Beckman Coulter HIAC 9703+ User manual

DOC026.98.80097

HIAC 9703+ Liquid Particle

Counter

10/2013, Edition 5

User Manual

Bedienungsanleitung

Manuale d'uso

Manuel d'utilisation

Manual del usuario

English...................................................................................................................................................................................................3

Deutsch...............................................................................................................................................................................................21

Italiano.................................................................................................................................................................................................39

Français..............................................................................................................................................................................................57

Español...............................................................................................................................................................................................75

2

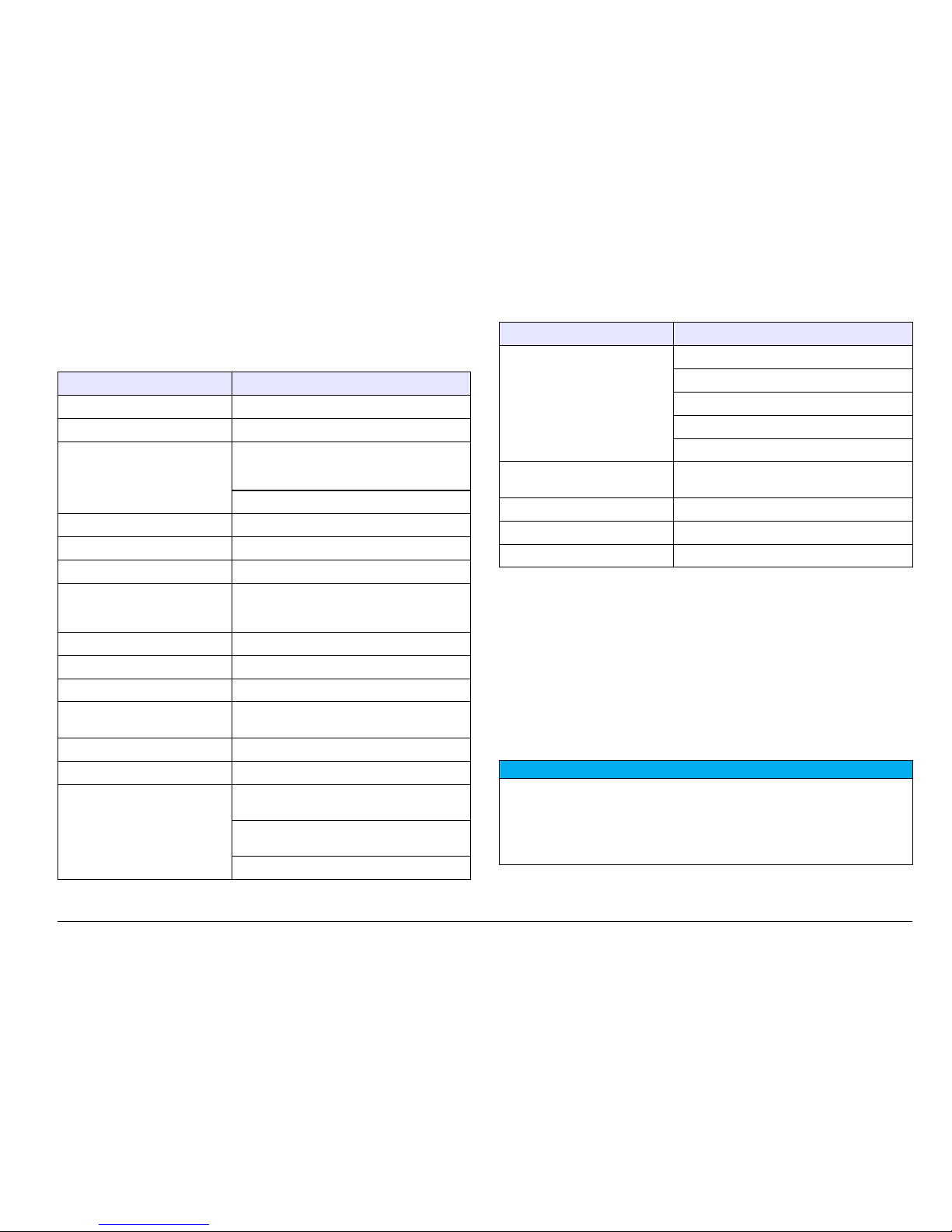

Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions (W x D x H) 343 x 337 x 482 mm (13.5 x 13.3 x 19.0 in.)

Weight 10.7 kg (23.6 lb)

Power requirement External Class III power adapter:

100–240 VAC, 50–60 Hz, 2.5 A input;

24 VDC, 3.75 A output

Instrument: 24 VDC, 75 W maximum

Viscosity limits < 50 cp

Coincidence loss limit 7,500

Operating temperature 5 °C to 40 °C (41 °F to 104 °F)

Operating humidity 0 to 80% relative humidity for temperatures

up to 31 °C decreasing linearly to 50% RH at

40 °C

Maximum altitude 2,000 m (6,560 ft)

Sample bottle clearance 153 mm (6.02 in.)

