Interface GOLD STANDARD User manual

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 1 of 45

Load Calibration Frame

Software and Configuration Manual 15-330

Rev. A

GOLD STANDARD®

CALIBRATION SYSTEM

Next Generaon Force Measurement Soluons

The World Leader in Force Measurement Soluons™

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 2 of 45

TABLE OF CONTENTS

............................................................................ 4

License Agreement ....................................................................................................... 4

Limited Warranty .......................................................................................................... 4

Soware Warranty ....................................................................................................... 4

Hardware Warranty ...................................................................................................... 4

Computer Equipment Warranty ................................................................................... 4

Customer Remedies ..................................................................................................... 5

No Other Warranes .................................................................................................... 5

No Liability for Consequenal Damages ....................................................................... 5

................................................................................................ 6

Document Convenons ................................................................................................ 6

User Responsibilies .................................................................................................... 6

Safety Pracces............................................................................................................. 6

Operang Safety Procedures ........................................................................................ 7

Emergency Stops .......................................................................................................... 7

Interlock Devices .......................................................................................................... 7

Stay Clear of Loading Piston ......................................................................................... 7

Dangers of Sudden Movements ................................................................................... 7

Stay Clear of Tesng System ......................................................................................... 7

Pressing down buon with load string connected ....................................................... 8

Effects of control adjustment....................................................................................... 8

Loss of control feedback signal ..................................................................................... 8

Avoid servo valve silng ............................................................................................... 8

Electrical power failures ............................................................................................... 9

Disconnect power before servicing .............................................................................. 9

.................................................................................................................... 10

....................................................................................... 11

........................................................... 13

Uncrang And Locang Equipment ........................................................................... 13

Electrical Power .......................................................................................................... 13

Hydraulic Fluid ............................................................................................................ 14

................................................................................................................ 15

...................................................................................................... 18

Menu Commands ....................................................................................................... 18

Buon Bar Commands ............................................................................................... 18

Setup & Calibraon .................................................................................................... 18

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 3 of 45

Main Menu ................................................................................................................. 18

Analysis Menu ............................................................................................................ 18

Tools Menu ................................................................................................................. 19

....................................................................................................19

............................................................................................................21

.................................................................................................22

......................................................................................................23

............................................................................................................24

.................................................................................................................24

........................................................................................................24

......................................................................................................24

.....................................................................................................................24

...................................................................................................................25

Paths Screen ............................................................................................................... 25

ADC Congure Screen................................................................................................. 25

Auto Congure Screen ................................................................................................ 26

...............................................................................26

.........................................................................28

......................................................................28

...............................................................................................................29

....................................................................................................30

..............................................................................................................31

Filter Maintenance ..................................................................................................... 31

Accumulator Charging ................................................................................................ 31

Checking and Replacing Hydraulic Oil ........................................................................ 31

...................................................................................................................32

System Block Diagram ................................................................................................ 33

4 Channel 9840-400-1-T Intelligent Indicator ............................................................. 34

9840 Intelligent Indicator ........................................................................................... 35

Model SGA AC/DC Powered Signal Condioner ......................................................... 36

12802 Cable Drawing ................................................................................................. 37

12679 Cable Drawing ................................................................................................. 38

Load Frame Dimensions ............................................................................................. 39

Wiring Diagram ........................................................................................................... 40

Hydraulic Power Unit Diagram ................................................................................... 41

Project Box for Load Calibraon Frame Diagram ........................................................ 42

Cal Adaptors Drawing DUT & One Standard ............................................................... 43

Cal Adaptors Drawing DUT & Two Standards ............................................................. 44

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 4 of 45

1. GRANT OF LICENSE. Interface grants to the user the right to use one copy of the Interface Inc. soware pro-

gram (the “SOFTWARE”) on a single terminal connected to a single computer (i.e., with a single CPU). The

user may not network the SOFTWARE or otherwise use it on more than one computer or computer terminal

at the same me.

2. COPYRIGHT. Interface Inc. or its suppliers own the SOFTWARE and is protected by United States copyright

laws and internaonal Treaty provisions. Therefore, the SOFTWARE must be treated like any other copyright-

ed material (e.g., a book or musical recording) except that the user may make one copy of the SOFTWARE

on to a oppy disk medium solely for backup or archival purposes. The wrien materials accompanying the

soware may not be copied.

