BBI MagnaSpread Pull Type User manual

MagnaSpread Pull-Type

WARRANTY REGISTRATION FORMS AND PROCEDURES

WARRANTY REGISTRATION & DEALER INSPECTION FORM

The following section contains the necessary documents used to register a new BBI unit for warranty.

In order to activate the new equipment warranty, these forms should be returned to BBI no later than 30

(thirty) days from the date of sale to the end user.

These forms are in triplicate and distributed as follows:

1. Dealer retains one set for his / her records

2. One set returned to BBI

3. One set remains in operator’s manual and given to end user at time of delivery

These documents are as follows:

This form is completed when the dealer is preparing to deliver the new unit to the end user. It certies

the dealer has inspected the equipment, it operates correctly and all safety signs and guards are in

place. Any modications made to the equipment by the dealer should also be noted.

This form certies that the customer was instructed on safe and proper use, the equipment operates

correctly, warranty was explained and a copy of the owner’s manual was delivered. This form also

certies that if electronic rate control is installed, the customer has been given proper instruction as

to the operation of the system. Furthermore, a dealer service contact name and number has been

provided.

Please return the executed copies to BBI within 30 days to activate the warranty.

The copies can be sent via email to: [email protected], faxed to: 706-778-2787,

or mailed to: BBI Spreaders P.O. Box 630 Cornelia, GA 30531.

This form certies that if the unit is equipped with Tractor Supplied Hydraulics, proper return

requirements were discussed.

Important Tractor-Supplied Hydraulic Systems Information

Customer’s Warranty Registration

Dealer Inspection Form

MagnaSpread Pull-Type

WARRANTY REGISTRATION & DEALER INSPECTION FORM

DEALER EQUIPMENT AND SAFETY INSPECTION REPORT

To have a fully-executed warranty, the dealer must ll this form out at time of delivery. There is no warranty

without a fully-executed warranty registration and dealer inspection form.

All warning signs and safety signs are in place

All guards are in place

Modications to equipment (write details below)

Conveyor chain tension is properly adjusted

Equipment congured as ordered

Equipment is properly assembled

Equipment is functional and operates properly

Model & Serial Number:

Comments / equipment modications:

Signature of Set-Up Person Dealer Name Date

DELIVERY INSPECTION - DEALER COPY

MagnaSpread Pull-Type

CUSTOMER’S WARRANTY REGISTRATION - DEALER COPY

CUSTOMER’S WARRANTY REGISTRATION

Customer’s warranty protection on this equipment is only valid when this certication form is completed

and signed by both the customer and dealer at the time of delivery of the equipment and registered with

the manufacturer.

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

DEALER’S SIGNATURE INDICATES:

CUSTOMER’S SIGNATURE INDICATES:

All systems were explained and understood

Customer received a copy of the operator’s manual

Receipt of instructions on safe and proper use

If equipped with Electronic Rate control, this system was explained and owner’s manual was received

A dealer parts/service representative contact has been provided

Warranty was explained to the customer

Electronic Rate control programmed and operates correctly

Equipment operates properly and customer was instructed in safe and proper operation

Acceptance of equipment

Receipt of owners manual and clear understanding of warranty

Dealer name: Customer name:

Address: Address:

City, State, Zip: City, State, Zip:

Model & Serial Number:

Date of Delivery:

Chain tension and adjustment section reviewed and discussed

Clear understanding of chain tension and adjustment

MagnaSpread Pull-Type

On units equipped with tractor-supplied hydraulics the return must be connected to a 0 (zero) pressure

return. Gear motor systems require no pressure return.

DO NOT connect the system unless 0 (zero) pressure can be veried on return or damage to the motors

will result! Connecting to a pressurized return will VOID THE WARRANTY.

Various tractor manufacturers use different language for their brand to identify a 0 (zero) pressure return.

Please consult your manufacturer to insure the proper 0 (zero) pressure return is identied.

To maintain maximum operational efciency, your tractor needs to have 42 GPM (Gallons Per Minute)

overall, with 2 remotes each at 21 GPM and 2,000 PSI (Pounds per Square Inch) in order to operate the

tractor-supplied hydraulic system.

IMPORTANT TRACTOR-SUPPLIED HYDRAULIC SYSTEMS INFORMATION

TRACTOR-SUPPLIED HYDRAULICS - DEALER COPY

IMPORTANT!

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

MagnaSpread Pull-Type

WARRANTY REGISTRATION & DEALER INSPECTION FORM

DEALER EQUIPMENT AND SAFETY INSPECTION REPORT

To have a fully-executed warranty, the dealer must ll this form out at time of delivery. There is no warranty

without a fully-executed warranty registration and dealer inspection form.

