Becca ENVIRO 300 PowerClean User manual

Aug 2011, V 1.0 BECCA INC. Instruction Manual S300A Spray Gun Cleaner

1

INSTRUCTION MANUAL

S300A Spray Gun Cleaner

° Warranty ° Service Parts

° Safety ° Troubleshooting Guide

° Operation ° Accessory Information

Aug 2011, V 1.0 BECCA INC. Instruction Manual S300A Spray Gun Cleaner

2

TABLE OF CONTENTS

PAGE

WARRANTY INFORMATION........................................................................................ 3

SPRAY GUN CLEANER SPECIFICATIONS................................................................. 4

SAFETY AND WARNING.............................................................................................. 5

General Safety...................................................................................................... 5

Danger and Warning Labels ................................................................................. 5

General Safety Rules............................................................................................ 6

Personal Safety .................................................................................................... 6

Unit Use and Care ................................................................................................ 7

Safety Rules ......................................................................................................... 7-8

INTRODUCTION ........................................................................................................... 9

OPERATION GUIDELINES........................................................................................... 9 –12

TROUBLESHOOTING GUIDE ...................................................................................... 13 –14

MAINTENANCE SCHEDULE........................................................................................ 15

SOLVENTWASH FILTER CHANGE INSTRUCTIONS……………………………………… 16

SCHEMATIC OF UNIT .................................................................................................. 17 - 24

PARTS DESCRIPTION ................................................................................................. 25

WARRANTY INFORMATION / TECHNICAL ASSISTANCE ......................................... 26

Aug 2011, V 1.0 BECCA INC. Instruction Manual S300A Spray Gun Cleaner

3

LIMITED WARRANTY

Solvent Recyclers & Paint Gun Washers

24 MONTH LIMITED WARRANTY

BECCA Solvent Recyclers and Paint Gun Cleaners components are warranted to be free of defects

in material or workmanship for 24 months from established purchase date to the original user or

from original shipment whichever is sooner. During months 1 through 6 BECCA will repair or

replace any component including labor that is found to be defective in material or workmanship as

determined by BECCA factory certified service technician. For months 6 through 24 BECCA will

furnish parts only (no travel, diagnostic or repair labor is provided) to replace any component that

is found to be defective in material or workmanship as determined by BECCA factory certified

service technician. In all cases defective parts shall be returned to BECCA for inspection and final

approval.

There is no other express warranty, implied warranties, including those of merchantability and fitness for

a particular purpose, are limited to one year from purchase and to the extent permitted by law any and all

implied warranties are excluded. This is the exclusive remedy and liability for consequential and incidental

damages under any and all warranties are excluded to the extent exclusion is permitted by law.

CONDITIONS OF WARRANTY

BECCA has no control over working conditions, solvents involved in usage and under which

purchaser stores, handles or uses BECCA product. We make no warranty or condition, either

expressed or implied with respects to usage or mistreatment of product. These warranties apply

only to the original purchaser and do not apply if the unit has been misused, subjected to

overloading, neglect, accident, altered or used for any other purpose. BECCA shall not be liable

for loss, damage or delay due to, without limitation, acts of God, transportation delays, accident,

fire, action of civil or military authority, adverse weather or any other causes beyond BECCA’s

control. This warranty does not cover transportation, interior or exterior finishes. The use of

unauthorized chemicals or solvents with acid content in this unit shall render this warranty null

and void. BECCA shall not be responsible or liable for any consequential or incidental damages,

including without limitation, loss of production or faulty production, loss of use or loss of profit.

Attempts at repair or alterations by the owner shall also constitute a violation of this warranty.

Only BECCA certified personnel shall start-up, train, repair or alter BECCA equipment. Spray Gun

Cleaner Brushes, Filters, and Gun Clips & Solvent Recycler Gaskets/Seals, Oil, and Bags are

subject to be replaced due to normal usage, wear and tear within the warranty period and are

excluded from this warranty.

These warranties replace all other warranties expressed or implied by nature or otherwise, and are not assignable or

transferable from original purchaser.

