Novalynx 255-110-B Series User manual

DOC 255-110x-B UM 20210324

255-110x-B

User Manual

255-110-B Evaporation Gauge Reader (inches)

255-110M-B Evaporation Gauge Reader (millimeters)

Evaporation Gauge Reader

Phone (530) 823-7185

NovaLynx Corporation

255-110x-B Page 2 March 2021

Receiving and Unpacking

Carefully unpack all components and compare to the packing list. Notify NovaLynx Corporation

immediately concerning any discrepancy. Inspect equipment to detect any damage that may have

occurred during shipment. In the event of damage, any claim for loss must be filed immediately with

the carrier by the consignee. Damages to equipment sent via Parcel Post or UPS require the consignee

to contact NovaLynx Corporation for instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00 a.m. and 4:00

p.m. Pacific Time to request a Return Authorization Number (RA#). Include with the returned

equipment a description of the problem and the name, address, and daytime phone number of the

sender. Carefully pack the equipment to prevent damage or additional damage during the return

shipment. Call NovaLynx for packing instructions in the case of delicate or sensitive items. If packing

facilities are not available take the equipment to the nearest Post Office, UPS, or other freight service

and obtain assistance with the packaging. Please write the RA# on the outside of the box.

Warranty

NovaLynx Corporation warrants that its products are free from defects in material and workmanship

under normal use and service for a period of one year from the date of shipment from the factory.

NovaLynx Corporation's obligations under this warranty are limited to, at NovaLynx's option: (i)

replacing; or (ii) repairing; any product determined to be defective. In no case shall NovaLynx

Corporation's liability exceed product's original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by NovaLynx Corporation, or that has been

subjected to misuse, negligence, or accident. It is expressly agreed that this warranty will be in lieu of

all warranties of fitness and in lieu of the warranty of merchantability.

Address

NovaLynx Corporation

431 Crown Point Circle, Suite 120

Grass Valley, CA 95945-9531 USA

Phone: (530) 823-7185

Email: nova@novalynx.com

Website: www.novalynx.com

Copyright © 1988-2021 by NovaLynx Corporation

NovaLynx Corporation

255-110x-B Page 3 March 2021

CONTENTS

1 FORWARD ....................................................................................................................................................................... 4

2 INTRODUCTION ............................................................................................................................................................... 4

3 SPECIFICATIONS .............................................................................................................................................................. 5

4 CONNECTIONS ................................................................................................................................................................. 5

5 APPLICATION: Evaporation Monitoring .......................................................................................................................... 6

6 APPLICATION: Evaporation Logging ................................................................................................................................ 7

7 APPLICATION: Evaporation Gauge Chain Installation ..................................................................................................... 7

8 APPLICATION: Evaporation Gauge Calibration Checkup ................................................................................................. 7

9 BATTERY REPLACEMENT ............................................................................................................................................... 10

NovaLynx Corporation

255-110x-B Page 4 March 2021

1 FORWARD

Thank you for purchasing NovaLynx products. NovaLynx has been designing and manufacturing

weather instruments since 1988. NovaLynx represents several well-known brands of quality

manufacturers, including Gill Instruments, RM Young, Kipp & Zonen, and Vaisala. It is our hope that our

products will meet all your monitoring requirements.