All warning signs and safety signs are in place

All guards are in place

Modications to equipment (write details below)

Equipment congured as ordered

Equipment is properly assembled

Equipment is functional and operates properly

Model & Serial Number:

Comments / equipment modications:

Signature of Set-Up Person Dealer Name Date

DEALER INSPECTION - BBI COPY

Conveyor chain tension is properly adjusted

MagnaSpread Pull-Type

CUSTOMER’S WARRANTY REGISTRATION - BBI COPY

CUSTOMER’S WARRANTY REGISTRATION

Customer’s warranty protection on this equipment is only valid when this certication form is completed

and signed by both the customer and dealer at the time of delivery of the equipment and registered with

the manufacturer.

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

DEALER’S SIGNATURE INDICATES:

CUSTOMER’S SIGNATURE INDICATES:

All systems were explained and understood

Customer received a copy of the operator’s manual

Receipt of instructions on safe and proper use

If equipped with Electronic Rate control, this system was explained and owner’s manual was received

A dealer parts/service representative contact has been provided

Warranty was explained to the customer

Electronic Rate control programmed and operates correctly

Equipment operates properly and customer was instructed in safe and proper operation

Acceptance of equipment

Receipt of owners manual and clear understanding of warranty

Dealer name: Customer name:

Address: Address:

City, State, Zip: City, State, Zip:

Model & Serial Number:

Date of Delivery:

Chain tension and adjustment section reviewed and discussed

Clear understanding of chain tension and adjustment

MagnaSpread Pull-Type

On units equipped with tractor-supplied hydraulics the return must be connected to a 0 (zero) pressure

return. Gear motor systems require no pressure return.

DO NOT connect the system unless 0 (zero) pressure can be veried on return or damage to the motors

will result! Connecting to a pressurized return will VOID THE WARRANTY.

Various tractor manufacturers use different language for their brand to identify a 0 (zero) pressure return.

Please consult your manufacturer to insure the proper 0 (zero) pressure return is identied.

To maintain maximum operational efciency, your tractor needs to have 42 GPM (Gallons Per Minute)

overall, with 2 remotes each at 21 GPM and 2,000 PSI (Pounds per Square Inch) in order to operate the

tractor-supplied hydraulic system.

IMPORTANT TRACTOR-SUPPLIED HYDRAULIC SYSTEMS INFORMATION

TRACTOR-SUPPLIED HYDRAULICS - BBI COPY

IMPORTANT!

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

MagnaSpread Options:

8’, 10’ Single-axle

10’, 12’, 14’, 16’ Tandem-axle

Tractor-supplied or self-contained

hydraulic systems

OPERATOR MANUAL

This manual is valid for all MagnaSpread

Pull-Type congurations

Your serial number can be found here:

MagnaSpread Pull-Type

TABLE OF CONTENTS

2 TABLE OF CONTENTS

3 A MESSAGE FROM BBI

4-6 DELIVERY AND WARRANTY CHECKLISTS

7 WARRANTY

8-10 SAFETY INSTRUCTIONS

11 TRACTOR PREPARATION AND HOOK-UP

12 HYDRAULIC CONFIGURATION

13-17 IDENTIFYING COMPONENTS

18-21 FIELD TESTING

22-23 MACHINE OPERATION

24-25 LUBRICATION AND MAINTENANCE

26-28 CHAIN TENSION ADJUSTMENT

29 TIPS & TRICKS

30 PARTS AND SHIPPING

31 PARTS IDENTIFICATION AND ORDERING

32-48 ASSEMBLY AND PARTS IDENTIFICATION

49-54 GROUND SPEED TABLES AND RATE CHARTS

2

MagnaSpread Pull-Type

The BBI team takes pride in producing superior spreaders that will provide many years of

service. In bringing the best spreaders to the industries of agriculture, poultry, and construction,

we carefully select components with a proven performance record and availability. Our skilled

employees give special attention to detail in design and assembly to make certain our equipment

will meet or exceed your expectations in the eld.

Our parts department stands ready to serve you with replacement parts at affordable prices. We

stock a large inventory to assure support for our customers, and take pride in offering “same day

service” for those orders received before mid-afternoon.

At BBI, we provide quality service with a friendly atmosphere. BBI stands hand-in-hand with our

dealers in the eld. Our local dealers are your rst point of contact and empowered to solve your

problems. If that fails, we are prepared to serve you at any time. We strive to quickly provide

solutions for your needs in order to minimize any downtime or delays.

Our company takes safety very seriously, and we give great concern to our products in an

ongoing effort to reduce any potential safety issues, whether with equipment or in the workplace.

