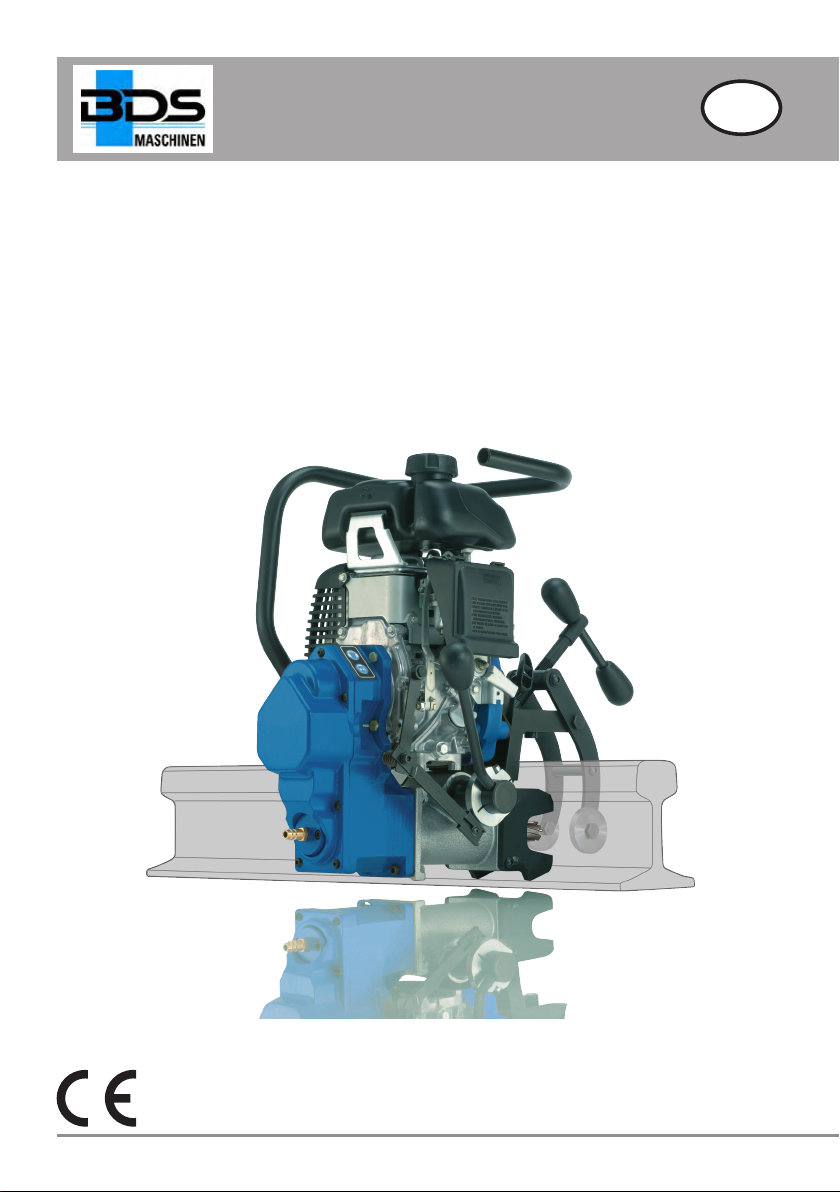

BDS RailMAB 960 User manual

RailMAB 960

Translation of the Original-

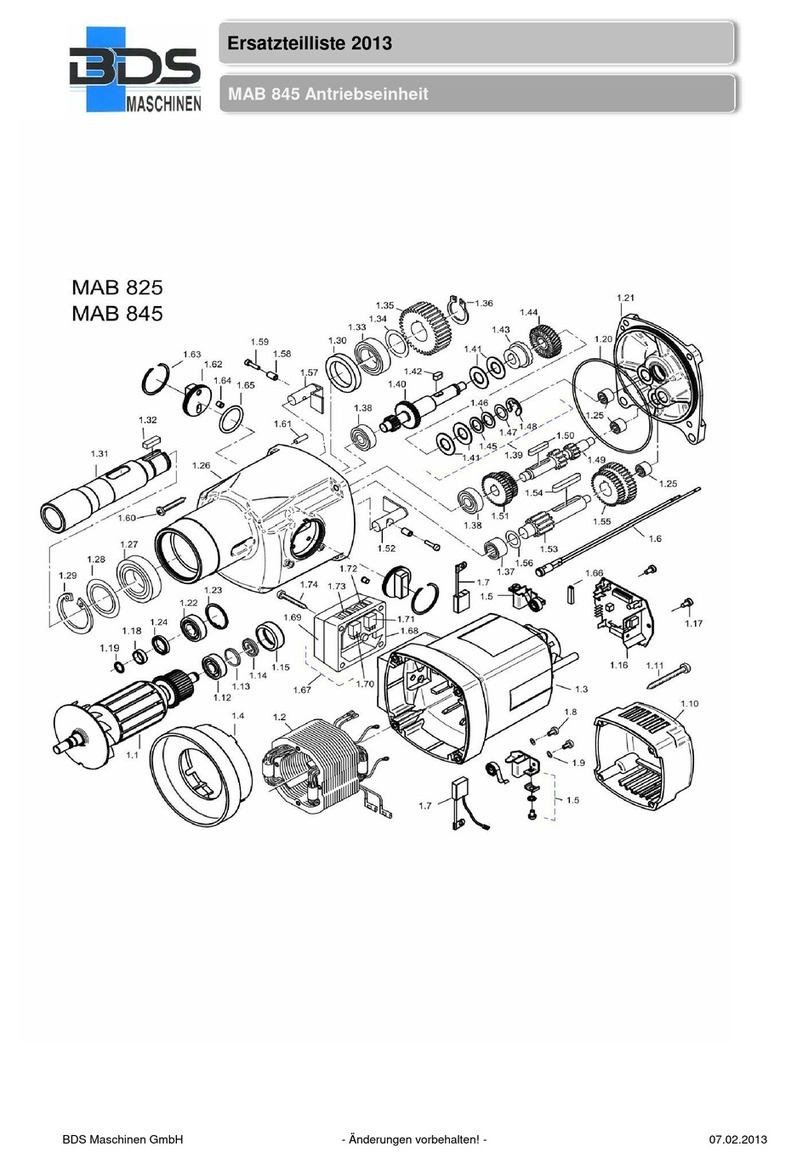

Operating Instructions

GB

3

12

10 8

5

11

7

6

14

16

15

2

6

1

18

17

4

9

13

3RailMAB 960

GB

Table of Contents

General instructions ................3

Safety ............................5

Components/delivery contents .......9

Before using for the rst time ........9

Preparation. . . . . . . . . . . . . . . . . . . . . . .10

Use .............................14

Eliminating blockages. . . . . . . . . . . . . .17

Cleaning .........................18

Maintenance......................18

Storage ..........................19

Troubleshooting ..................19

Technical data ....................20

EC Declaration of Conformity .......21

Dear Customer,

Before using the machine, please read the

instructions contained in these operating

instructions on startup, safety, intended use

as well as cleaning and care.

The links and illustrations in these instruc-

tions refer to the illustrations on the inside

of the cover.

Keep these operating instructions for later

use and pass them onto the next owner of

the machine.

General instructions

Copyright

This document is copyrighted. Any dupli-

cation or reprinting, in whole or in part, and

the reproduction of the illustrations even

in modied form is only permitted with the

written approval of the manufacturer.

Liability disclaimer

All technical information, data and instruc-

tions for commissioning, operation and

maintenance of the machine contained in

these operating instructions represent the

latest status at the time of printing.

The manufacturer assumes no liability for

damage or injury resulting from failure to

observe the operating instructions, use for

other than the intended purpose, unprofes-

sional repairs, unauthorised modications

or use of non-approved spare parts and

accessories, tools and lubricants.

Instructions on disposal

The packaging materials used can be

recycled. When no longer required,

dispose of the packaging materials in

accordance with the local regulations in

force.

This product may not be disposed of

