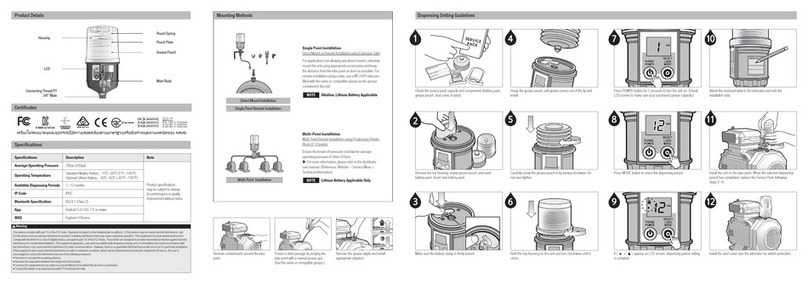

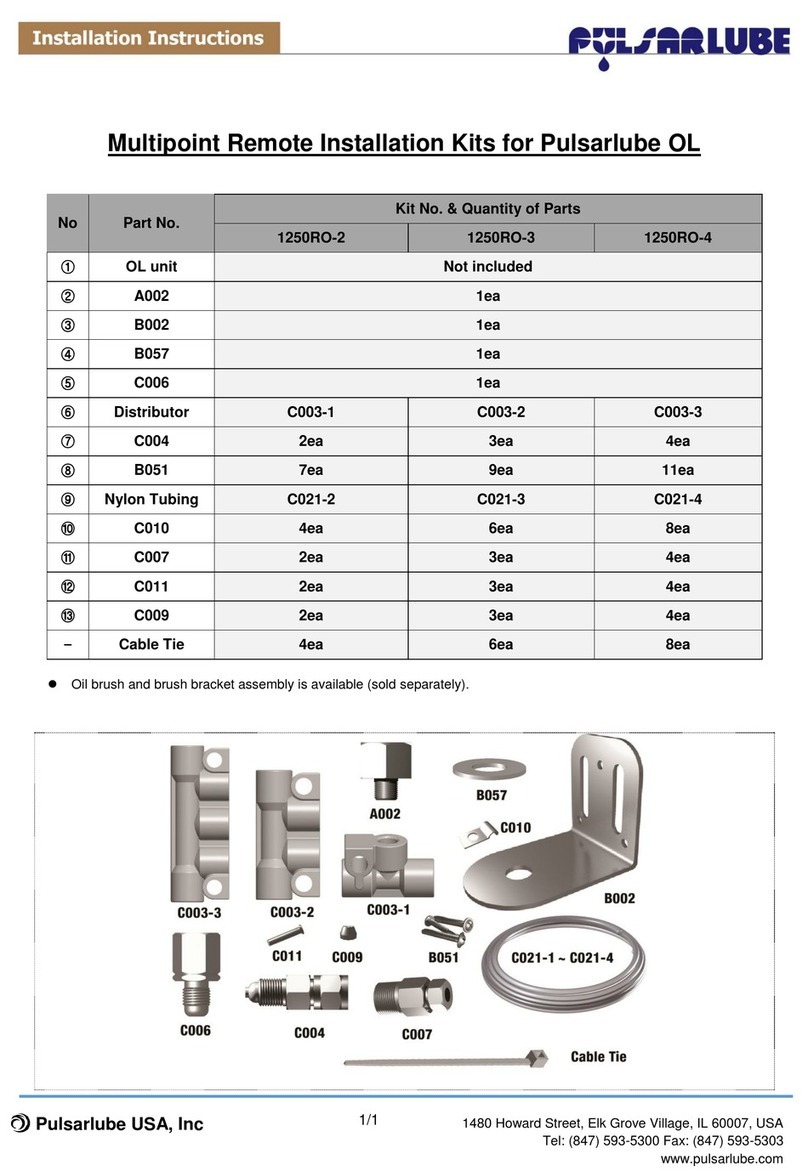

Kit No. 1250RO-2 ~1250RO-4

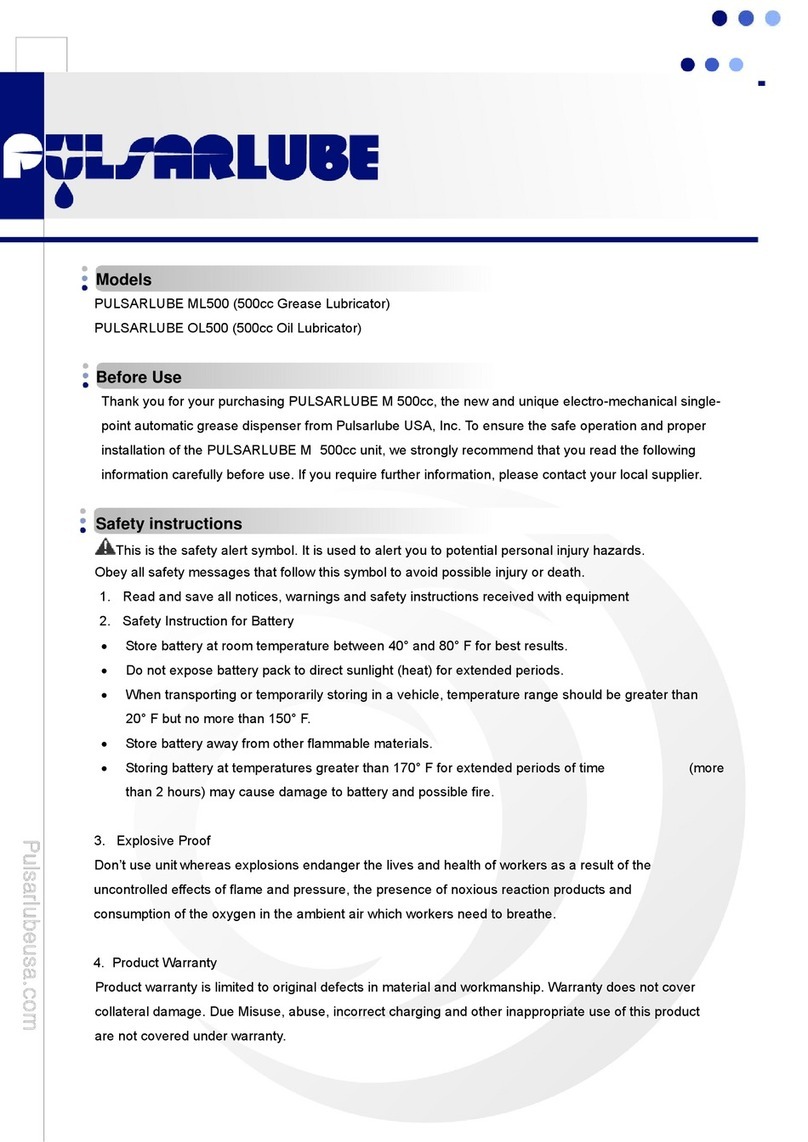

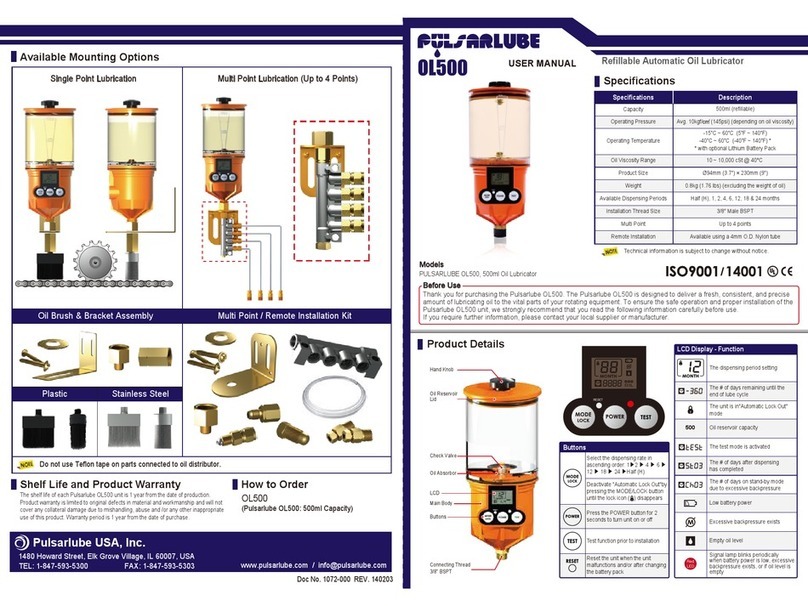

Warning

For oils below ISO VG 100, place the oilers below the lube points

and twist the lube lines a couple of times to avoid oil leaks caused

by gravity.

For oils below ISO VG 100 – OL500 products should be installed

below the lube points.

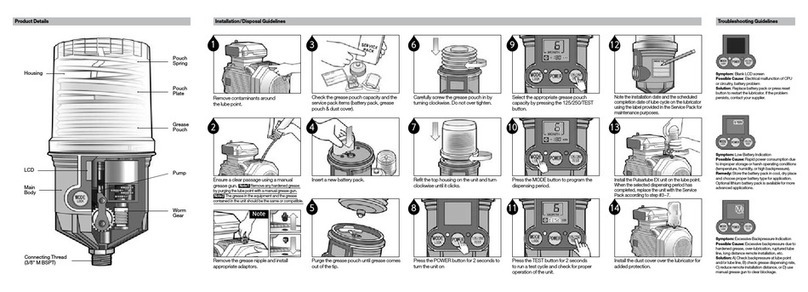

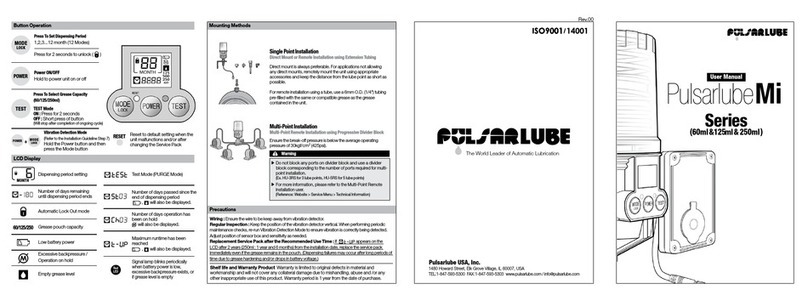

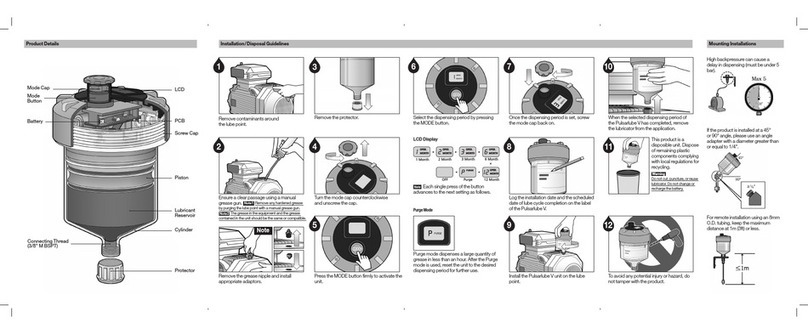

INSTALLATION INSTRUCTION

DETAILED PARTS AND ASSEMBLY PROCEDURE

www.pulsarlube.com

Multipoint Remote Installation Kit for Pulsarlube OL

Rev.00

OL500 Unit

B057

C006

C003-1

C003-2

A002

B002

C021-2 C021-3

B051

C003-3

C009

C004

C004

C004

Reducer, PT 1/8"F X M8 X 1P

Distributor, 3(1P) M8 x 1P

Distributor, 4(2P) M8 x 1P

C010

Tube Clamp,

Dia. 4mm x 1R

Distributor, 5(3P) M8 x 1P

Resistance Valve, #1 Distributor Spray

C007

Tube Fitting,

Dia. 4mm x PT1/8"M

Washer

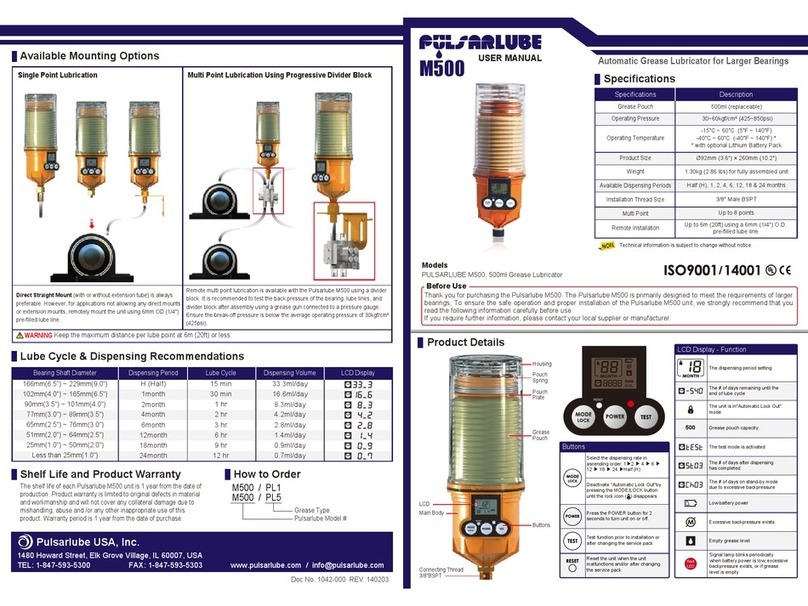

Pulsarlube OL500

Reducer, 3/8"F X 1/8"M Adaptor

Mounting Bracket, "L"Shape

Distribution Tubing,

O.D. 4mm x I.D. 2.5mm

Nylon Tubing 20ft (6m)

Ø4 X Ø2.5 Insert

Sleeve Ring, Dia. 4mm

Distribution Tubing,

O.D. 4mm x I.D. 2.5mm

Nylon Tubing 30ft (9m)

C021-4

Distribution Tubing,

O.D. 4mm x I.D. 2.5mm

Nylon Tubing 40ft (12m)

Self Drilling Screw, #8 X 20

11

11

C011

12

ASSEMBLY PROCEDURE

1. Install the mounting bracket ( ) at a proper location using

screws ( ) to allow for easy installation and filling of oil.

Apply PTFE Tape around the thread on fittings ( ) and ( )

and on the tip of the lubricator.

Do not use PTFE Tape on parts ( ) , ( ) , or ( ) .

Output volume may vary depending on oil viscosity, length of

lube line, ambient temperature, etc.

2. Install the lubricator using the reducer ( ), washer ( ),

and reducer ( ).

3. Remove the oil reservoir lid and fill the cartridge with oil to

the 500ml level on the label. Turn the hand knob counter

clockwise 1~2 turns before closing the lid to open the vent

and relieve vacuum pressure.

4. Press the “TEST” button for 2 seconds to run test mode.

Confirm that the unit is dispensing oil properly.

5. Assemble the reducer ( ) and the fitting connector ( ).

6. Connect one end of the tubing to the resistance valve ( )

and the other end of the tubing to the fitting connector ( ).

Assemble the insert ( ) and sleeve ring ( ) in order, as

shown in the circled image on the left.

( If an oil brush and bracket assembly is to be used, connect

brush to a fitting connector ( ) at the end of lube line using

an appropriate socket. )

7. Use the tube clamps ( ) and screws ( ) to affix the tubing

( ) to a wall.

8. Install lubricator and follow lubricator operation insturctions

on user manual.

COMMENTS

ox

NOTE : All parts above are Metric thread.