We design our equipment intentionally to minimize pinch points and provide guards where they

do exist. BBI places decals on our equipment to identify and caution against areas containing

pinch points and hazardous moving parts.

Please be sure that those who operate BBI equipment receive proper training. Never conduct

maintenance or repairs unless the equipment is fully disabled with the power source turned

off. Never stand inside the unit while in operation or moving. Since we design our spreaders to

project materials in patterns ranging from 30 to 90 feet, depending on the specic equipment,

standing too close to equipment can result in injury. Please use extreme caution when operating

all equipment.

Thank you for choosing BBI spreading equipment. You will be glad you did.

Richard B. Hagler

President

“Driving Value”

A MESSAGE FROM BBI

3

MagnaSpread Pull-Type

WARRANTY REGISTRATION & DEALER INSPECTION FORM

DEALER EQUIPMENT AND SAFETY INSPECTION REPORT

To have a fully-executed warranty, the dealer must ll this form out at time of delivery. There is no warranty

without a fully-executed warranty registration and dealer inspection form.

All warning signs and safety signs are in place

All guards are in place

Modications to equipment (write details below)

Equipment congured as ordered

Equipment is properly assembled

Equipment is functional and operates properly

Model & Serial Number:

Comments / equipment modications:

Signature of Set-Up Person Dealer Name Date

DELIVERY INSPECTION - CUSTOMER COPY

4

Conveyor chain tension is properly adjusted

MagnaSpread Pull-Type

CUSTOMER’S WARRANTY REGISTRATION - CUSTOMER COPY

5

CUSTOMER’S WARRANTY REGISTRATION

Customer’s warranty protection on this equipment is only valid when this certication form is completed

and signed by both the customer and dealer at the time of delivery of the equipment and registered with

the manufacturer.

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

DEALER’S SIGNATURE INDICATES:

CUSTOMER’S SIGNATURE INDICATES:

All systems were explained and understood

Customer received a copy of the operator’s manual

Receipt of instructions on safe and proper use

If equipped with Electronic Rate control, this system was explained and owner’s manual was received

A dealer parts/service representative contact has been provided

Warranty was explained to the customer

Electronic Rate control programmed and operates correctly

Equipment operates properly and customer was instructed in safe and proper operation

Acceptance of equipment

Receipt of owners manual and clear understanding of warranty

Dealer name: Customer name:

Address: Address:

City, State, Zip: City, State, Zip:

Model & Serial Number:

Date of Delivery:

Chain tension and adjustment section reviewed and discussed

Clear understanding of chain tension and adjustment

MagnaSpread Pull-Type

IMPORTANT TRACTOR-SUPPLIED HYDRAULIC SYSTEMS INFORMATION

On units equipped with tractor-supplied hydraulics the return must be connected to a 0 (zero) pressure

return. Gear motor systems require no pressure return.

DO NOT connect the system unless 0 (zero) pressure can be veried on return or damage to the motors

will result! Connecting to a pressurized return will VOID THE WARRANTY.

Various tractor manufacturers use different language for their brand to identify a 0 (zero) pressure return.

Please consult your manufacturer to insure the proper 0 (zero) pressure return is identied.

To maintain maximum operational efciency, your tractor needs to have 42 GPM (Gallons Per Minute)

overall, with 2 remotes each at 21 GPM and 2,000 PSI (Pounds per Square Inch) in order to operate the

tractor-supplied hydraulic system.

Signature of Dealer Dealer Name Date

Signature of Customer Customer Name Date

TRACTOR-SUPPLIED HYDRAULICS - CUSTOMER COPY

IMPORTANT!

6

MagnaSpread Pull-Type

BBI warrants, to the original user, that each product of its manufacture is free from defects in material

and workmanship if serviced and operated under normal conditions for 180 days from the date of the

customer’s bill of sale.

BBI’s obligation under this warranty is limited to the correcting of the defect(s) without charge at its factory

or one of its authorized dealers. Transportation charges will be pre-paid. BBI requires the opportunity to

examine all parts in question in order to determine the original cause of defect. Correction of such defects

by repair to or supplying of replacements for defective parts shall constitute fulllment of all obligations to

the original user.

This warranty shall not apply to any BBI product which must be replaced because of normal wear, misuse,

negligence or accident.

This warranty shall not apply to products which have been repaired or altered outside of the BBI factory

without written factory authorization.

BBI shall not under any circumstances be liable for any incidental or consequential damages arising from

the loss of property or other damages or loses owing to the failure or use of BBI products beyond the cost

of repair or replacement of any defective product. The repair or replacement of defective product shall be

the sole and only obligation of BBI.