3. OTHER RESTRICTIONS. The user may not rent or lease the SOFTWARE to other pares, but may transfer the

SOFTWARE and accompanying wrien materials on a permanent basis provided no copies are retained and

that the recipient agrees to the terms of this Soware License Agreement. No one may reverse engineer, de-

compile, or disassemble the SOFTWARE. If the SOFTWARE is an update, any transfer to another party must

include the update version together with all oppy disk copies of all prior versions.

4. DUAL MEDIA SOFTWARE. If the SOFTWARE has been supplied with both hard disk and Compact Disc, the

disks of the type appropriate for a single user computer may be used. The other disks may not be used on

another computer and may not be loaned, rented, leased, or transferred to another user except as part of a

permanent transfer (as provided above) of all SOFTWARE and wrien materials.

Interface warrants that the SOFTWARE will perform substanally in accordance with the accompanying wrien

materials for a period of 90 days from the date of receipt. Any implied warranes on the SOFTWARE are limited

to 90 days. Some states do not allow limitaons on duraon of an implied warranty, so the above limitaon may

not apply.

Interface warrants that the hardware manufactured by Interface, including the plug in board, the Mul Step

Transfer Standard, and accessories, will be free from defects in materials and workmanship under normal use

and service for a period of 90 days from the date of receipt. Any implied warranes on the hardware are limited

to 90 days. Some states do not allow limitaons on duraon of an implied warranty, so the above limitaon may

not apply.

Computers and peripheral equipment provided by Interface but manufactured by another manufacturer are

warranted by that manufacturer per the statements accompanying the equipment.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 5 of 45

Interface’s enre liability and the user’s exclusive remedy shall be, at Interface’s opon, either (a) return of the

price paid or (b) repair or replacement of the SOFTWARE or hardware that does not meet Interface’s Limited

Warranty and which is returned to Interface with a copy of the purchase receipt. This Limited Warranty is void

if failure of the SOFTWARE or hardware has resulted from accident, abuse, or misapplicaon. Any replacement

SOFTWARE will be warranted for the remainder of the original warranty period or 30 days, whichever is longer.

These remedies are not available outside of the United States of America.

Interface disclaims all other warranes, either express or implied, including but not limited to implied warranes

of merchantability and tness for a parcular purpose, with respect to the SOFTWARE, the accompanying writ-

ten materials, and accompanying hardware. This limited warranty provides specic legal rights. There may be

other rights, which vary from state to state.

In no event shall Interface Inc. or its suppliers be liable for any damages whatsoever (including, without lim-

itaon, damages for loss of business prots, business interrupon, loss of business informaon, damage to

equipment or facilies, or other pecuniary loss) arising out of the use of or inability to use this Interface product,

even if Interface has been advised of the possibility of such damages. Because some states do not allow such

exclusion of liability, the above limitaon may not apply.

Should there be any quesons concerning this Agreement, please contact:

Interface, Inc., 7418 E. Helm Dr., Scosdale, AZ 85260.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 6 of 45

The following internaonal symbols will be used in this document with the appropriate meanings:

This icon accompanies text dealing with hazards to personnel. When present, it indicates that

a potenal hazard to your personal safety exists if informaon stated within the “WARNING”

paragraph is not adhered to or procedures are executed incorrectly.

CAUTION

This icon accompanies text dealing with potenal damage to equipment. When present, it

indicates that there is a potenal danger of equipment damage, soware program failure or that

a loss of data may occur if informaon stated within the “CAUTION” paragraph is not adhered to

or procedures are executed incorrectly.

NOTE

This idener accompanies text dealing with potenal situaons which might cause inaccurate

data to be gathered or it makes the system easier to operate.

The user of this equipment is required to supply proper electrical power and ground to the system in order

for it to funcon properly. Isolated and stable electrical ground is required; a copper pipe buried 2 m into the

ground near the lab can be used as the ground.

Read the safety pracces and operang safety consideraons before operang the hydraulic

power supply. Failure to read and understand the operaons manual and/or follow the

recommended safety pracces can result in serious personal injuries and/or damage to the

equipment!

CAUTION

Never exceed the maximum equipment rang and capabilies!

