BECHEM 125 User manual

Seite 1/20

BECHEM Lubricator 125

technical manual

Page 2/20

1. Introduction and intended use

2. Safety instructions

2.1 Use

2.2 Safety and warning instructions

2.3 Reports and certificates

3. Product setup and technical data

3.1 Setup and functionality of the BECHEM Lubricator

3.2 Technical data

4. Storage

5. Installation

6. Start of operation

6.1 Putting the BECHEM lubricator into operation

6.1.1 Activation of lubricator

6.1.2 Runtime setting

6.1.3 Interruption and recommissioning

6.2 Use of extension tubes

7. Maintenance

8. Optional component parts

9. Disassembly and replacement

10. Environment, disposal and recycling

11. Error search and error correction

Table of contents

Page

3

3

4

4

6

7

7

9

10

11

13

13

13

13

14

15

16

16

16

17

18

Page 3/20

These instructions contain impor-

tant information on function, appli-

cation possibilities, assembly and

disposal of the BECHEM lubrica-

tor and shall contribute to a maxi-

mum of safety during use and an

efficient product application.

The BECHEM Lubricator 125 is

an electrochemically driven device

for automatic supply of lubrication

points with lubricating grease or

lubricating oils. For this purpose, the

lubricator is screwed into the thread

hole of the previously removed

lubrication fitting. Over a certain

period of time it dispenses a pre-

set amount of lubricant quantity.

The lubricator is particularly suit-

able for supplying lubricant to

(difficult to access) single lubri-

cation points. It can be used at

lubrication points of plain and

roller bearings, linear guides,

shafts, spindles, roller and toothed

chains, seals, ropes and open

gears. If necessary, extension

tubes can also be used.

These safety instructions make no

claim to completeness. If you have

any questions or problems please

contact your BECHEM sales part-

ner. The BECHEM Lubricator 125

has been developed and manu-

factured according to the state of

the art and the accepted safety

regulations. Please read the follo-

wing general safety and warning

instructions carefully before putting

the lubricator into operation to

avoid personal injury or damage

to property.

When reselling this product, the

technical manual must always be

included or accessible. The latest

version can be downloaded from

https://www.bechem.de/bechem_

lubricator in several languages.

Resellers are obliged to provide

the information properly in the

respective national language.

1. Introduction and

intended use 2. Safety instructions

2.1 Use

The intended use requires that

these instructions and especi-

ally chapter 2 on safety instruc-

tions are read and observed. The

BECHEM Lubricator 125 is a pro-

duct according to the machine-

ry directive 94/9/EC. Assembly,

commissioning, operation and

maintenance should principal-

ly be carried out by trained and

qualified personnel only, as this

requires basic knowledge of me-

chanics, related technical terms

as well as of pertinent standards,

regulations and accident preven-

tion measures.

2.2 Safety and warning

instructions

The safety instructions point out

dangers of personal injury and

damage to property. Please pay

particular attention to sections

marked with this symbol:

Indicates a danger to the health of

persons, which can lead to seri-

ous injuries.

General safety instructions:

• Please note the country-specific

regulations for accident preven-

tion, environmental protection

and workplace.

• Use the lubricator only in techni-

cally flawless.

• Check the product for obvious

defects such as cracks in the ca-

sing, missing covers and seals.

• The lubricator must not be

changed, opened or modified,

otherwise the manufacturer‘s

warranty will become void and

personal injury or application

damage may occur.

• Opening the top part by remo-

ving the anthracite-colored ring

may only be performed by quali-

fied personnel.

• Please pay attention to the safety

data sheets and the technical

data sheets of the filled BECHEM

lubricants.

• Use the device exclusively in the

area of application specified in

chapter 1, introduction and in-

tended use.

• Always switch off the power

supply before assembly/disas-

sembly.

Page 4/20

Page 5/20

Safety instructions for handling

batteries:

• Avoid contact of eyes, skin and

clothing with battery substances.

• Do not swallow leaking battery

substances.

• All relevant safety data sheets

must be observed.

• Do not throw batteries into open

fire. The temperature specifica-

tions of the batteries must be

observed.

• Do not open the batteries.

• The batteries must be disposed

of according to the regulations.

Safety instructions for installation

and use:

• Wear protective gloves, protec-

tive clothing and eye protection

during installation.

• During assembly, ensure that the

lubricator and its components

are securely fastened.