Sample temperature 5 °C to 40 °C (41 °F to 104 °F)

Flow rate 10 to 100 mL/min (determined by the sensor

calibration flow rate)

Flow rate accuracy > 95%

Volume accuracy > 95% of syringe size1

Tare volumes for probes

0.091 mL for 8.1 cm (3.2 in.)/1.2 mm

(0.047 in.) ID

0.172 mL for 15.4 cm (6.1 in.)/1.2 mm

(0.047 in.) ID

1.57 mL for 14 cm (5.5 in.)/large bore

Specification Details

Sensor concentration limits

(particle per ml)

HRLD150: 18,000

HRLD150JA: 18,000

HRLD400: 10,000

HRLD600JS: 6,000

MC05: 9,000

Wetted materials PTFE Teflon®, TFE Teflon, PFA Teflon, Kel-F,

316 Stainless steel, Glass, Viton®

Number of channels 4 (2 for light scatter, 2 for light extinction)

Number of bins 65,536 (16,384 bins per channel)

Certification CE

1Under ideal conditions, inaccuracy in flow rate is ≤1% of syringe size.

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

NOTICE

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

English 3

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

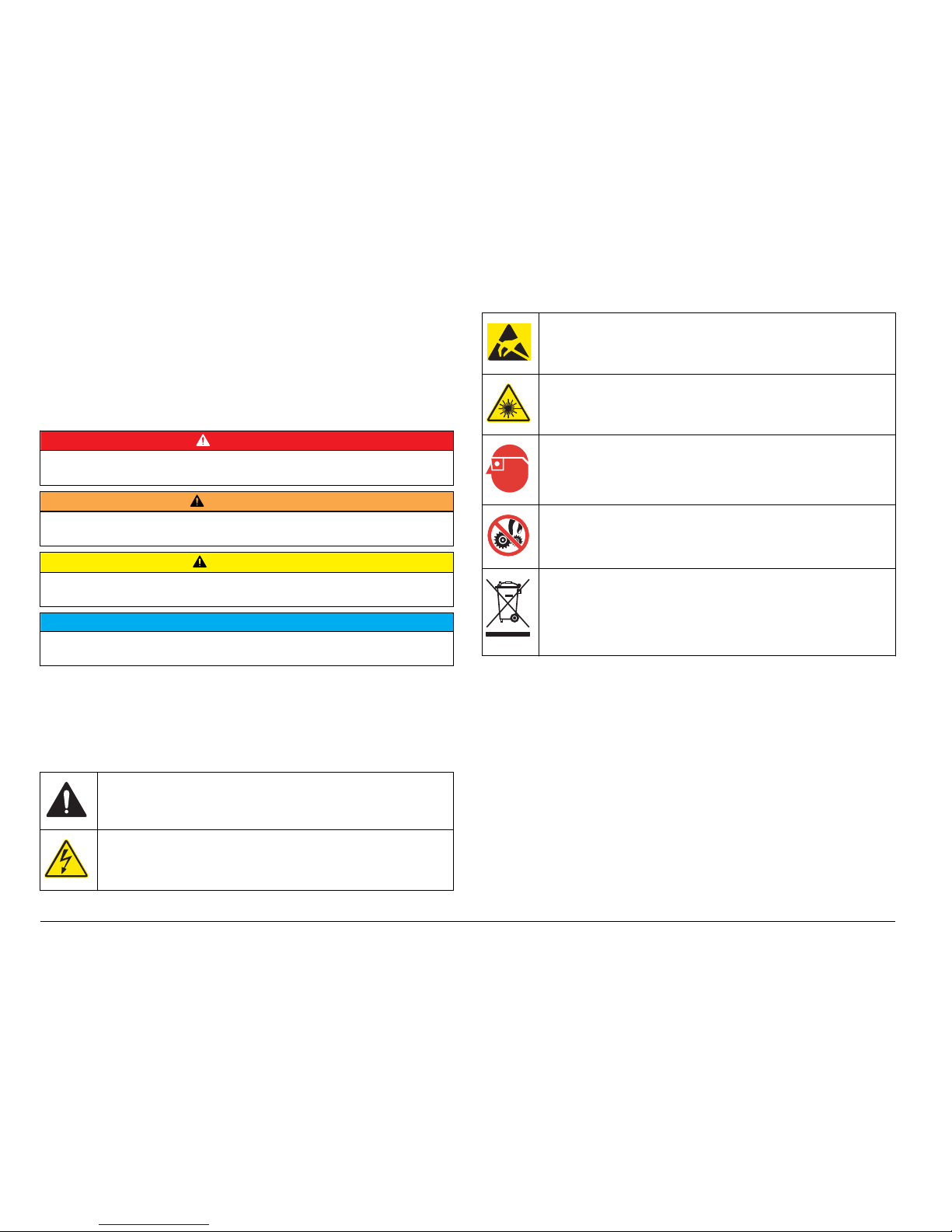

Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

NOTICE

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol, if noted

on the instrument, will be included with a danger or caution statement in

the manual.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

This symbol indicates that a risk of electrical shock and/or

electrocution exists.

This symbol indicates the presence of devices sensitive to Electro-

static Discharge (ESD) and indicates that care must be taken to

prevent damage with the equipment.

This symbol indicates a laser device is used in the equipment.

This symbol indicates the need for protective eye wear.