Review these guidelines to ensure that your current operang procedures do not result in hazardous

situaons. Although all hazards may not be able to be eliminated, the following guidelines can be used to

idenfy hazards so that the proper training, operang procedures, and safety equipment can be implemented.

System operators should fully review the documentaon supplied to gain an understanding of the system

funcons. Figures will be placed throughout the manual and should be reviewed.

To ensure smooth system operaon during the rst execuon of the control soware, the user should be very

familiar with this secon and the specic test module to be used.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 7 of 45

The following operang safety procedures are applicable to most tesng systems. The user is required to read

each item below and determine if it is applicable to the tesng system for which this hydraulic power supply

will be used. The user is also required to obtain and review all safety instrucons on specic tesng equipment

used in the system.

Determine the locaon of system emergency stop buons to allow for quick emergency stops.

Interlock devices, such as the Emergency Stops, should always be used and properly adjusted.

Test all interlock devices immediately before each test. Because of the possibility of operator

error, system maladjustment, or component failure, interlock devices cannot be relied on to

protect personnel, unit under test, or test equipment. Thus, standard precauons about staying

clear of the ram should always be followed.

When system power is on, stay clear of each end of the actuator piston rod. The area on the

base plate used for component installaon should be worked around with cauon. Never place

any part of your body between the actuator piston rod and base plate when the hydraulic pres-

sure is on. Due to unit under test failure, operator error, or other factors, the actuator could

unexpectedly react and cause personal injury.

High forces and rapid moons are usually present in tesng systems. Unexpected actuator

responses can be very dangerous. Likely causes of dangerous actuator reacons are operator

error and equipment failure due to damaged or abused equipment. An actuator piston rod that

reacts suddenly can strike an operator installing a unit under test or damage the load cell or

expensive components. For the above reasons, anyone who operates, maintains, or modies

a system should read all provided manuals to acquire a thorough knowledge of the system’s

operang characteriscs.

Never allow bystanders to touch unit under test or equipment while the system is operang.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 8 of 45

CAUTION

If pressing down buon with load string connected, the load cells may be overloaded.

CAUTION

Do not make mechanical, or soware adjustments to system components unless you know

exactly how the adjustment will aect system operaon. In many cases a slight adjustment can

throw the system out of calibraon and cause divergence between the command and feedback.

Consult an experience user when in doubt about any adjustment procedure.

CAUTION

If the control feedback signal is interrupted during operaon, the controller senses an error.

The actuator will aempt to correct the error by stroking at maximum force unl it reaches

an internal or external mechanical limit. The external mechanical limit may be any type of

obstrucon that is in the path of a stroking actuator (such as tools, specimens, or hands). Be

aware that the full force of the actuator will be applied to an external mechanical limit or

obstrucon. The only eecve way to minimize the stac force capability of a system is to reduce

the system hydraulic/pneumac pressure. The error detectors in the controller minimize the

potenal for device under test or equipment damage caused by loss of feedback or larger than

normal feedback errors.

CAUTION

Due to servo valve silng, an actuator can develop random instability or errac operaon

at unusually low hydraulic pressures, especially if the system uses large servo valves or the

hydraulic uid is dirty.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 9 of 45

The failure or shuto of electrical power to the tesng system when pressure is being applied

can cause considerable and unpredictable actuator reacon. Under these condions, loss

of electrical power on servo controlled systems will generally cause the actuator to stroke

at maximum velocity in either direcon or, if a device under test is aached, to apply full

tensile or compressive force. Many systems contain hydraulic/pneumac accumulators that

store enough energy to temporarily operate the actuator at full force capacity even when the

hydraulic/pneumac pressure is shut o. For this reason, the usual interlock devices will not

prevent hazardous actuator stroking. If a power failure does occur, please make sure that Gold

Standard Soware has been reset before powering on the Load Frame. This will protect stop the

connuaon of the previous load selecon.

If servicing the interior components of the hydraulic power supply, power to the unit must be

turned o. Servicing the hydraulic power supply without turning the power o is very dangerous

due to the high voltages present!

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 10 of 45

The Interface Gold Standard Force Calibraon System provides an integrated force

calibraon soluon, making possible high accuracy calibraons. The system consists of a

hydraulic load frame, feedback control system, high accuracy load cell measurement and

soware tuned to automacally operate the load frame. When used in conjuncon with

the Interface 1600 or 1800 Series load cell standards, the system provides the user with an

accurate tool for easy and quick calibraon of load cells in tension or compression.

