Locating Blockage in Series-Flo®Systems

Page 2

30101

R

PERFORMANCE INDICATORS

Trabon®Performance Indicators are pressure-sensitive devices

that pinpoint excessive pressure in Trabon series progressive

lubricating systems. These devices, which are installed in the

indicator ports of divider valves, signal a fault either by causing

an indicator pin to protrude or by releasing lubricant to the

atmosphere.

All Performance Indicators respond quickly to protect the lube

system and locate lube line blockage. Two of these devices - the

Reset Indicator with Memory and the Rupture Indicator - will stop

lube system operation when a fault occurs. If, however, lube

system operation must continue in spite of a single line being

blocked, the Automatic Relief Indicator should be used. Rupture-

to-Atmosphere Indicators for Trabon pumps are also included.

It is recommended that some type of Performance Indicator be

used to monitor every working outlet of a Trabon Centralized

Lubrication System.

Reset Indicator with Memory —

Reset Indicators stop lube system operation when a fault occurs.

These devices can be used in either master or secondary divider

valves. When a lube line becomes blocked, the resultant high

pressure pushes the indicator pin through the opening in the cap.

The high pressure prevents the affected divider valve piston from

completing its cycle, causing a pressure backup through the

divider valve which trips a pressure switch upstream from the

valve and shuts off the pump. The indicator pin remains extended

until it is reset manually. This helps locate the lube line that is

blocked.

Rupture Indicator —

Rupture Indicators are used on MSH divider valve applications

where lube system pressures exceed 2500 psi. The high

pressure from lube line blockage causes a disc to rupture. The

lubricant then forces an indicator pin to protrude, locating the

blockage. The high pressure backs up through the system and

trips a switch to shut the system off. When the fault is corrected,

the disc must be replaced and the pin reset manually.

Automatic Relief Indicator —

These Performance Indicators pinpoint lube line blockage but

allow the lube system to continue to supply lubrication to points

that are not blocked. They are used primarily in secondary

divider valves. The excessive pressure created by line blockage

moves a piston, enabling the lubricant to escape through a vent.

When the pressure is relieved, the spring resets the piston.

Because these devices permit the lube system to keep operating

when a lube point is blocked, a separate pressure switch

connected to an audible or visual alarm should be used to warn

of high pressure.

Rupture-to-Atmosphere Indicator —

These indicators, which are standard on all Lubriquip pumps,

provide pump protection and give visual indication of excessive

system pressure. The pressure disc ruptures at a predetermined

pressure setting, venting lubricant to the atmosphere and

relieving the high pressure. A spud assembly is available to

return vented lubricant to the reservoir by way of a tube. A high

pressure switch is recommended to provide an audible or visual

warning alarm that high system pressure has occurred.

LOCATING BLOCKAGE

If a blockage exists in a Trabon Series-Flo system it is caused

by one of the following reasons:

(1) Crushed transmission line in the System.

(2) Blocked bearing in the system.

(3) Improperly drilled fitting in the system.

(4) Blocked divider valve in the system.

All servicing and disassembling should be carried out under

the cleanest conditions possible. A blockage in a Trabon

Series-Flo system will be centrally signalled by a pressure

gauge, pressure switch, controller or by the pump relief

indicator, exhausting lubricant. Before proceeding as outlined,

make a visual inspection of the system and check for crushed

lines or improper divider valve installation. Verify that each

divider valve outlet required to discharge lubricant can do so

and that no pipe plugs have been installed in an outlet

designed to serve a bearing or another divider valve.

Use Filtered Lubricant Only.

Note: Dirt and foreign material are the worst enemies of any

lubricating system.

Procedure —

Step No. 1 —

Use a manual pump with a gauge. Fill the pump with clean,

filtered lubricant common to the system. Connect the manual

pump into the inlet of the master divider valve and slowly

operate pump. If system will not cycle freely below 1,500 PSI,

see Step 2.