2 INTRODUCTION

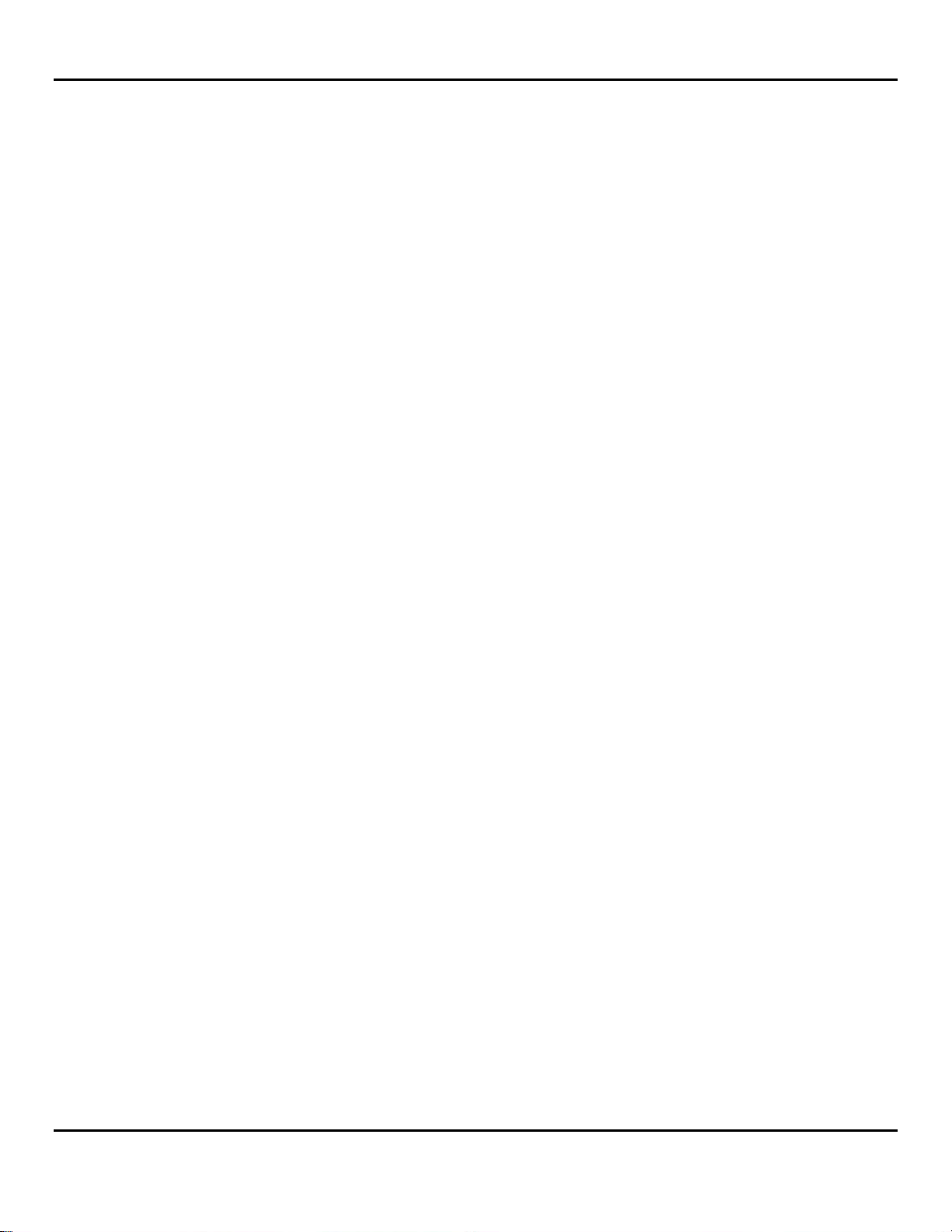

The 255-110x-B Evaporation Gauge Reader is a portable display for the NovaLynx 255-100 Analog

Output Evaporation Gauge. The reader is calibrated in inches or millimeters, depending on the model

chosen. Readings from the display indicate relative depth of water in the gauge. The difference

between readings on successive days indicates the amount of evaporation.

The reader may be used during installation of the evaporation gauge and for checking the operation of

the evaporation gauge during regular maintenance. The large LCD display is visible through the clear

protective cover even in bright sunlight.

The NovaLynx 255-110x-B Reader is pre-calibrated using a generic slope with zero offset. Since the

float in the 255-100 Evaporation Gauge does not rise until a certain amount of water is present, the

display will not correspond to the actual depth of the water in the pan. However, since evaporation is a

relative quantity (the difference in level between two points in time), the offset is not important, as

long as the float is not resting on the bottom.

It is possible to calibrate the reader to a specific evaporation gauge using a two-point method, which

will adjust the slope and offset so that the readings match (within reason) the depth of water in the

evaporation pan. NovaLynx 195-BHW-KIT includes software and a USB cable for programming the

slope and offset. Instructions for programming the display are available in the NovaLynx 255-704-B

Evaporation Logger User Manual, available on our website at www.novalynx.com.

