High-Pressure Pump (Stationary and Portable)

SER 8540-A1

Alemite Corporation 3 Revision (7-98)

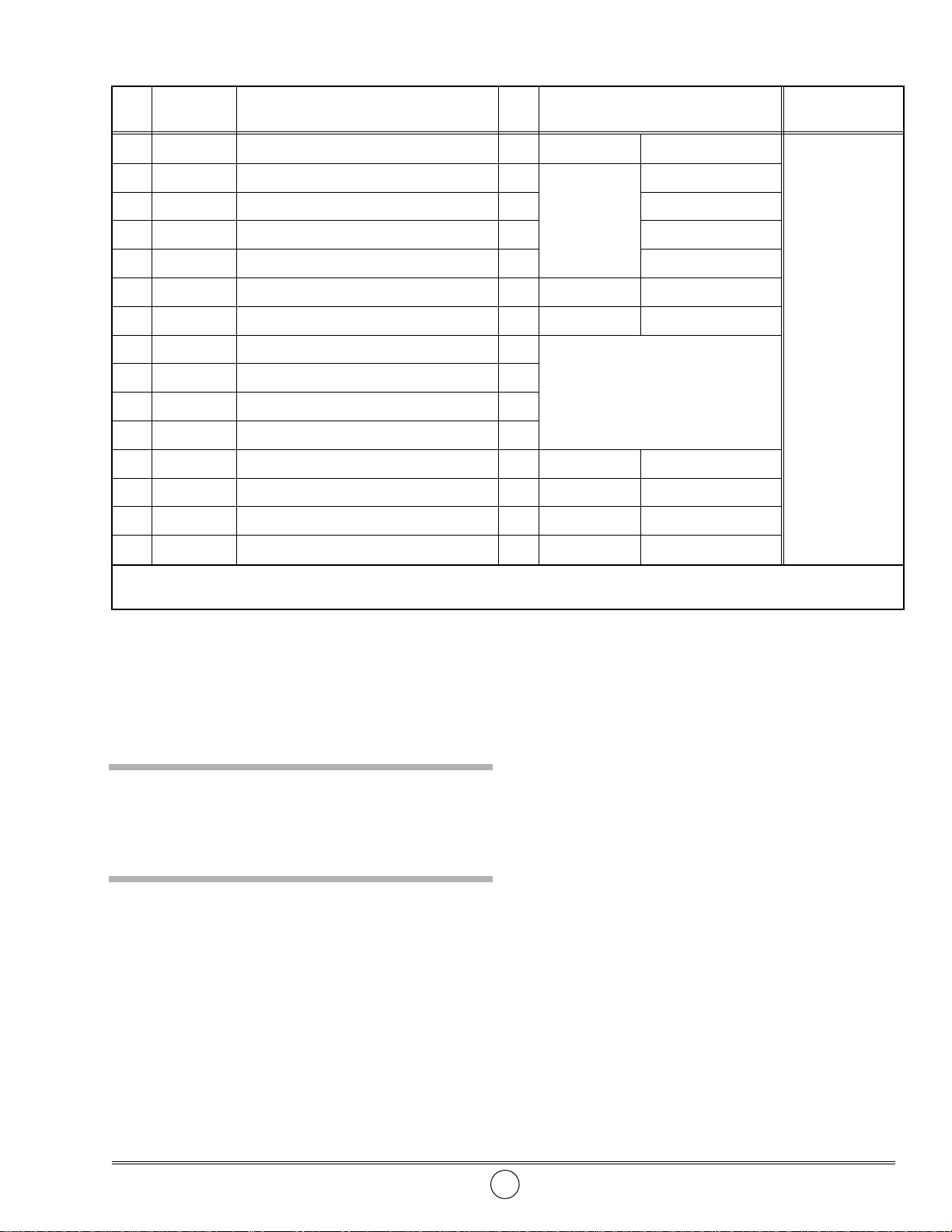

Item

No. Part No. Description Qty Notes Numeric Order

Part # (Item #)

18540-B Pump Assembly, High-Pressure 1 See SER

8540-B

6320-3 (4)

2 317875-7 Hose Assembly, Material 1

Model 8541-5

8540-B (1)

3 44734 Adapter, 3/8 “ NPTF (m) x 1/2 " -27 1

17804

(8)

4 6320-3 Valve Assembly, Control 1 See SER

6320-3

44734 (3)

5 B52752 Z-Swivel Assembly, High-Pressure 1 See

Figure 3

48018 (11)

6 315943 Bushing 1 B52752 (5)

7 338371 Cover Assembly 1

77009

(12)

8 Washer, 1/4 " 3

Included w/ 338371

77786

(10)

9 Washer, Lock, 1/4 " 3

170561

(13)

10 Capscrew, 1/4 " -20 x 1/2 " 3

172207-1

(9)

11 48018 Screw, Thumb, 1/4 " -28 x 1-1/8 " 3 315953 (6)

12 Washer, Internal Tooth Lock, 1/4 " 1 316315-5 (15)

13 Screw, 1/4 " -20 x 5/16 " 1 317875-7 (2)

14 338802 Plate, Follower 1 320998-B4 (7)

15 316315-5 Dolly Assembly 1 Model 8541-5 See SER

316315-5

338802 (14)

Legend

:

Part numbers left blank (or in

italics

) are not available separately

Assembly

NOTE

: Refer to

Figure 2

for component

identification on all assembly procedures.

