Becca S50M User manual

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

1

INSTRUCTION MANUAL

S50M Solvent Spray Gun Cleaner

° Warranty ° Service Parts

° Safety ° Troubleshooting Guide

° Operation ° Accessory Information

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

2

TABLE OF CONTENTS

PAGE

WARRANTY INFORMATION........................................................................................ 3

SPRAY GUN CLEANER SPECIFICATIONS................................................................. 4

SAFETY AND WARNING.............................................................................................. 5

General Safety...................................................................................................... 5

Danger and Warning Labels ................................................................................. 5

General Safety Rules............................................................................................ 6

Personal Safety .................................................................................................... 6

Unit Use and Care................................................................................................ 7

Safety Rules......................................................................................................... 7-8

INTRODUCTION ........................................................................................................... 9

OPERATION GUIDELINES........................................................................................... 9 –11

TROUBLESHOOTING GUIDE ...................................................................................... 12-13

MAINTENANCE SCHEDULE........................................................................................ 14

FILTER CHANGE INSTRUCTIONS…………………………..……………………………….. 15

WARRANTY INFORMATION / TECHNICAL ASSISTANCE......................................... 16

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

3

LIMITED WARRANTY

Solvent Recyclers & Paint Gun Washers

24 MONTH LIMITED WARRANTY

BECCA Solvent Recyclers and Paint Gun Cleaners components are warranted to be free of defects

in material or workmanship for 24 months from established purchase date to the original user or

from original shipment whichever is sooner. During months 1 through 6 BECCA will repair or

replace any component including labor that is found to be defective in material or workmanship as

determined by BECCA factory certified service technician. For months 6 through 24 BECCA will

furnish parts only (no travel, diagnostic or repair labor is provided) to replace any component that

is found to be defective in material or workmanship as determined by BECCA factory certified

service technician. In all cases defective parts shall be returned to BECCA for inspection and final

approval.

There is no other express warranty, implied warranties, including those of merchantability and fitness for

a particular purpose, are limited to one year from purchase and to the extent permitted by law any and all

implied warranties are excluded. This is the exclusive remedy and liability for consequential and incidental

damages under any and all warranties are excluded to the extent exclusion is permitted by law.

CONDITIONS OF WARRANTY

BECCA has no control over working conditions, solvents involved in usage and under which

purchaser stores, handles or uses BECCA product. We make no warranty or condition, either

expressed or implied with respects to usage or mistreatment of product. These warranties apply

only to the original purchaser and do not apply if the unit has been misused, subjected to

overloading, neglect, accident, altered or used for any other purpose. BECCA shall not be liable

for loss, damage or delay due to, without limitation, acts of God, transportation delays, accident,

fire, action of civil or military authority, adverse weather or any other causes beyond BECCA’s

control. This warranty does not cover transportation, interior or exterior finishes. The use of

unauthorized chemicals or solvents with acid content in this unit shall render this warranty null

and void. BECCA shall not be responsible or liable for any consequential or incidental damages,

including without limitation, loss of production or faulty production, loss of use or loss of profit.

Attempts at repair or alterations by the owner shall also constitute a violation of this warranty.

Only BECCA certified personnel shall start-up, train, repair or alter BECCA equipment. Spray Gun

Cleaner Brushes, Filters, and Gun Clips & Solvent Recycler Gaskets/Seals, Oil, and Bags are

subject to be replaced due to normal usage, wear and tear within the warranty period and are

excluded from this warranty.

These warranties replace all other warranties expressed or implied by nature or otherwise, and are not assignable or

transferable from original purchaser.