The system is the result of over two decades of experience to develop the hardware and

soware for high precision force calibraon. The load cell measurement includes signal

condioning circuitry for the transducer bridge, analog-to-digital converter, and logic

circuitry to interface with the PC. With an extremely high sensivity of 0.1 microvolt per

increment, extra low noise, and superior stability, the circuitry provides state-of-the-art

measurement of strain gage transducer signals.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 11 of 45

GS-SYS

4 column loading frame

150mm (6 inch) stroke

Alignment swivel coupler/slack adapter

Static calibration in tension or compression

Top swivel coupler thread – 2”-12 male

Bottom actuator thread – 2”-12 female

21MPa (3000 psi) hydraulic power unit

25,000 lbf. load capacity/24.4 to 30.4 inches working length

55,000 lbf. load capacity/24.4 to 30.4 inches working length

55,000 lbf. load capacity/38.4 to 44.4 inches working length

100,000 lbf. load capacity/38.4 to 44.4 inches working length

208/230 VAC, single phase, 50/60 hertz

Power – 3.5 kVA

Amps (continuous) – 16

Minimum protection circuit current – 30 Amps

Normal operaon 2600 psi

Maximum pressure 3000 psi

10 gal ISO 32 hydraulic oil.

Moog Direct Drive Valve D633-303B-R02K01M0NSM2

Flow Rang: 6 lpm ( 1.6 gpm)

Seal Material: NBR

Minimum Supply Pressure: 15 bar ( 220 psi)

Maximum Supply Pressure: 350 bar (5000 psi)

Filtraon for Normal Operaon: 10 micron absolute

Fluid Cleanliness Level: ISO 4406 15/13/10 or NAS 1638 Class 4

Coil Resistance: 25 Ω

Command Signal: ± 600mA

Power Consumpon: 9 W (at I = 600 mA and R = 25 Ω)

Delta Computer: RMC75E-AA2 with AP2 and D8 expansion modules

Primary Communicaon Type: Ethernet

Monitor Port: USB

Control Loop Time: User selectable from 0.5 to 4 ms

Voltage: +24 VDC ± 20%

Current: Typical for base model 200 mA at 24 VDC

DC-DC Converter Isolaon: 500 VAC input to controller

Operang Temperature: +32 to +140 °F

(L6-30R Connector on system)

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 12 of 45

Omega LD620-7.5 with LD-p Output +/- 5 VDC

Measuring Range: +/-7.5mm (+/-0.3 inches) Excitaon Voltage – 10-30 VDC

Non-Linearity - <+/-0.2% FSO

Control Load Cell bridge

CAUTION

DO NOT OPERATE the system with the Control Load Cell bridge cable disconnected, as the system

will immediately seek maximum load.

SGA

Excitaon = 10 VDC

Bandwidth = 1kHz

Built into crosshead. Spherical washers for tension and compression load.

All surfaces hardened steel.

LVDT senses slack posion. Natural posion is o-contact, midway between compression and

tension contacts. With command signal of zero, system will always seek the o-contact posion.

Momentary. Useful for lowering the ram to install or remove test arcles.

CAUTION

DO NOT USE the Ram Down Switch unless load string is uncoupled, as a tension force would

result.

(Le Hand of Panel) Pushed In All power shut-o to system. At end of day, use to shut-o

system.

Pulled Out Cooling fan operates Hydraulic Unit is o.

(middle of panel) Momentary pushed in The light around this buon will inially ash. While ashing,

the system starts the HPU, oats the slack adapter, and zeros

out the control load channel; this sequence does not take

much me. Once these steps are complete, the light will

go solid to indicate the system is ready to start the actual

calibraon process.

(Load limit of 5% of load cell capacity.

Momentary pushed in (again) De-acvates system in between calibraon runs.

Push/Hold Holding the “Acvate” buon for longer than 2 seconds simply

toggles the HPU on/o but leaves the rest of the system idle.

(Right hand of Panel) Push to move piston down Acve while pushing buon.

No illuminaon.

Hydraulic Power Unit powers on.

