Status / Status / Condition Code

Reektor innerhalb der der Toleranz

Reector within tolerance A

Réecteur dans les limites de la tolérance A (Operating range)

100 ms grüne LED an / green LED on / LED verte alluminée

900 ms LED aus / o / éteinte

Reektor innerhalb der der Toleranz B

Reector within tolerance B

Réecteur dans les limites de la tolérance B (Boundary range)

2x 50 ms grüne LED an / green LED on / LED verte alluminée

880 ms LED aus / o / éteinte

Reektorsignal zu schwach

Reector signal too weak

Signal du réecteur trop faible

3x 50 ms grüne LED an / green LED on / LED verte alluminée

800 ms LED aus / o / éteinte

Objekt zwischen Sensor und Reektor

Object between sensor and reector

Objet entre le capteur et le réecteur

wie oben zusätzlich 100 ms gelbe LED an

as above with additional yellow LED on

comme ci-dessus avec supplémentaire LED jaune

Elektronikfehler / Hardware fault / Défaut de matériel 50 ms rote LED an / red LED on / LED rouge alluminée

50 ms LED aus / o / éteinte

CAN Abwurf (Fehlfunktion)

CAN bus o (malfunction)

Arrêt du bus CAN (dysfonctionnement)

50 ms magenta LED an / on / alluminée

150 ms LED aus / o / éteinte

Adresszuweisung fehlgeschlagen

Address claim failed

Assigment d‘ addresse failli

50 ms magenta LED an / on / alluminée

50 ms LED aus / o / éteinte

Warten auf Adresszuweisung

Waiting for Master ECU adress claim

En attendre il assignment d‘ adresse du maître ECU

500 ms magenta LED an / on / alluminée

500 ms LED aus / o / éteinte

Andere / other / autre blaue LED / blue LED / LED bleue

Grundinformation CAN - basic information CAN -

informations de base CAN

ISO Name

ISO name

Nom ISO

Manufacturer code:

ECU instance:

Function instance:

Function:

System:

System instance:

Industry group:

Arbitration capable:

343 (Baumer Group)

0

4

255 (non specic)

127 (non specic)

0

2

1

Geräteadresse

Device address

Adresse de l‘appareil

Unterstützt / supports „commanded address“ /

supporte adresse commandée (PGN 0xFED8)

im Bereich / in range / dans l‘ interval:

0x80 ... 0xCF (Standard / default / défault 0x80)

SAE J1939 Memory

Access (MA)

Protokoll / protocol /

protocole

Tool Anforderungen / requirements / exigences

- user level = 1

- Key for access is seed from sensor

- direct spatial addresses (is pointer)

- r/w command memory length = 1

- use transfer length from proceed reply

- ISO name Function eld = 129

- ISO name Industry group eld = 0

Objektdetektion und Zähler – object detection and counter – détection et comptage d‘objets

PGN CAN Nachricht / CAN message / Message CAN : 0xC000

Start

bit

Bits Abstand

oset

décaillage

Skalierung

scaling

écaillage

Beschreibung / description / description

1 2 0 1 Sensorstatus / Sensor status / état de capteur

0 = Kein Fehler / no error / Pas d‘ erreur

1 = Reversibler Fehler / reversible error / erreur reversible

2 = Irreversibler Fehler / irreversible error / erreur irréversible

3 3 0 1 Sensorstatus nach Teach / sensor status after reector teach / état du capteur après Teach du reecteur

0 = Kein Fehler / no error / pas d‘erreur

1 = Signal zu schwach / signal too weak / signal trop faible

2 = Reektor ausserhalb Gültigkeitsbereich / reector outside valid range / Réecteur en dehors de la plage valable

1,2 = Teach nicht akzeptiert / teach not accepted / Teach non accepté

6 1 0 1 Status Objektdetektion / Object detection status / État de la détection des objets

0 = Kein Objekt zwischen Sensor und Reektor / No object between sensor and reector /

Aucun objet entre le capteur et le réecteur

1 = Objekt zwischen Sensor und Reektor / object between sensor and reector / Objet entre le capteur et le réecteur

7 2 0 1 Reektorpositoin / Reector position / Position du réecteur

0 = Reektor im Betriebsbereich (A) / Reector in operating range (A) / Réecteur en zone fonctionnement

1 = Reektor im Grenzbereich (B) / Reector in boundary range (B) / Réecteur en zone limite

2 = Reektor ausserhalb Bereich (A/B) / Reector outside of range (A/B) / Réecteur en dehors de la plage valable

3 =Reektorsignal zu schwach / Reector signal too weak / Le signal du réecteur est trop faible

9 32 0 1 Zähler für Objektdetektionsereignisse / Counter for object detection events / Compteur d‘événements de détection

d‘objets : 0…4’294’967’296

41 12 0 1 N/A

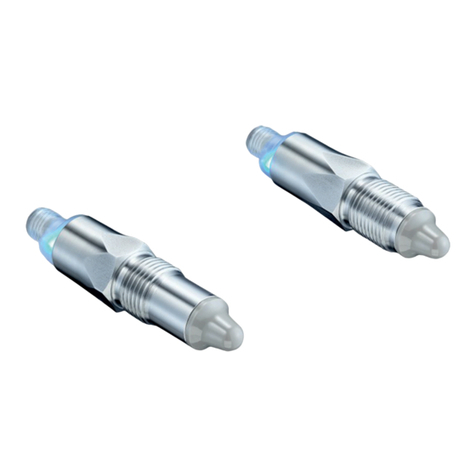

Reflector

e. g. fixed

machine part

LED green

flashing

Boundary range

LED green

flashing (fast)

Reflector position R

B

A

Reektorposition R setzen

Set reector position R

Régler la position du réecteur R

(SAE J1939 Memory Access)

Reektordistanz in mm an Adresse schreiben 0x07E388

Write reector distance in to address 0x07E388

Inscrivez la distance du réecteur en mm à l‘adresse

0x07E388

Teach Reektorposition R

Teach reector position R

Teach du reecteur R

(SAE J1939 Memory Access)

Wert 1 auf Adresse 0x07E389 schreiben

Write value 1 to address 0x07E389

Inscrivez la valeur 1 à l‘adresse 0x07E389

2/4

Visuelle Diagnose - Visual diagnostic - Diagnostic visuel

CAN Kommunikation - CAN communication - communication CAN

Für weitere Informationen lesen Sie bitte die Bedienungsanleitung - For further information please refer to the user manual - Pour plus d‘ informations, veuillez vous référer au manuel d‘ utilisation

Reektorposition - Reector Position - Position du réecteur