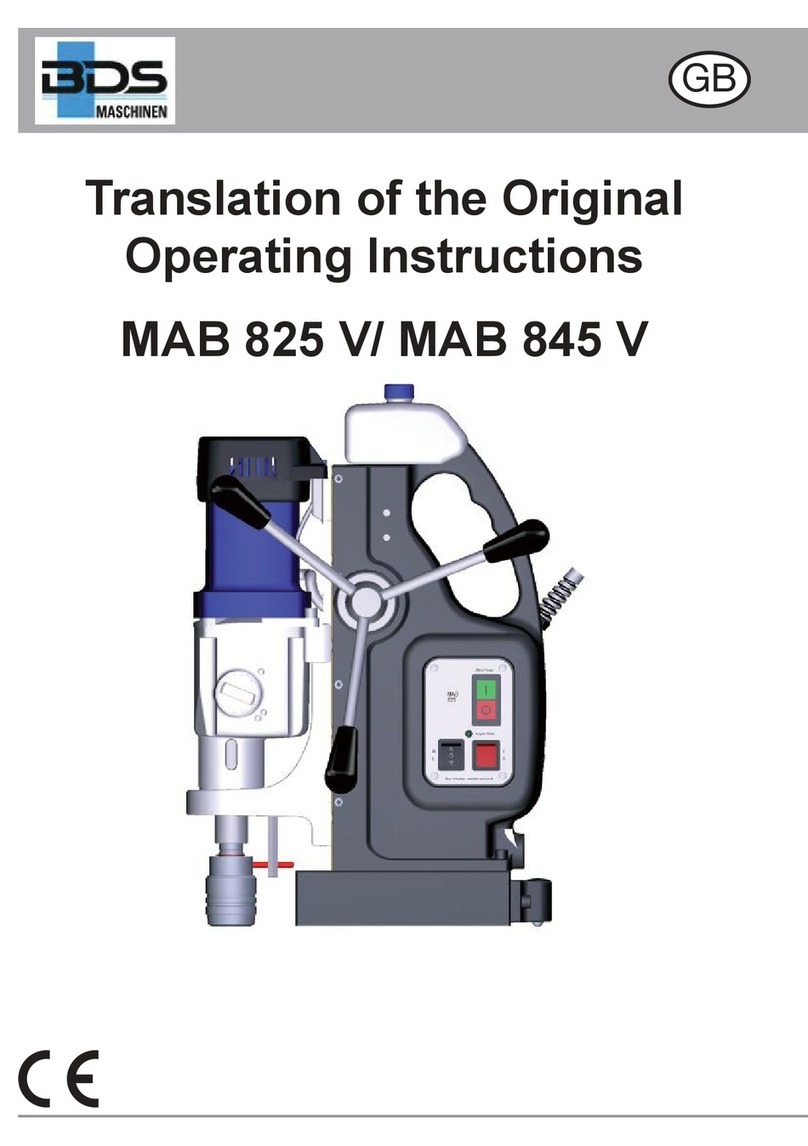

BDS AirMAB 5000 User manual

AirMAB 5000

Original-

Operating Instructions

GB

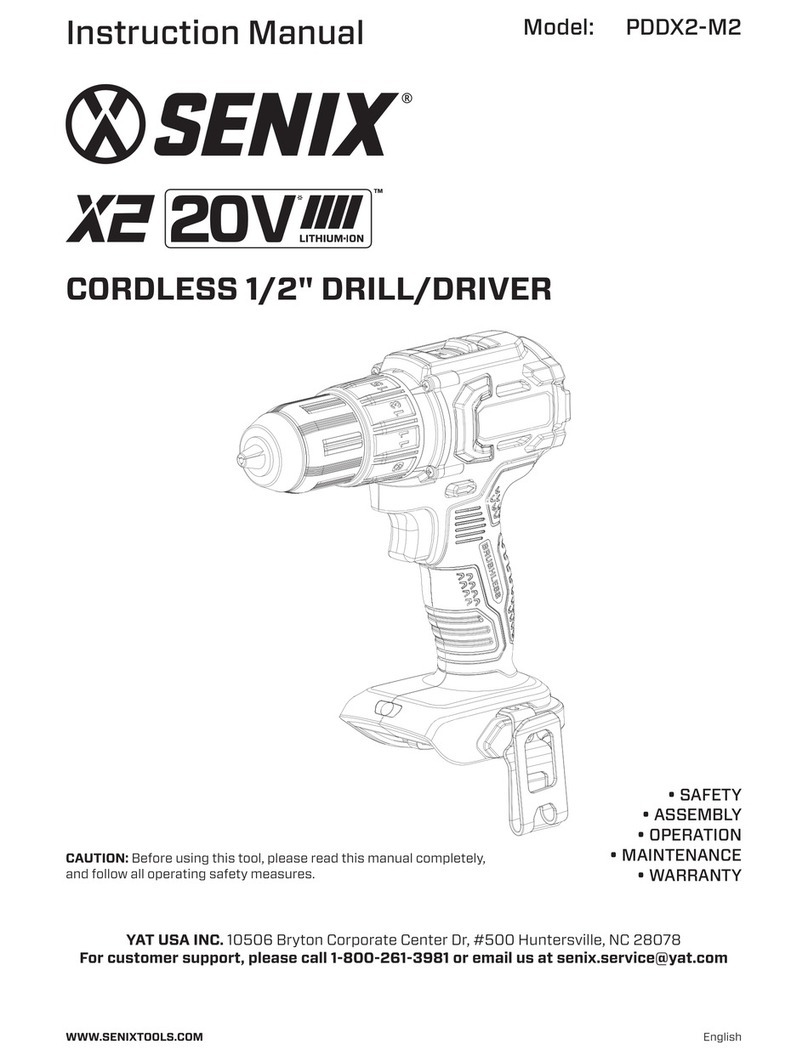

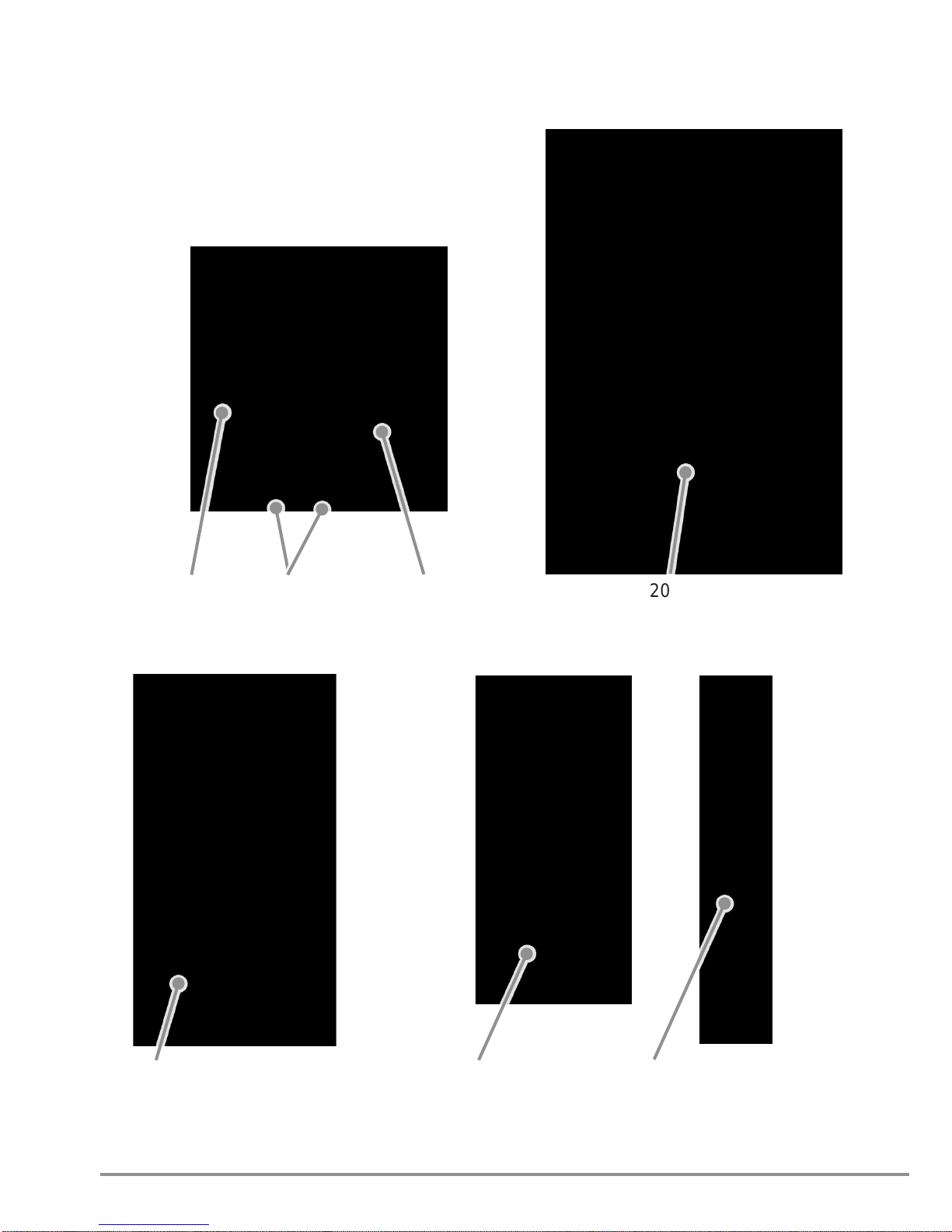

8

5

4

2

1

6

3

7

9

10

11

12

21

A B C

202223

3

General instructions

AirMAB 5000

GB

Table of Contents

General instructions . . . . . . . . . . . . . . . .3

Safety............................5

Components / delivery contents . . . . . .8

Before using for the rst time . . . . . . . .9

Preparation. . . . . . . . . . . . . . . . . . . . . . . .9

Use.............................13

Eliminating blockages. . . . . . . . . . . . . .14

Cleaning .........................15

Maintenance......................15

Storage .........................16

Troubleshooting . . . . . . . . . . . . . . . . . .16

Technical data . . . . . . . . . . . . . . . . . . . .17

EC Declaration of Conformity . . . . . . .18

Dear Customer,

Before using the machine, please read the

operating instructions contained in these

operating instructions on startup, safety,

intended use as well as cleaning and care.

The links and illustrations in these instruc-

tions refer to the illustrations on the inside

of the cover.

Keep these operating instructions for later

use and pass them onto the next owner of

the machine.