When buon is released, Hydraulic Power Unit connues to

run for approx. 10 seconds and then shuts o.

Emergency Stop Buon Acvate/De-acvate Buon Down Buon

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 13 of 45

Inspect all crates and boxes for damage, including the state of any shock and/or lt sensors.

Photograph any damage and save for possible insurance claim.

Using a forkli, li the crate and the load frame from the HEAVY END (actuator end and it is also

marked on the crate) to prevent pping.

Remove the load frame from the crate. Set the load frame in place and leave at least one (1) meter

(~40 inches) of space on all sides for maintenance access.

Adjust the (4) leveling feet to evenly distribute the load and prevent the load frame from rocking. The

load frame should be approximately level. Tighten the jam nut on each foot.

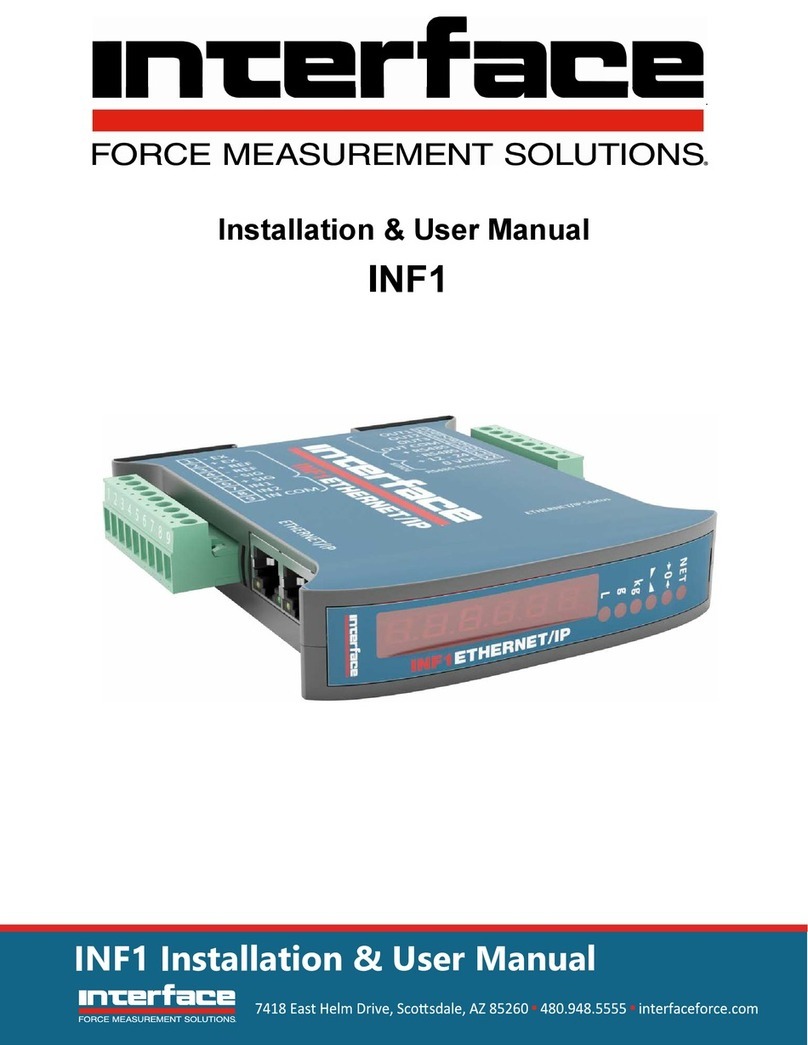

Circuit Breakers

Delta Controller Enclosure

HPU Electronics Enclosure

Delta Controller Enclosure HPU Electronics Enclosure

Rear of Cabinet (cover removed) Front of Cabinet (cover removed)

Fuses

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 14 of 45

One 208-240 VAC, 30 amp, single phase circuit is needed for the hydraulic power supply. The plug

supplied with the system is NEMA 6-20.

Install the LVDT posion sensor on top of the load cap using (2) cap screws (see Figure 3).

CAUTION

Do not change the locaon of the LVDT in the bracket.

The shipping gasket must be removed and replaced with the breather lter before operang system.

The gasket can be accessed by removing the breather cover on lter housing (Figure 4).