in the domestic refuse within the

European Union. Dispose of the

device via communal collection points.

General instructions

4RailMAB 960

GB

Safety warning structure

The following warnings are used in these

operating instructions:

DANGER

A warning of this category indicates

an impending dangerous situation.

If the dangerous situation is not avoided,

it may lead to serious injury or even

death.

►Follow the instructions in this warning

to avoid possible danger of serious

injury or even death.

WARNING

A warning of this category indicates a

potentially dangerous situation.

If the dangerous situation is not avoided,

it may lead to injuries.

►Follow the instructions in this warning

to avoid possible danger of serious

personal injuries.

CAUTION

A warning of this category draws

attention to potential material damage.

If the situation is not avoided, it may lead

to material damage.

►Follow the instructions in this warning

to avoid material damage.

NOTE

►A note indicates additional information

that simplies the use of the machine.

Intended use

The machine is intended solely for drilling

operations in rails within the limits specied

in the technical data.

Any use other than previously stated is

considered as improper use.

WARNING

Danger resulting from improper use!

If not used for its intended purpose and/

or used in any other way, the machine

may be or become a source of danger.

►Use the machine only for its intended

purpose.

►Observe the procedures described in

these operating instructions.

No claims of any kind will be accepted for

damage resulting from use of the appliance

for other than its intended purpose.

The risk must be borne solely by the user.

NOTE

►If used commercially, pay attention to

compliance with the accident preven-

tion and occupational safety regula-

tions.

General instructions

5RailMAB 960

GB

Safety

WARNING

When using engine-powered tools, the

following fundamental precautions

must be taken to protect against elec-

tric shock, re, injuries and damage to

property!

Fundamental safety precautions

■Do not use the machine in ammable or

potentially explosive environments.