Warranty is in effect after receipt of Registration information & full payment

2010 Cobb International Blvd Ste H Kennesaw, GA 30152 Phone 1-800-655-5649 Fax 1-800-655-5684

Revision 1/8/05

Aug 2011, V 1.0 BECCA INC. Instruction Manual S300A Spray Gun Cleaner

4

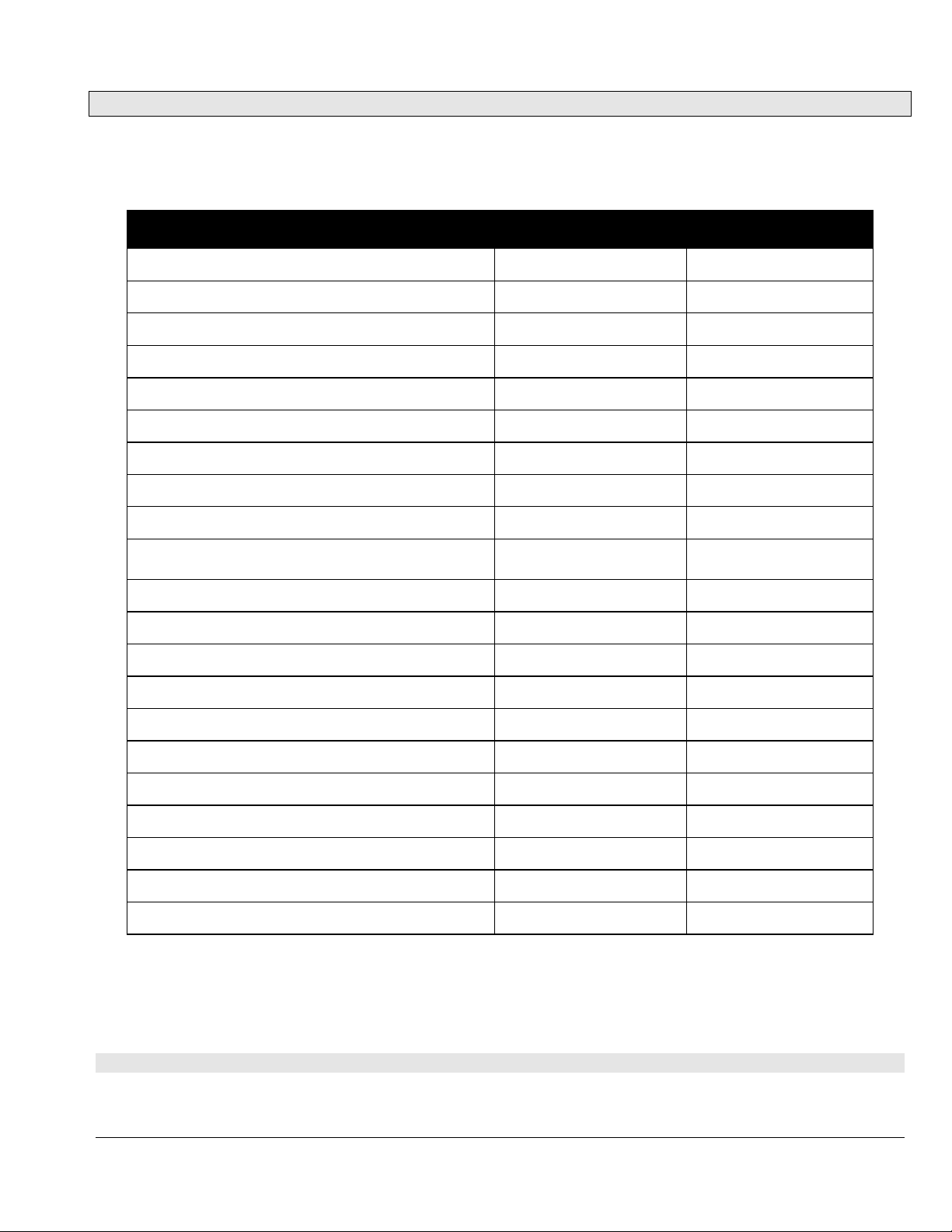

SPRAY GUN CLEANER SPECIFICATIONS

SPECIFICATION FOR ENVIRO 300 POWER CLEAN™ SPRAY GUN CLEANERS

SPECIFICATIONS

U.S. UNITS

METRIC UNITS

Weight

94 Lbs.

43 Kg

Height

42.5"

1,063 mm

Width

15"

375 mm

Length

26"

650 mm

Wash Basin Height

15"

375 mm

Wash Basin Depth

20"

300 mm

Wash Basin Width

12"

300 mm

Solvent Capacity of Container (2)

5 Gallons

20 Liters

Diameter of Vapor Chimney

4"

100 mm

Air Consumption by each Suction Nozzle at 90

psi / 8 Bar

8 –10 cfm

.0038-.0047 cms

Capacity of Spray Gun per Wash

2

2

Air Supply Operating Pressure

75 - 85 psi.