• During installation and mainte-

nance on machines and systems,

the relevant operating instruc-

tions and safety instructions must

be observed and complied with.

• Ensure that all seals and covers

are correctly installed and unda-

maged to prevent the intrusion

of foreign objects.

• Make sure that all electrical con-

nections are in use or closed.

Only put a fully installed product

into operation.

• Make sure that the lubricant

supply is ensured.

Safety instructions for

maintenance:

• Do not clean the lubricator with

solvents or aggressive cleaning

agents.

• Avoid electrostatic charges by

cleaning the lubricator from the

outside with an antistatic cloth

using little pressure.

• The lubricator must be disposed

of in accordance with the rele-

vant national regulations.

Obligations of the operator:

The operator of the lubricator must

regularly inform his personnel

about the following topics:

• Observance of the technical

manual and the legal regulations.

• Correct operation and use of the

lubricator.

• Observe the instructions of the

factory security and the opera-

ting instructions of the operator.

• Behavior in case of emergency.

Page 6/20

2.3 Reports and certificates

The lubricator has been tested by

the following testing institutes:

• Fraunhofer-Institut für Grenzflä-

chen und Bioverfahrenstechnik

• FMPA Forschungs- und Material-

prüfungsanstalt Baden-Württem-

berg

•Food testing values and food law

regulations were met

• Prüflabor ELMAC GmbH

CE test certificate No. 76087-

1BCD

• Physikalisch-Technische Bun-

desanstalt (PTB) Certificate of

conformity

• DEKRA EXAM GmbH

• Specialist office for safety of

electrical equipment

• EC type-examination certificate

for explosion endangered areas

BVS 03 ATEX E 223 according to

directive 94/9/EC

• 2nd supplement to the test

report BVS PP 03.2138 EC

Page 7/20

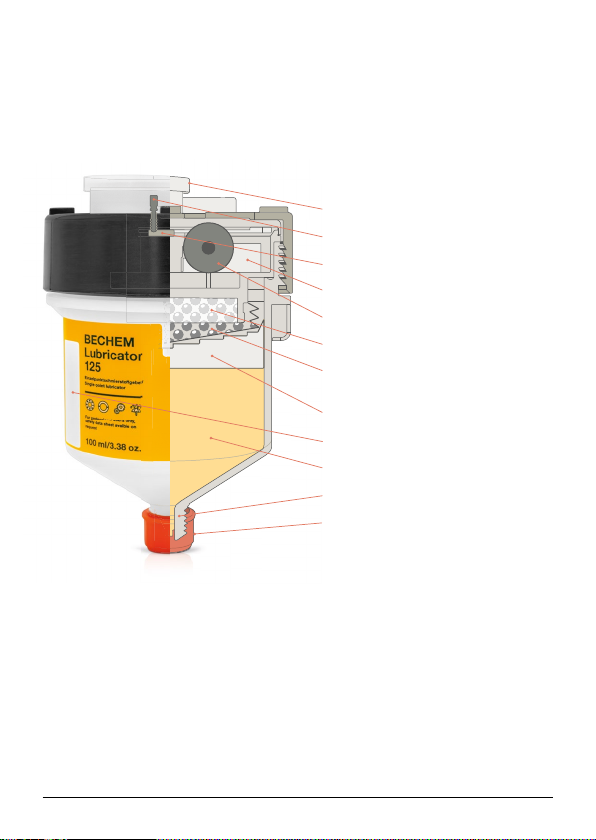

3.1 Setup and functionality of

the BECHEM Lubricator

The BECHEM Lubricator 125 is

activated by closing the con-

tacts by using the jumper. This

triggers an electrochemical re-

action, producing nitrogen as an

intermediate product, which leads

to a pressure build-up in the ni-

trogen chamber. This pressure

is transferred to the piston by a

bellow. The piston displaces the

lubricant, which is supplied to

the lubrication point via the outlet

opening. The lubricant delivery

quantity can be regulated by four

jumper positions (see setting the

running time under 6.1.2).

3. Product setup and

technical data

Page 8/20

The lubricator can be used inde-

pendent of the position. A visual

control of the filling level is possible.

After expiration of the operating

time the lubricator will be replaced

by a new unit. The housing is

weatherproof, splash-proof, corro-

sion resistant and offers protection

against temporary submersion

(IP67).