General instructions

Copyright

This document is copyrighted. Any duplica-

tion or reprinting, in whole or in part, and

the reproduction of the illustrations, even

in modied form, is only permitted with the

written approval of the manufacturer.

Liability disclaimer

All technical information, data and instruc-

tions for commissioning, operation and

maintenance of the machine contained in

these operating instructions represent the

latest status at the time of printing.

The manufacturer assumes no liability for

damage or injury resulting from failure to

observe the operating instructions, use for

other than the intended purpose, unprofes-

sional repairs, unauthorised modications

or use of non-approved spare parts and

accessories, tools and lubricants.

Instructions on disposal

The packaging materials used can be

recycled. When no longer required,

dispose of the packaging materials

according to local environmental regula-

tions. This product may not be disposed of

in the domestic refuse within the

European Union. Dispose of the

device via communal collection points.

4

General instructions

AirMAB 5000

GB

Safety warning structure

The following warnings are used in these

operating instructions:

WARNING

A warning of this category indicates a

potentially dangerous situation.

If the dangerous situation is not avoided,

it may lead to injuries.

Follow the instructions in this warning►to avoid possible danger of serious

personal injuries.

CAUTION

A warning statement for this safety

risk class indicates a damage risk.

If the situation is not avoided, it may lead

to material damage.

Follow the instructions in this warning►to avoid material damage.

NOTE

A note indicates additional information►

that simplies the use of the machine.

Intended use

The machine is intended solely for drilling

operations in magnetic and non-magnetic

metals within the limits specied in the

technical data.

Any use other than previously stated is

considered as improper use.

WARNING

Danger resulting from improper use!

If not used for its intended purpose and/

or used in any other way, the machine

may be or become a source of danger.

Use the machine only for its intended►purpose.

Observe the procedures described in►these operating instructions.

No claims of any kind will be accepted for

damage resulting from use of the appliance

for other than its intended purpose.

The risk must be borne solely by the user.

NOTE

If used commercially, pay attention to►compliance with the accident preven-

tion and occupational safety regula-

tions.

5

Safety

AirMAB 5000

GB

Safety

WARNING

When using tools driven by com-

pressed air, pay attention to the

following basic safety measures for

protection against injuries and damage

to property!

Fundamental safety precautions

Do not use the machine in ammable or ■potentially explosive environments.

Persons who are unable to operate the■machine due to their physical, mental or

motor response abilities may only use

the machine under supervision of or

instruction by a responsible person.

Children must not be allowed to use the■machine.

Check the machine and do not put a■damaged machine into operation.

Check the compressed air line for vis-■ible external damage before use and do

not put a damaged compressed air line

into operation.

Before beginning any work, check for■proper condition of the safety chain and

the function of the operating elements

of the machine.

Only allow repairs to the machine to be■carried out by an authorised workshop

or customer service. Unqualied repairs

can lead to considerable danger for the

user.

Repairs to the machine during the war-■ranty period may only be carried out

by a service centre authorised by the

manufacturer otherwise the guarantee

will be invalidated.

Defective parts may only be replaced■with original spare parts. Only original

spare parts guarantee that the safety

requirements are met.

Do not leave the machine unsupervised■during operation.

Store the machine in a dry, temperate■location out of the reach of children.

Do not leave the machine standing out-■doors and do not expose it to moisture.

Make sure that your work area is suf-■

ciently lit (>300 Lux).

Do not use low-power machines for■heavy working.

Make sure that your workplace is clean.■

Keep the machine clean, dry and free of■oil and grease.

Follow the instructions on lubricating■and cooling the tool.

6

Safety

AirMAB 5000

GB

Danger in conjunction

with polymers

WARNING

Risk to health from PTFE (synthetic

fully uorinated polymers)

Absorbing or inhaling PTFE is a health

risk!

Pay attention to the following safety notes

to avoid danger from PTFE because

PTFE particles can deposit on the inside

of the housing as a result of operating the

drive unit:

Do not smoke when carrying out►maintenance work.

PTFE particles may not come into►

contact with naked ames, embers

or heat

Motor parts must be cleaned with a►cleaning solution and not by blowing

compressed air.

After completing all work, wash your►hands.

Danger from compressed air

WARNING

Risk of injury when applying non-per-

missible pressures!

Pay attention to the following safety notes

to avoid danger from compressed air:

Only operate the machine with►prescribed air quantity and operating

pressure.

Danger of explosion if not observed.

Risk of injury

WARNING

Risk of injury from motor starting

unintentionally!

Pay attention to the following safety

notes to avoid danger from motor starting

unintentionally:

To completely stop the motor:►Move the motor switch to the OFF

position.

Disconnect the compressed air sup-

ply.

WARNING

Improper handling of the machine

increases the risk of injury!

Observe the following safety precautions

to avoid injuring yourself and/or others:

Operate the machine only with the►protective equipment stipulated in

these operating instructions (see

Personal protective equipment

section).

Do not►wear protective gloves when

the machine is running. A glove can

be caught by the drilling machine and

torn off the hand. Risk of losing one

or more ngers.

Remove loose jewellery before begin-►ning work. Wear a hair net if you have

long hair.

Always switch off the machine before►changing tools, performing main-

tenance or cleaning. Wait until the

machine has come to a complete

standstill.

Always disconnect the compressed►air supply before changing tools,

cleaning or performing maintenance

work in order to avoid unintentional

starting of the machine.