Warranty is in effect after receipt of Registration information & full payment

2010 Cobb International Blvd Ste H Kennesaw, GA 30152 Phone 1-800-655-5649 Fax 1-800-655-5684

Revision 1/8/05

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

4

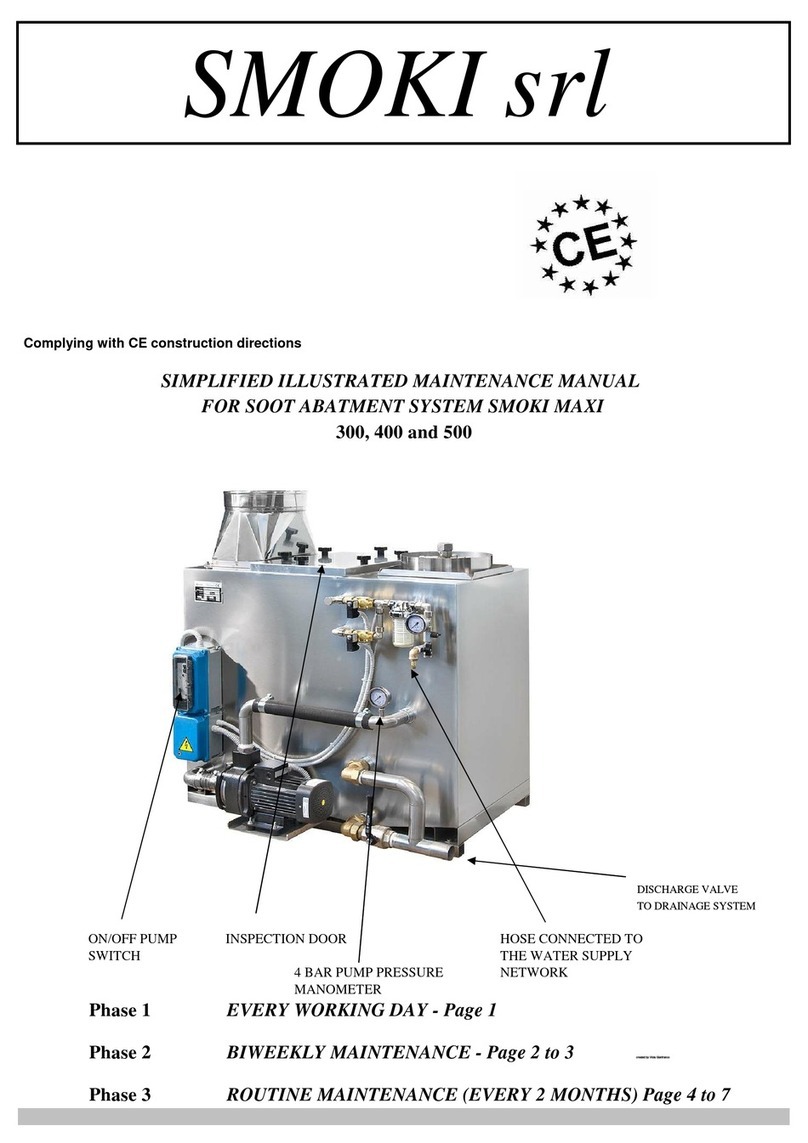

SPRAY GUN CLEANER SPECIFICATIONS

SPECIFICATION FOR FLEX 50 POWER CLEAN™ SPRAY GUN CLEANERS

SPECIFICATIONS

U.S. UNITS

METRIC UNITS

Weight

50 Lbs.

23 Kg

Height

24"

610 mm

Width

18"

457 mm

Length

12"

305 mm

Wash Basin Height

12"

305 mm

Wash Basin Depth

14"

356 mm

Wash Basin Width

16.75"

426 mm

(Optional) Leg Kit

Add 35.5”

916 mm

Fluid Capacity of Container

5 Gallons

20 Liters

Air Supply Operating Pressure

75 - 85 psi.

