4. Side e ects

There are no known side effects.

5. General sa ety instructions

•This medical product is designed for: single patient, multiple use.

•Fitting/service of this medical device is only allowed by a certificated orthopedic

professional.

•Improper modification or application to the product is not allowed. In case of non

observance, the function of the product may be impaired, so that product liability

is excluded.

6. Instruction

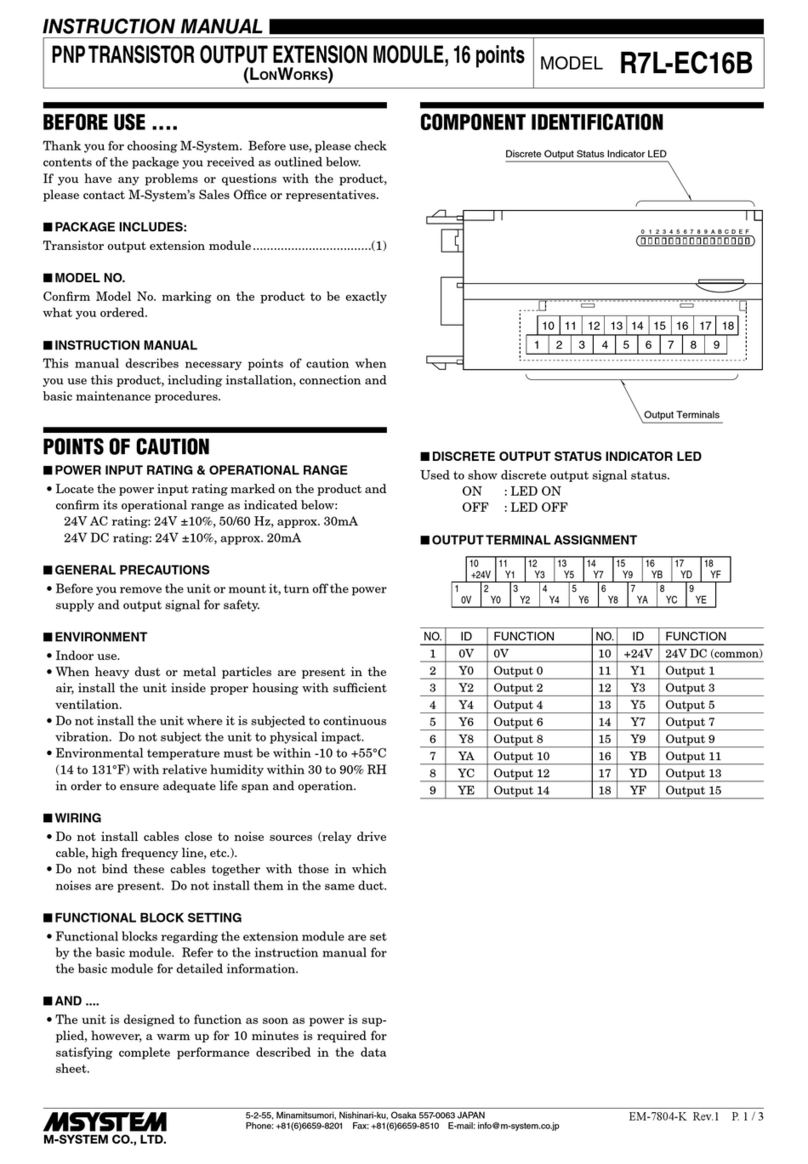

1. Use the E VO7 valve dummy when setting up a thigh socket with a V08 valve and

the E V17 valve dummy when setting up a thigh socket with a V13 valve.

2. Mark the spot where the valve is to be positioned on the plaster.

3. Drill a 2.5 mm wide hole for the plaster positiv bolt. Secure Dummy 1 (bottom

part) with the plaster positiv bolt to ensure the material around the dummy is of

an even thickness.

4. Draw the heated plate material over the center of the model with Dummy 1,

vacuum, then leave to cool off.

5. Wrap a 4 mm wide strip of deep drawn plate material around Dummy 1.

6. Remove the plaster bolt and bolt Dummy 2 to Dummy 1 using a threaded bolt.

7. Laminate or deep draw the deep drawn model in the usual way.

8. Remove Dummy 1 and Dummy 2 once the outer socket has been made.

9. In order to mount the socket valve, install the inner valve housing, working from

the inside of the socket.

10. Working from the outside of the socket, draw the valve sealing ring over the inner

valve housing. Working from the outside, screw down the outer ring of the valve

housing and tighten with the installation wrench. (E V08 installation wrench for

V08 valve, E V19 installation wrench for V13 valve)

4 5

Scope of delivery: both valves consist of an inner and outer valve housing with a

sealing ring and a valve body with a sealing ring.

Suitable dummies ( or V08: E-V07; or V13: E-V17) are not included in the scope

o delivery.

7. Maintenance and Cleaning

As part of regular prosthesis maintenance the valves must be checked and cleaned

every 6 months at the most.

Cleaning:

•Compressed Air up to 2 bar

•Soap and hand warm water

•Do not use aggressive solvents for cleaning.

8. CE-Con ormity

The product satisfies the requirements of Regulation (EU) 2017/745 of the European

Parliament and of the Council (MDR) and bears the CE mark. All major incidents related

to the product needs to be informed to Uniprox and the competence European

Authority.

9. Warranty and Guarantee

With regular maintenance, the valve can be used for the duration of the prosthesis use

(usually 5 years).

Warranty is provided under the terms of sale and supply of Uniprox GmbH & Co. KG

provided that the above conditions are met.

10. Storage and Disposal

The product is disposable with standard household garbage.

Please direct any questions to:

Customer Service: + 49 (0) 36628 66 33 70

Fax: + 49 (0) 36628 66 33 77