7

Safety

AirMAB 5000

GB

WARNING

Do not put your hand into the ma-►chine while it is in operation. Remove

swarf only when the machine is at

a standstill. Wear protective gloves

when removing swarf.

When working on scaffolding, the op-►erator must be secured with a safety

belt as the machine can oscillate

dangerously in the event of failure of

the compressed air supply.

Check for secure clamping of the►magnets on the substrate before

every use (see Preparation section).

Secure the machine with the safety►chain (D) supplied when working in

an inclined or vertical position and

during overhead work. The machine

could fall down when the magnet is

released.

Check that the tool is tightened►securely before using (see Inserting

the tool section).

Do not allow the compressed air line►to hang over edges (trip wire effect).

Preventing damage

CAUTION

Potential damage to property if the

machine is improperly used!

Observe the following instructions to

avoid property to damage:

Only use the prescribed air quality, air►quantity and operating pressures for

compressed air supply (see section

Preparing).

Always carry the machine by the►handle.

CAUTION

Do not crush the compressed air line.►

Do not expose the compressed air►line to heat or chemical liquids.

Do not pull the compressed air line►across sharp edges or hot surfaces.

Lay the compressed air line in such ►a way that it cannot be caught and

wound up in the rotating part of the

machine.

Safety appliances

Symbols on the machine

The symbols on the machine have the fol-

lowing meaning:

Symbol Meaning

Read the operating instructions

before beginning work!

Wear protective goggles and

ear protection!

8

Components / delivery contents

AirMAB 5000

GB

Personal protective equipment

Wear the following protective equipment at

all times when operating the machine:

Symbol Meaning

Close-tting work protection

clothing with a low tear strength

Goggles for protecting eyes

against ying parts and liquids

and ear protection in areas with

noise emission >80 dB(A)

Safety shoes for protecting feet

against falling objects

Also wear the following protective equip-

ment during special work:

Symbol Meaning

Helmet for protecting your head

against falling objects

Wear a harness where there is

a danger of falling

Gloves for protection against

injuries

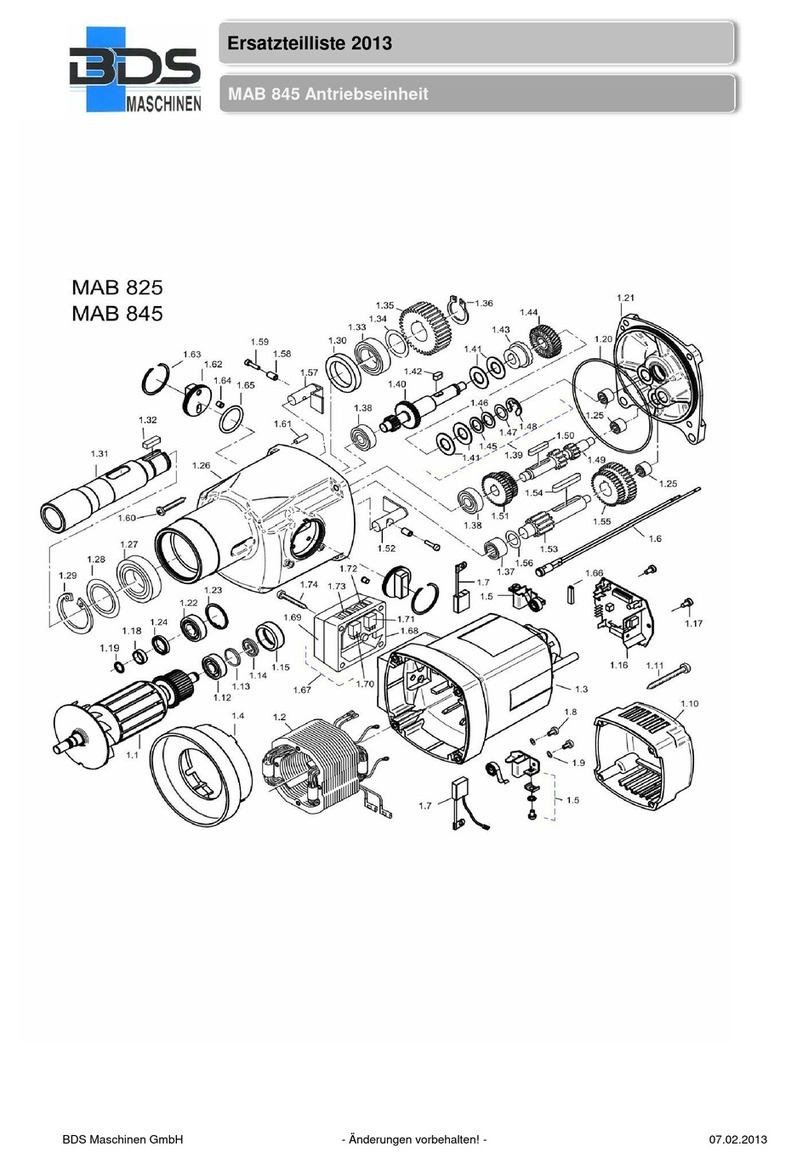

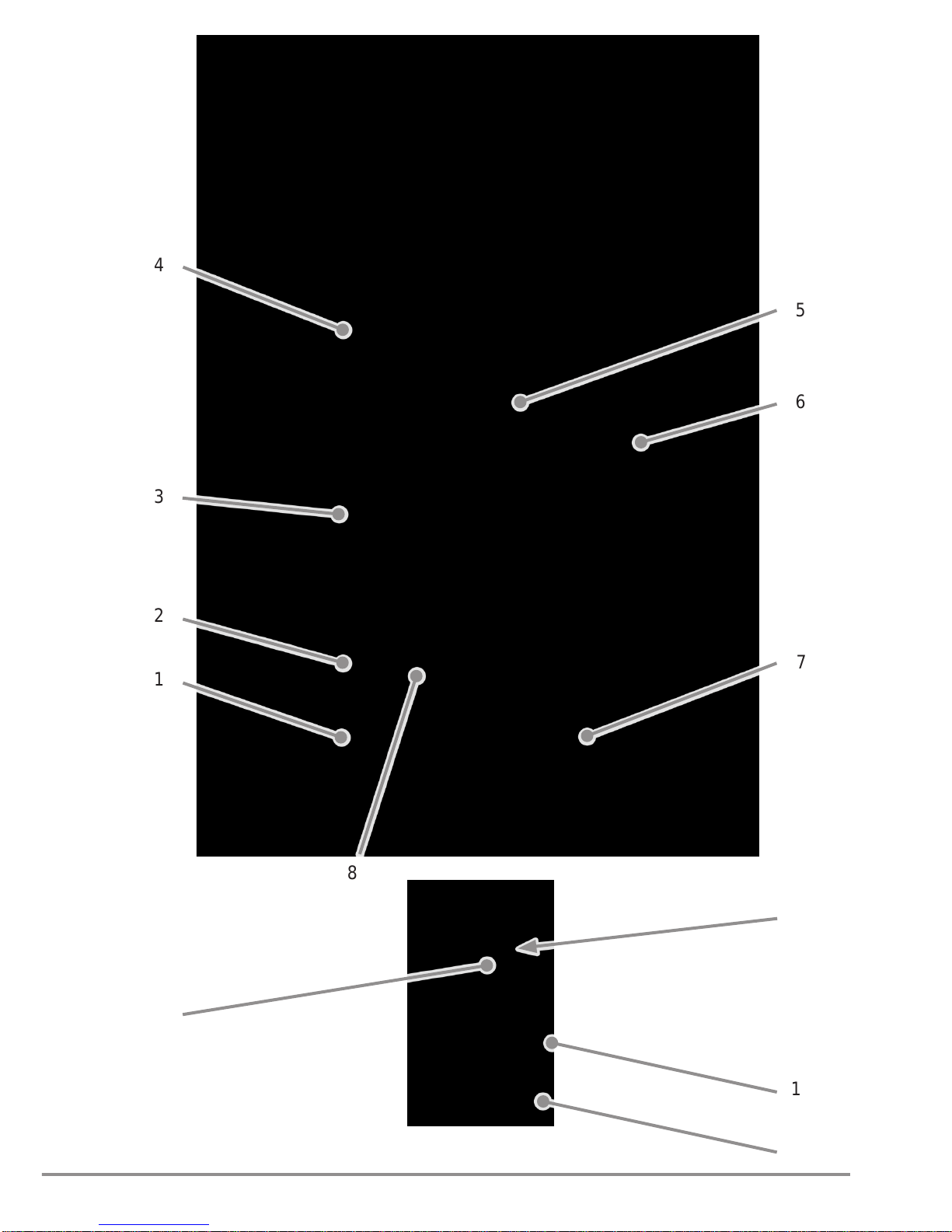

Components / delivery

contents

Machine overview

1 Core drill

(not supplied as standard)

2 Tool mounting

3 MK2 spindle taper

4 Drive motor (pneumatic)

5 Handle

6 Hand lever (3-stage)

7 Magnetic foot

8 Machine slide and guide

9 Compressed air connection

10 Motor switch

11 Operating lever for the magnetic foot

12 Lock for the operating lever

of the magnetic foot

Scope of supply

20 Magnetic core drilling machine

21 Pump bottle

for cutting oil/drilling emulsion

22 ZAK075 and ZAK100 ejector pin

23 Transport case

AKEYLESS quick-change drill chuck

system 19 mm Weldon (3/4")

B Safety chain

C MK2 ejector pin

9

Preparation

AirMAB 5000

GB

Before using for the rst time

Transport inspection

As standard, the machine is supplied with

the components indicated in the Compo-

nents/delivery contents"section.

NOTE

Check for visible signs of damage or►missing items on delivery. Report an

incomplete or damaged delivery to

your supplier/retailer immediately.

Preparation

This section contains important instructions

on the required preparation before begin-

ning any work.

Additional safety measures for

certain work

Additional safety precautions must be

taken for the following operations with the

machine:

Non-horizontal work position

WARNING

Risk of injury from a falling machine.

When working in inclined or vertical

position and during overhead work, the

machine must be secured to prevent it

from falling using the safety chain (B)

supplied.

Check the safety chain for proper►function before every use. A dam-

aged safety chain must not be used.

Replace a damaged safety chain

immediately.

WARNING

Attach the safety chain in such a way►that the machine moves away from

the operator in the event of slipping.

Lay the safety chain as tightly as ►possible around the handle of the

machine.

Check the secure tting of the safety ►chain and lock before starting work.

Use the protective equipment stipu-►lated in the section Personal protec-

tive equipment.

Work on scaffolding

WARNING

Risk of falling from sudden oscillating

movements of the machine.