■Never operate the machine in closed

rooms.

■Never refuel the machine when it is hot.

■When refuelling the machine, use suita-

ble auxiliary resources (e.g.: funnel,...)

■Only use the prescribed fuels and

lubrication.

■Persons who are unable to operate the

appliance due to their physical, mental

or motor response abilities may only

use the appliance under supervision or

instruction by a responsible person.

■Children must not be allowed to use the

machine.

■Before using, check the machine for

damage and do not put a damaged

machine into operation.

■Before beginning work, check the con-

dition of the machine and the function of

the operating elements.

■Repairs to the machine may only be

carried out by an authorised specialist

workshop or by the works customer

service. Unqualied repairs can lead to

considerable danger for the user.

■Repairs to the machine during the

warranty period may only be carried out

by a service centre authorised by the

manufacturer otherwise the guarantee

will be invalidated.

■Defective parts may only be replaced

with original spare parts. Only original

spare parts guarantee that the safety

requirements are met.

■Do not leave the machine unsupervised

during operation.

■Store the machine in a dry, temperate

location out of the reach of children.

■Do not allow the machine to stand out-

side and do not expose to moisture.

■Make sure that your work area is suf-

ciently lit (>300 Lux).

■Do not use low-power machines for

heavy working.

■Make sure that your workplace is clean.

■Keep the machine clean, dry and free of

oil and grease.

■Follow the instructions on lubricating

and cooling the tool.

Safety

6RailMAB 960

GB

Dangers from exhaust gases

DANGER

Danger to life from exhaust gases!

Inhaling the exhaust of the engine (12)

can lead to suffocation!

Observe the following safety instructions

to avoid danger from exhaust gases.

►Never operate the machine in closed

rooms.

►Avoid inhaling exhaust gases.

►Pay attention the engine specica-

tions of the manufacturer (12).

Risk of injury!

WARNING

Danger of injury, re and explosion!

Pay attention to the following safety

notes to avoid danger:

►Only touch the engine (12) after it has

cooled down.

►Refuel the machine only when it has

been switched off.

►Only handle fuels in a well-ventilated

environment.

►Pay attention to the product data

sheet of the fuel.

►Pay attention the engine specica-

tions of the manufacturer (12).

WARNING

Risk of injury from engine starting

unintentionally!

Pay attention to the following safety notes

to avoid danger from the engine (12)

starting unintentionally:

For safe stopping of the engine (12):

►Move the accelerator (19) to the MIN

position.

►Move the ignition switch (20) of the

engine (12) to the OFF/AUS position.

►Close the fuel tap (21).

►Pay attention to the engine specica-

tions of the manufacturer (12).

Safety

7RailMAB 960

GB

WARNING

Improper handling of the machine

increases the risk of injury!

Observe the following safety precautions

to avoid injuring yourself and/or others:

►Operate the machine only with the

protective equipment stipulated in

these operating instructions (see

section Personal protective equip-

ment).

►Do not wear protective gloves when

the machine is running. A glove can

be caught by the drilling machine and

torn off the hand. Risk of losing one

or more ngers.

►Remove loose jewellery before begin-

ning work. Wear a hair net if you have

long hair.

►Always switch off the machine before

changing tools, performing main-

tenance or cleaning. Wait until the

machine has come to a complete

standstill.

►Ensure that the machine is in a safe

condition before changing any tools

and before maintenance and cleaning

in order to avoid unintentional starting

of the machine.

WARNING

►Do not put your hand into the ma-

chine while it is in operation. Remove

swarf only when the machine is at

a standstill. Wear protective gloves

when removing swarf.

►Before using each time, check for

rm stability of the quick clamping

system (5) on the rail (see section

Preparation).

►Check that the tool is tightened

securely before using (see section

Inserting the tool).

Preventing damage

CAUTION

Potential damage to property if the

machine is improperly used!

Observe the following instructions to

avoid damage:

►Use the prescribed operating materi-

als (fuel, oil...) only.

►Pay attention the engine specica-

tions of the manufacturer (12).

►Always carry the machine by the

handle (2).

►Always keep the machine upright.

Safety

8RailMAB 960

GB

Safety equipment

Oil level monitoring

The engine (12) is also equipped with oil

level monitoring. The machine cannot be

started if the oil level is not sufcient before

starting.

Check the oil level:

►See section "Preparing the engine and

checking/lling oil".

Symbols on the machine

NOTE

►Pay attention to the documentation of

the manufacturer.

The symbols on the machine have the

following meaning:

Symbol Meaning

Read the operating instructions

before beginning work!

Wear protective goggles and

ear protection!

Personal protective equipment

Wear the following protective equipment at

all times when operating the machine:

Symbol Meaning

Close-tting work protection

clothing with a low tear strength

Goggles for protecting eyes

against ying parts and liquids

and ear protection in areas with

noise emission >80 dB(A)

Safety shoes for protecting feet

against falling objects

Wear the following additional protective

equipment during special operations:

Symbol Meaning

Helmet for protecting your head

against falling objects

Wear a safety belt where there

is a danger of falling.