EXCEPT AS SPECIFICIALLY SET FORTH HEREIN, BBI MAKES NO WARRANTY ON ITS PRODUCTS

(EXPRESSED, IMPLIED OR STATUTORY) INCLUDING, WITHOUT LIMITATION, NO WARRANTY OF

FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY.

No person, agent or dealer is authorized to give any warranties or make representations on behalf of BBI

or assume for BBI any other liability in connection with any of its products unless made in writing by an

ofcer of BBI.

Any warranty provision outside of these bounds needs to be negotiated before service commences. The

warranty does not include transportation. Warranty service is provided by the dealer. It is the customer’s

responsibility to seek warranty from your dealer.

WARRANTY

DEALER’S WARRANTY SERVICE CONTACT INFORMATION:

Dealer Service Representative:

Phone number:

Email:

WARRANTY

7

MagnaSpread Pull-Type

Please read and understand the safety warnings contained in this manual before operation.

We cannot stress enough the need for personal safety. BBI strongly urges you to make safety your top

priority when operating any equipment. Anyone allowed to operate our equipment must be thoroughly

trained and tested to prove that they understand the fundamentals for safe operation.

Our intention is that the following guidelines cover general usage of BBI equipment and assist you in

avoiding accidents. There will be times when you will run into situations that are not covered in this

section. At those times, the best standard to use is caution guided by your own common sense. If, at any

time, you have a question concerning these guidelines, please call your authorized BBI dealer or the BBI

factory at (800) 282-3570.

