Becca SOLVENT SAVER User manual

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

1

INSTRUCTION MANUAL

VACUUM ASSIST

(For Solvent Recyclers)

° Warranty ° Service Parts

° Safety ° Troubleshooting Guide

° Operation ° Contact Information

1-800-655-5649

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

2

TABLE OF CONTENTS

PAGE

WARRANTY INFORMATION.......................................................................................... 3

SOLVENT RECYCLER SPECIFICATIONS..................................................................... 4

SAFETY AND WARNING................................................................................................ 5

General Safety........................................................................................................ 5

Danger and Warning Labels ................................................................................... 5

General Safety Rules.............................................................................................. 6

Personal Safety ...................................................................................................... 6

Unit Use and Care .................................................................................................. 7 - 8

Safety Rules ........................................................................................................... 8 - 9

VACUUM DISTILLATION PRINCILPLES ....................................................................... 10 - 13

OPERATING METHOD................................................................................................... 14 - 15

VACUUM SYSTEM INSTALLATION............................................................................... 15

STARTING PROCEDURE............................................................................................... 15

VACUUM SYSTEM DIAGRAM ....................................................................................... 16

SERVICE PART NUMBERS FOR VACUUM ASSIST .................................................... 17

IMPROTANT NOTICE .................................................................................................... 18

TROUBLESHOOTING GUIDE ........................................................................................ 19

CONTACT INFORMATION ............................................................................................ 20

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

3

LIMITED WARRANTY

Solvent Recyclers 3 & 6 Gallon & Paint Gun Washers

24 MONTH LIMITED WARRANTY

BECCA Solvent Recyclers and Paint Gun Washers components are warranted to be free

of defects in material or workmanship for 24 months from established purchase date to

the original user or from original shipment whichever is sooner. During months 1

through12 BECCA will repair or replace any component including labor that is found to be

defective in material or workmanship as determined by BECCA factory certified service

technician. For months 13 through 24 BECCA will furnish parts only (no travel, diagnostic

or repair labor is provided) to replace any component that is found to be defective in

material or workmanship as determined by BECCA factory certified service technician. In

all cases defective parts shall be returned to BECCA for inspection and final approval.

There is no other express warranty, implied warranties, including those of merchantability and

fitness for a particular purpose, are limited to one year from purchase and to the extent permitted

by law any and all implied warranties are excluded. This is the exclusive remedy and liability for

consequential and incidental damages under any and all warranties are excluded to the extent

exclusion is permitted by law.

CONDITIONS OF WARRANTY

BECCA has no control over working conditions, solvents involved in usage and under

which purchaser stores, handles or uses BECCA product. We make no warranty or

condition, either expressed or implied with respects to usage or mistreatment of product.

These warranties apply only to the original purchaser and do not apply if the unit has

been misused, subjected to overloading, neglect, accident, altered or used for any other

purpose. BECCA shall not be liable for loss, damage or delay due to, without limitation,

acts of God, transportation delays, accident, fire, action of civil or military authority,

adverse weather or any other causes beyond BECCA’s control. This warranty does not

cover transportation, interior or exterior finishes. The use of unauthorized chemicals or

solvents with acid content in this unit shall render this warranty null and void. BECCA

shall not be responsible or liable for any consequential or incidental damages, including

without limitation, loss of production or faulty production, loss of use or loss of profit.

Attempts at repair or alterations by the owner shall also constitute a violation of this

warranty. Only BECCA certified personnel shall start-up, train, repair or alter BECCA

equipment. Paint Gun Washer Brushes, Filters, and Plastic Gun Clips & Solvent Recycler

Gaskets/Seals, Oil, and Bags are subject to be replaced due to normal usage, wear and

tear within the warranty period and are excluded from this warranty.

These warranties replace all other warranties expressed or implied by nature or

otherwise, and are not assignable or transferable from original purchaser.

Warranty is in effect after receipt of Registration information & full payment

2010 Cobb Intl Blvd Suite H Kennesaw, GA 30152 Phone 1-800-655-5649 Fax 1-800-655-5684

Revision 3/27/07

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

4

VACUUM ASSIST SPECIFICATIONS

SPECIFICATIONS

U.S. UNITS

METRIC UNITS

Weight

20 Lbs.

9.1 Kg

Height

16"

406 mm

Width

11"

279 mm

Depth

21"

533 mm

Certification

Class 1 Division I

Group D

Class 1 Division I

Group D

Temperature Elevation by Vacuum

30 –40 ºF

1 -4 ºC

Solvent Capacity of Tank

10 Gallons

40 Liters

Air Consumption by Vacuum System at 90

psi. / 8 Bar

10 –15 cfm

.283 - .425 cmm

Vacuum Pressure

15 –25 in Hg

281- 635 mm Hg

Air Supply Operating Pressure

40-65 psi min

6 –7 Bar

Acoustic Pressure Level LpAm ISO-3746

68.4 dB(A)

68.4 dB(A)

Acoustic Power Level LpAm ISO-3746

79.2 dB(A)

79.2 dB(A)

Vacuum Tank Material

Stainless steel

Stainless steel

Warranty

24 months

24 months

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

5

SAFETY AND WARNING

GENERAL SAFETY

1. Carefully inspect the shipping carton for any signs of transport damage. The damage to the

carton often indicates possibility of transport damage to the equipment inside.