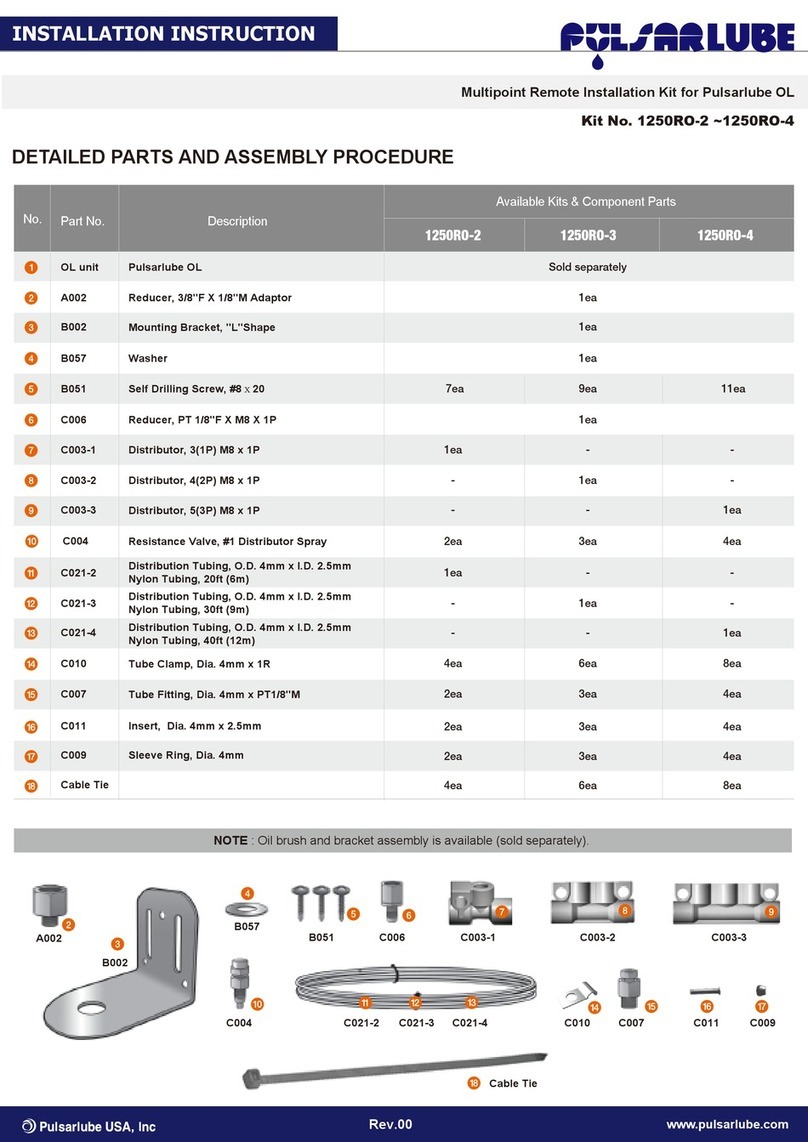

Basic concept

BECHEM Lubricator 125

Cover

Jumper

Electronic board

Battery chamber

Batteries

Nitrogen chamber

Electrochemical

pressure buildup

Piston

Fill level indicator

Lubricant

Outlet threat

Screw cap

Fassung 4 – nur EN US

BECHEM Lubricator 125

Page 9/20

Type BECHEM Lubricator 125

Content 100 ml

Measurements:

height x diameter

130 x 80 mm

Connection thread G ¼

Tare weight approx. 230 g

Operating pressure up to max. 5 bar

Operating voltage 3 V

Battery capacity 3000 mAh

IP 67

Battery (standard version) Varta Industrial 4006 (firmly

installed, no change intended)

Service temperature range approx. -20 °C – +50 °C

Relative air humidity 30 % – 80 %, non-condensing

Lubrication duration, adjust-

ment range

3, 6, 9 and 12 months

Explosion protection BVS 03 ATEX E 223

Identification 8II 2G Ex ib IIC T4 / T3 Gb

I M2 Ex ib I Mb

3.2 Technical data

Page 10/20

Observed standards and guidelines

RL 94/9/EG Devices and protective systems for

use as intended in potentially explosive

atmospheres

RL 98/37/EG „Safety of machines“

RL 97/23/EG „Safety of pressure equipment“

RL 89/336/EWG „Electromagnetic compatibility“

EMC Guideline

Storage conditions for the lubri-

cator and its components:

• Relative air humidity 30 % – 80 %,

non-condensing.