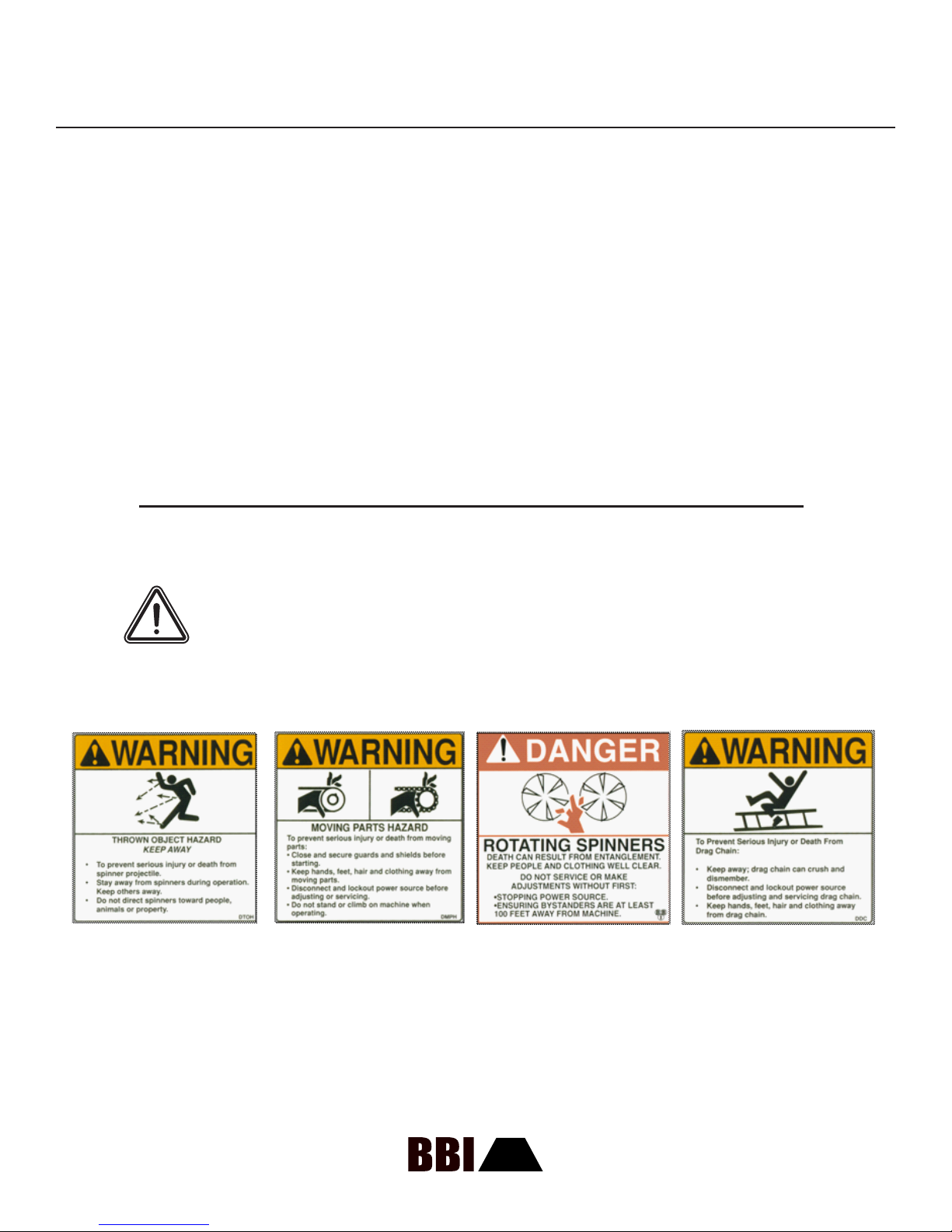

TAKE NOTE: THIS SAFETY ALERT SYMBOL, FOUND THROUGHOUT

THIS MANUAL, IS USED TO CALL YOUR ATTENTION TO INSTRUCTIONS

INVOLVING YOUR PERSONAL SAFETY AND THAT OF OTHERS; FAILURE

TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN INJURY OR DEATH.

In this manual and on safety signs placed on your spreader, the words

“DANGER”, “WARNING,” “CAUTION,” and “IMPORTANT” are used to indicate

the following:

Indicates an imminently hazardous situation that, if not avoided, WILL result in

death or serious injury. This signal word is to be limited to the most extreme

situations and typically for machine components that, for functional purposes,

cannot be guarded.

Indicates a potentially hazardous situation that, if not avoided, COULD result in

death or serious injury. This includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe practices.

Indicates a potentially hazardous situation that, if not avoided, MAY result in

moderate or minor injury. It may also be used to alert against unsafe practices.

Indicates critical information regarding potential damage or deterioration of

equipment if not heeded. Generally would not involve personal injury.

SAFETY WARNINGS

DANGER!

WARNING!

CAUTION!

IMPORTANT!

SAFETY INSTRUCTIONS

8

MagnaSpread Pull-Type

Most accidents, whether they occur in industry, on the farm, at home, or on the highway, have causes

stemming from the failure of individuals to follow simple and fundamental safety rules and precautions.

For this reason, people can prevent most accidents by recognizing their real, potential causes and

rectifying these causes before they ever allow accidents to occur.

Regardless of the care used in the design and construction of any type of equipment, there are many

conditions that we cannot completely safeguard against without interfering with reasonable accessibility

and efcient operation.

A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST AN ACCIDENT. THE COMPLETE

OBSERVANCE OF ONE SIMPLE RULE WOULD PREVENT THOUSANDS OF SERIOUS INJURIES

EACH YEAR.

THAT RULE IS:

NEVER CLEAN, OIL, OR ADJUST A MACHINE WHILE IT IS UNDER POWER.

- National Safety Council

1. Keep safety decals and signs clean and legible at all times.

2. Replace safety decals and signs that are missing or have become illegible.

3. Replaced parts that displayed a safety sign should also display the current safety sign.

4. Safety Decals are available from your local BBI dealer’s Parts Department or our factory at BBI.

If you use your spreader to transport chemicals, check with your chemical

supplier regarding the applicable DOT (Department of Transportation)

regulations.

AVOID ACCIDENTS

DECAL MAINTENANCE INSTRUCTIONS

SAFETY DECALS

CAUTION!

SAFETY INSTRUCTIONS

9

MagnaSpread Pull-Type

1. Refrain from wearing loose tting clothing on or around this piece of machinery. There are many

places that loose clothing may become wrapped or pulled into devices.

2. Be aware of any moving parts on this machinery. Make sure that any person or persons on or

around this piece of machinery are aware of the dangers as well. There are many places where

injury may occur. Learn about your unit and the dangers of it. Always use caution in the operation

of this piece of machinery.

3. Be sure that any individuals operating this equipment are trained and are aware of the dangers of

this equipment.

4. Check for rocks, sticks, or anything that may cause bodily harm to you or damage your unit.

5. Never attempt to work on or repair this piece of equipment while it is running. The PTO and/or

any other power source must be completely disengaged while working on this unit.

6. Those working around this unit should remain at least 100 feet from it while it is in operation. The

fans are able to propel objects at a high speed up to this distance.

7. Be aware of the dangers of hydraulic systems. Hydraulic uid is under very high pressure, and

may cause serious injury if it hits the facial area, especially the eyes.

8. Shut down the entire system before checking hydraulic uid level or adding uid to the system.

HAZARDS

SAFETY INSTRUCTIONS

10

MagnaSpread Pull-Type

Look over the entire unit, checking that all guards and fasteners are in place and fasteners are properly

tightened, including lug nuts.