Raw Scaled

Units: Volts Inches

Value 1: 0.00000 0.00000

Value 2: 2.50000 9.44400

Raw Scaled

Units: Volts millimeters

Value 1: 0.00000 0.00000

Value 2: 2.50000 239.89000

255-110-B Generic Calibration

255-110M-B Generic Calibration

NovaLynx Corporation

255-110x-B Page 5 March 2021

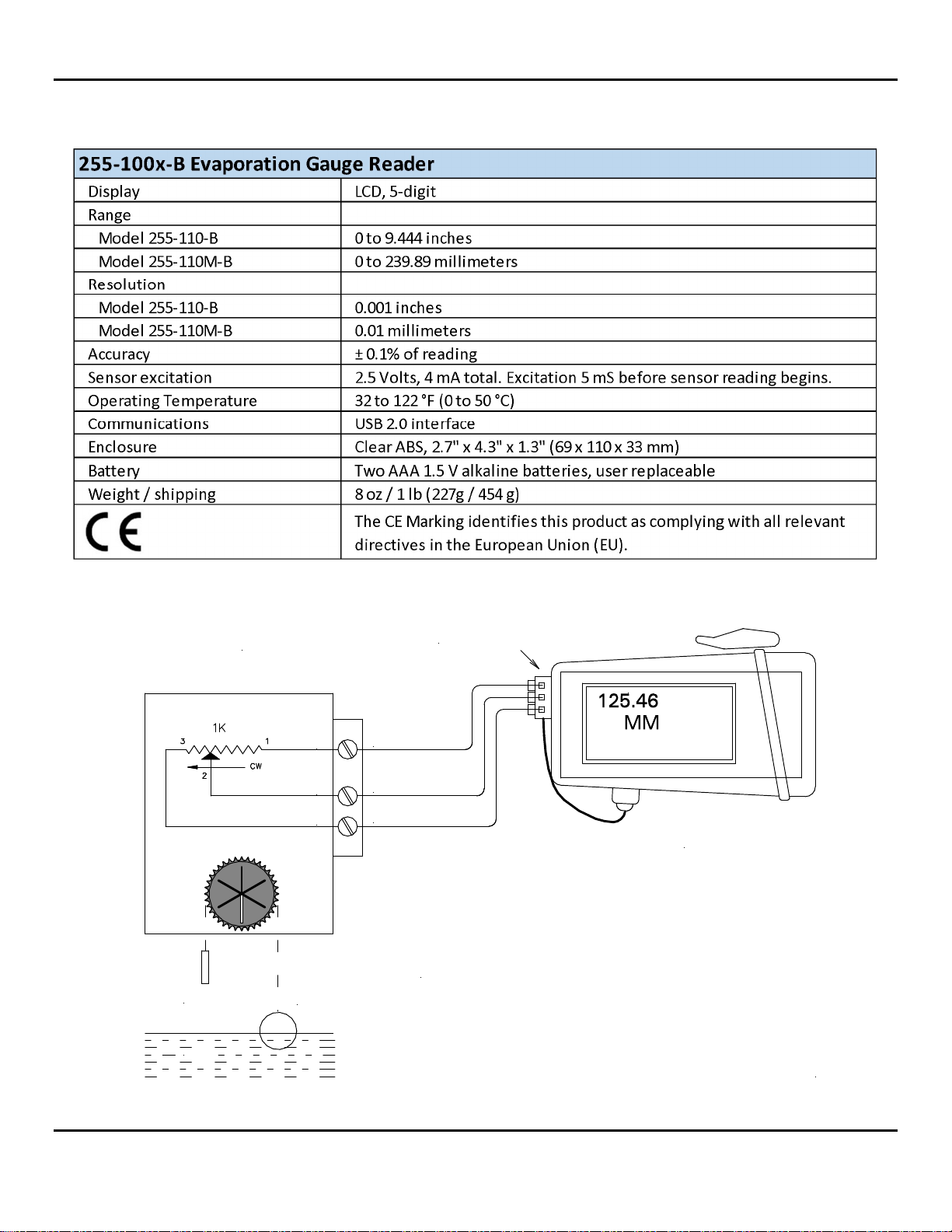

3 SPECIFICATIONS

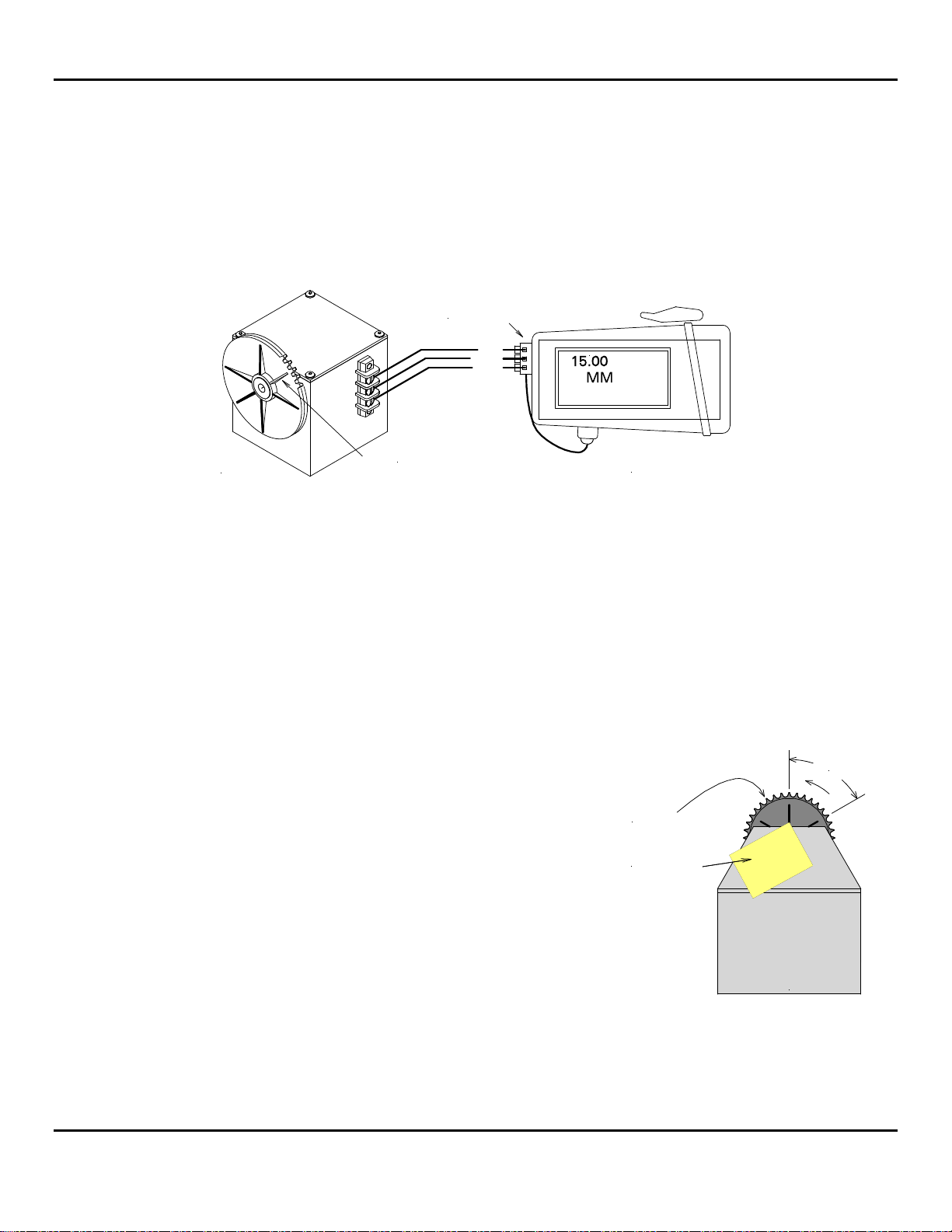

4 CONNECTIONS

255-100 ANALOG OUTPUT

EVAPORATION GAUGE

RED (+Vreg)

WHITE (Signal)

BLACK (Gnd)

1

2

3

Counter-

weight Float

255-110x-B EVAPORATION

GAUGE READER

Screw Terminals

Water

DWG 890-0092-01

CAUTION

To avoid damage to the display, connect the black

and white wires first. Connect the red wire last.

To disconnect, please disconnect the red wire first.

NovaLynx Corporation

255-110x-B Page 6 March 2021

The 255-110x-B Evaporation Gauge Reader uses very little power, and can typically run for a full year

on the two replaceable AAA batteries. The display remains on even when not in use, so it is ready to

take readings as soon as it is connected to the evaporation gauge.

1. Use a small screwdriver to loosen each screw on the terminal block.

2. Connect the black (ground) and white (signal) wires to the color-coded

terminals.

3. Connect the red (+Vreg) wire last.

4. The display will update with the water level reading within 15 seconds.

5. After recording the water level reading, disconnect the red wire first,

to avoid possible damage to the reader.

