CPS/MAX/0617 Page 3

Safety

ALWAYS read the original manufacturer’s manual rst

ALWAYS start the engine in the open air

DO NOT smoke when refuelling

DO NOT mix OIL with the fuel

ALWAYS stop the engine before making any adjustments, refuelling, moving or

cleaning, or when the unit is unattended

USE ONLY fuel from containers designed for this purpose - refuel outdoors only and

replace the tank cap securely

IN CASE of petrol spillage move the machine away from the area of spillage and

allow the petrol vapours to dissipate before starting the engine

DO NOT remove any safety guards that are tted

DO NOT touch any moving parts or attempt any maintenance whilst the machine is

running - KEEP HANDS AND FEET AWAY

BEFORE starting work clear the work area of any objects that could damage the

machine

DO NOT allow children or anyone uninstructed to operate the machine - KEEP

ANIMALS AWAY

DO NOT use on slopes or banks of more than 20o

ALWAYS wear suitable clothing to give personal protection including footwear that

offers a good grip

AVOID wearing loose garments that may catch in moving parts

KNOW how to stop the machine in an emergency

NEVER interfere with any control settings on the engine

NEVER select reverse gear with your back to a wall or other immovable object

IF A FAULT develops DO NOT attempt any repair - immediately contact the supplier

from whom the machine was obtained

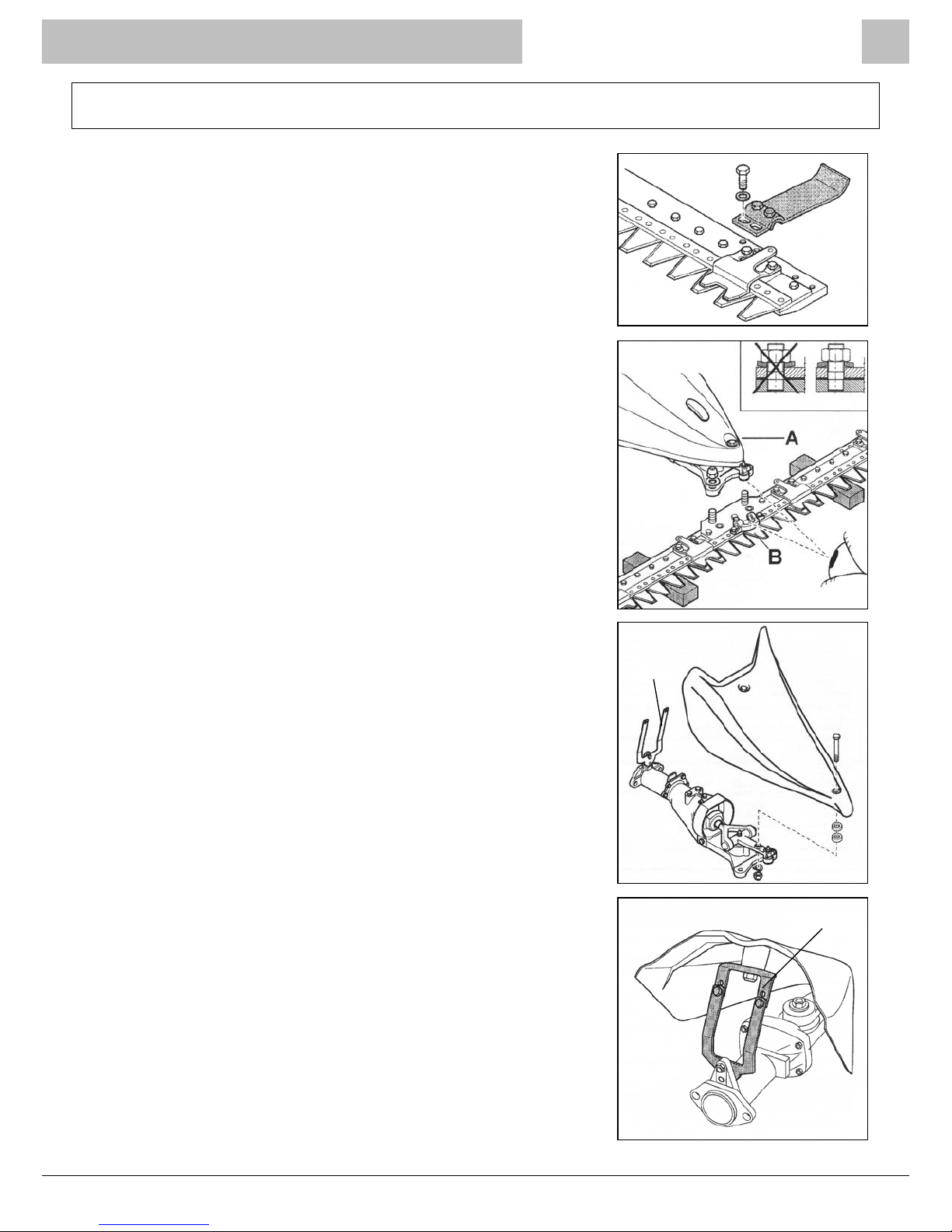

VISUALLY INSPECT the machine before use - ensure all blades, nuts and bolts are

tight and not worn or damaged and replace blades if necessary

KEEP IN MIND the operator is responsible for accidents or hazards occurring to

people or property