6 –7 Bar

Acoustic Pressure Level LpAm ISO-3746

68.4 dB(A)

68.4 dB(A)

Acoustic Power Level LpAm ISO-3746

79.2 dB(A)

79.2 dB(A)

Ball valve

Brass

Brass

Pump

1 Dual diaphragm

1 Dual diaphragm

Pump Capacity

1 Gal/min Actual

4 Liters/min Actual

Fluid containers

1 (Included)

1 (Included)

Outside Frame steel

Powder Paint

Powder Paint

Wash Basin

Stainless steel

Stainless steel

Warranty - Limited

24 months

24 months

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

5

SAFETY AND WARNING

GENERAL SAFETY

1. Carefully inspect the shipping carton for any signs of transport damage.The damage to the carton often

indicates possibility of transport damage to the equipment inside.

2. Carefully remove your BECCA Spray Gun Cleaner from the shipping carton.

3. Check your equipment immediately to ensure that it is free of transport damage. Report any transport

damage to the carrier without delay for possible claim procedures. BECCA Inc. is not responsible for

damage to equipment after it leaves our warehouse.

4. Check the equipment list and compare it with the parts you have received. If any parts are missing,

contact the supplier you purchased the equipment from.

Before operating the BECCA SPRAY GUN CLEANER, read this Instruction Manual completely. All

BECCA products are engineered and manufactured to the highest performance standards and have

been subjected to detail testing before shipment from the factory.