CAUTION

Failure to replace shipping gasket could result in excess pressure or vacuum inside the tank and

damage to the pump.

Check the system oil level (Figure 5).

Remove the piston retainer if installed (Figure 6).

(Piston) (Piston Retainer)

NOTE: Shipping gasket must

be removed before pung

hydraulic unit into service.

Shipping gasket Installaon Remove breather

lter for shipping and insert shipping gasket

between breather cover and lter housing.

Breather Filter

Breather Cover

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 15 of 45

CAUTION

Do not complete the threaded adapter string unl the system has been tested to ensure the

LVDT will control the piston height. This can be done by turning the pump on when the load

frame is empty and manually liing the swivel adapter. The piston should retract to the lowest

posion.

1. Read the “Operating Safety Procedures”.

2. Install the Standard load cell on the piston.

3. If the Standard load cell does not have an integral Control Load Cell bridge, install a Control Load Cell on

the Standard load cell. Control Load Cell bridge may be part of the 1600 or 1800 series load cell or may be

a separate load cell. The Control Load Cell bridge must be trimmed to 2 mV/V for proper control. Any

Load Cell trimmed to 4 mV/V and with twice the capacity of the Load Cell Standard may be used as a

Control Load Cell. For example: a 50 klbf Load Cell trimmed to 4 mV/V may be used to control the frame

with a 25 klbf Load Cell Standard. The goal is to have a 2 mV/V control signal at the rated load.

4. Install the DUT load cell using a standard or custom threaded adapter. Custom adapters are available from

Interface Inc.

5. Attach the Control Load Cell cable (15700) from the Control Cell Bridge to the connector shown as “Control

Load Cell” on the back of the load frame (see Figures 7 and 10). Do not disconnect this cable while the

hydraulic pump is running or damage may occur.

6. Attach the DA-101-USB cable (15936) from the “Set Point Command” connector on the back of the load

frame to the DA-101-USB Analog Output connector (see Figures 7 and 10).

7. Attach the Reference Standard cable (CT-177) to the Load A connector on the 9840 indicator. Attach the

Device Under Test (DUT) cable (CT-338) to the Load B connector on the 9840 indicator (See Figure 9).

Please consult Interface Inc. if the connection on your cable does not match your load cell. In most cases,

Interface Inc. can supply you with the one you need. Attach the 208/240 VAC 1 PH system power using the

supplied mating connector (see Figure 7).

8. Set up the computer. The computer and monitor may be plugged into the power outlet on the back of the

load frame (see Figure 7). Connect DA-101-USB power cord to DA-101-USB power input connector and AC

outlet. Connect the USB cable from DA-101-USB to computer. Turn on the pump at the Start/Stop switch.

As the piston raises, carefully raise the slack adapter swivel stem by hand to the top position. The piston

should immediately begin to lower. If not, the control cables to the Control Load Cell or the LVDT must be

checked for proper connection.

CAUTION

Do not aempt to complete the threaded adapter string unl the LVDT control is working

properly.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 16 of 45

DRAW ROD

THREADED COLLAR

THREADED COLLAR

ADAPTER

1020, 1120, 1220

BASE ADAPTER

2.00-12 F

2.00-12 M

9. Lower the piston to the boom by pressing the

down buon and turn the pump o (See gure 8).

10. Install the threaded adapters to come within 5”

of the slack adapter. Make the last connecon

between two threaded adapters and not the swivel

stem (See gure 9).

Acvate/De-acvate Buon

Down Buon

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 17 of 45

CAUTION

Ensure all threaded connecons are engaged at least one (1) diameter length of the threads.

CAUTION

Threaded connecons that boom out must be backed o one full turn to avoid binding.

11. Turn on the pump and carefully guide the last threaded connecon between the adapters. As the threads

make inial contact, the slack adapter will raise the LVDT and stop when it is in the center of travel.

Never posion any bodily part between threaded connecon adaptors.

12. Carefully begin to make the nal thread connecon. As the threads are engaged, the piston will follow

the engagement to keep the LVDT centered. Stop when at least 1 diameter of threads are engaged on all

threaded connecons.

13. Turn on the pump and carefully guide the last threaded connecon between the adapters.

As the threads make inial contact, the slack adapter will raise the LVDT and stop when it is

in the center of travel.