Gloves for protection against

injuries

Safety

9RailMAB 960

GB

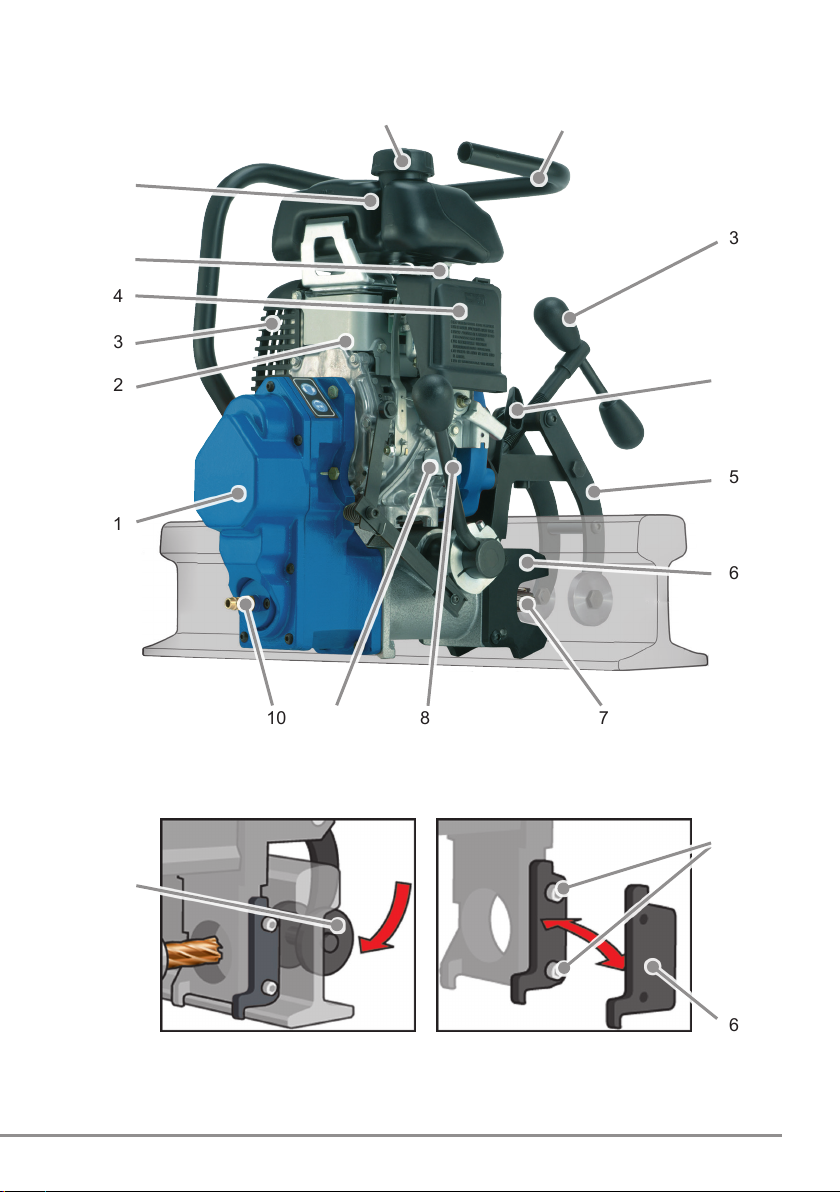

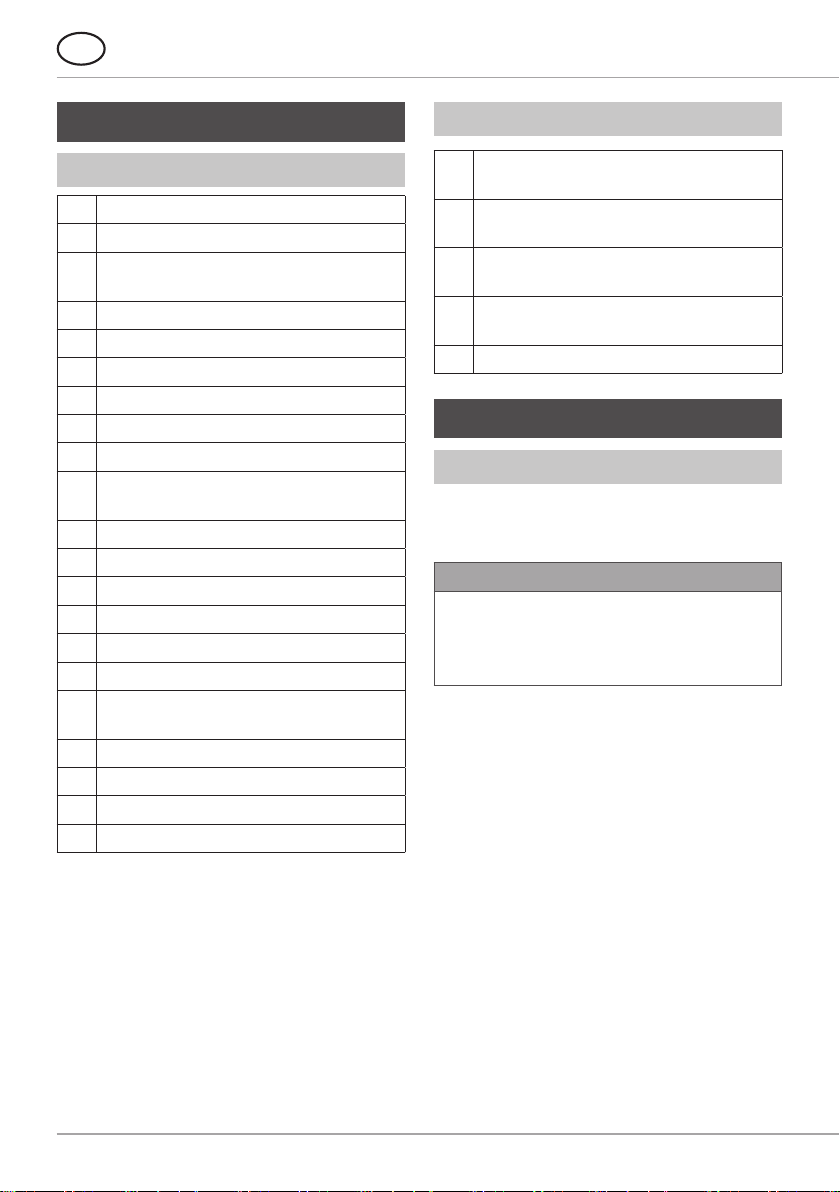