2. Carefully remove your Becca Solvent Recycler from the shipping carton.

3. Check your equipment immediately to ensure that it is free of transport damage. Report any

transport damage to the carrier without delay for possible claim procedures. Becca Recycling

Technologies Inc. is not responsible for damage to equipment after it leaves our warehouse.

4. Check the equipment list and compare it with the parts you have received. If any parts are

missing, contact the supplier you purchased the equipment from.

Before operating the BECCA VACUUM ASSIST, read this Instruction Manual completely. All

BECCA products are engineered and manufactured to the highest performance standards

and have been subjected to detail testing before shipment from the factory.

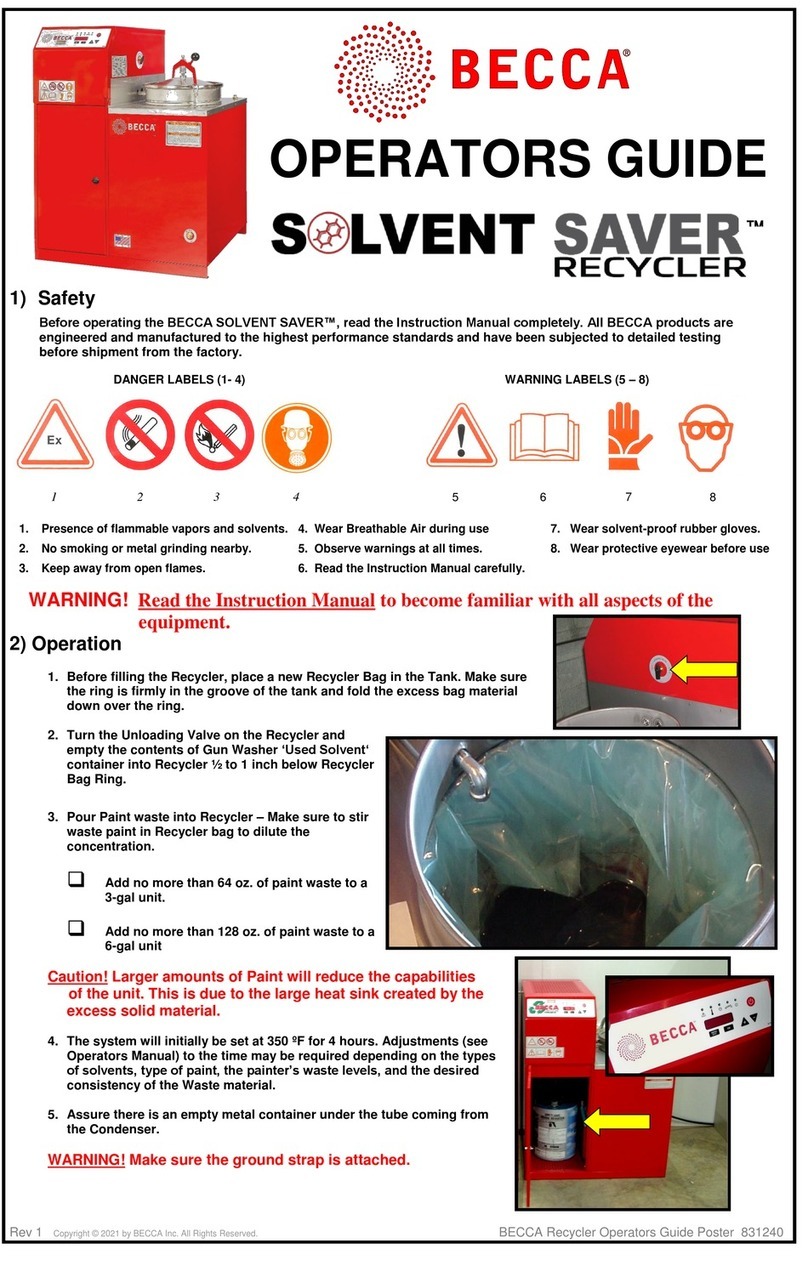

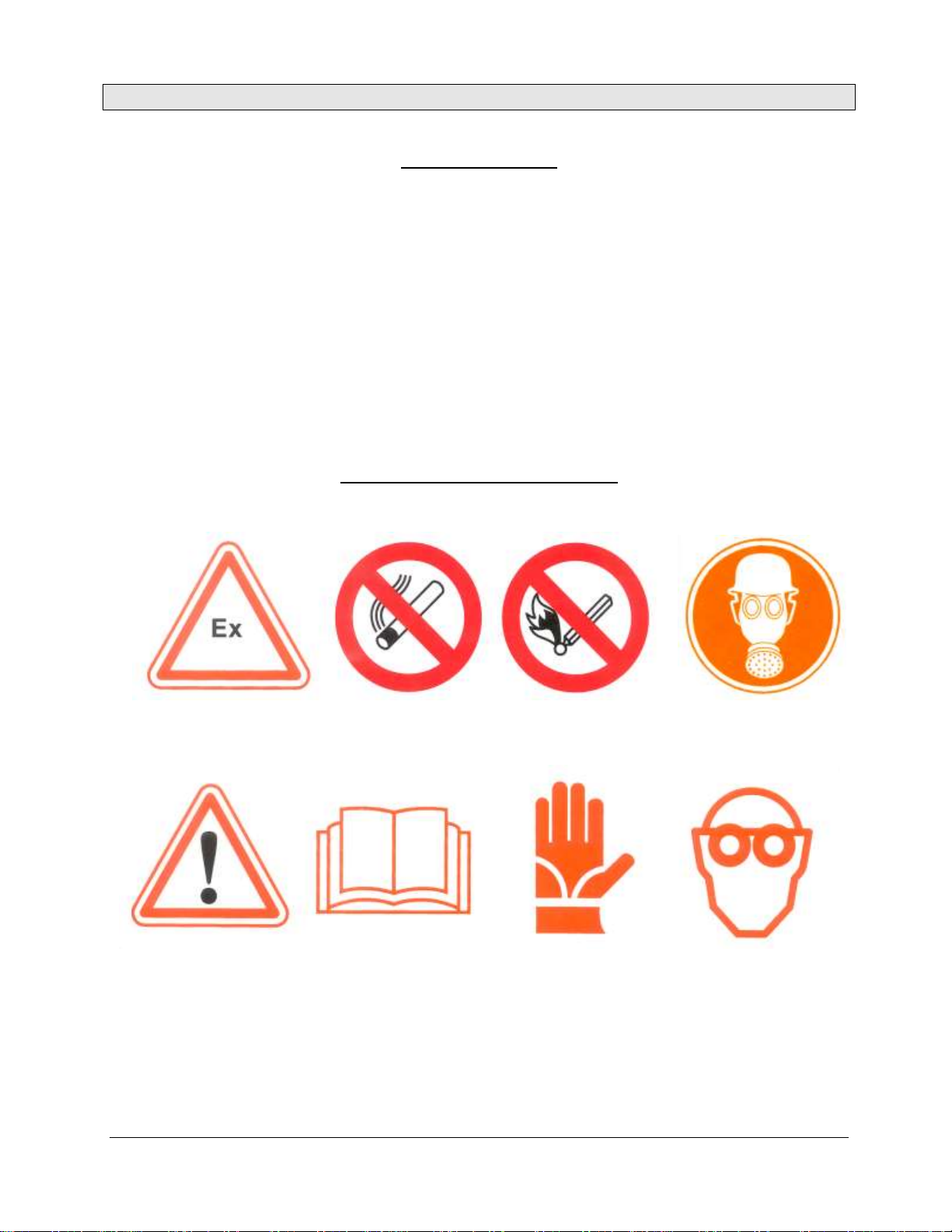

DANGER AND WARNING LABELS

DANGER

1 2 3 4

WARNING

5 6 7 8

1. Presence of flammable vapors and solvents. 5. Observe warnings at all times.

2. No smoking or metal grinding nearby. 6. Read the Instruction Manual carefully.

3. Keep away from open flames. 7. Wear solvent-proof rubber gloves.

4. Wear Breathable Air during use. 8. Wear protective eyewear before use.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

6

SAFETY AND WARNING (cont’d)

WARNING

« READ ALL INSTRUCTIONS » Failure to follow the SAFETY RULES identified by a BULLET

(°) symbol listed BELOW and other safety precautions may result in serious personal injury.

« SAVE THESE INSTRUCTIONS »

GENERAL SAFETY RULES

° KEEP WORK AREA CLEAN.

° KEEP CHILDREN AWAY. Do not let visitors come in contact with the equipment. All visitors

should be kept away from the work area.

PERSONAL SAFETY

° GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces, for

example: pipes, radiators. Solvent resisting rubber gloves and non-skid footwear is

recommended where damp or wet ground may be encountered. A ground fault circuit interrupter

protected power line must be used for these conditions.

° DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in the moving

parts. Wear protective hair covering to contain long hair.

° USE SAFETY EQUIPMENT. WEAR SAFETY GOGGLES or glasses with side shields.

° STAY ALERT. USE YOUR COMMON SENSE. Concentrate on what you are doing. Do not

operate the unit when you are tired or under the influence of drugs.

° DO NOT OVERREACH. Keep proper footing and balance at all times.

° BEFORE CONNECTING THE RECYCLER UNIT to an electric line outlet, be sure the power is

the same as that specified on the nameplate of the Solvent Recycler. An electric line with power

greater than that specified on the Solvent Recycler can seriously injure the user –as well as

damage the Solvent Recycler. If in doubt, DO NOT plug in the unit. Using an electric line outlet

with power less than the power specified on the nameplate is harmful to the motor.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

7

SAFETY AND WARNING (cont’d)

UNIT USE AND CARE

° DO NOT FORCE THE UNIT. It will perform better and safer atthe ratefor which it was designed.

° THE USE OF ANY OTHER ACCESSORIES not specified in this manual may create a hazard.

° DISCONNECT THE UNIT when not in use, before servicing.

° DO NOT ALTER OR MISUSE THE UNIT. These units are precision built. Any alteration or

modification not specified is misuse and may result in a dangerous situation.

Only trained repairmen should attempt (°) ALL REPAIRS, electrical or mechanical. Contact the

nearest Becca repair service facility. Use only Becca replacement parts, any other parts may

create a hazard.

SAFETY RULES

° THE OPERATOR MUST WEAR protective solvent-proof rubber gloves to prevent contact

between his hands and the products used for washing.

° THE OPERATOR MUST WEAR protective eyewear to prevent spatter from coming in contact

with his eyes.

° STAY ALERT at the start of the wash cycle. Make sure the solvent is not «corrosive».

Immediately stop the recycler and replace the solvent whenever you note signs of corrosion on

the unit.

° IF EYES COME IN CONTACT WITH SOLVENTS rinse thoroughly with water.

° BEFORE USING the Solvent Recycler, make sure that all safety devices are in perfect

operating condition.

° BECOME FAMILIAR WITH THE CONTROLS and their functions before commencing work.

° BE CAREFUL when you load or unload the solvent in the unit. Make sure you do not splash

or spill the contents on the workshop floor.

° THE OPERATOR MUST PERIODICALLY check the level of the clean solvent contained in the

collection pail to prevent it from overflowing.

° DO NOT USE ELECTRICAL OR PNEUMATICAL TOOLS WITH THE UNIT. AVOID

GASEOUS AREAS. Do not operate portable electric tools in explosive atmospheres in the

presence of flammable liquids or gases. Motors in these tools normally spark, and donot scrape

or scratch the machine with metal objects; the sparks might ignite fumes.

SAFETY AND WARNING (cont’d)

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

8

° DO NOT ALLOW FAMILIARITY GAINED FROM FREQUENT USE OF YOUR SOLVENT

RECYCLER TO BECOME COMMONPLACE. Always remember that a careless fraction of a

second is sufficient to inflict severe injury.

° DO NOT ALTER OR MISUSE THE UNIT. Any alteration or modifications is a misuse and may

result in serious personal injuries.

° FIRE EXTINGUISHING SYSTEMS must be installed in the same room or close to the unit in

case of emergency. These appliances must be kept efficient and inspected every year by a

certified person.

° THE INSTALLATION SITE MUST PERMIT PERSONNEL TO EASILY AND QUICKLY MOVE

AWAY FROM DANGER ZONES IN CASE OF AN EMERGENCY.

° DO NOT USE THE UNIT TO wash or degrease objects designed to come in contact with food.

° COMPLY WITH LAWS IN THE COUNTRY where the Solvent Recycler is installed regarding

the use and disposal of the products used to wash clean objects.

THINK SAFETY! SAFETY IS A COMBINATION OF THE OPERATOR’S COMMON SENSE,

KNOWLEDGE OF THE SAFETY AND OPERATING INSTRUCTIONS AND ALERTNESS AT ALL

TIMES WHEN THE UNIT IS BEING USED.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

9

WARNING FOR THE VACUUM ASSIST UNIT

The operating staff must be fully instructed on the use and function of the unit as well as on the

correct application of the protection devices. The instructions must be repeated in regular intervals.

It is essential to keep the Instruction Manual inside the door slot of the Recycler or close to the

unit.

Operator must wear anti-static clothes, avoiding clothes made of synthetic material (nylon, rayon,

etc.).

When unloading residues, it is recommended to use gloves and an anti-vapor mask.

Do not use any metallic tools as they could provoke sparks.