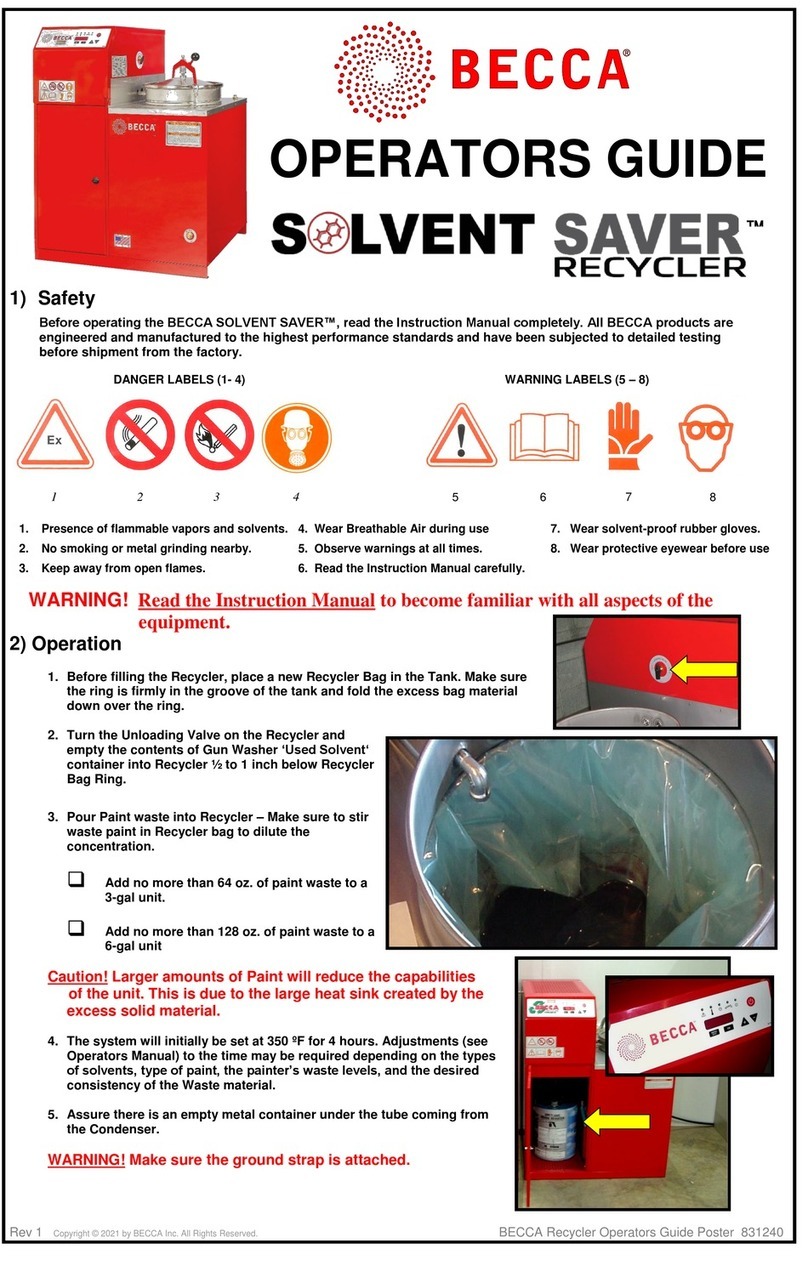

DANGER AND WARNING LABELS

DANGER

1 2 3 4

WARNING

5 6 7 8

1. Presence of flammable vapors and solvents. 5. Observe warnings at all times.

2. No smoking or metal grinding nearby. 6. Read the Instruction Manual carefully.

3. Keep away from open flames. 7. Wear solvent-proof rubber gloves.

4. Wear Breathable Air during use. 8. Wear protective eyewear before use.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

6

SAFETY AND WARNING (cont’d)

WARNING

« READ ALL INSTRUCTIONS » Failure to follow the SAFETY RULES identified by a BULLET (°) symbol

listed BELOW and other safety precautions may result in serious personal injury. « SAVE THESE

INSTRUCTIONS »

GENERAL SAFETY RULES

° KEEP WORK AREA CLEAN.

° KEEP CHILDREN AWAY. Do not let visitors come in contact with the equipment. All visitors should be

kept away from the work area.

PERSONAL SAFETY

° GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces, for example:

pipes, radiators. Solvent resisting rubber gloves and non-skid footwear is recommended where damp or

wet ground may be encountered. A ground fault circuit interrupter protected power line must be used for

these conditions.

° DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in the moving parts.

Wear protective hair covering to contain long hair.

° USE SAFETY EQUIPMENT. WEAR SAFETY GOGGLES or glasses with side shields.

° STAY ALERT. USE YOUR COMMON SENSE. Concentrate on what you are doing. Do not operate the

unit when you are tired or under the influence of drugs.

° DO NOT OVERREACH. Keep proper footing and balance at all times.

° BEFORE CONNECTING THE UNIT to an air line outlet, be sure the pressure is the same as that

specified on the nameplate of the Spray Gun Cleaner. An air-line with pressure greater thanthat specified

on the Spray Gun Cleaner can seriously injure the user –as well as damage the Spray Gun Cleaner. If

in doubt, DO NOT connect the unit. Using an air-line with pressure less than the pressure specified on

the nameplate is harmful to the pump.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

7

SAFETY AND WARNING (cont’d)

UNIT USE AND CARE

° DO NOT FORCE THE UNIT. It will perform better and safer at the rate for which it was designed.

° THE USE OF ANY OTHER ACCESSORIES not specified in this manual may create a hazard.

° DISCONNECT THE UNIT when not in use, before servicing.

° DO NOT ALTER OR MISUSE THE UNIT. These units are precision built. Any alteration or modification

not specified is misuse and may result in a dangerous situation.

Only trained repairmen should attempt (°) ALL REPAIRS, electrical or mechanical. Contact the nearest

BECCA repair service facility. Use only BECCA replacement parts, any other parts may create a hazard.

SAFETY RULES

° THE OPERATOR MUST WEAR protective solvent-proof rubber gloves to prevent contact between his

hands and the products used for cleaning.

° THE OPERATOR MUST WEAR protective eyewear to prevent spatter from coming in contact with his

eyes.

° THE SPRAY GUN CLEANER is designed exclusively to wash spray guns and small objects.

° STAY ALERT at the start of the cleaning cycle. Make sure the solvent is not «corrosive». Immediately

stop washing and replace the solvent whenever you note signs of corrosion on the worktable.

° IF EYES COME IN CONTACT WITH SOLVENTS rinse thoroughly with water.

° BEFORE USING the Spray Gun Cleaner, make sure that all safety devices are in perfect operating

condition.