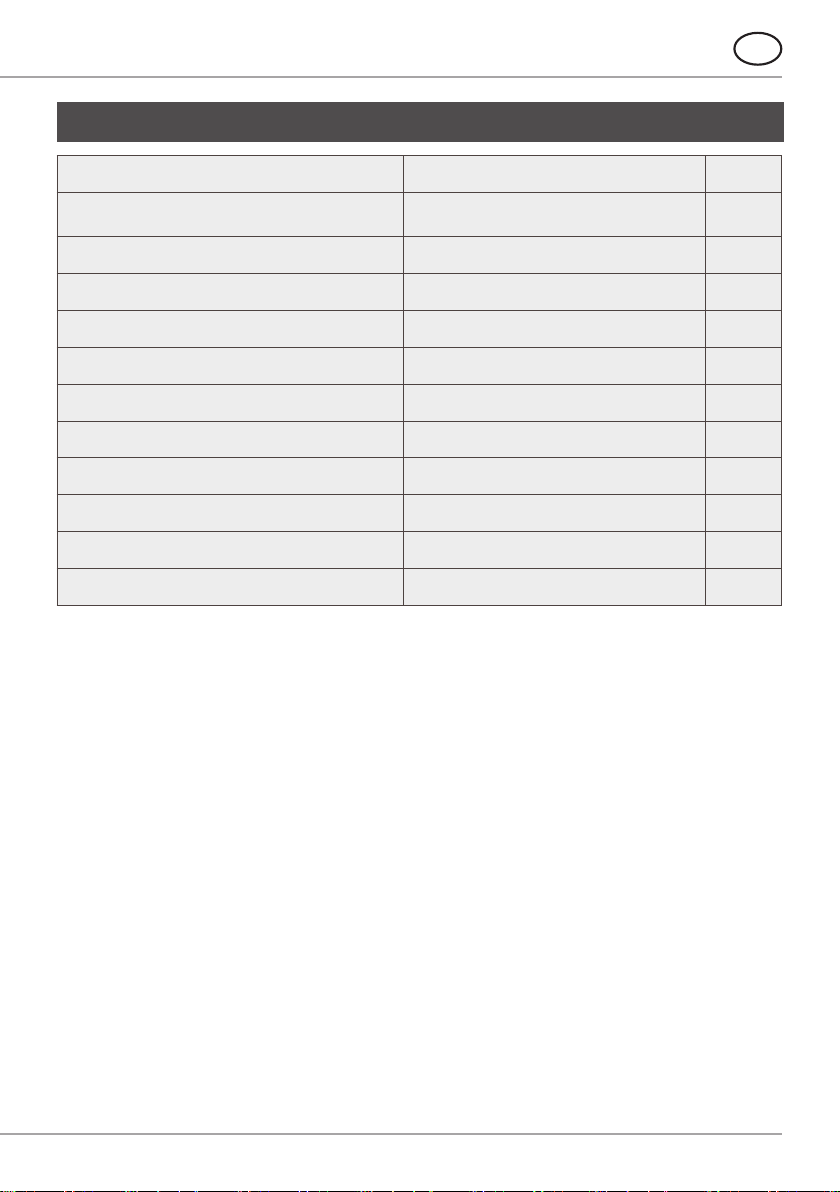

Components / scope of supply

Machine overview

1 Tank cover

2 Carrying handle

3 Spindle key

(fast clamping system)