This symbol indicates a potential pinch hazard.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

4 English

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

The HIAC 9703+ liquid particle counter system measures particles in a

variety of liquids with a syringe sampler and sensor. The instrument

must connect to a computer for operation and data management. Refer

to Figure 1 and Figure 2.

An external sensor is used with the HIAC 9703+ liquid particle counter

system. Refer to Figure 1, item 2. The external sensors are classified as

Class 1 Laser Products. Refer to the sensor manual for FDA and IEC

compliance.

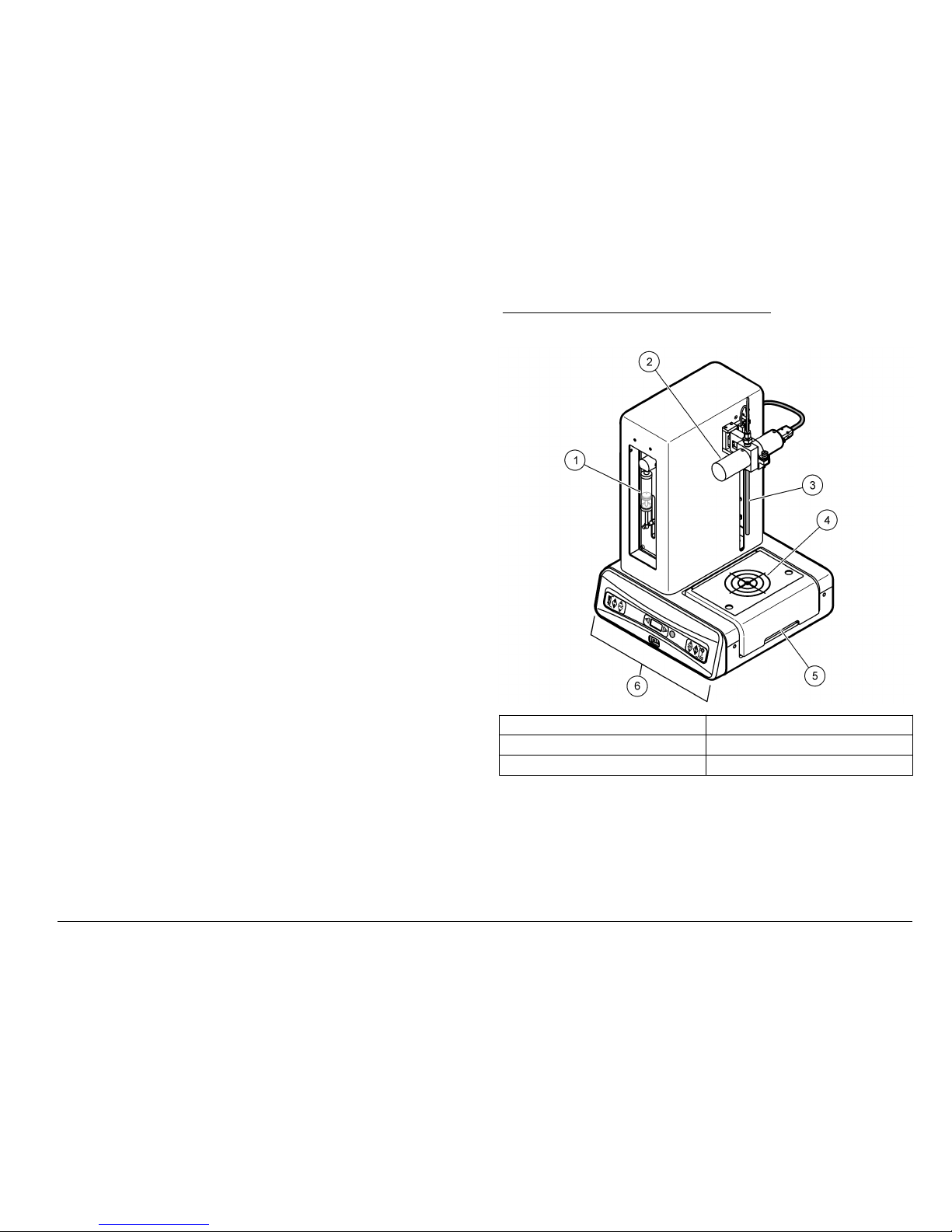

Figure 1 HIAC 9703+ liquid particle counter

1 Syringe 4 Sample target

2 Sensor 5 Docking module

3 Sample probe 6 Front panel

English 5

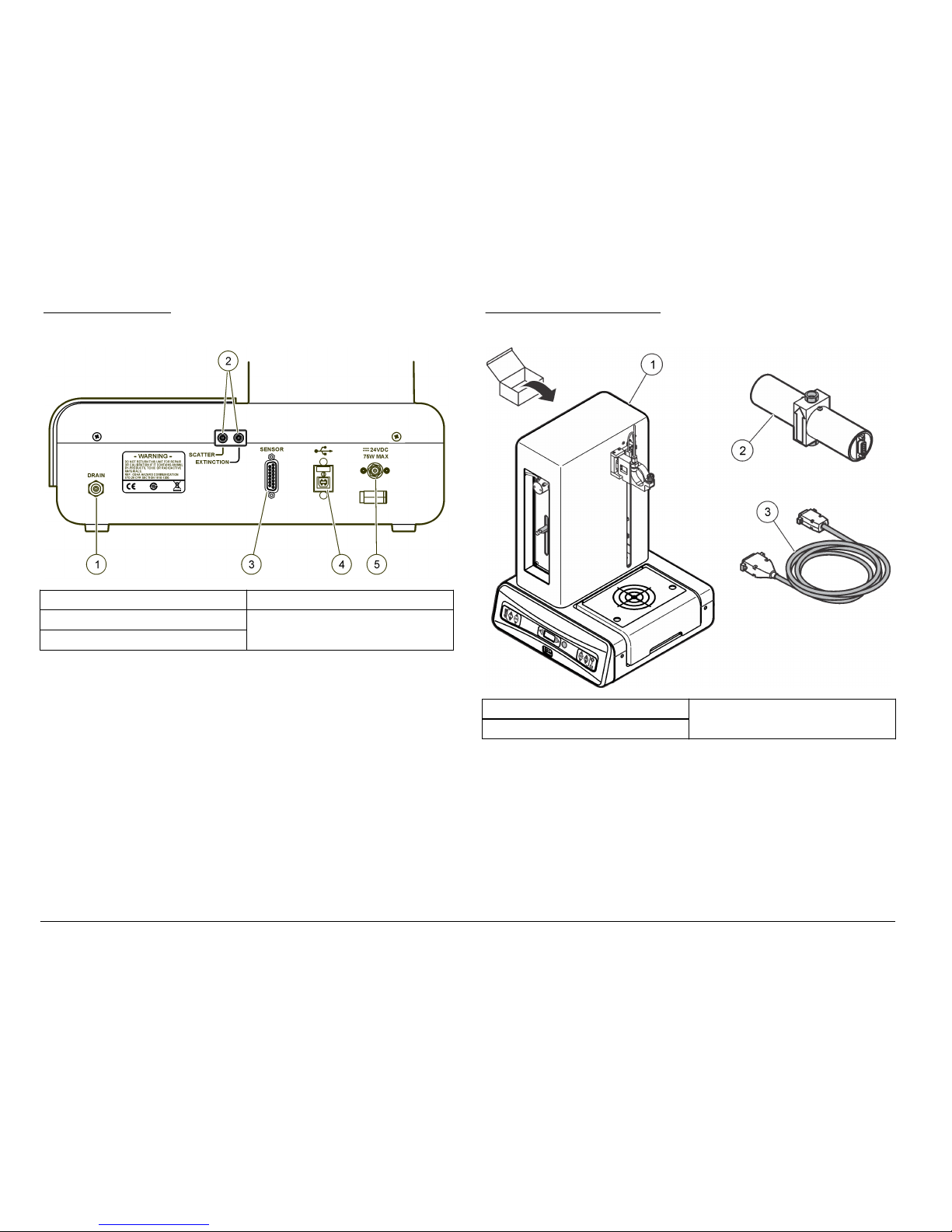

Figure 2 Back panel

1 Drain fitting 4 USB connector