NOTE: when not connected to the evaporation gauge the readings on the

display will fluctuate randomly. This is normal. Connection Terminals

5 APPLICATION: EVAPORATION MONITORING

Evaporation is calculated as the difference in water level readings taken at regular intervals, typically

every 24 hours. To begin, the evaporation pan and analog output evaporation gauge must be set up

and filled with water. The installation and operation of the NovaLynx 255-100 Evaporation Gauge and

NovaLynx 255-200 Evaporation Pan are discussed in their respective user manuals, available at

www.novalynx.com

Each day (or other regular interval), connect the reader to the evaporation gauge following the

instructions (Section 4). Record the measurement in your log. Note: If the water in the pan is not still

(possibly due to wind), take two or more readings, calculate the average and record.

Observe the water level in the evaporation pan. The level should be maintained between 2 to 3 inches

below the rim of the evaporation pan. Avoid letting the level fall more than 5 inches.

If it is necessary to re-fill the pan, be sure you have recorded your daily reading first, then refill

the pan.

If a significant amount of precipitation has fallen it may be necessary to remove some water

from the pan. Be sure you have recorded your daily reading first, then remove excess water

from the pan.

After adjusting the water level, wait until the water is still and then take a new reading. Record

the new level along with a note that the evaporation pan was refilled or water was removed.

The evaporation gauge reader may be left attached to the evaporation gauge or it may be

disconnected and used at another evaporation monitoring site. If the reader is to be left connected,

provide a shelter that will keep the sun and rain off of the reader, otherwise moisture on the terminals

could cause corrosion, and strong sunlight could overheat the display.

NovaLynx Corporation

255-110x-B Page 7 March 2021

6 APPLICATION: EVAPORATION LOGGING

The display in the 255-110x-B Evaporation Gauge Reader is the same device as the logger that is

incorporated in the NovaLynx 255-704-B Evaporation Logger. If the reader is going to be used at only

one site, and it is feasible to leave the reader connected throughout the season, then it can be used to

log the water level in the evaporation pan on a continuous basis. Please refer to the 255-704-B

Evaporation Logger User Manual (www.novalynx.com) for instructions on how to operate as a logger.

7 APPLICATION: EVAPORATION GAUGE CHAIN INSTALLATION

The 255-110x-B Evaporation Gauge Reader can be used to verify proper installation of the evaporation

gauge, as well as being the method for reading the gauge. The evaporation gauge consists of a

precision potentiometer connected to a sprocket which is turned by the float and counterweight

mechanism (diagram, below). It is important when setting up the evaporation gauge that the sprocket

is correctly synchronized with the chain that holds the float and counterweight. The reason is that the

potentiometer has an electrical "dead band" where the resistance is infinite and the readings from the

gauge would be meaningless.

Chain Installation Using the Reader

1. Make sure the gauge is empty of water.

2. Connect the reader (Section 4).

3. Turn the sprocket until the display

reads within the following range:

Between 0.40 to 0.75 inches

Or

Between 10.0 to 20.0 mm

Note: The white pointer will be at

approximately 11:00 o'clock or 30

degrees to left of top.

4. Lift the chain until all the slack is taken

up, but the float is still resting on the

bottom of the gauge. Drape the chain over the sprocket so that the float is on the right and the

counterweight is on the left. If the indication on the reader is not within range, re-adjust the sprocket.

Note: This method will not work correctly if the generic calibration of the display has been changed.

8 APPLICATION: EVAPORATION GAUGE CALIBRATION CHECKUP

The 255-110x-B Evaporation Gauge Reader can be used to check the accuracy of the potentiometer as

part of a regular maintenance cycle. At a minimum, the operation of the potentiometer should be

checked at the beginning of a monitoring season. The following procedure applies to the reader when

it is calibrated to the generic factory settings.

255-110x-B EVAPORATION

GAUGE READER

Screw Terminals

Counter-

weight

Float

Float Touching Bottom

of Evaporation Gauge

DWG 890-0092-01

30°

White Pointer

11:00 o'clock

Deadband

(Red)

(White)

(Black)

NovaLynx Corporation

255-110x-B Page 8 March 2021

Disassembly

1. Remove the four screws holding the evaporation gauge cover and lift the cover off.

2. Remove the chain from the sprocket by lifting the counterweight. Drape the counterweight and

chain over the outside of the gauge. Do not attempt to remove the float.