1. Adjust tractor hitch and drawbar as close to horizonal as you can. Adjust drawbar so hitch pin hole

is directly below center line of PTO shaft. Make sure drawbar is in a stationary position.

2. Back tractor to spreader and connect with a minimum ¾” diameter hitch pin. Secure with a locking

or cotter pin.

3. Attach the safety chains.

4. Raise jack stand.

5. Either connect hydraulic hoses (as discussed in the Tractor-supplied Hydraulic Section),

or connect PTO shaft to tractor PTO in the case of a Self-contained Hydraulic System.

Be cautious of pinch points.

6. Install and connect Dual Switch Control Box and any other electronic controls needed.

7. Check to be sure that no loose parts or other material are in the hopper, on the conveyor or on the

spinners. Be sure to remove any loose pieces and ensure all guards are in place.

PRIOR TO START-UP

TRACTOR PREPARATION AND HOOK-UP

TRACTOR PREPARATION AND HOOK-UP

Pressurized hydraulic uid can penetrate body tissue and result in death, serious

infection, or other injuries. Fluid injected under skin must be IMMEDIATELY

removed by a surgeon familiar with this type of injury. Make sure connections are

tight and hoses and ttings are not damaged before applying system pressure.

Leaks can be invisible. Keep away from suspected leaks. Relieve pressure

before searching for leaks or performing any system maintenance.

WARNING!

Ensure that you always keep your hose ends clean using a cloth. Never use a

dirty coupling. If it does drop in the dirt, clean it up before you apply or damage

to your tractor can occur.

NOTE: Do not load spreader with material until after completing initial

start-up steps.

IMPORTANT!

IMPORTANT!

11

MagnaSpread Pull-Type

This unit is congured for an electronic rate control system. You should be able to interface your BBI

applicator to any type of controller commercially available today. The unit may be operated manually. The

decision for which conguration to apply needs to be made and implemented before starting up the unit.