2 Service-only ports 5 Power connector

3 Sensor connector

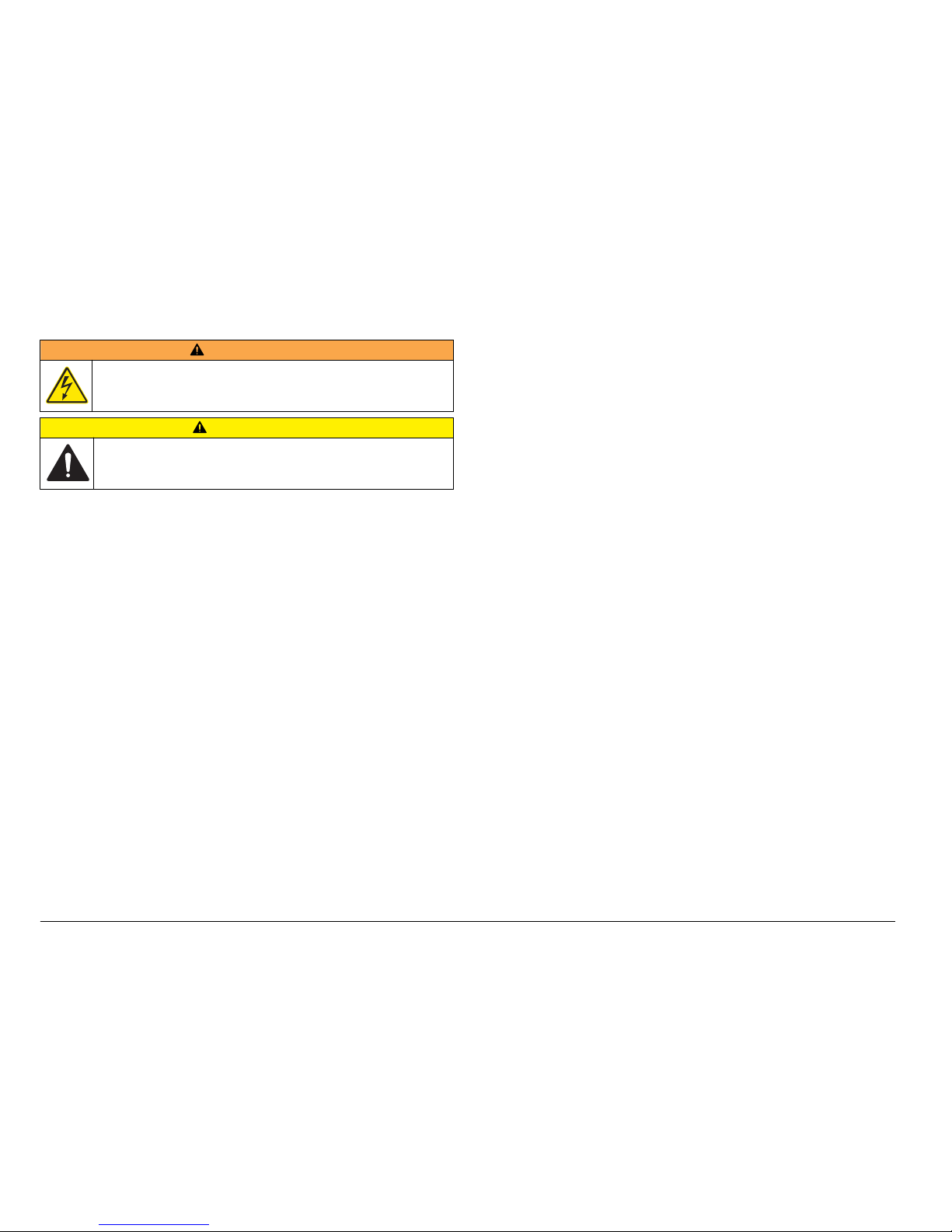

Product components

Make sure that all components have been received. Refer to Figure 3,

Figure 4 and Figure 5. If any items are missing or damaged, contact the

manufacturer or a sales representative immediately.

Figure 3 HRLD components

1 HIAC 9703+ liquid particle counter 3 Cable, sensor

2 Sensor, HRLD

6 English

Figure 4 MC05 components

1 HIAC 9703+ liquid particle counter 2 Sensor, MC05

Figure 5 Shipping kit

1 Nut 7 Probe, small bore

2 Hex Key, 1.5 mm 8 Cable, USB

3 Syringe, 10 ml 9 Power supply, 24V

4 Power cord, AC 10 O-rings

5 Stir Bar, Teflon 11 Tubing

6 Probe, large bore 12 Power cord, European

English 7

Installation

W A R N I N G

Electrical shock hazard. Externally connected equipment must have an

applicable country safety standard assessment.

CAUTION

Multiple hazards. Only qualified personnel should conduct the tasks

described in this document.

Site location

Position the instrument on a dry, level surface. The location must be

indoors and near an electrical outlet and a computer. Make sure the

power switch is accessible.

Install the HRLD sensor

The sensor is held in place by the holding arm. A sampling probe and

tubing must connect to the sensor for sample flow. A cable must connect

to the sensor for signal transmission. To install the sensor, refer to the

illustrated steps.

Note: Do not put Teflon tape on the fitting threads.

8 English

English 9

10 English

Install the MC05 sensor

The sensor is held in place by the holding arm. A sampling probe and

tubing must connect to the sensor for sample flow. A cable must connect

to the sensor for signal transmission. To install the sensor, refer to the

illustrated steps.

Note: Do not put Teflon tape on the fitting threads.

