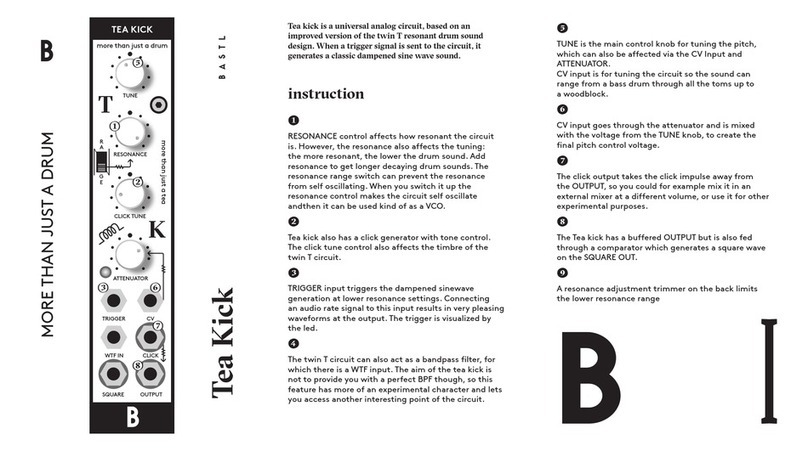

Bastl Instruments Timber User manual

Bastl Instruments

Bastl Instruments Tea Kick User manual

Bastl Instruments

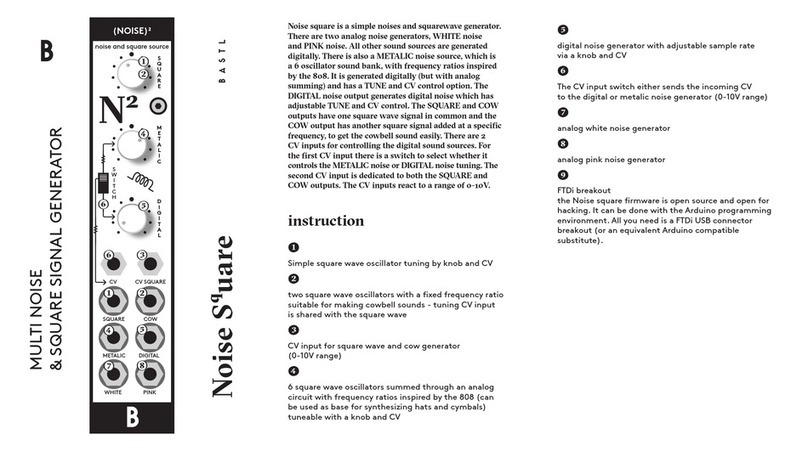

Bastl Instruments Noise Square User manual

Bastl Instruments

Bastl Instruments Thyme User manual