The unit must undergo a revision and control according to its grade of use. Maintenance must be

carried out by qualified personnel and according to the indications of the Manufacturer.

Before using a Vacuum Assist unit, which has been out of use for a long time, it must be checked

and brought back into optimal condition in order to guarantee the operator’s security at all times.

According to the type of liquid to be distilled and the kind of operation to be performed, it is

important to adopt adequate personal protection rules.

Nitrocellulose which is an ester of cellulose and nitric acid and is a component in many lacquers,

inks, adhesives and cements cannot be recycled. It automatically ignites at 135°-166°C (275°-

330°F) and can be extremely volatile.

If repairs are necessary shut off the power supply IMMEDIATELY.

Do not smoke, cause sparks or use open flames near the recycler or vacuum assist units.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

10

WARNING FOR THE VACUUM ASSIST (cont’d)

Under these conditions, the unit shall be spaced a minimum of 5 feet (1.5 meters) from potential

sources of ignition such as electrical receptacles, switches, pilot light fixtures, contacts and other

similar equipment that can produce sparks. If the equipment is used in higher ambient

temperatures an increase in spacing from sources of ignition shall be considered.

PROTECTION OF THE NATURAL ENVIRONMENT

The user must provide protection of the environment so that the recycler may not be the cause for

emission of vapors or odors and that the residues are treated and disposed of in a correct way.

VACUUM DISTILLATION PRINCIPLES

The boiling temperature of the solvents reported on pages 26-27 of the Solvent Recycler Manual

are measured for atmospheric pressure operation of 1,000 hPa (760 mm Hg).

It is well known that by reducing the pressure, theboiling temperature of any substance is reduced.

When vacuum is created inside the distillation appliance, the boiling temperature is considerably

reduced.

With Units 9711-V and 9725-V, operating with vacuum, the distillation temperature is reduced

about 30%.

Vacuum distillation is recommended in the following cases:

1. When processing solvents with ignition point too close to their boiling temperature can create

a hazard or the solvent can degenerate and become an acid base and therefore cannot be re-

used. One of the most common solvents, that have this feature, is mineral spirit (varsol). This

solvent has a boiling point at 302°-374°F (150°-190°C) and its ignition point at 489°F (254°C).

2. When processing chlorinated solvents.

Atmospheric pressure distillation allows only a partial recovery of these solvents; at the end of

the process the residues will still contain 20% of solvents.

VACUUM DISTILLATION PRINCIPLES (cont’d)

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

11

This occurs due to the fact that as long as the distillation process takes place, the percentage

of oil in the boiling solvent increases, so does the boiling temperature.

These solvents have a specific critical temperature which once exceeded, provoke the

decomposition of the solvents, causing the formation of hydrochloric acid with the consequent

acidity of the product, it will be impossible to re-use it. Operating with atmospheric pressure,

once critical temperature is reached will distill only 80% of the solvent. With vacuum distillation

it is possible to achieve a yield of 100% without reaching the critical temperature.

Examples

Product to be distilled: Perchloroethylene

Distillation temperature at atmospheric pressure: 250°F

Distillation temperature at vacuum condition (223 hPa): 183°F

Critical temperature of decomposition: 302°F

A. Boiling range of clean perchloroethylene at atmospheric pressure: 1,000 hPa.

Temperature °F

250

0 100% Quantity

B. Boiling range of clean perchloroethylene at vacuum condition: 223 hPa.

Temperature °C

183

0 100% Quantity

VACUUM DISTILLATION PRINCIPLES (cont’d)

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

12

C. Boiling range at atmospheric pressure (1,000 hPa) of a mixture of 90% perchloroethylene +

10% of oil.

Temperature °F

338

302

250

0 80% 100% Quantity

D. Distillation temperature at vacuum condition (223 hPa) of a mixture of 90% perchloroethylene

+ 10% of oil.

Temperature °C

302

248

183

0 100% Quantity

GRAPHIC (A) –(B)

The distillation temperature of a clean solvent remains the same until the process of the whole

cycle is complete.

GRAPHIC (C) –(D)

The distillation temperature of the contaminated solvents increases during the process; this

variation depends on the degree of contamination and on the type of contaminating substances.

GRAPHIC (C)

Once a temperature of 302°F (150°C) is reached, which is the critical non-supportable

temperature, only 80% of perchloroethylene will be recovered.

VACUUM DISTILLATION PRINCIPLES (cont’d)

GRAPHIC (D)

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

13

Operating with vacuum condition, 100% of perchloroethylene will be recovered when set at 248°F

(120°C) and very far from the critical temperature of 302°F (150°C).