English 11

12 English

English 13

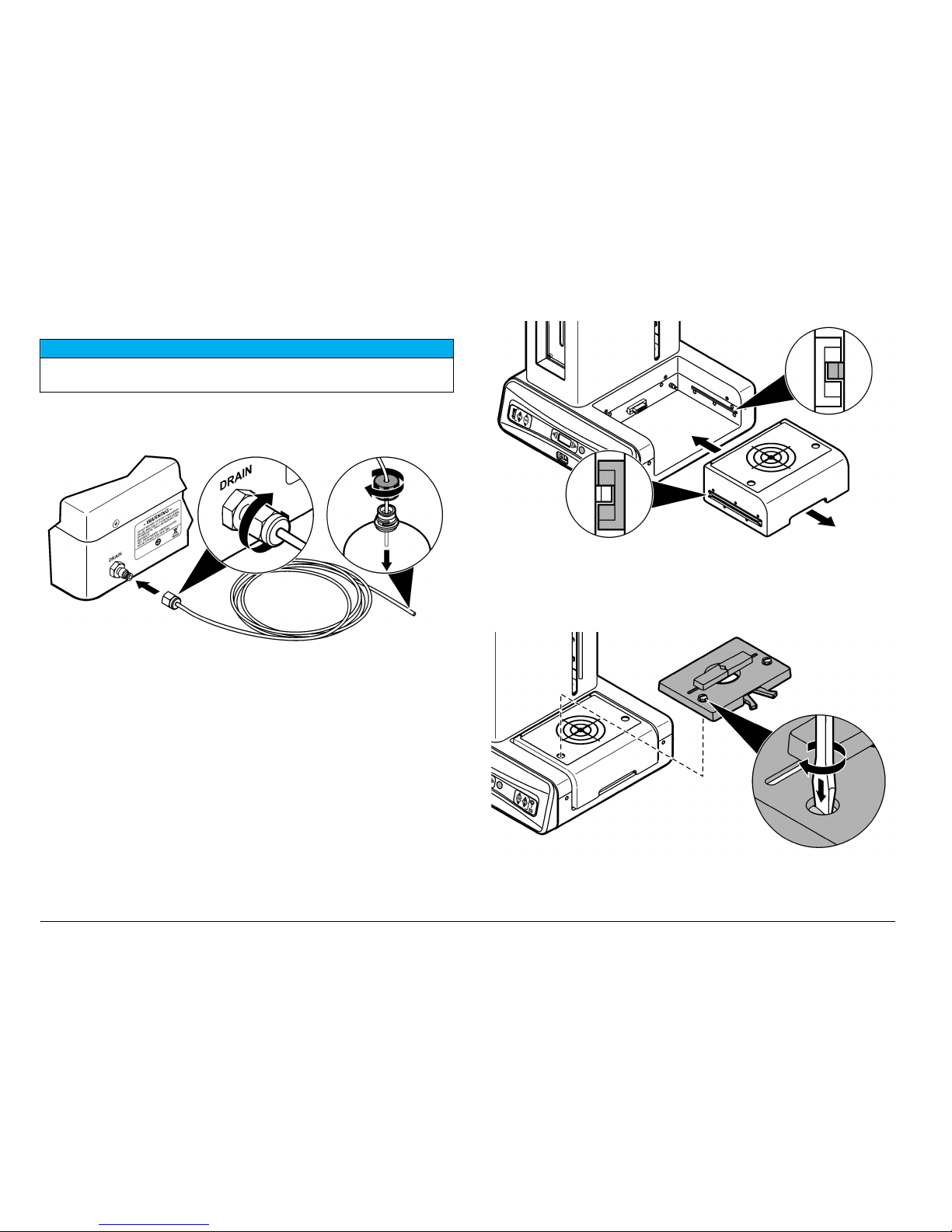

Connect the drain line

NOTICE

Dispose of waste in accordance with local, state and national environmental

regulations.

The sample waste from the instrument must be collected in a compatible

waste container. Monitor the liquid level in the waste container to prevent

overflow.

Install or remove the docking module

Docking modules are available for single or multiple-container sampling.

Install the small-vial clamp

The optional small-vial clamp connects to the docking module with

2 screws.