14. Carefully begin to make the nal thread connecon. As the threads are engaged, the piston

will follow the engagement to keep the LVDT centered. Stop when at least 1 diameter of

threads are engaged on all threaded connecons. Threaded connecons that boom out

must be backed o one full turn to avoid binding.

15. Through the front access door, check the oil level in the sight glass (See gure 10).

16. Check the oor of the Calibraon Rig for indicaons of oil leaks, if no leaks are visible, close

the front access door.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 18 of 45

The Interface Inc. Gold Standard Soware product, WCGold, consists of 3 separate executable programs as

follows:

• is used to congure all WCGold program parameters.

• is used to calibrate the 9840 instrument using a transducer simulator such as the Interface Inc.

Model CX-0610 or CX-0440.

• is the main transducer calibraon program.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 19 of 45

(Creates any of the following user generated custom printable reports. Any number of

each type of report can be created. Aer a report is created and saved, it can then be printed from the

corresponding Analysis Menu item.)

See online help from within the Report Designer for further informaon. Designer.pdf found in the installed

program directory is a complete wrien manual for the Report Designer.

(Creates user denable eld tles for items not currently dened elsewhere. Useful

for entries such as accounng/asset tag numbers, work order etc. Field denions made here will appear

as entries when lling out the DUT Cell Informaon window.)

PERFORM CALIBRATION

Select Perform Calibraon buon on toolbar or from pull down Main Menu.

Enter all DUT informaon.

Select DUT mode (Tension or Compression)

Enter Set Point Informaon. (See Calibraon Set Point File Creaon)

Select Standard Mode (Tension or Compression). Normally this is the same as the DUT Mode.

Select the Connue Buon. If the set points were newly entered, or an exisng set point le has been

edited, a screen will be displayed asking to Save? Selecng Yes will then display a Select File window where

an exisng le can be selected to overwrite or a new le name entered.

Determine Oset.

The system will determine the oset voltage prior to exercising or calibrang the DUT. This is the voltage

required to move a load frames actuator from zero posion to start of load being applied. Refer to the

AUTO.CFG le parameters found in the WGoldCfg program.

Exercise DUT.

Selecng Yes checks the zero reading of the DUT and provides a set point for proper exercise loading based

on the Exercise Load parameter found in the GOLDINT.LMT or GOLDUSR.LMT les. Note that the system

does not record the exercise readings.

7418 East Helm Drive • Scosdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Page 20 of 45

The system will exercise the cell based on the number of cycles indicated by the ExerciseCycle parameter

set in the AUTO.CFG parameter secon of the WgoldCfg program. The system will rst apply a load

approximang the percent load indicated by the InialLoad parameter. The output of the standard is

compared against a nominal output based on the set point le sengs. The output of the DUT is compared

against a nominal output based on the values found in the GOLDINT.LMT or GOLDUSR.LMT les. If either

reading is found to be out of tolerance, a FAIL SAFE prompt will be displayed and the calibraon cycle

aborted. Refer to the AUTO.CFG le parameters in the WGoldCfg program.

Calibrate DUT.

The set point box located in the lower le corner should now read 0. When ready for the inial zero to be

taken, select the START buon. The set point number will change to a highlighted color and aer a few

seconds a beep will be heard indicang the reading has been taken. The next desired set point will then be

displayed in the set point box.

Increase the load unl the STANDARD meter is within the limits dened in the ADC.CFG le. (Automated

systems will automacally increase the load as needed) The set point number will change to a highlighted

color. Connue holding steady unl a beep is heard and the next set point is displayed. The nal set point

number is for zero load will equal inial zero reading taken on the standard. All load should be removed

and the system will record the return zero.

The gauge display can be used as a reference. When the set point meter display matches the reference

standard meter display, the gauge indicator will be centered.

Pressing the ESC key at any me during the calibraon will abort the calibraon and return to step to the

beginning of step 10.

Performance Analysis.

The system will now display the performance results. Output, Nonlinearity, Hysteresis and SEB parameters

are compared against limits found in the GOLDINT.LMT or GOLDUSR.LMT les. A High Or Low displayed to

the right of these parameters indicates this parameter exceeds the limits found.

The following buons are displayed in the lower right corner.

Displays results for a mulple bridge transducer.