3. Rotate the sprocket by hand to verify that it turns freely 360° without binding. It should spin freely

when given a small push.

255-110x-B EVAPORATION

GAUGE READER

Screw Terminals

(Red)

(White)

(Black)

White Stripe

DWG 890-0060-03

Testing with Evaporation Gauge Reader

Setup

1. Note that one ridge on the sprocket face has been painted with a white stripe. The other ridges are

not painted and are spaced 60° around the face of the sprocket. The back side of the sprocket has

similar ridges but none are painted.

2. Connect the reader to the evaporation gauge and verify that it responds to small movements of the

sprocket. Remember, the display updates only once every 15 seconds. Be patient.

Procedure

1. Adjust the position of the sprocket until the display reads 9.00"

or 228.6 mm. The white stripe on the front of the sprocket

should be at approximately 1 o'clock position as viewed from the

front.

2. While looking at the back of the sprocket, use a sticky-note as a

pointer and apply it to the top of the evaporation gauge housing,

aligning one corner to point at a rib on the back side of the

sprocket.

3. Enter the measured value as the starting point in the table (next

page). View from Back of Sprocket

4. Rotate the sprocket 60° counter-clockwise to the next ridge and record the measured value.

5. Continue recording measurements in 60° increments.

White Pointer

DWG 880-0002-01

60°

Sticky Note

NovaLynx Corporation

255-110x-B Page 9 March 2021

6. Compare the actual readings with the expected readings at each measured point, and determine

the Pass/Fail status.

Remedial Steps

If the white stripe is not between 12:00 and 1:00 o'clock at the starting point (9.00" or 228.6 mm),

the sprocket may have slipped on the shaft and be out of position.

If the readings on the display are progressively worse the farther the sprocket is turned, the

potentiometer may be out of specification, or there is added resistance in the circuit. Check all

connections.

If successive readings are non-linear then the potentiometer may need to be replaced.

The measured depth of water and the display will not agree when calibrated to the generic

settings, because the amount of water required to raise the float is not accounted for. This is

normal as the amount of evaporation is relative (i.e. the difference of two readings). If precise

agreement is desired, the display can be re-calibrated (Section 2).

Reassembly

Refer to Section 7 for instructions on synchronizing the chain and sprocket. Replace the cover of the

evaporation gauge. Fill the evaporation pan and take a reading after the water has settled.