14 English

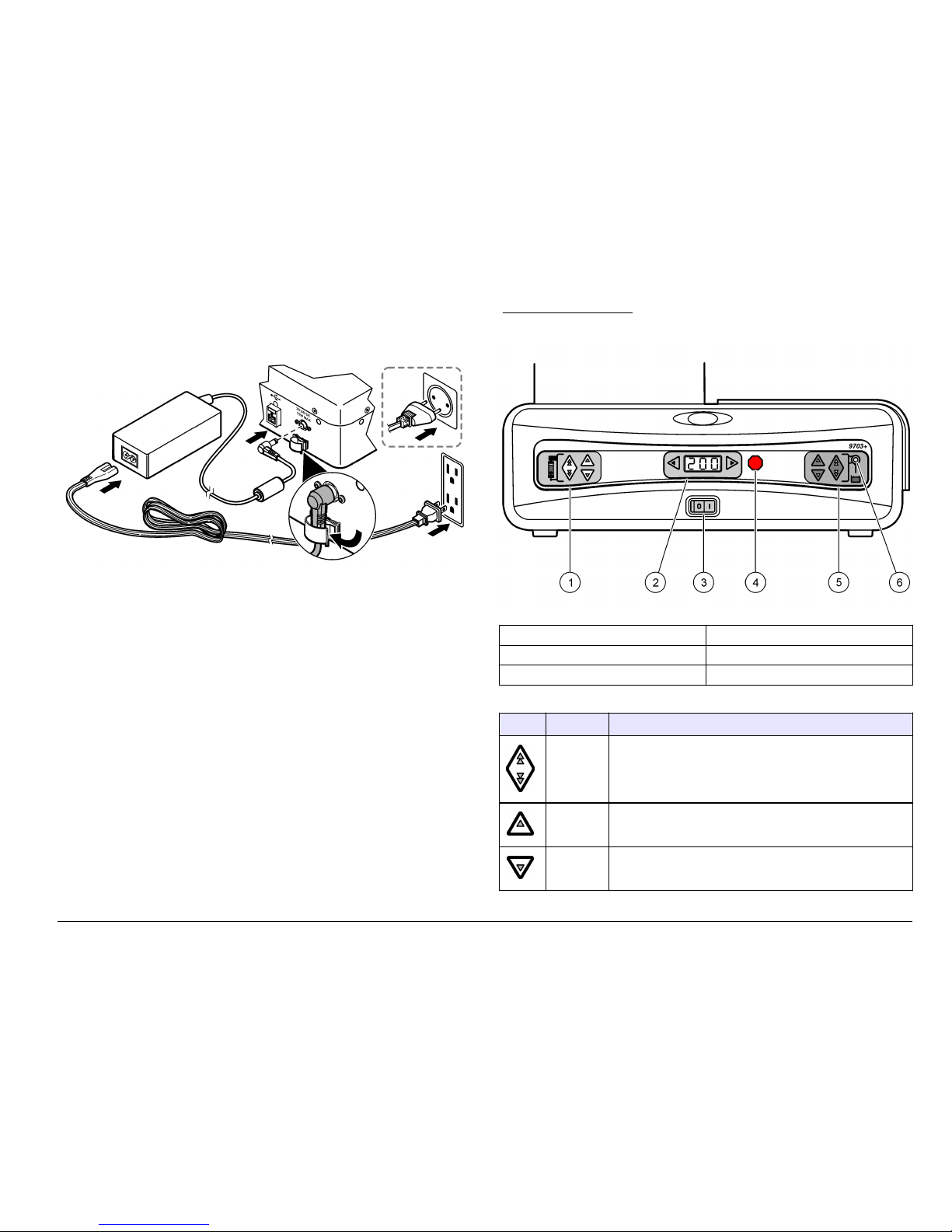

Connect the power cord

A power supply unit is used to supply power to the instrument.

Remove the magnetic stirrer

The magnetic stirrer in the docking module can be removed if necessary.

1. Pull the tab on the docking module away from the instrument to

remove the module.

2. Remove the four screws on the bottom plate of the module. Separate

the bottom plate from the module enclosure.

3. Remove the screw that holds the magnet to the motor shaft. Hold the

shaft with pliers so that the shaft does not move.

4. Remove the magnet and install the screw. Hold the shaft with pliers

so that the shaft does not move.

5. Put the bottom plate on the module enclosure and install the four

screws.

User interface

The buttons on the front panel allow the user to operate the syringe,

sample probe and stirrer. Refer to Figure 6, Table 1 and Table 2.

Figure 6 Front panel

1 Syringe controls 4 Stop button

2 Stirrer speed (RPM) 5 Sample probe controls

3 Power switch 6 LED status indicators

Table 1 Button descriptions

Button Name Description

Load Sends the syringe plunger to the top or bottom position.

Clean Flushes the system.

Back-flush Back-flushes the system when held for 3 seconds.

English 15

Table 1 Button descriptions (continued)

Button Name Description

Stop Stops the movement of the syringe and probe. Sampling is

stopped. The stirrer continues to operate.

Set Moves the sample probe up or down. Hold to increase

speed.

Lift/Lower Sends the sample probe to the top or bottom position.

Table 2 LED status indicators

LED color Description

Green Instrument is powered on

Yellow Instrument is sampling

Flashing yellow Shows the boot up sequence

Operation

DANGER

Fire hazard. This product is not designed for use with flammable

liquids.

W A R N I N G

Explosion hazard. Make sure that the drain tube is free of all

obstructions. If the drain tube has a blockage or is pinched or bent,

high pressure can build up in the instrument.

CAUTION

Chemical exposure hazard. Obey laboratory safety procedures and

wear all of the personal protective equipment appropriate to the

chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

Turn the instrument on or off

When power is applied to the instrument, the sampling probe

automatically moves to the top position and the magnetic stirrer starts.

The display on the front panel shows the stirrer speed in RPM.

1. Make sure that there are no obstructions to the movement of the

probe.

2. Push the ON/OFF switch to turn the instrument on or off.

Note: Push the STOP button to immediately stop the movement of the syringe

and sample probe.

Attach the syringe

The syringe drive mechanism must be at the bottom position to attach or

remove the syringe.

16 English

Figure 7 Attach the syringe

1 Plunger bolt 3 Syringe drive

2 Syringe 4 Valve

1. Push the ON/OFF switch to turn the instrument on.

2. Push the LOAD button under the syringe compartment to set the

plunger bolt at the lowest point. Refer to Figure 7.

3. Loosen and remove the plunger bolt from the syringe drive.

4. Hold the syringe and push the bolt through the plunger hole.

5. Push the bolt in the syringe drive hole and turn the bolt by hand to

tighten.

6. Pull the syringe barrel up and install the syringe threads in the valve.

7. Turn the syringe by hand to tighten.

Note: Do not overtighten.

Set the sample probe position

The lift mechanism for the sample probe can be set to automatically go

to the correct position for sampling.

English 17

1. Put a sample container on the module. If a small vial is used, refer to

Put a vial in the small-vial clamp on page 18.

2. Push the SET button to lower the sample probe to the correct

position.

3. Push the LIFT/LOWER button to raise the sample probe to the top

position.

4. Push the LIFT/LOWER button to automatically move the sample

probe down and stop at the correct bottom position.

Note: This position is recognized by the external software.

The bottom position is saved until a new bottom position is set.

Flush the syringe

Flush the syringe when a new syringe is installed or when a new sample

is used. To optimize the performance of the syringe:

• Do not operate the syringe for more than a few cycles without liquid.

• Thoroughly flush the syringe with distilled or deionized water after use.

1. Push the LIFT/LOWER button to raise the sample probe.

2. Put the container with the flushing liquid under the sample probe.

3. Push the LIFT/LOWER button to lower the sample probe in the

flushing liquid.

4. Push the CLEAN button. The syringe fills with the flushing liquid and

pushes the liquid out to the drain.