° BECOME FAMILIAR WITH THE CONTROLS and their functions before commencing work.

° USE GROUNDABLE CONTAINERS (Containers, solvents are supplied in, are recommended) for

the collection of solvents.

° BE CAREFUL when you load or unload the solvent in the unit. Make sure you do not splash or spill the

contents on the workshop floor.

° THE OPERATOR MUST PERIODICALLY check the level of the dirty solvent contained in the collection

pail to prevent it from overflowing.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

8

SAFETY AND WARNING (cont’d)

° IT IS STRICTLY FORBIDDEN to place unsuitable sized object or objects that weigh more than 18 Lbs.

/ 8 Kg on the work surface of the Spray Gun Cleaner.

° CLEAN OR REPLACE the mesh filter periodically.

° DO NOT USE ELECTRICAL OR PNEUMATICAL TOOLS WITH THE UNIT. AVOID GASEOUS

AREAS. Do not operate portable electric tools in explosive atmospheres in the presence of flammable

liquids or gases. Motors in these tools normally spark, and do not scrape or scratch the machine with

metal objects; the sparks might ignite fumes.

° DO NOT ALLOW FAMILIARITY GAINED FROM FREQUENT USE OF YOUR SPRAY GUN WASHER

TO BECOME COMMONPLACE. Always remember that a careless fraction of a second is sufficient to

inflict severe injury.

° DO NOT ALTER OR MISUSE THE UNIT. Any alteration or modifications is a misuse and may result in

serious personal injuries.

° FIRE EXTINGUISHING SYSTEMS must be installed in the same room or close to the unit in case of

emergency. These appliances must be kept efficient and inspected every year by a certified person.

° THE INSTALLATION SITE MUST PERMIT PERSONNEL TO EASILY AND QUICKLY MOVE AWAY

FROM DANGER ZONES IN CASE OF AN EMERGENCY.

° DO NOT USE THE UNIT TO wash or degrease objects designed to come in contact with food.

° COMPLY WITH LAWS IN THE COUNTRY where the Spray Gun Cleaner is installed regarding the use

and disposal of the products used to wash clean objects.

THINK SAFETY! SAFETY IS A COMBINATION OF THE OPERATOR’S COMMON SENSE, KNOWLEDGE

OF THE SAFETY AND OPERATING INSTRUCTIONS AND ALERTNESS AT ALL TIMES WHEN THE

UNIT IS BEING USED.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

9

INTRODUCTION

This Instruction Manual provides installation, operation and maintenance instructions for the ENVIRO E50M

Spray Gun Cleaner unit, which shall be referred to as Spray Gun Cleaners in the following pages. Spray

Gun Cleaners are totally pneumatic units designed for Manual & Hands-Free cleaning of spray guns and

small parts.

It is very practical, time saving and economic for cleaning Spray Guns and small parts. The unit is supplied

with a pneumatic pump that pulls solvent from the container below in the cabinet. The solvent that you will

use will depend on the type of paint that you are using. The manufacturer of the paint will give you the

information you need regarding this.

This manual is an integral part of the product. It must be properly stored, kept ingood conditionand available

for consultation atany time during the entire working life of the Spray Gun Cleaner. Proper washer operation,

economy anddurability depend oncommon senseandcompliance with theinstructions given in this manual.

OPERATION GUIDELINES

Read the following sections carefully. They will help you use your Spray Gun Cleaner correctly and

help you select the correct function for your task.