• No direct sunlight.

• Storage temperature

-20 °C – +50 °C.

• The storage period depends on

the intended duration: based on

a total sum of 24 months, this

results in for 9 months running

time a storage time of 15 months,

4. Storage

for 12 months a storage time of

12 months.

• The lubricant may leak if stored

improperly.

• Store the lubricator with the

opening pointing downwards.

• Before storage, check lubricator

for leak-tightness.

• Too long storage time or improper

storage can lead to malfunctions

of the lubricator.

Page 11/20

Before mounting the lubricator

the bearing/lubrication point has

to be greased properly with a

hand operated grease gun. Possi-

ble blockages and resin deposits

have to be removed professional-

ly before. The applied pressure for

lubrication of the bearing or actu-

ator should not exceed 0.5 bar.

Then remove the grease fitting

from the casing.

Screw in a suitable adapter (con-

nection thread BECHEM Lubricator

125: G ¼). Before screwing in

the lubricator the adapter must

be completely filled with the lu-

bricant. Mount the lubricator by

screwing it down with a tightening

torque of 6 Nm (at 20 °C). If a hose

extension to the lubricating point

is used, it should be filled with the

same BECHEM lubricant as the

lubricator.

5. Installation

Page 12/20

Remove the transparent protec-

tive cover from the lubricator cas-

ing and activate the lubricator first

by short-circuiting contacts A with

the jumper provided. For setting

the running time, please refer to

ch a pte r 6 .1. 2.

At temperatures above +50 °C,

the lubricator must be distanced

from the heat source by means of

a tube extension (Attention: Note

the length of the line), see chap-

ter 6.2. For lateral mounting of the

lubricator we recommend a pipe

clamp (see chapter 8).

• The lubricator may only be in-

stalled by qualified personnel

(see general safety instructions

on page 3).

• Wear protective gloves, protec-

tive clothing and eye protection

during assembly.

• Do not install the lubricator direct-

ly on vibration sources.

• Do not install the lubricator on

heat sources.

• A protective cover is recom-

mended for outdoor installation.

• The lubricator must not be in-

stalled in electromagnetic areas.

Page 13/20

6.1 Putting the BECHEM lubri-

cator into operation

Before the lubricator is installed,

the lubrication points must be pre-

lubricated sufficiently to remove

possible blockages and resin de-

posits. For this purpose a hand

operated grease gun with nano-

meter is suitable.

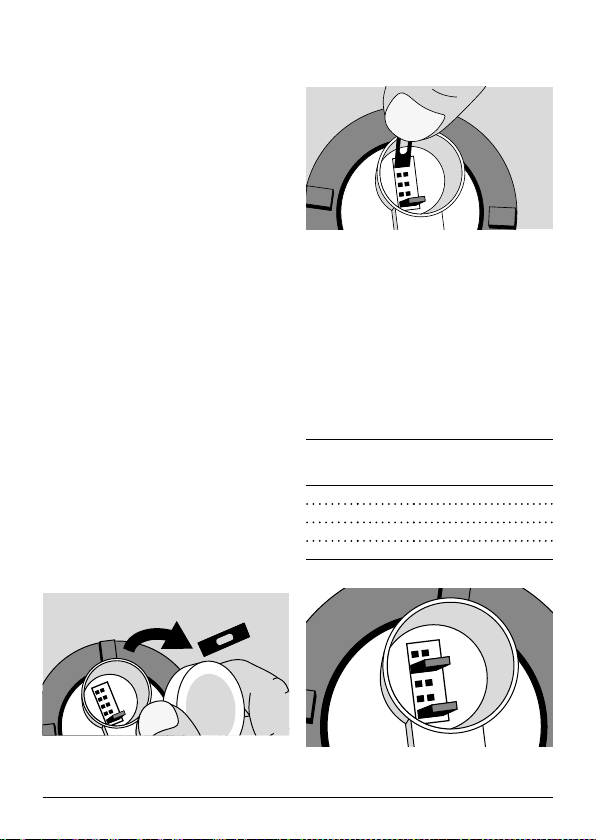

6.1.1 Activation of lubricator

If the lubricator is mounted on

the lubrication point, remove the

transparent protective cover from

the upper part of the casing and

activate the lubricator with the

supplied loose jumper. To do this,

plug it into position A as shown in

the illustration. The jumper on the

slot not marked with a letter is a

spare jumper.