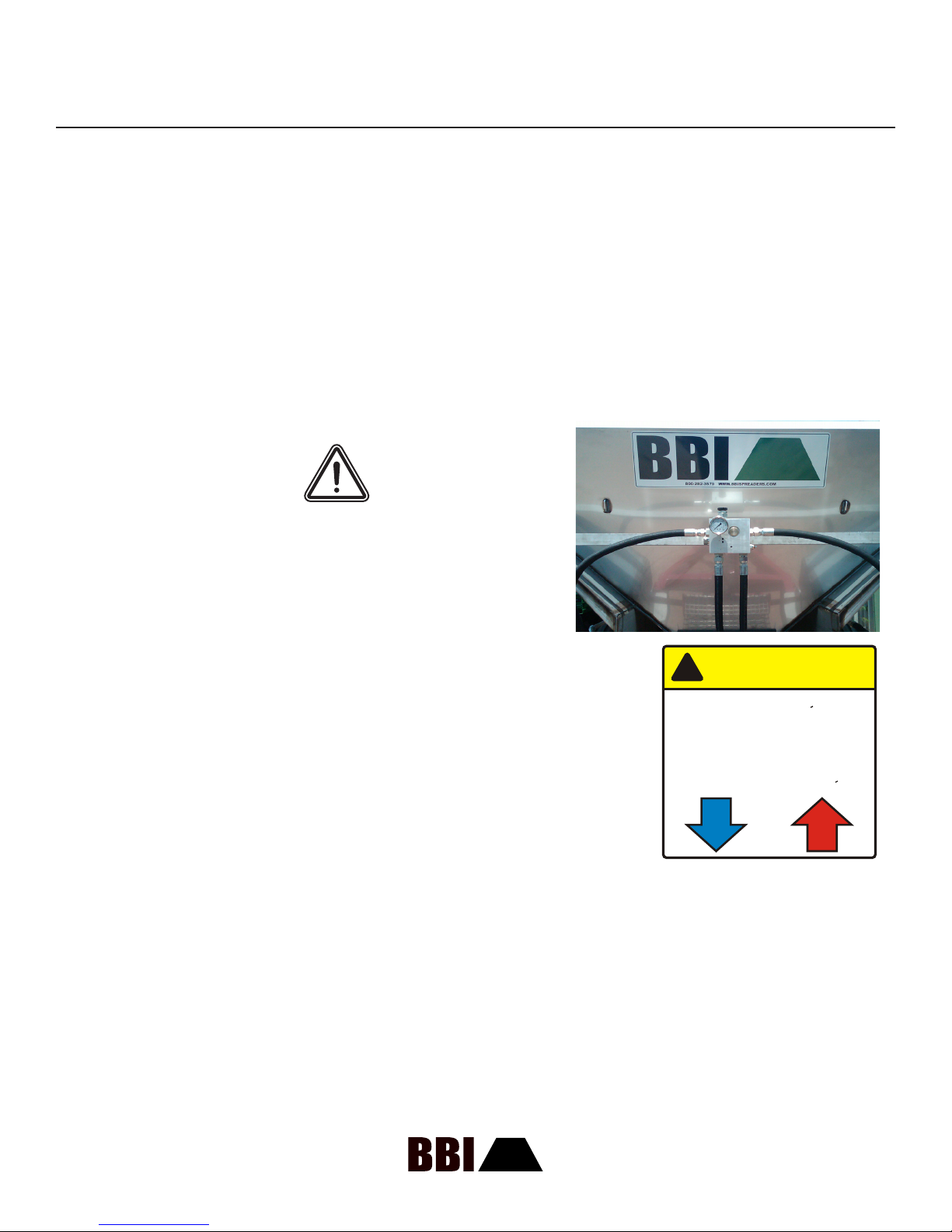

For spreaders powered by the tractor’s hydraulic system, you will need to connect two sets of remote

hydraulic ports, one set for the conveyor system and one for the spinners.

Make sure that you match and properly connect the pressure and return hoses with each set of remote

ports. Mismatched hoses or return hoses that are not properly connected will cause damage to hydraulic

components on the spreader.

PRIOR TO INITIAL START-UP - CHOOSE YOUR CONTROLS

1. TRACTOR-SUPPLIED HYDRAULIC SYSTEM

On units equipped with tractor-supplied hydraulics the return

must be connected to a 0 (zero) pressure return. Gear motor

systems require no pressure return.

DO NOT connect the system unless 0 (zero) pressure can

be veried on return or damage to the motors will result!

Connecting to a pressurized return will VOID THE WARRANTY.

Various tractor manufacturers use different language for their brand to

identify a 0 (zero) pressure return. Please consult your manufacturer to

insure the proper 0 (zero) pressure return is identied.

To maintain maximum operational efciency, your tractor needs to have

42 GPM (Gallons Per Minute) overall, with 2 remotes each at 21 GPM

and 2,000 PSI (Pounds per Square Inch) in order to operate the tractor-

supplied hydraulic system.

IMPORTANT!

HYDRAULIC CONFIGURATION

If your spreader is self-contained, simply connect your PTO shaft which will turn the pump to make the

hydraulic uid ow.

Never attempt to work on or repair this piece of equipment while it is running. The PTO and/or

any other power source must be completely disengaged while working on this unit.

2. SELF-CONTAINED HYDRAULIC SYSTEM

RED

(ROJO)

=

PRESSURE

(PRESION)

BLUE

(AZUL)

=

RETURN

(RETORNO)

!

IMPORTANT

HYDRAULIC CONNECTIONS

(CONEXIONES HIDRAULICAS)