Description of the valves

- a: Foot Pedal

- b: Flow Brush Valve

- c: POWER CLEAN Connection

- d: POWER PISTOL

Description for using the Spray Gun Cleaner unit

The first step in learning to use the Spray Gun Cleaner is to become familiar with the unit. The cleaner

basically consists of one (1) pump and one (1) container. Operations are carried out via the controls

placed on the top front panel which the operator can control the use.

a –The “Foot Pedal” supplies air to the pump for all fluid functions. Fluid will not flow without

depressing the foot pedal.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

10

OPERATION GUIDELINES (cont’d)

b –The “Manual Flow Brush” valve allows you to operate the Manual Flow Brush. When engaged

the pump will pull solvent from the container through the flow brush. There is also a flow control

at the end of the flow brush handle to adjust the rate of fluid flow.

c–The “POWER CLEAN” connection is a High Flow Quick Disconnect that connects to the air-side

of the spray gun to protect the air passageways and seals during cleaning. There is also a flow

control next to the QD to adjust the rate of airflow through the spray gun

d–POWERPISTOLTM is mounted in the top of the spray gun cleaner and is activated by turning the

valve to the POWERPISTOL position for cleaning the hard to reach areas of the spray gun. There

is also a flow control attached to the POWERPISTOLTM to adjust the rate of fluid flow for cleaning.

IMPORTANT: DO NOT POUR LEFTOVER PAINT INTO THE WASH BASIN.

Manual Cleaning

To manually wash your spray guns start by removing the cup from the spray gun, empty the cup's

residues into a separate pail. Pour approximately ½ inch of used solvent by turning the “Manual Brush

Wash” valve (b) to the ON position into cup and clean with the brush.

This fluid is returned into the fluid container for reuse.

A brush has been added to the unit to help clean parts and paint guns. The solvent will come out from

the center of the brush.

You can also clean parts or spray guns with POWERPISTOLTM. POWERPISTOLTM is mounted in the

top of the spray gun cleaner and is activated by turning the valve to the POWERPISTOL position for

cleaning the hard to reach areas of the spray gun. Be sure to connect POWER CLEAN to the spray

gun before cleaning to protect the air passageways of the gun.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

11

OPERATION GUIDELINES (cont’d)

OPTIONAL Filtration Recycling System

The unit has an Optional Filtration Recycling System to remove particulate from the solvent. This system

filters out particulate down to 75 micron. Some processes may require the solvent to be purged periodically

due to a build-up of activate type solvents.

The Filters are easily changed by a replacement kit (825258K) that includes two 75 micron filters and two

seals (seals are normally useless once the housing is opened).

Identification of the Spray Gun Cleaner

Every spray gun washer has an identification plate that indicates:

Manufacturer brand

Manufacturer name and address

Spray washer model and serial number

Information on this identification plate must always be specified when asking for service and/or spare parts.

Periodical check and maintenance

Please follow the rules and regulations listed below to safely maintain the Spray Gun Washer:

Periodically make sure that safety devices are complete and efficient.

Periodically replace the mesh filter.

Periodically clean the working surface and the cover from any eventual deposits.

It is strictly forbidden to remove or tamper with safety devices.

According to the instructions given in this manual, only qualified and specialized personnel must perform

maintenance on the Spray Gun Cleaner.

Disconnect the compressed air supply when it is necessary to repair or perform maintenance on the

appliance.

Maintenance must be performed carefully, following the instructions given in this manual for replacing

damaged or worn parts.

The symbolic labels attached to the Spray Gun Cleaner give clear guidelines for preventing accidents.

These labels must always be kept clean and immediately replaced if they are even partially removed or

damaged. It is strictly forbidden to operate the Spray GunWasher when even only one of these symbolic

labels is missing from the point where the Manufacturer placed it.

Always use BECCA GENUINE REPLACEMENT PARTS during repair and maintenance.