Note: The system can also be flushed with the external software.

Put a vial in the small-vial clamp

The small-vial clamp holds small vials under the center of the sample

probe. To install the clamp assembly, refer to Install the small-vial clamp

on page 14.

Stop all operations

The STOP button can be used to simultaneously stop movement of the

syringe and sample probe. Use the buttons or external software to

resume operations.

Connect the computer cable

A USB cable connects the instrument to a computer.

1. Install a compatible software application on the computer.

2. Turn on the instrument power.

3. Connect the USB cable to the USB port on the instrument and to the

computer.

Operate the instrument by computer

The instrument must connect to a computer for configuration, calibration,

data collection and data management. Refer to the software user

manual for specific instructions.

18 English

Maintenance

CAUTION

Personal injury hazard. Only qualified personnel should conduct the tasks

described in this section of the manual.

NOTICE

Do not disassemble the instrument for maintenance. If the internal components

must be cleaned or repaired, contact the manufacturer.

Clean the instrument

Clean the exterior of the instrument with a moist cloth and a mild soap

solution and then wipe the instrument dry.

Clean the syringe

Frequent use and dirty sample material make it necessary to clean the

syringe more often. Clean the syringe daily or weekly to make sure that it

works properly. Use a mild detergent for standard applications. To find

whether a different cleaning solution is compatible with the instrument,

refer to Specifications on page 3.

1. Put a container with the cleaning solution on the docking module.

2. Push the LIFT/LOWER button to lower the sample probe.

3. Push the LOAD button to fill the syringe with the cleaning solution.

Note: If the plunger does not move easily in the syringe barrel, remove the

plunger, wipe the plunger with alcohol and wet the plunger seal with deionized

water.

4. Allow the solution to stay in the syringe for a minimum of 30 minutes.

5. Push the LOAD button to send the cleaning solution to the drain.

6. Push the LIFT/LOWER button to raise the sample probe.

7. Put a container with distilled or deionized water on the docking

module.

8. Push the LIFT/LOWER button to lower the sample probe.

9. Push the CLEAN button to flush the syringe with the rinse water.

10. Repeat the flush with rinse water for a minimum of 10 cycles.

Troubleshooting

Back-flush the system

A large particle can reduce or stop the liquid flow. If this occurs, a flush

in the reverse direction can push the particle out through the sample

probe.

1. Put a small waste container under the sample probe.

2. Push the LIFT/LOWER button to lower the sample probe.

3. Push and hold the BACK-FLUSH button until the back-flush cycle

starts.

The syringe fills with liquid from the drain tubing. When the syringe

closes, the liquid is sent through the sensor and sample probe.

4. Repeat the back-flush cycle as necessary until a flush in the forward

direction with a clean sample flows at a normal rate.

How to clean spills

CAUTION

Chemical exposure hazard. Dispose of chemicals and wastes in

accordance with local, regional and national regulations.

1. Obey all facility safety protocols for spill control.

2. Discard the waste according to applicable regulations.

Replacement parts and accessories

W A R N I N G

Personal injury hazard. Use of non-approved parts may cause

personal injury, damage to the instrument or equipment malfunction.

The replacement parts in this section are approved by the

manufacturer.

Note: Product and Article numbers may vary for some selling regions. Contact the

appropriate distributor or refer to the company website for contact information.

English 19

Replacement parts

Description Item no.

Cable, USB, 2 m 460-400-4799

Fitting, probe to HRLD sensor 90630002

O-rings, sensor, pkg/4 808-010-200

Power cord, 230 VAC, 1.8 m (6 ft) VP623500

Power cord, 115 VAC, 1.8 m (6 ft) VP623501

Power supply 230-300-7052

Sampling probe, 14 cm (5.5 in.), large bore 90620008

Sampling probe, 15.4 cm (6.1 in.), 1.2 mm (0.047 in.) ID 90450001

Stir bar, Teflon, pkg/5 600-100-0003

Syringe, 10-mL 690-300-4808

Tubing Assy, drain 089208-01

Modified coupling 047156-03

Accessories

Description Item no.

Cleaning floss 660-850-0001

Small vial sampling kit (includes 2089099-01,

90450004 and 690-300-4805) 2089006-01

Module, small-vial clamp 2089099-01

Sampling probe, 8.1 cm (3.2 in.), 1.2 mm (0.047 in.) ID 90450004

Syringe, 1-mL 690-300-4805

Syringe, 25-mL 690-300-4809

HRLD Sensor holder 2089290-01

Accessories (continued)

Description Item no.

MC05 Sensor holder 2089291-01

Cable, HRLD to 9703+, 0.9 m (3 ft) 2089179-01

20 English

Table of contents

Languages:

Other Beckman Coulter Cash Counter manuals

Popular Cash Counter manuals by other brands

Kübler

Kübler CODIX 521 operating instructions

Leader Electronics Corp.

Leader Electronics Corp. LDC-824 instruction manual

DIEBOLD NIXDORF

DIEBOLD NIXDORF DN Series 100D FL operating manual

Nautilus Hyosung

Nautilus Hyosung MS500 Operator's manual

PASCO

PASCO SN-7927A instruction sheet

Milesight

Milesight VS133-P user guide