When distilling chlorinated solvents, the vacuum distillation is indispensable; this type of process

is also necessary for minimal quantities of contaminants because of two specific reasons:

1. Yields 100%.

2. If the residual oil is contaminated with more than 2% of solvent, those oil waste-recycling

companies authorized for the waste collections will not accept it.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

14

VACUUM DISTILLATION OPERATING METHOD

Before reading this section, it is compulsory to read the previous section regarding the distillation

at atmospheric pressure.

Unlike what occurs during atmospheric distillation, the distillation unit and the distillate collection

tank are a single body.

A pneumatic vacuum pump joined at the solvent recovery tank provides the creation of the vacuum

circuit.

Boiler Condenser Tank

The vacuum pump is fed with compressed air with a maximum negative pressure of 20-27 in.Hg.

(590 mm Hg) on the gage.

NOTE: MAKE SURE TO DISTILL SOLVENTS WITH DISTILLATION TEMPERATURE

HIGHER THAN 140°F (60°C) AT ATMOSPHERIC PRESSURE.

For example, distilling at vacuum condition the Acetone, which has a distillation temperature of

133°F (56°C) at atmospheric pressure, will reach a boiling point of 101°F (39°C). Since the

condenser is air cooled, if the temperature is higher than 70°F (20°C) you will obtain a partial

condensation of the solvent with an emission of Acetone vapor in the air.

OPERATING METHODS

DISTILLATION : AT ATMOSPHERIC PRESSURE

DRYING :

When processing solvents with distillation temperature lower than 140°F (60°C), with high levels

of liquid products.

DISTILLATION : AT ATMOSPHERIC PRESSURE

DRYING : AT VACUUM CONDITIONS

When processing solvents with distillation temperature lower than 140°F (60°C), with high levels

of solid products.

DISTILLATION : AT VACUUM CONDITIONS

DRYING :

In this case the process of the solvent reducers as mentioned on page 7 (1 & 2), with distillation

temperatures between 140°-392°F (60°-200°C) , and high levels of liquid products.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

15

OPERATING METHODS (cont’d)

DISTILLATION : AT VACUUM CONDITIONS

DRYING : AT VACUUM CONDITIONS

In this case the process of the solvent reducers as mentioned on page 7 (1 & 2), with distillation

temperatures between 40°-392°F (60°-200°C), and high levels of solid products.

VACUUM SYSTEM INSTALLATION

Placing your BECCA VACUUM ASSIST SYSTEM in accordance with the same procedures

as the Solvent Recycler. (See page 7 of the Solvent Recycler Manual) Use the VACUUM

ASSIST INSTALLATION GUIDE.

PRESSURE OF COMPRESSED AIR: 4 BAR

CONSUMPTION OF AIR: 32 L/MIN

STARTING OPERATIONS

NOTE: During vacuum distillation some solvents foamwith a consequent pollution of the distillate

and vapors may leak from the cover.

The problem can be eliminated as follows:

Utilize anti-foam discs.

Reduce about 20% of the loading of solvent to be distillate.

Reduce the compressed air pressure at the vacuum pump. In that way the vacuum will be

reduced.

Reduce the working temperature.

Wait at least 48 hours after utilizing the solvent before starting the next distillation.

When filling up, pay attention not to pour solvent into the vapor manifold. The first solvent can

come out dirty.