12

MagnaSpread Pull-Type

IDENTIFYING COMPONENTS

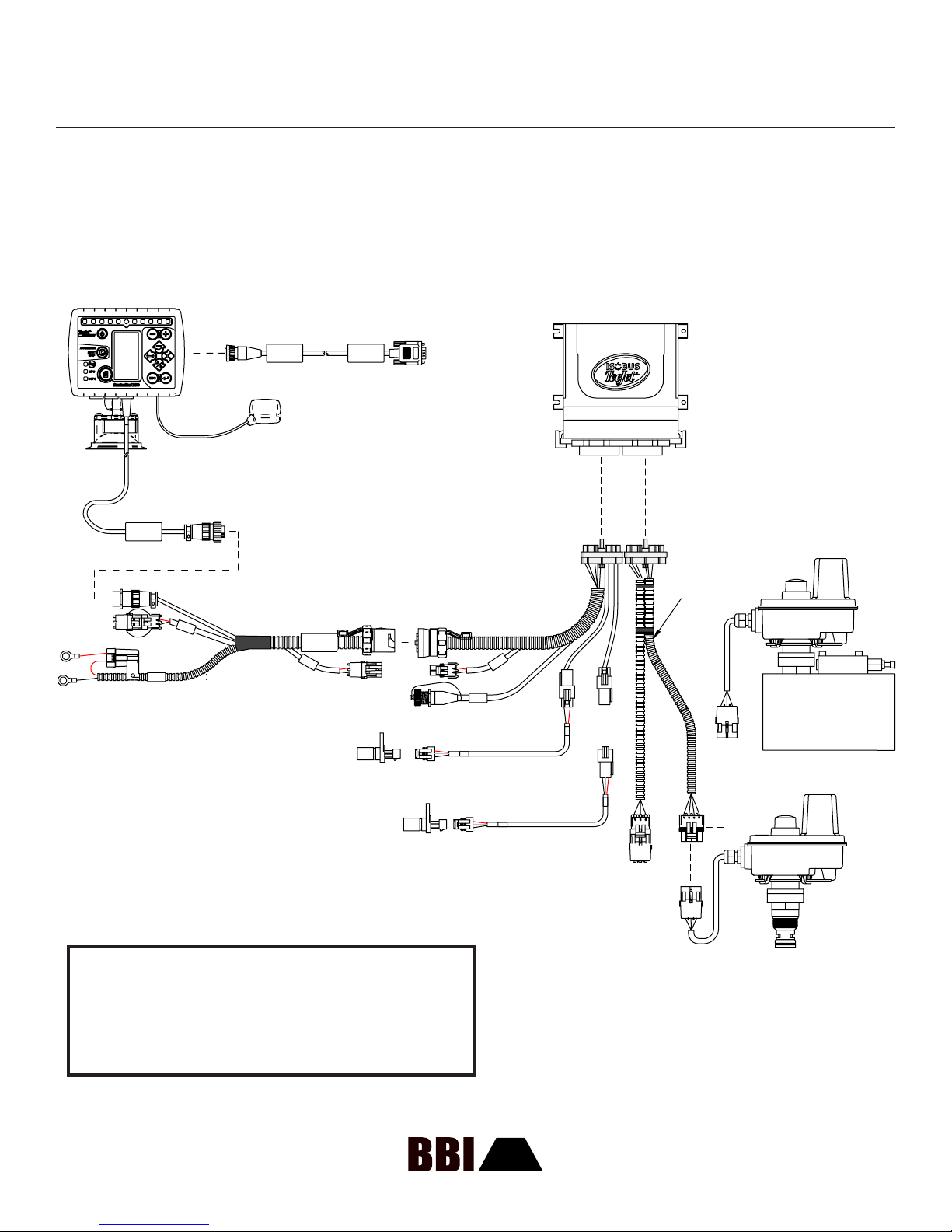

The CenterLine 250 - IC18 Electronic Control platform comes standard with the MagnaSpread line of dry

broadcast applicators, but the system can be adapted to multiple electronic congurations for dry rate

controllers. The IC18 is also available for variable-rate applications as an ISOBUS 11783-compliant ECU

and can plug up to any ISOBUS 11783 compliant Virtual Terminal with Task Control capabilities.

IC-18 CONSTANT NUMBERS

20” Mesh Chain 105 (Standard)

18” Mesh Chain 120

16” Mesh Chain 130

COMPONENTS OF THE STANDARD CL 250 STRAIGHT-RATE CONTROLLER

0345-10114

XX/XX

CONNECT

TO

BATTERY

0345-10114

CL250 & Power

to Hitch IC18

REMOTE

MASTER

REMOTE

MASTER

Hitch to IC18

Harness

0345-10115

REMOTE

MASTER

Belt

Belt

Belt 0345-05762 Belt

Replacement cable

Speed

0316-05000

Sensor

Spinner

Spinner

0345-05694

Spinner Cable

(Optional)

0316-05000

Sensor

IC 18 Spreader

0378-08063

CL 250

0390-02582

CL250 Kit

GPS Antenna

S/N

0390-02595

Data Out Kit (Optional)

0345-10116

IC18 to Valves

0335-02127 Valve

with Kit 0390-02559

for hydraulic spreaders

without BBI Binary

Manifold

0335-05013 cartridge

w/Kit 0390-02558

for spreaders with

BBI Binary Manifold

13

Table of contents

Popular Spreader manuals by other brands

Chapin

Chapin 8003A use and care manual

Meyer

Meyer 7200 Operator and parts manual

Warren

Warren AC-1820A Owner / Operator Manual & Parts Reference Guide

Western

Western WB-160D Owner's manual and installation instructions

SnowEx

SnowEx SP-2400 Owner's/operator's manual

Meyer

Meyer V-MAX 2636 Operators Operator's manual

Art's Way

Art's Way X350 Operator manual & illustrated parts list

Brinly-Hardy

Brinly-Hardy Spyker Spreaders ROS 6 quick start guide

Dcm

Dcm 2500 PRO manual

Kugelmann Maschinenbau

Kugelmann Maschinenbau DUPLEX INOX operating instructions

Shindaiwa

Shindaiwa RS600 quick start guide

Shindaiwa

Shindaiwa RS60 parts catalog