6. Start of operation

A

B

C

D

A

B

C

D

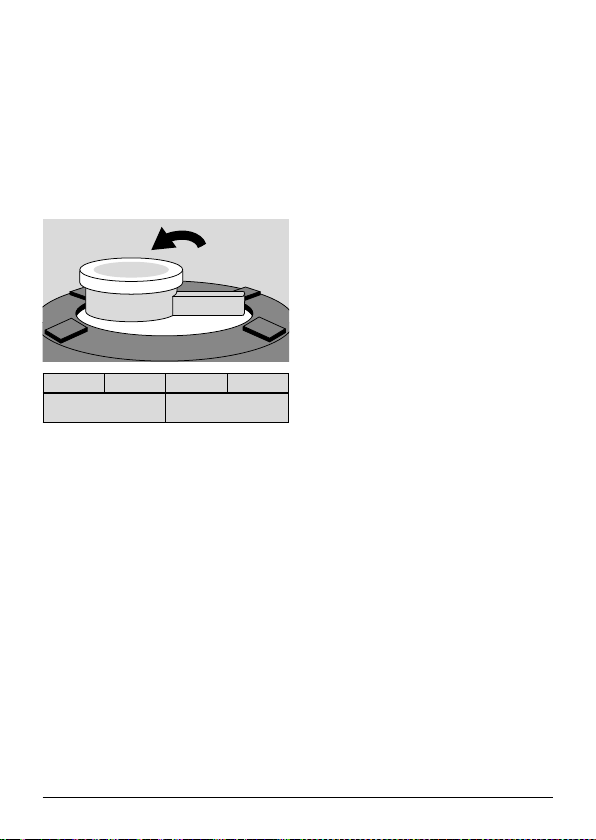

6.1.2 Runtime setting

Within 24 hours the pressure is

built up in the lubricator. After

pressure build-up place the jumper

to the desired running time A, B, C

or D.

Position Duration Daily lubricant release at

filling with grease (appro-

ximate values)

A 1 month 3,33 cm3

B 3 months 1,11 cm3

C 6 months 0,55 cm3

D 12 months 0,28 cm3

A

B

C

D

Page 14/20

After setting the running time, the

sealing cover must be carefully re-

placed. The installation date and

running time can be marked on

the label.

1 3 6 12

Installed: Expired:

When filled with lubricating oil, the

running time is extended by up to

40 %. Due to various influencing

variables such as ambient tempe-

rature, length of the extension line

and different lubricant properties,

e.g. density, the above values are

only a rough guide. If the lubrica-

tor is not activated by occupying

slot A, but the jumper is plugged

directly into the desired running

time, the pressure build-up times

are extended: A = 1 day, B = 3 days,

C = 6 days, D = 10 days.

The running time and lubricant

delivery quantity of the lubricator

may vary if the optimum operating

temperature/ambient temperature

changes over a longer period

of time. Short-term temperature

deviations up or down have little

or no influence on the total running

time of the lubricator.

6.1.3 Interruption and recom-

missioning

By removing the jumper, the lubri-

cant delivery is interrupted. The

pressure built up in the nitrogen

chamber is maintained for about

five days. After reactivation of the

lubricator the lubricant delivery

starts again with a short time delay.

The slot (the running time) can be

changed if required when reacti-

vating the lubricator.

Page 15/20

• Check the lubricator for external

damage.

• Check the installation of the lubri-

cator.

• Check the filling level and func-

tion of the lubricator regularly.

• Check whether the jumpers are

set correctly.

• Protect the lubricator from direct

overheating.

6.2 Use of extension tubes

If supply lines are installed between

lubricator and lubrication point,

these must be filled with the same

lubricant used in the lubricator

before installation. A mixing of dif-

ferent lubricants must be avoided

at all costs. The length of the supply

lines depends on the consistency

of the lubricating grease or the

viscosity of the lubricating oil as

well as on the respective environ-

mental parameters. When using

lubricators with oil filling, it is re-

commended to install a 0.2 bar

non-return valve upstream of the

lubrication point to prevent the

line from running empty.

Lubri-

cant

Max. length of

the line

Required min.

inner diameter of

the line

Greases,

pastes

0,5 m 6 mm

Oil 2 m 6 mm

Only one lubricator should be used

per lubrication point. A lubrication

point requiring more lubricant can

be additionally supplied with 2 lubri-

cators via a T-lead-in-connector.