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

12

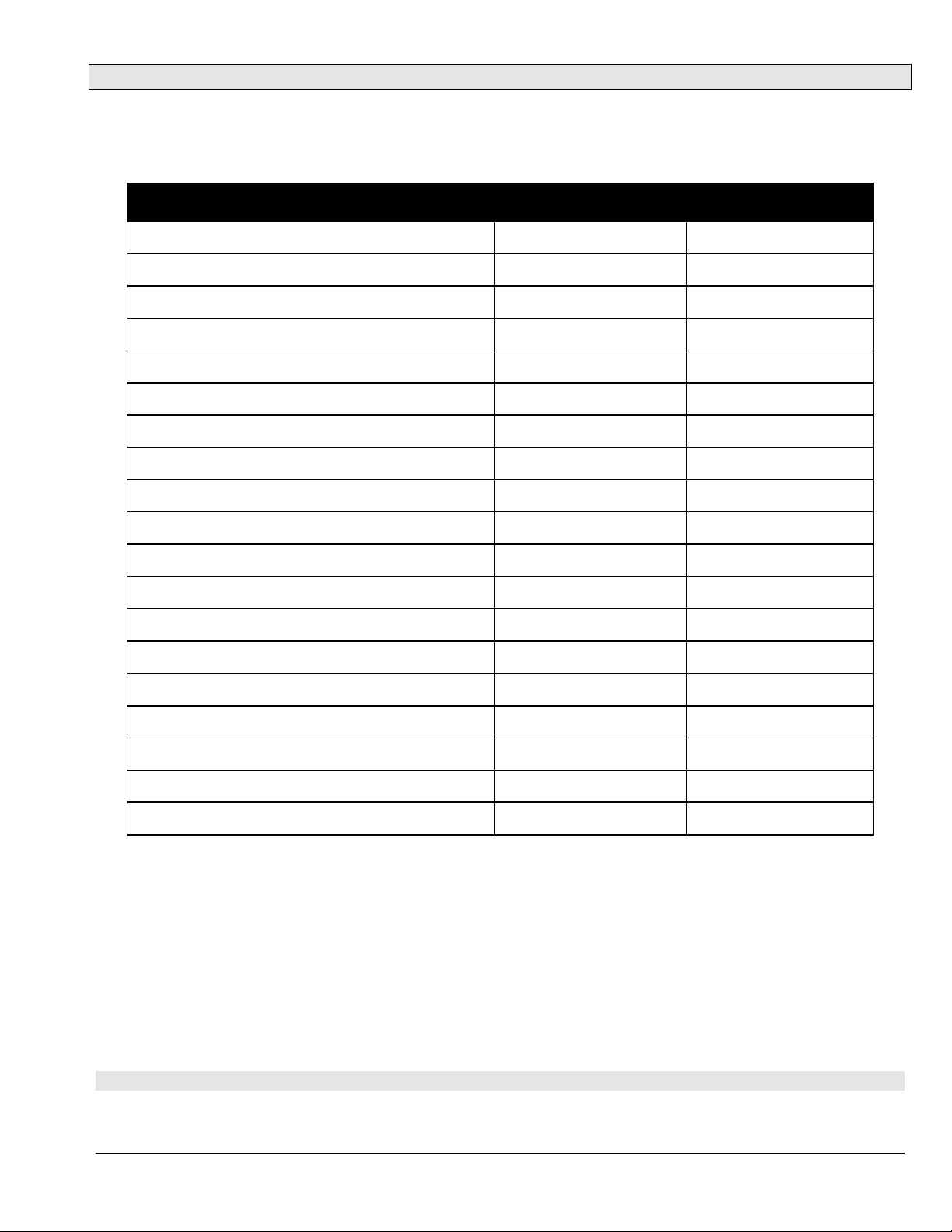

TROUBLESHOOTING GUIDE

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

13

TROUBLESHOOTING GUIDE

Troubleshooting method to isolate the system (Pump) from the Filtration Recycling Systems:

Remove filters from housings, re-attach empty housings and run the gun cleaner (it will take several minutes

for the housings to fill up). If the system runs normally, the problem was caused by the filters. If the system

does not run correctly, the problem was caused by the pump.