SHUNT CAL

Select if shunt cal reading(s) are desired.

The program defaults to a value to provide Auto shuntcal output of about 70% of calibrated full scale on

a 350 ohm bridge if possible. If an external resistor is to be used, select Manual and enter its value in the

edit eld.

PRINTER

Generates a hard copy of the performance results.

A menu will be displayed to select the desired report to print. These reports are created using the Report

Designer found on the Tools menu from the main screen.

This will produce a load vs. error plot. Before prinng, it is recommended that the color be changed to

black and white.

Table of contents

Other Interface Measuring Instrument manuals

Interface

Interface DMA2 Manual

Interface

Interface INF1 Instruction Manual

Interface

Interface 9825 Instruction Manual

Interface

Interface BlueDAQ BX8 User manual

Interface

Interface 9840-400 User manual

Interface

Interface 9325-NU User manual

Interface

Interface 9860 User instructions

Interface

Interface INF1 User manual

Interface

Interface 9860 User manual

Interface

Interface 9860 User manual

Popular Measuring Instrument manuals by other brands

Full Spectrum Laser

Full Spectrum Laser FSL300 user manual

PCE Instruments

PCE Instruments PCE-DFG NF Series user manual

Forkardt

Forkardt SKM 1200 operating instructions

Pro-dig

Pro-dig Intelli-Tork H200 instruction manual

Lumel

Lumel N32U user manual

Agilent Technologies

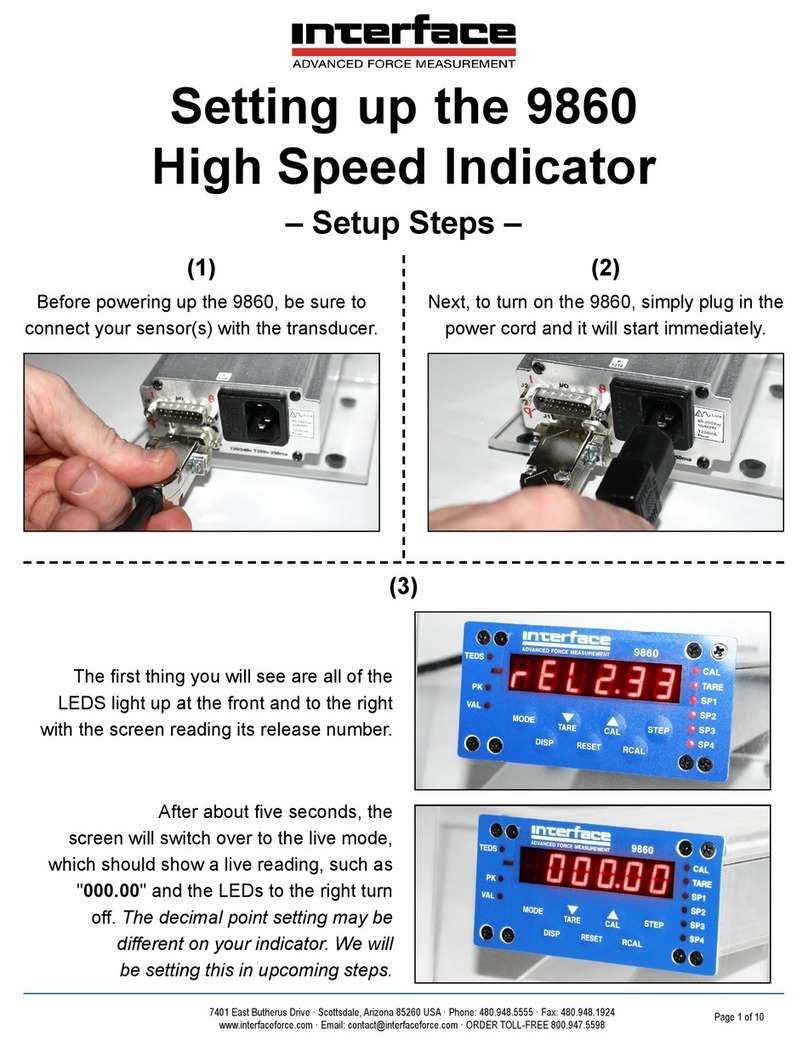

Agilent Technologies E5270 Series user guide