When working on scaffolding, the

machine can make a sudden oscillating

movement on starting or in the event of

failure of the compressed air supply.

Secure the machine with the safety►chain supplied.

Wear a safety harness to protect►yourself against falling.

10

Preparation

AirMAB 5000

GB

Check the condition

of the substrate

The magnetic clamping force is depend-

ent on the condition of the substrate. The

clamping force is signicantly reduced by

paint, zinc and scale coatings and rust.

The substrate must satisfy the following

conditions in order to achieve sufcient

magnetic clamping force:

The substrate must be magnetic.■

The clamping surface and the magnetic■foot (7) must be clean and grease-free.

The clamping surface must be com-■pletely smooth and level.

NOTE

Clean the substrate and the magnetic►foot (7) of the machine before use.

Remove any unevenness and loose►rust from the substrate.

The BDS range of accessories in-►cludes special holding devices.

The best clamping effect is obtained on

low-carbon steel substrate with a thickness

of at least 20 mm.

Steel with low thickness

When drilling into low thickness steel, an

additional steel plate (minimum dimensions

100 x 200 x 20 mm) must be placed under

the workpiece. Secure the steel plate to

prevent it from falling.

NF metals or workpieces with an uneven

surface

A special holding device must be used

when drilling into NF metals or into work-

pieces with an uneven surface.

NOTE

BDS offers a range of accessories►with special clamping devices for

tubes and non-magnetic materials.

Inserting the tool

The machine is equipped with an MK tool

holder.

Depending on the type of tool to be used,

corresponding drill chucks, quick-clamping

systems or adapters must be used.

Tool Tool holder to be used

Tools

with Weldon-

19 mm shank

Use KEYLESS (A)

quick-change drill chuck

system

Tools

with MK

taper

Insert the tool directly into

the spindle taper (3)

Tools with

straight

shank

Use drill chuck with MK2/

B16 tapered mandrel

(available as an accessory).

WARNING

Risk of injury!

Do not use damaged, soiled or worn►tools.

Change tools only when the machine►is switched off and at a standstill. Dis-

connect the compressed air supply

11

Preparation

AirMAB 5000

GB

WARNING

Risk of injury!

After inserting, check that the tool is►engaged securely.

Only use tools, adapter and accesso-►ries that match the machine.

MK tool mounting

Inserting the tool

Before mounting, clean the shank ofthe tool, adapter or drill chuck and the

spindle taper (3) of the machine.

Insert the tool into the spindle taper (3)of the machine from below.

WARNING

Risk of injury from incorrectly inserted

tool!

Check the proper seating of the tool,►adapter or drill chuck in the MK tool

mounting.

Removing the tool

Insert the ejector pin (C) into theejector pin holder of the spindle taper

MK2 (3).

Lever out the tool with the ejector pin (C) or loosen the tool by tapping

against the ejector pin.

Using the drill chuck

Inserting the tool

Insert the drill chuck onto the taperedmandrel and insert the combina-

tion into the spindle taper (3) of the

machine.

Open the drill chuck and insert the toolinto the drill chuck.

Close the drill chuck by hand and thentighten the drill chuck with the chuck

key.

Removing the tool

Loosen the drill chuck with the chuck key and remove the tool.

WARNING

Risk of injury!

Only tighten the drill chuck with the►chuck key provided.

Always remove the chuck key from►the drill chuck after tightening or

loosening.

12

Preparation

AirMAB 5000

GB

Keyless quick-change drill chuck

system

Inserting the tool

Before mounting, clean the shank ofthe tool, adapter or drill chuck and the

spindle taper (3) of the machine.

Push the KEYLESS quick-change drill chuck system (A) from below into the

spindle taper of the machine.

Connect the line of the pump bottle forcutting oil/drilling emulsion (21) to the

connection for the KEYLESS quick-

change drill chuck system.

Open the KEYLESS quick-change drill chuck system by pushing up the

outside sleeve and insert the tool into

the chuck.

NOTE

Insert the appropriate ejector pin►before inserting the core drill.

WARNING

Risk of injury from incorrectly inserted

tool or tool mounting!

Check by briey turning the tool ►whether the collet is engaged.

Removing the tool

Open the KEYLESS quick-change drill chuck system (A) by pushing up the

outside sleeve and pull the tool down

out of the chuck.

Compressed air supply

Perfect function and performance of the

drive unit depends on the air quality and

the quantity of air supplied.

The following requirements must be met

by the compressed air in order to achieve

perfect function and performance of the

drive unit:

The air quality is optimum at a dew■point of 10 °C and precipitation of solid

particles larger than 15 micrometres as

well as 90 % of liquid water.

The compressed air must contain oil■in order to guarantee the required air

lubrication.

Set the oil quantity according to the air■requirement.

L= air consumption (1/sec)

D= number of drops per minute

(1 drops = 15 mm²); L * 0.2 = D.

The compressed air connection must■have an operating pressure of 6 - 7 bar

= 600 - 700 kPa = 6 - 7 kp/cm².

Before connecting, blow through the■compressed air hose carefully to clean

it.

Hose diameter: min.10 mm (3/8").

NOTE

Only connect to the machine when it►is switched off.

Air consumption of the motor is►1000 l/min.

The motor performance is reduced

when the air supply is decreased!

13

Use

AirMAB 5000

GB

Use

Activating/deactivating the mag-

netic clamp

Activating the magnetic clamp

Turn the lever for the permanentmagnet (11) to the right (ON position)

to activate the magnets.