6 –7 Bar

Acoustic Pressure Level LpAm ISO-3746

68.4 dB(A)

68.4 dB(A)

Acoustic Power Level LpAm ISO-3746

79.2 dB(A)

79.2 dB(A)

Ball valve

Brass

Brass

Pump

Dual diaphragm

Dual diaphragm

Pump Capacity

1 Gal/min Actual

4 Liters/min Actual

Groundable containers

2 (Not Included)

2 (Not Included)

Outside Frame steel

Powder Paint

Powder Paint

Wash Basin and work table

Stainless steel

Stainless steel

Warranty - Limited

24 months

24 months

Aug 2011, V 1.0 BECCA INC. Instruction Manual S300A Spray Gun Cleaner

5

SAFETY AND WARNING

GENERAL SAFETY

1. Carefully inspect the shipping carton for any signs of transport damage. The damage to the carton

often indicates possibility of transport damage to the equipment inside.

2. Carefully remove your BECCA Spray Gun Cleaner from the shipping carton.

3. Check your equipment immediately to ensure that it is free of transport damage. Report any transport

damage to the carrier without delay for possible claim procedures. BECCA Inc. is not responsible for

damage to equipment after it leaves our warehouse.

4. Check the equipment list and compare it with the parts you have received. If any parts are missing,

contact the supplier you purchased the equipment from.

Before operating the BECCA SPRAY GUN CLEANER, read this Instruction Manual completely. All

BECCA products are engineered and manufactured to the highest performance standards and

have been subjected to detail testing before shipment from the factory.