Page 16/20

• The lubricator must not be

opened.

• Make sure that no liquid can in-

gress.

• Clean the lubricator only from

the outside.

• Clean the lubricator only with a

damp cloth.

• Do not use any aggressive sol-

vents or cleaning agents.

• Check the grease level and func-

tion of the lubricator regularly.

7. Maintenance

Please contact us regarding pos-

sible component parts for the

BECHEM Lubricator 125.

8. Optional

component parts

Installation dimensions „pipe

clamp“ for mounting the BECHEM

Lubricator 125:

Mounting dimensions in mm

Typ A B C D

125 112 95 6,5 16

• Switch off the lubricator and the

system before carrying out any

assembly work.

• Deactivate the lubricator by re-

moving the jumper.

• If the lubricator is fixed with a

pipe clamp, loosen the clamping

screw of the pipe clamp.

• Remove the lubricator and close

the outlet opening.

• Now install a new lubricator,

retighten the clamping screw.

9. Disassembly and

replacement

B

C

A

D

Page 17/20

• Avoid contact with possibly lea-

king lubricant. The lubricant can

cause irritation of the skin and

mucous membranes and conta-

minate clothing.

• Wear protective gloves, protec-

tive clothing and eye protection.

• When using oil, the outlet open-

ing should point upwards after

removing the lubricator and be

closed with a cover.

• BECHEM lubricators must be dis-

posed of according to the natio-

nal regulations of the respective

country.

• Used BECHEM lubricators can

be returned to the manufacturer

ALS, where they will either be

recycled or disposed of by a

certified waste management

company.

• Lubricant residues must be dis-

posed of according to the safe-

ty data sheets of the respective

lubricant.

10. Environment, disposal

and recycling

Page 18/20

11. Error search and error correction

Observation Possible causes Proposed solution

There is no lubricant

release.

The lubricator is not activa-

ted or the jumper is inserted

incorrectly or the contact is

short-circuited.

Plug the jumper in

correctly according

to the operating

instructions.

The jumper was not placed

on slot A for activation but set

directly to a longer running

time B, C or D. Result:

pressure build up 3 to 10 days.

Change the jumper to

A and plug it into the

slot for the desired

running time after

pressure is built up.

The bearing to be greased is

blocked.

If necessary, clean

the bearing properly

and lubricate it with a

hand operated grease

gun.

Batteries have no charge. Replace the lubricator.

Water in the plastic

cover/condensation

water.

Aggressive cleaning by high-

pressure cleaner.

Replace the lubricator.

The cover was not placed

correctly (does not seal).

Replace the lubricator.

Page 19/20

The information, data and

notes provided in this technical

manual corresponded to the

atest status at the time of publi-

cation. Details, illustrations and

descriptions may differ from

those of lubricators already

supplied. Claims based on them

cannot be asserted. BECHEM

does not assume any liability

for damages and malfunctions

resulting from improper hand-

ling, improper use or disregard

of the technical manual of the

BECHEM lubricator.

© Copyright ALS Schmiertech-

nik GmbH & Co. KG and CARL

BECHEM GMBH

BECHEM and BECHEM Rhus-

blüte are registered trademarks

of CARL BECHEM GMBH.

Logos, pictograms, and illus-

trations depicted in this ma-

nual are subject to copyright

protection. Any authority of

disposal, such as copying and

passing on rights, is with ALS

Schmiertechnik GmbH & Co. KG

and CARL BECHEM GMBH.

We reserve the right to make

changes.

Seite 20/20

MADE IN GERMANY

CARL BECHEM GMBH

Weststr. 120 · 58089 Hagen · Germany · Phone +49 2331 935-0 · Fax +49 2331 935-1199

Manufactured for BECHEM by ALS Schmiertechnik GmbH & Co. KG

Maybachstr. 32 · 71332 Waiblingen · Germany · Phone +49 7151 5020830

+49 (0) 6131-232466 (Poison Emergency Call Mainz)

Table of contents

Popular Lubrication System manuals by other brands

Gruetzner

Gruetzner Lubricus M operating instructions

Lincoln

Lincoln 85418 instruction manual

Atlas Copco

Atlas Copco BLG 30 Safety and operating instructions

Sealey

Sealey SM221 instructions

Barudan

Barudan BEVT Series instruction manual

Alemite

Alemite Carbon Shield Installation, operation and maintenance manual