Deactivating the magnetic clamp

Hold the handle tightly (5) to stop themachine from slipping.

Push the locking button (12) and turnthe lever (11) for the magnetic clamps

to the left (OFF position) to release the

magnets.

Switching the machine ON/OFF

Switching on the machine

Turn the motor switch (10) to the ONposition to activate the motor.

Switching off the machine

Turn the motor switch (10) to the OFFposition to deactivate the motor.

WARNING

Risk of injury from motor starting

unintentionally!

Pay attention to the following safety

notes to avoid danger from motor starting

unintentionally:

To completely stop the motor:►Move the motor switch to the OFF

position.

Disconnect the compressed air sup-

ply.

Drilling with the machine

Drilling with core drills

When drilling with core drills, proceed as

follows:

Mount the KEYLESS quick-change drill chuck system (A).

Install the appropriate ejector pinin the core drill and insert the core

drill into the quick-change drill chuck

system.

Place the machine at the working loca-tion, align it and switch on the mag-

netic clamps.

NOTE

Observe the following instructions when

drilling with core drills:

Drilling with core drills does not re-►quire great force. The drilling process

is not accelerated by higher pres-

sure. The drill wears faster and the

machine can be overloaded.

Use the pump bottle for cutting oil/►drilling emulsion (21) with BDS 5000

high-performance cutting oil supplied

for the machine.

When working overhead, use►ZHS 400 high-performance grease

spray. Spray the drill with grease

spray on the inside and outside

before drilling. Repeat this procedure

when drilling deeper holes.

Make sure that swarf is removed►regularly. With larger drilling depths,

break the chip.

14

Eliminating blockages

AirMAB 5000

GB

Drilling with twist drills

When drilling with twist drills, proceed as

follows:

Push twist drills with MK taper into thespindle taper (3) of the machine from

below.

Push twist drills with straight shank

into the drill chuck after tting the drill

chuck.

Place the machine at the working loca-tion, align it and switch on the mag-

netic clamps.

NOTE

Under excessive pressure, the drill►can wear out and the machine can be

overloaded.

Make sure that swarf is removed►regularly. With larger drilling depths,

break the chip.

Eliminating blockages

WARNING

Danger of cut injuries from broken

tool parts or swarf.

Put protective gloves on before start-►ing work.

Blockages caused by a broken tool:

Switch the machine off using the mo-

tor switch. Leave the magnetic clamp

switched on.

Disconnect the compressed air supply

Use the handle to move the machineslide to the upper position.

Replace defective tool. Remove swarf.

Other blockages:

Switch the machine off using the mo-

tor switch. Leave the magnetic clamp

switched on.

Disconnect the compressed air supply

Use the handle to move the machineslide to the upper position.

Remove swarf and check tool.

WARNING

Risk of injury from motor starting

unintentionally!

Pay attention to the following safety

notes to avoid danger from motor starting

unintentionally:

To completely stop the motor:►Move the motor switch to the OFF

position.

Disconnect the compressed air sup-

ply.

15

Maintenance

AirMAB 5000

GB

Cleaning

WARNING

Switch off the machine and discon-►nect from the compressed air supply

before performing maintenance or

cleaning.

When using compressed air for►cleaning, wear protective goggles and

gloves and protect other persons in

the working area.

Motor parts must be cleaned with►cleaning solution and not by blowing

compressed air.

Do not smoke when servicing.►

After completing all work, wash your►hands.

CAUTION

Never immerse the machine in water►or other liquids.

After every use

Remove the inserted tool.

Remove swarf and coolant residues.

Clean the tool and the tool holder onthe machine.

Clean the guide of the machine slide.

Put the machine and accessories intothe transport case.

Maintenance

WARNING

Danger caused by unqualied repairs!

Unqualied repairs can lead to consider-

able danger for the user and cause dam-

age to the machine.

Repairs to and maintenance on the►drive motor may only be carried out

by the works customer service or by

specialists trained by the manufac-

turer.

Adjusting the machine slide guide

If the machine slide guide (8) exhibits too

much clearance, it must be adjusted. To do

this, proceed as follows:

Loosen the clamping bolts.

Tighten the adjusting screws evenly.

Tighten the clamping bolts again.

Customer service/service

Should you have any questions on cus-

tomer service/service, please contact BDS.

We will be happy to give you the address of

your nearest service partner.

16

Troubleshooting

AirMAB 5000

GB

Storage

If you do not intend to use the machine for a longer period of time,

clean it as described in the section Cleaning. Store the machine and all its accessories in

the transport case at a dry, clean and frost-free location.