PROBLEM

CAUSE

SOLUTION

Pump

Locks Up –No Flow

Pump Shuttle has centered and

needs to be reset

To reset the shuttle:

1) Disconnect Compressed Air

2) Turn Flow Brush Valve to “On” position

3) Reconnect Compressed Air

4) If this does not work- Replace Pump

Pump

No fluid flow, loud air noise

from Exhaust Muffler

Air is by-passing to exhaust in

the pump

Replace the pump

Foot Pedal

Air Blowing to exhaust

(50 & 100 Series Units Only)

Air lines on foot pedal are

reversed

Disconnect air lines from foot pedal and reverse

connection

Optional

Filtration Recycling

System

Pump

Rapid Acceleration

After recent filter change

Air is getting into the fluid lines

Check the filter canisters –make sure they are

screwed on snugly (hand tightened)

Check the seals in the filter canisters:

Make sure they are NEW

Make sure they are seated correctly

Optional

Filtration Recycling

System

Diminished Fluid Flow

Filters are almost loaded

Change filter(s) –either the 75 micron filter or

both filters, depending on the filter change

schedule (see instructions with Filter Kit

Optional

Filtration Recycling

System

Pump

Rapid Acceleration

with little to no fluid flow

Filters are loaded

Make sure containers have fluid.

Make sure suction line is in the fluid

Change filter(s) –either the 75 micron filter or

both filters, depending on the filter change

schedule (see instructions with Filter Kit)

See Below for Troubleshooting method

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

14

MAINTENANCE SCHEDULE

Each day

- Wipe-down the unit with solvent. The paint and decals are solvent

resistant.

- Remove any contaminants from under the Splash Pad

Every 2 - 3 Months

- Filter System See page 15.

Semi-Annually

- Change out “Used Solvent” Container.

- Replace Back Splash Pad (825163) in back panel.

- Replace Bottom Splash Pad (825162) in Basin.

- Replace BECCA Protect™ Maintenance Coating (ECP 831004)

- Review Ground Clamp (823079)

Annually

- Replace Manual Flow Brush (824610)

- Review & Replace illegible or damaged Decals

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

15

Filtration Recycling Filter Replacement

Filtration Recycling System

(Optional)

Filter Replacement Instructions

825265K- Dual Cartridge Replacement Kits = 2-75 Micron & 1-25Micron Filters & 3 Seals

825258K –Single Cartridge Replacement Kit = 2-75 Micron Filters & 2 Seals

FILTER CHANGE PROCEDURE

1. Important! Before removing the Filter Housing:

Lift the line out of the container

Then allow the pump to continue to run with the Wash Basin or Flow Brush in the

“On” position.

Run the unit to remove some of the solvent from the Housing (3-5”).

2. Turn the Filter Housing with the provided Wrench. If stuck, lightly tap housing with a

rubber mallet to break the seal. Care should be taken so not to crack the housing.

3. Make sure to replace the filter and place it in the correct position

4. Make sure to replace the seal in the Filter Housing. (Note: The old seal will not work

after the Filter Housing has been removed)

5. Make sure Filter is located in the Guide located on the threaded top before spinning

housing. Tighten The Filter Housings to a snug position. (Do Not Over Tighten!!)

6. When Running the Spray Gun Cleaner it will take a few minutes to fill the Filter

Housing before flowing out of the selected function.

7. Used Filters (are Hazardous until proven different) should be allowed to dry and

then dispose per local jurisdiction requirements.

You are ready to use your system!

Aug 2011, V 1.0 BECCA INC. Instruction Manual S50M Spray Gun Cleaner

16

WARRANTY INFORMATION / TECHNICAL ASSISTANCE

The Warranty of your system begins with the Certified Start-up by your local BECCA Distributor.

Make sure this is completed and you receive a copy of the Certified Start-up document.

For more information, prices or technical assistance,

contact your local BECCA distributor or call / fax our

BECCA Care™ Numbers:

2010 Cobb International Blvd Ste H

Kennesaw, GA 30152

Tel: (800) 655-5649 Fax: (800) 655-5684

Copyright © 2010 by BECCA Inc. All Rights Reserved

Table of contents

Other Becca Cleaning Equipment manuals