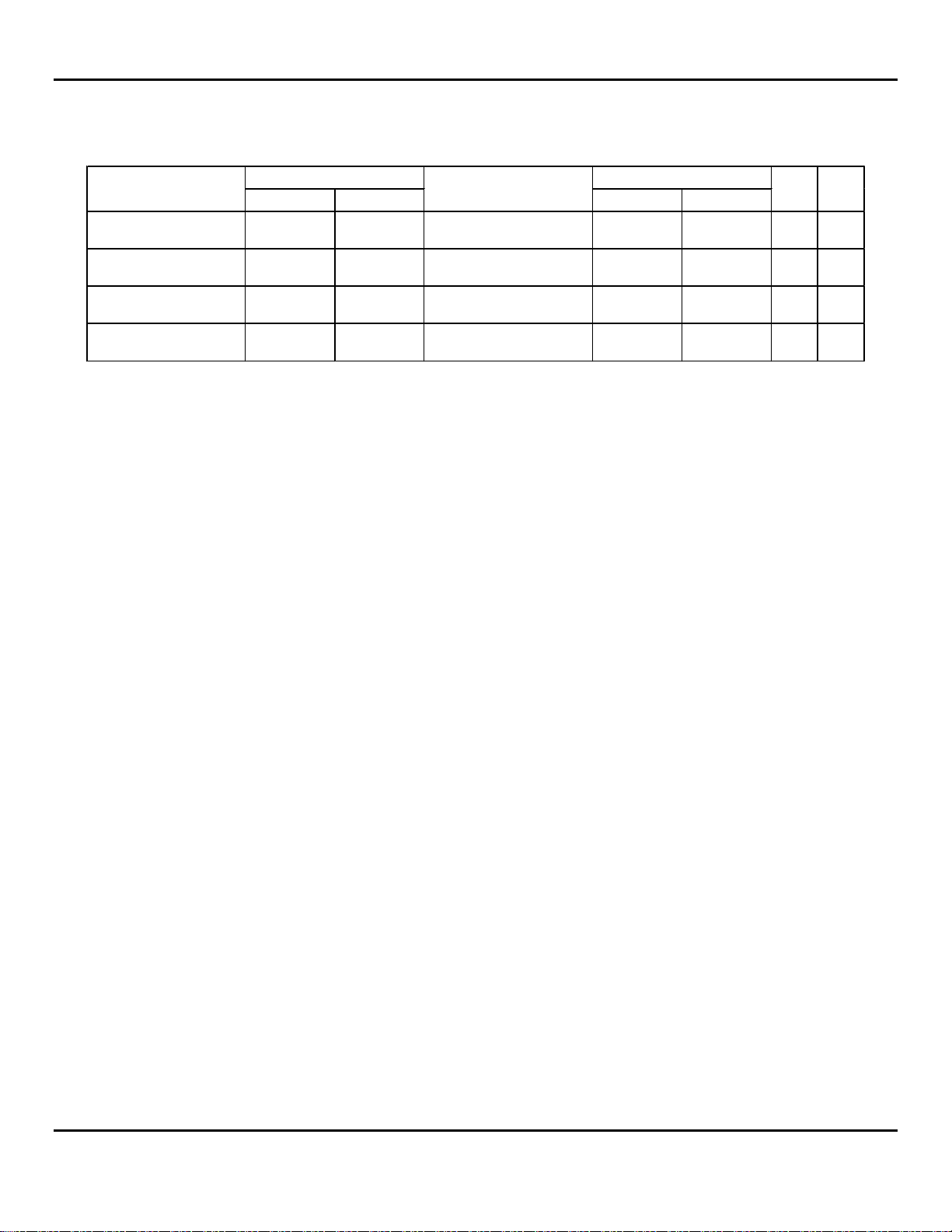

inches millimeters inches millimeters

9.00" Starting point 9.000 228.6 ±0.074 ±1.9

Rotated 60° 7.333 186.2 ±0.074 ±1.9

Rotated 120° 5.666 143.9 ±0.074 ±1.9

Rotated 180° 4.000 101.6 ±0.074 ±1.9

Sprocket Position

Expected Value

Measured Value

Acceptable Limit

Pass Fail

NovaLynx Corporation

255-110x-B Page 10 March 2021

9 BATTERY REPLACEMENT

WARNING: Keep all batteries away from small children. Dispose of used batteries properly.

The battery status indicator is located in the upper right corner

of the display screen. Replace the batteries at the beginning of

the season, and as required. Battery life can vary depending on

circumstances from 7 months to a year.

IMPORTANT: When the batteries are removed all programming is

lost and the display will go blank UNLESS you provide power to

the display while the batteries are being changed.*

FIRST: Connect a USB cable from your logger to a computer, USB

wall charger, or USB output battery pack. The cable type is USB

2.0 A to Mini-B.

1. Open the battery door on the back of the logger.

2. Remove the old batteries.

3. Insert two new batteries observing polarity.

4. Reinsert the battery door and snap it back into place.

Note: A desiccant pack may be inside the logger box. It can be

replaced or re-dried if needed.

* If the programming is lost, either return the unit to NovaLynx for inspection and reprogramming, or

obtain the software (free download) and re-program the unit. Instructions for programming the display

are detailed in the NovaLynx 255-704-B Evaporation Logger User Manual, available on our website at

www.novalynx.com.

This manual suits for next models

2

Table of contents

Other Novalynx Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

janitza

janitza UMG 503 operating instructions

NIEUWKOOP

NIEUWKOOP LX-93 user manual

Xact Gauge

Xact Gauge XG-110 quick start guide

MONARCH INSTRUMENT

MONARCH INSTRUMENT Pocket Laser Tach 200 instruction manual

Kusam-meco

Kusam-meco KM 033 Operation manual

Bosch

Bosch Professional GLM 50-27 C Original instructions

ELKOR

ELKOR WattsOn-MCM Installation & user guide

RKC INSTRUMENT

RKC INSTRUMENT AF110 instruction manual

TSCHORN

TSCHORN 3D Digital operating instructions

Bosch

Bosch UniversalLevel 3 Original instructions

Agilent Technologies

Agilent Technologies OmniBER 725 Configuration guide

GasTech

GasTech GasCheck 3000 user manual