4 Starter handle

5 Fast clamping system

6 Rail adapter

7 Core drill (not supplied as standard)

8 Feed lever

9Oil ller neck

10 Pressure connector for coolant/lubrica-

tion supply

11 Reduction gear

12 Drive engine

13 Exhaust

14 Air lter

15 Choke

16 Tank

17 Fixing screws

(rail adapter)

18 Clamping jaw (fast clamping system)

19 Accelerator

20 Ignition switch

21 Fuel tap

Delivery contents

Rail core driller

with petrol engine

A Rail adapter of your choice

(no special designs)

Offset screwdriver

(SW 4 + 5); (not illustrated)

High-pressure container 5l for cutting/

drilling emulsion (not illustrated)

Operating instructions

Before using for the rst time

Transport inspection

As standard, the machine is supplied with

the components indicated in the Delivery

contents section.

NOTE

►Inspect the delivery for completeness

and obvious signs of damage. Report

an incomplete or damaged delivery to

your supplier/retailer immediately.

Components / scope of supply

10 RailMAB 960

GB

Preparation

This section contains important instructions

on required preparation before starting

work.

The machine is intended to be used in

a horizontally-aligned work position at

close proximity to the ground.

Additional safety measures when

not in a horizontal work position at

close proximity to the ground

WARNING

Risk of injury from a falling machine.

When not working in a horizontal work

position at close proximity to the ground,

the machine must be secured against

falling down.

►Use suitable slinging or hoisting

equipment to secure the machine.

►Before beginning any work, check

secure positioning of the safety

measures.

►Use the protective equipment stipulat-

ed in the section Personal protective

equipment.

Checking the rail type

The holding force of the fast clamping

system (5) depends on the tting accuracy

of the rail adapter (6) to the rail.

The following requirements must be fullled

in order to establish sufcient holding force:

■Only the rail adapters (6) associated

with the rail type may be used.

NOTE

►In addition to the rail adapters (A) list-

ed in the range of accessories, BDS

offers special adapters for special

rails on request.

Preparation

11RailMAB 960

GB

Mounting the rail adapter

The machine is equipped with a socket for

various rail adapters (A).

The corresponding adapter set must be

used according to the type of rail.

Rail type Order number

rail adapter

UIC 50 ZAS 250U

UIC 54 ZAS 254U

UIC 60 ZAS 260U

S 49 ZAS 249S

S 54 ZAS 254S

Other On request

WARNING

Risk of injury!

Incorrectly, damages or improperly

mounted rail adapters (6) decrease the

holding force of the fast clamping sys-

tem (5), this can lead to injuries

►Only use the matching rail adapter (6)

for the respective rail type.

►Do not use damaged, contaminated

or worn tools rail adapters (6).

►Change the rail adapter only when

the machine is switched off and at a

standstill. Put the machine into a safe

condition.

►Change the rail adapter only when

the fast clamping system (5) is not

tensioned.

WARNING

►After mounting, check for secure, rm

seating of the rail adapter (6).

►Only use tools, adapter and accesso-

ries that match the machine.

Mounting the rail adapter (6)

Loosen both xing screws (17) of the

rail adapter set on each respective

side.

Insert both rail adapters (6) and tight-

en the xing screws (17).

Dismantling the rail adapter

Loosen both xing screws (17) of the

rail adapter set on each respective

side.

Remove both rail adapters (6).

Preparation

12 RailMAB 960

GB

Inserting the tool

The machine is equipped with a 19 mm

Weldon (3/4") direct mounting.

Tools:

Only core drills with a 19 mm Weldon

shaft (3/4") can be used (HKK-R). The cut-

ting depth is limited by the maximum stroke

of 40 mm.

WARNING

Risk of injury!

►Do not use damaged, contaminated

or worn tools.

►Only perform tool changing when

the machine is switched off and not

moving.

►Ensure that the machine is in a safe

condition.

■Move the accelerator (19) to the

MIN position.

■Move the ignition switch (20) of

the engine (12) to the OFF/AUS

position.

■Close the fuel tap (21).

■Pay attention to the engine speci-

cations of the manufacturer (12).

►After inserting, check that the tool is

engaged securely.

►Only use tools, adapter and accesso-

ries that match the machine.

Inserting the tool

Before mounting, clean the shank of

the tool and the direct mounting of the

machine.

Insert the corresponding ejector pin

into the core drill.

Insert the tool into the direct mounting

of the machine from the front.

Secure the tool by tightening the safe-

ty screws (Allen head screws) in the

direct mounting.

WARNING

Risk of injury!

Risk of injury from incorrectly inserted,

not secured or improperly secured tool.