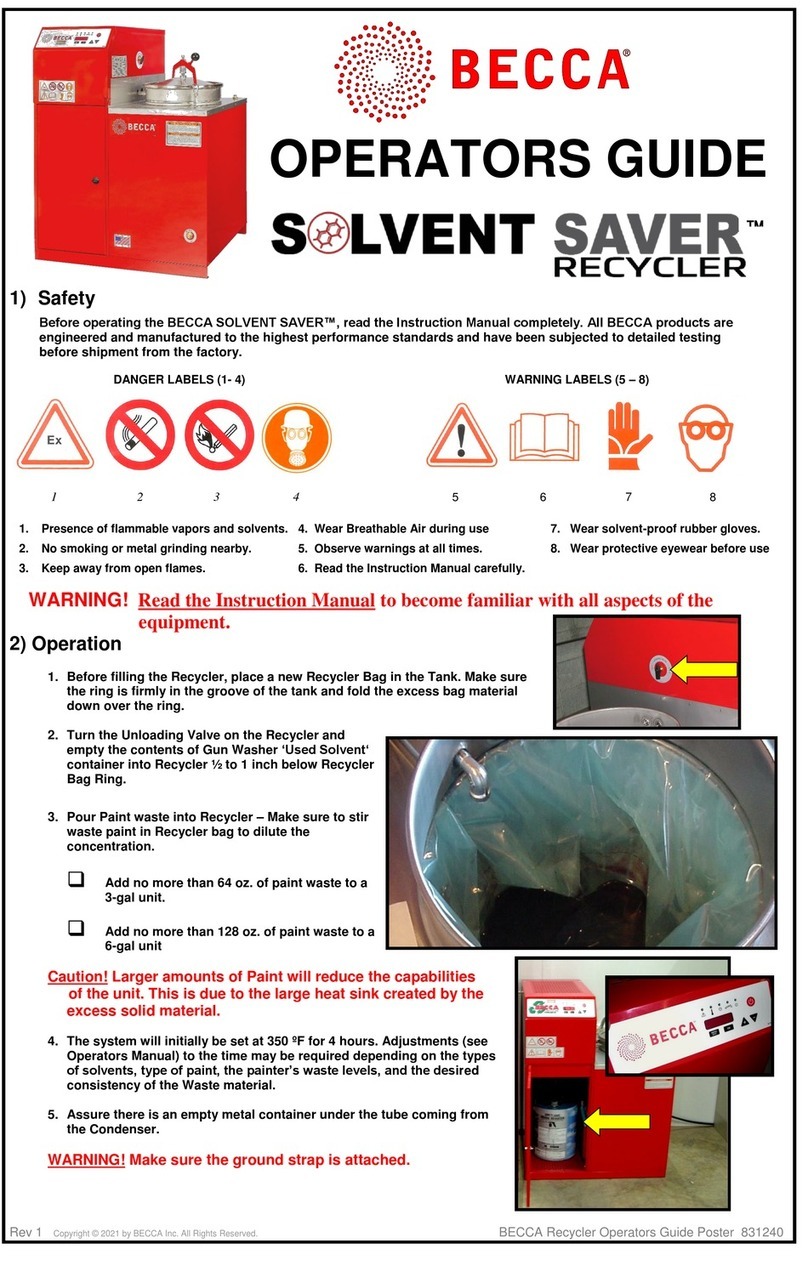

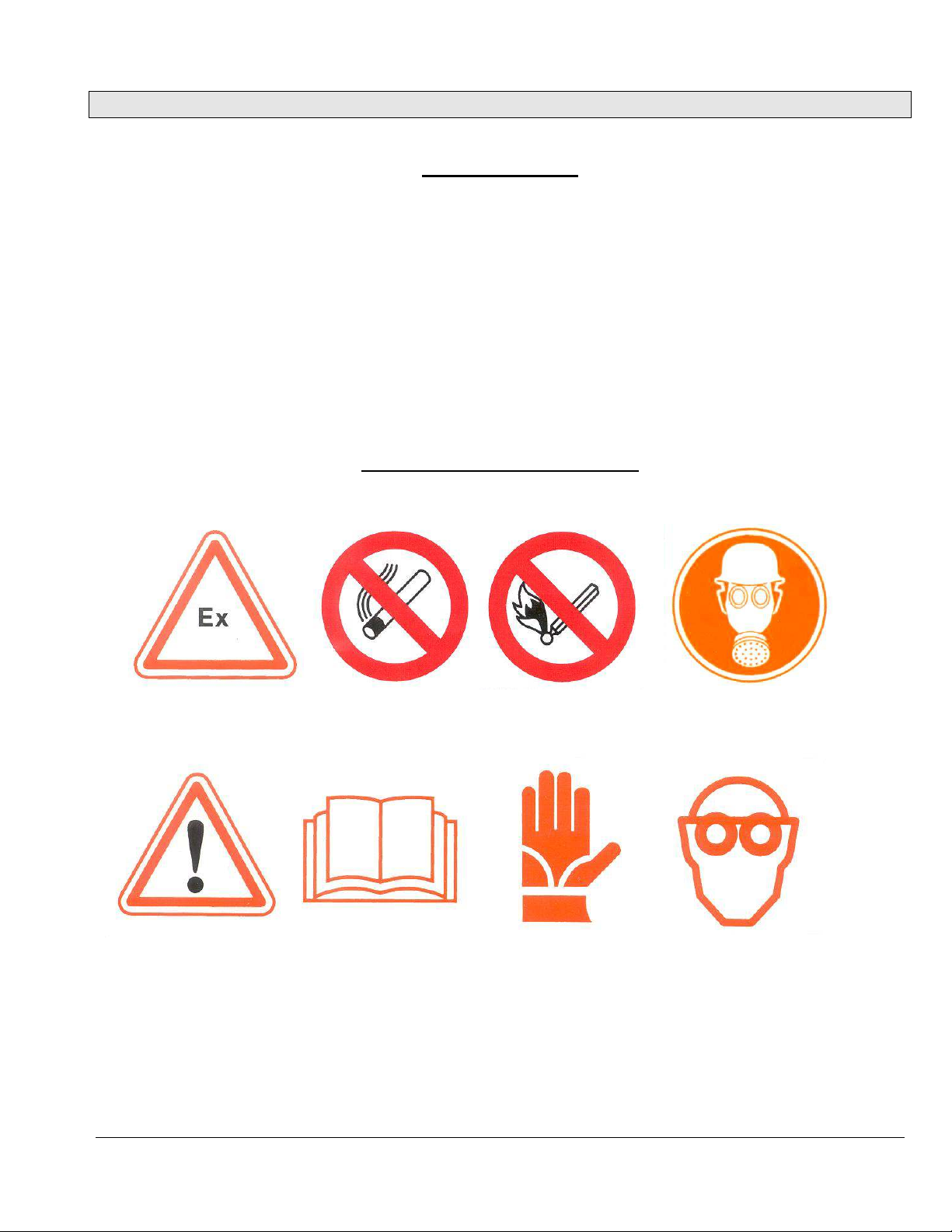

DANGER AND WARNING LABELS

DANGER

1 2 3 4

WARNING

5 6 7 8

1. Presence of flammable vapors and solvents. 5. Observe warnings at all times.

2. No smoking or metal grinding nearby. 6. Read the Instruction Manual carefully.

3. Keep away from open flames. 7. Wear solvent-proof rubber gloves.

4. Wear Breathable Air during use. 8. Wear protective eyewear before use.

This manual suits for next models

3

Table of contents

Other Becca Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual