3651 WALNUT AVENUE, CHINO CA 91710 • PHONE (909) 664-9980 • APR-Rework.com

Page 3of 79 TB-10006 REV December 2018 © 2018 DESCO INDUSTRIES INC

Employee Owned

SAFETY AND REGULATORY INFORMATION

WARNING

•TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE SYSTEM TO MOISTURE.

•TO PREVENT FIRE OR SHOCK HAZARD, DO NOT USE FLAMMABLE SOLVENTS NEAR

OR ON THE SYSTEM WHILE CONNECTED TO A POWER SOURCE.

•TO PREVENT POSSIBILITY OF INJURY OR DAMAGE TO THE SYSTEM, DO NOT

OPERATE WITH ANY COVERS OR PANELS REMOVED.

•CHANGES OR MODIFICATIONS MADE TO THIS PRODUCT WITHOUT EXPRESS

APPROVAL FROM APR COULD VOID THE USERS AUTHORITY TO OPERATE THE

EQUIPMENT.

•Read and understand the entire Operator’s Manual before installation or operation of the

Scarab Site Cleaning System. Heed all warnings on the system and in the operating

instructions.

•The Scarab Site Cleaning System is only for the removal of residual solder and/or reworkable

glue from printed circuit boards or components by properly trained personnel. If you are not

familiar with the proper and safe operation of the unit, do not operate it until properly trained.

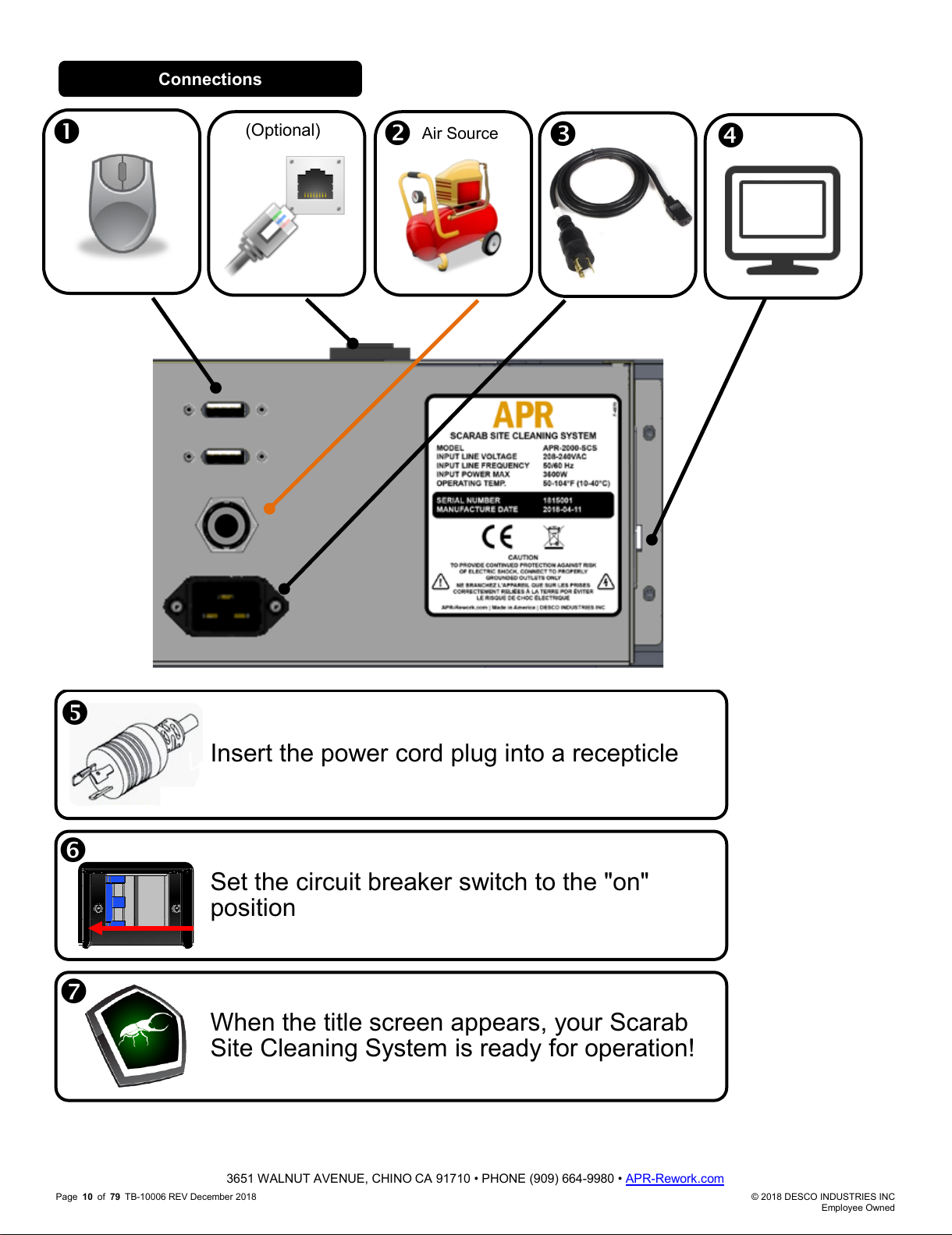

•Operate the unit from the type of power source indicated on the serial number label.

•Use only the supplied power cord. Avoid damage to the power cord. If damage should occur,

replace it with the approved APR replacement power cord.

•This CAUTION symbol on the equipment refers the user to the user guide for additional

information. This symbol appears next to the relevant information in the manual.

•This HOT symbol on the equipment warns the user of a hot surface and potential injury if

touched. This symbol appears next to the relevant information in the manual.

•This HEAVY LIFTING symbol on the packaging warns the user to team lift the Scarab Site

Cleaning System during removal from packaging and installation on the workbench. This

symbol appears next to the relevant information in the manual.

•This PINCH POINT symbol on the equipment warns the user of a potential injury. This symbol

appears next to the relevant information in the manual.

•This LASER symbol on the equipment warns the user of possible exposure to laser radiation.

This symbol appears next to the relevant information in the manual.

•This EYE PROTECTION symbol on the equipment warns the user of potential injury due to

flying debris. This symbol appears next to the relevant information in the manual.