►Check the proper seating of the tool

in the tool mounting.

►Only tighten the Allen head screws

of the direct mounting with a suitable

tool (offset screwdriver supplied).

►After tightening/untightening the Allen

head screws, pull the offset screw-

driver out of the screw.

Removing the tool

Loosen the safety screws (Allen head

screws) on the direct mounting.

Remove the tool from the direct

mounting from the front.

Preparation

13RailMAB 960

GB

Coolant/lubrication

The back of the machine is equipped with a

coolant/lubrication connector (10) in order

to connect the high-pressure container

supplied. This allows the core drill and the

cutting surface to be supplied with coolant/

lubrication.

Connect the high-pressure container:

Push the hose of the high-pressure

container into the coolant/lubrication

connector (10) until it audibly snaps in.

Release the high-pressure container:

Depressurise the high-pressure con-

tainer.

Remove the hose by pulling back the

safeguard on the connection coupling.

NOTE

►Remove excess coolant/lubrica-

tion with appropriate means (e.g.:

cloth,...).

Preparing the engine

WARNING

Risk of injury!

►Carry out all work on the engine (12)

only when the machine is switched off

and at a complete stop.

►Ensure that the machine is in a safe

condition.

■Move the accelerator (19) to the

MIN position.

■Move the ignition switch (20) of

the engine (12) to the OFF/AUS

position.

■Close the fuel tap (21).

■Pay attention to the engine speci-

cations of the manufacturer (12).

►Allow the machine to cool down

before starting any work on the en-

gine (12).

CAUTION

Potential damage to property if the

machine is improperly refuelled!

Observe the following instructions to

avoid damage:

►Only use the prescribed fuels and

lubrication as well as specied

amounts.

Recommended fuel:

Lead-free petrol, 95 octane

Recommended engine oil:

SEA 10W-30

(Pay attention to the manufacturer

documentation on the engine (12).)

►Absorb excess fuels and lubricants

immediately with suitable means.

►Carry out all work on the engine (12)

on a rm, at and level surface.

Preparation

14 RailMAB 960

GB

Refuelling the machine

Screw off the tank lid (1).

Fill with fuel

Screw in the tank lid (1).

Checking/lling oil

Open the oil ller neck (9).

Check the oil level with the help of

the dipstick on the cap of the oil ller

neck (9) (pay attention to the manufac-

turer documentation).

Rell with oil if necessary.

Close the oil ller neck (9) with the

cap.

Use

Fixing the machine

Tensioning the fast clamping system

Insert the machine with the rail adapt-

er (6) into the rail prole at right angles

to the rail.

Press the clamping jaw (18) onto the

rail by turning the spindle key (3).

Slackening the fast clamping system

Secure the machine at the handle (2)

to stop it from slipping.

Release the clamping jaw (18) from

the rail by turning the spindle key (3)

Remove the machine from the rail.

Switching the machine ON/OFF

Switching on the machine

Move the fuel tap (21) to the ON

position.

Move the choke (15) to the CLOSED

position.

(to restart a warm engine (12), leave

the choke (15) in the opened position.)

Move the accelerator (19) to the MAX

position.

Switch on the ignition (20)

(ON position).

Start the engine (12) with the help of

the starter handle (4). For this pur-

pose, pull the starter handle (4) lightly

until resistance is felt, then start the

engine (12) by pulling rapidly.

Allow the engine (12) to warm up

and move the choke (15) back to the

OPEN position.

Switching off the machine

Move the accelerator (19) to the MIN

position.

Switch off the ignition (20)

(OFF position).

Move the fuel tap (21) to the OFF

position.

NOTE

►Pay attention to the manufacturer

documentation when starting and

switching off the engine (12).

Use

15RailMAB 960

GB

WARNING

Risk of injury from engine starting

unintentionally!

Pay attention to the following safety notes

to avoid danger from the engine (12)

starting unintentionally.

For safe stopping of the engine (12):

►Move the accelerator (19) to the MIN

position.

►Move the ignition switch (20) of the

engine (12) to the OFF/AUS position.

►Close the fuel tap (21).

►Pay attention to the engine specica-

tions of the manufacturer (12).

Setting the speed

The rotation speed is determined by the

engine speed.

The position of the accelerator (19) deter-

mines the speed of the drill.

■MAX position

= max. speed (225 rpm)

■MIN position

= min. speed (150 rpm)

Drilling with the machine

Drilling with core drills

When drilling with core drills, proceed as

follows:

Insert the core drill into the 19 mm

Weldon (3/4") direct mounting of the

machine as described in the section

Inserting the tool.

Position the machine at the location of

use, align it and x the machine with

the fast clamping system (5).

Connect the high-pressure container

as described in the section Coolant/

lubrication.

Pressurise the cooling/lubrication sys-

tem (approx. 2-3 strokes with the hand

pumping device of the high-pressure

container).

Switch the machine on.

Guide the machine carriage with the

help of the feed lever (8) and without

exerting too much pressure until the

desired core drill is established.

Use

16 RailMAB 960

GB

NOTE

Observe the following instructions when

drilling with core drills:

►Drilling with core drills does not re-

quire great effort. The drilling process

is not accelerated by higher pressure.

The drill wears faster and the ma-

chine can be overloaded.

►Use the high-pressure container sup-

plied for cutting oil/drilling emulsion

with BDS 6000 cooling lubricant at

the machine.

►Pay attention to the production of

swarf. With larger drilling depths,

break the chip.

Eliminating blockages

WARNING

Danger of cutting by broken tool parts

or shavings.

►Put protective gloves on before start-

ing work.

Before eliminating a blockage, stop the

machine completely.

For safe stopping of the engine (12):

►Move the accelerator (19) to the MIN

position.

►Move the ignition switch (20) of the

engine (12) to the OFF/AUS position.

►Close the fuel tap (21).

►Pay attention to the engine specica-

tions of the manufacturer (12).

Blockages caused by a broken tool:

Move the machine carriage to the

base position with the help of the feed

lever (8).

Replace defective tool. Remove

shavings.

Other blockages:

Move the machine carriage to the

base position with the help of the feed

lever (8).

Remove shavings and check tool.

Eliminating blockages

17RailMAB 960

GB

Cleaning

WARNING

Risk of injury!

Risk of injury in the case of improper

cleaning work. To avoid injury, pay atten-

tion to the following instructions:

►Before any maintenance and clean-

ing, switch off the machine and stop

the engine (12) completely

■Move the accelerator (19) to the

MIN position.

■Move the ignition switch (20) of

the engine (12) to the OFF/AUS

position.

■Close the fuel tap (21).

■Pay attention the engine specica-

tions of the manufacturer (12).

►When using compressed air, wear

protective goggles and gloves.

►Protect other persons in the work

area.

CAUTION

►Never immerse the machine in water

or other liquids.

After every use

Remove the inserted tool.

Remove shavings and coolant resi-

dues.

Clean the tool and the tool holder on

the machine.

Clean the guide of the machine slide

(13).

Store the machine and accessories

at a suitable location (see section

Storage).

NOTE

►Pay attention to the manufacturer

documentation when cleaning the

engine and gear unit.

Cleaning/maintenance

18 RailMAB 960

GB

Maintenance

WARNING

Danger caused by unqualied repairs!

Unqualied repairs can lead to consid-

erable danger for the user and cause

damage to the machine.

►Maintenance work may only be car-

ried out by authorised qualied staff.

►Only original spare parts may be

used.

Adjusting the guide of the machine

slide

If the machine slide guide (13) exhibits too

much clearance, it must be adjusted. To do

this, proceed as follows:

Loosen the clamping bolts.

Tighten the adjusting screws uniformly.

Tighten the clamping bolts again.

NOTE

►Pay attention to the manufacturer

documentation when carrying out

maintenance on the engine and gear

unit.

Customer service/service

Should you have any questions about af-

ter-sales service or service, please contact

BDS. We will be happy to give you the

address of your nearest service partner.

Cleaning/maintenance

19RailMAB 960

GB

Storage

If you do not intend to use the machine for a longer period of time, clean it as described in

the section Cleaning. Store the machine and all accessories at a dry, clean and frost-free

location.

Troubleshooting

Fault Possible cause

The engine (12) does not

start.

Fuel supply faulty.

Check the fuel level

and refuel if necessary.

Open the fuel tap.

Motor oil level too low. Check the oil level

and rell if necessary.

Ignition (20) not switched on. Switch on the ignition.

Choke (15) not at a suitable start

position.

Check the position of the

choke.

(CLOSED position for cold

starting)

Pay attention to the manufacturer documentation for further

troubleshooting.

Tools wear excessively/

are damaged.

No lubrication or not sufciently

greased.

Supply lubrication (e.g.:use

high-pressure container for

cutting oil/drilling emulsion).

The fast clamping

system (5) does not x

the machine to the rail

properly.

Wrong rail adapter (A) selected. Select and mount a suitable

rail adapter (A).

NOTE

►If you cannot resolve the problem with the steps described above, please contact the

After-Sales Service.

Storage/troubleshooting

20 RailMAB 960

GB

Technical Specications

Model RailMAB 960 Unit

Dimensions

(L x W x H) 535 x 345 x 470 mm

Net weight approx. 21.5 kg

Cylinder capacity 49.4 cm3

Tank capacity 0.5 l

Motor power 1.5 kW

Max. torque 3.04 Nm at 4500 rpm W

Stroke 40 mm

Core drill (HKK-R) max. Ø 17 - 36 mm

Cutting depth max. 30 mm

Speed (adjustable) 150 - 225 rpm

Core drill assembly Weldon 19 mm (3/4")

Technical Specications

Table of contents

Other BDS Drill manuals