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

16

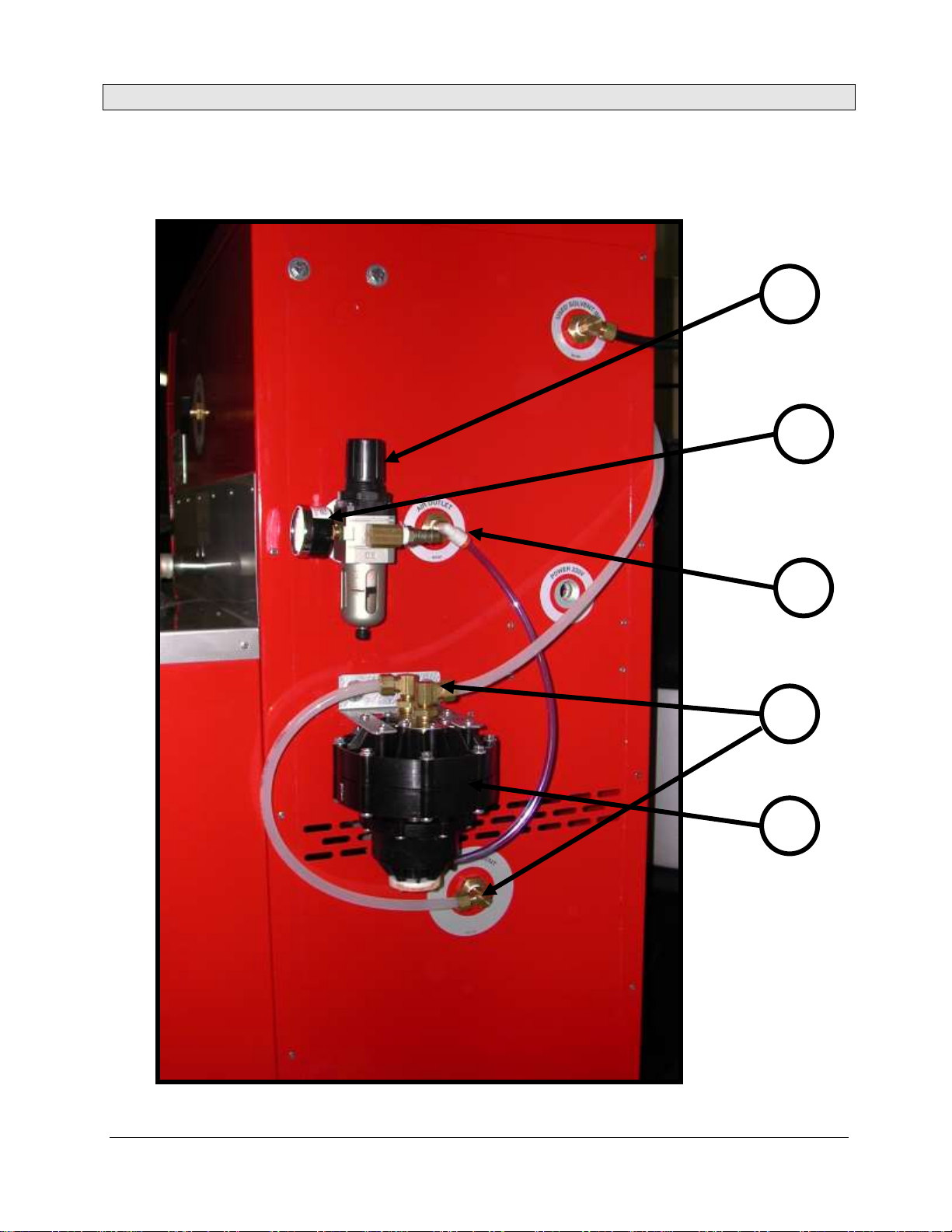

VACUUM ASSIST SCHEMATIC

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

17

VACUUM ASSIST SCHEMATIC (CONTINUED)

4

5

6

7

8

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

18

VACUUM ASSIST DIAGRAM (CONTINUED)