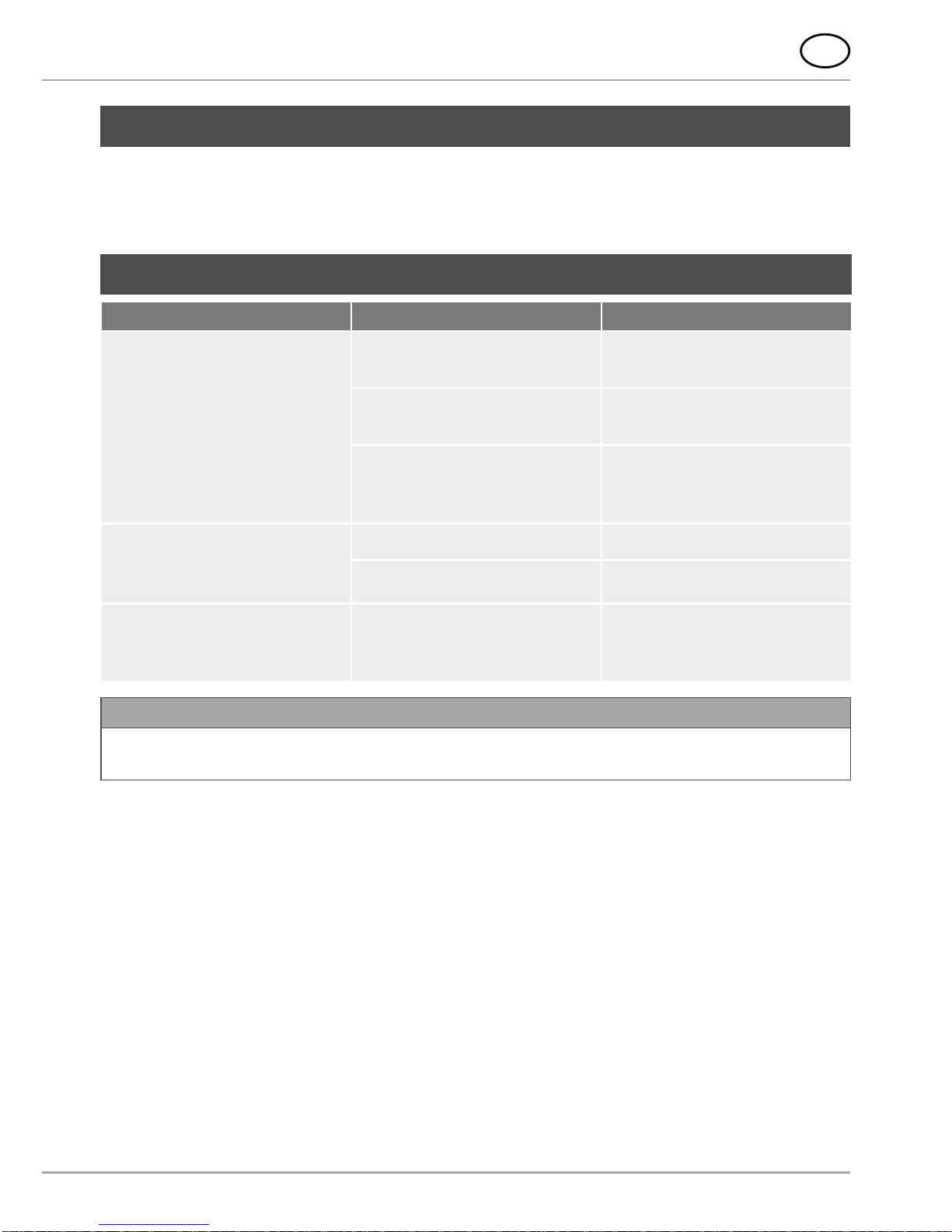

Troubleshooting

Fault Possible cause Remedy

The motor does not start after

pressing the ON/OFF switch

or stops during operation.

Compressed air supply not

connected. Connect the

compressed air supply .

Compressed air supply not

switched on. Switch on the compressed air

supply.

Compressed air supply not

sufcient.

Check the compressed air

supply and set up according

to specications.

The magnetic clamp does not

function.

Magnet not switched on. Switch on magnet.

The surface is not magnetic. Use a suitable base.

Tools wear excessively/are

damaged. No lubrication or not suf-

ciently greased.

Supply lubrication

(e.g.,:use pump bottle for cut-

ting oil/drilling emulsion (21)).

NOTE

If you cannot resolve the problem with the steps described above, please contact►customer service.

17

Technical data

AirMAB 5000

GB

Technical data

Model AirMAB 5000 Unit

Dimensions

(L x W x H) 165 x 322 x 345-535 mm

Magnetic foot (L x W x H) 90 x 190 x 60 mm

Approx. net weight. 17.5 kg

Motor power 830 W

Nominal torque 27 Nm

Air consumption 1000 l/min

Noise emission 96 db(A)

Vibration 1.55 m/s²

Stroke 160 mm

Core drill (short) max. Ø 12 - 35 mm

Cutting depth max. 55 mm

Twist drill max. Ø 23 mm

Gear stage 1 speed 290 - 575 rpm

Core drill assembly Weldon 19 mm (3/4“)

18

EC Declaration of Conformity

AirMAB 5000

GB

EC Declaration of Conformity

Name/address of the manufacturer: BDS Maschinen GmbH

Martinstraße 108

D-41063 Mönchengladbach

We hereby declare that the product

Model: Magnetic core drilling machine

Type AirMAB 5000

conforms to the following relevant regulations:

EC Directive 2006/42/EC on machinery■

The following harmonised standards were applied in whole or in part:

DIN EN ISO 12100-2010

●

DIN EN ISO 11148-3:2013●

Responsible person for documentation according to EC Directive 2006/42/EC - An-

nex II Pt.A.2. was:

_____________________________________________________________________

(Surname, forename, position in company of the manufacturer)

Mönchengladbach,

22nd January, 2014

Wolfgang Schröder, Technical Director

________________________________________

(Legally binding signature of the issuer)

Table of contents

Other BDS Drill manuals