Step No. 2 —

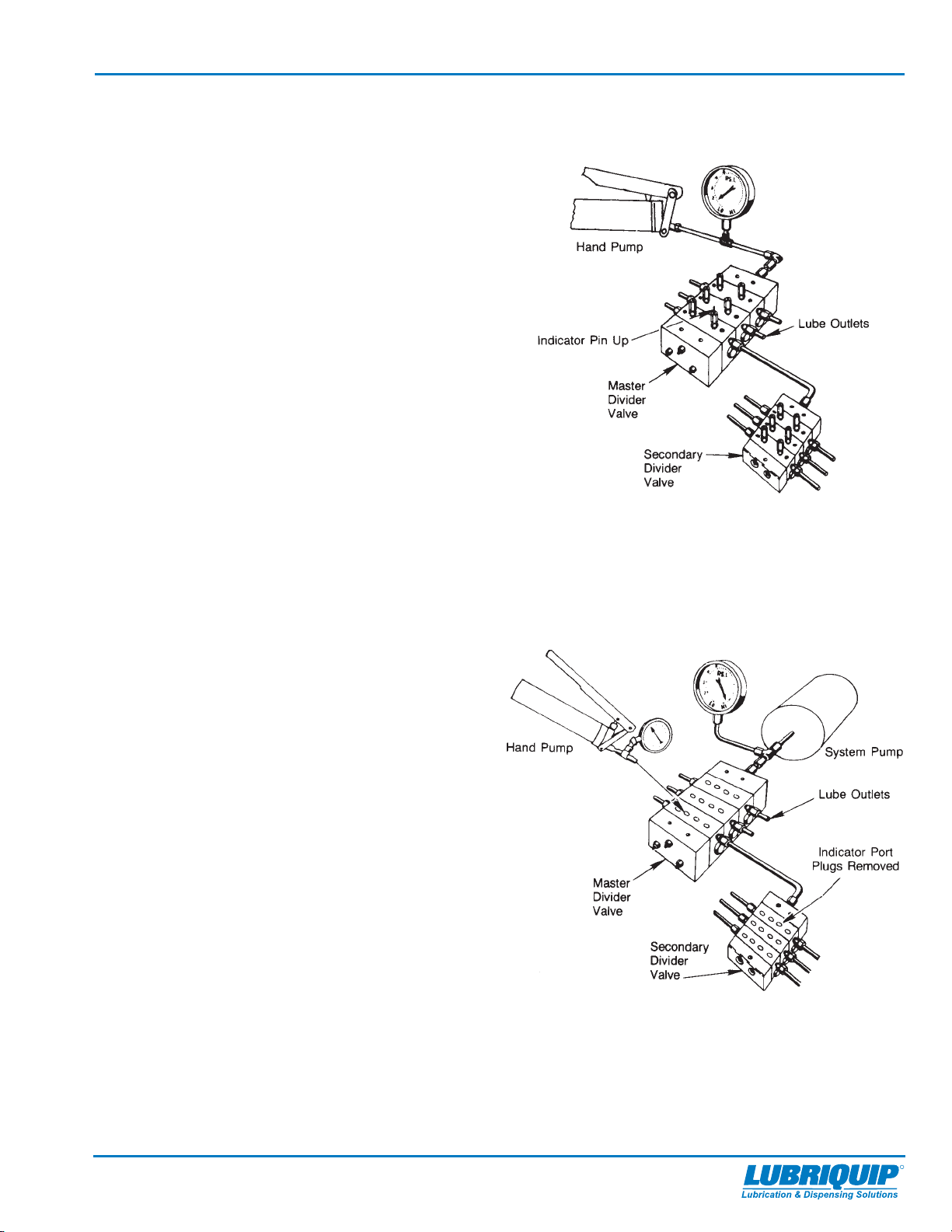

2-1. Master Divider Valve Equipped With Performance

Indicator:

With manual pump connected to the master divider valve as

outlined in Step 1, raise pressure to 2,000 PSI, the indicators

in the indicator ports will signal the location of the blockage.

An indicator in the up position indicates pressure is in that

outgoing line and signals the blockage is in the area being

served from this outlet, as shown in Figure C. See Step 3.

If no indicator pins are protruding, the blockage is in the

master divider valve.

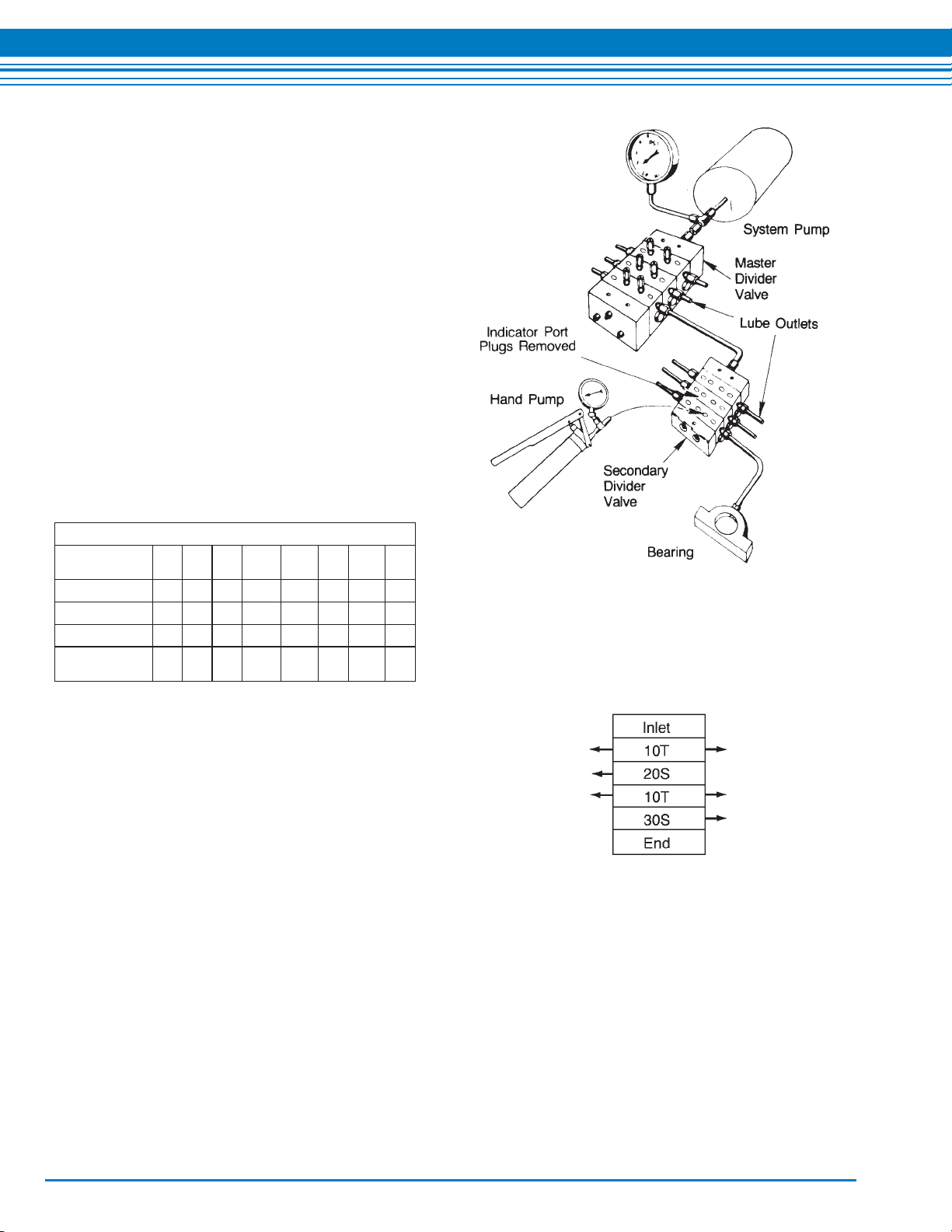

2-2. Master Divider Valve Without Performance

Indicators:

With pressure on the master as outlined in step 2-1, remove

one at a time each indicator port plug and attempt to operate

manual pump after each plug is removed. Do not exceed

2,000 PSI. If pressure drops and master cycles freely after an

indicator port plug is removed then blockage is downstream in

the area that is being served from that outlet. See Step 3.

If all indicator port plugs are removed and master will not

cycle, blockage is in this divider valve.

Note: When indicator port plug of a blocked area is removed

a small shot of trapped lubricant will usually surge out of this

outlet as the inlet pressure on the divider valve drops.

If testing in Step 2 (1 or 2) indicates a blockage in the master

divider valve, this divider valve must be disassembled and

cleaned. See Step 5 for instructions on correct procedure.