9

1

0

1

1

1

2

1

3

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

19

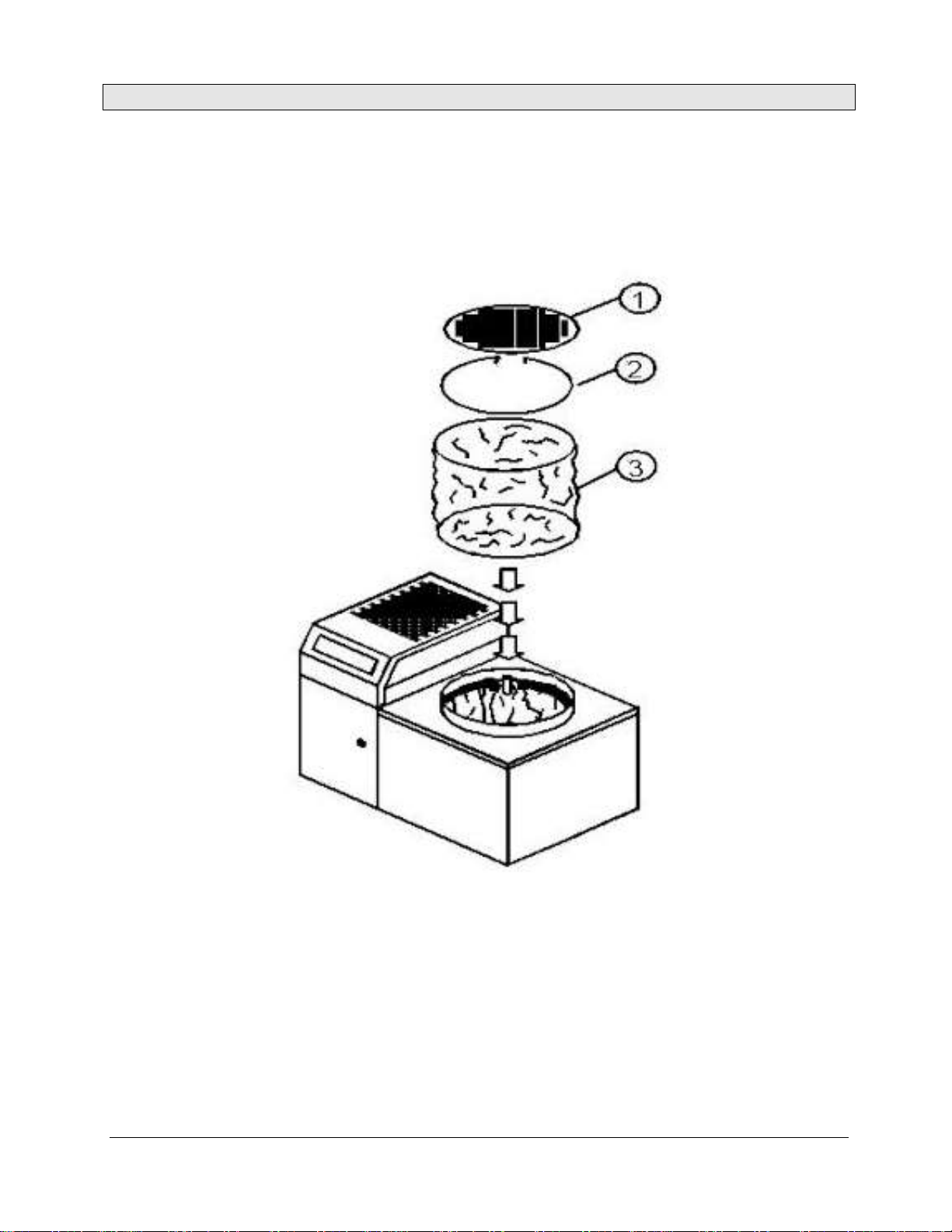

SPARE PARTS NUMBERS FOR VACUUM

INDEX

PART #

DESCRIPTION

QUANTITY

1

824021

ANTI-FOAM DISK FOR UNIT: 9711

Optional

824022

ANTI-FOAM DISK FOR UNIT: 9725

Optional

2

800011

BAG RETAINING RING: 9711

1

800012

BAG RETAINING RING: 9725

1

3

630003

PLASTIC BAG: 9711

25 or 100

660006

PLASTIC BAG: 9725

25 or 100

4

824013

FILTER & REGULATOR

1

5

824014

AIR GAUGE: 0 –160 P.s.i.

1

6

823111

ELBOW

1

7

823131

COMPRESSION FITTING

2

8

824549

PUMP

1

9

824002

VACUUM GENERATOR

1

10

824559

PUSH IN FITTING

1

11

824602

BRASS (T)

1

12

824001

VACUUM GAUGE

1

13

823131

COMPRESSION FITTING

1

824571

POLYURETHANE TUBING BLUE

824512

NYLON TUBING

824003

SOLENOID VALVE

1

Feb 2021, Rev. 1.0 BECCA INC. Instruction Manual Vacuum Assist

20

IMPORTANT NOTICE

1. Some solvents during the boiling phase create such a quantity of foam that a correct separation

of the solvent from the polluting product is not possible; in fact, in this case, the distillate will still

be dirty. To avoid this inconvenience, it will be necessary to obtain an anti-foam kit supplied as

an option.

824021 ANTI-FOAM KIT FOR: MODEL 1100 or 9711

824022 ANTI-FOAM KIT FOR: MODEL 25000 or 9725

2. Pay the utmost attention while the residue is drying; some polluting products with an increase

of temperature tend to carbonize with a considerable discharge of smoke from the apparatus.

IN CASE THIS OCCURS, IMMEDIATELY PRESS THE START / STOP KEY TO STOP THE

CYCLE.

In this case it is not possible to proceed to drying at atmospheric pressure; the problem may be

solved by proceeding to the distillation phase at atmospheric pressure and to the phase of

drying under vacuum; this technique will allow you to operate at a much lower temperature.

3. Opening the cover one hour before the distillation cycle is complete will cause the gasket to

swell.

4. Do not rotate and shake the unit once loaded or when operating.

5. The cover acts as a safety valve. In case vapors come out of the cover stop the unit

IMMEDIATELY and consult the table on page 29, "Defects, Causes and Remedies".

DO NOT MISHANDLE THE COVER LOCKING SYSTEM OR LOCK THE COVER IN ORDER

TO AVOID LEAKING.

6. Clean the diathermic oil expansion vessel only with a "wet" rag to avoid generating sparks.

Other manuals for SOLVENT SAVER

2

Table of contents

Other Becca Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Rothenberger

Rothenberger ROSANI Clean 15 Instructions for use

Ocean

Ocean Vac 8000 quick start guide

Schwamborn

Schwamborn OES 430 Translation of the original operating manual

Yamabiko

Yamabiko ECHO ProSweep MTA-PS Operator's manual

Redexim

Redexim Verti-Top Pulled User manual and parts book

Qleen

Qleen PURASTART E User information