CAUTION

Select a clean environment for all assembly proce-

dures. Prevent contamination from foreign mate-

rial. Damage to components can occur.

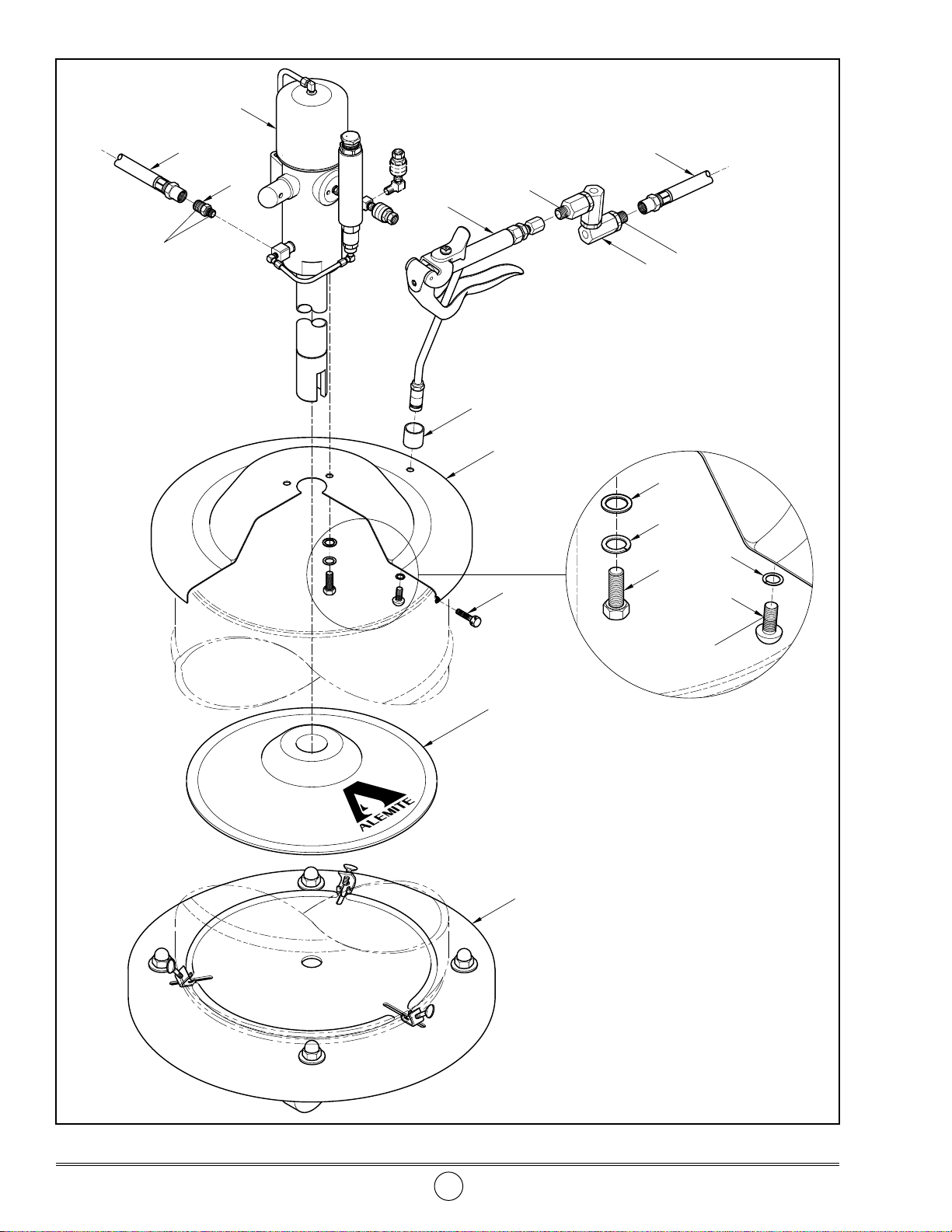

Pump Assembly and Cover

IMPORTANT: Make sure to remove the pro-

tective cover from the inlet of Pump Assem-

bly (

1

).

1. Install Pump Assembly (

1

) into Cover Assembly (

7

).

2. Secure the Pump Assembly to the Cover with

Washers (

8

), Lock Washers (

9

), and Capscrews (

10

).

• Tighten the Capscrews securely.

Cover Assembly and Follower Plate

3. Place Follower Plate (

14

) onto the top of the product.

• With a wobbling motion, eliminate any air that may

be trapped underneath the Follower Plate. Force the

product through the hole in the center of the Plate.

4. Guide the pump tube into the Follower Plate and fit the

Cover onto the container.

5. Secure the Cover to the container with Thumb

Screws (

11

).

NOTE

: On model 8541-5, secure the con-

tainer to Dolly (

15

). Refer to SER

316315-5

for details.