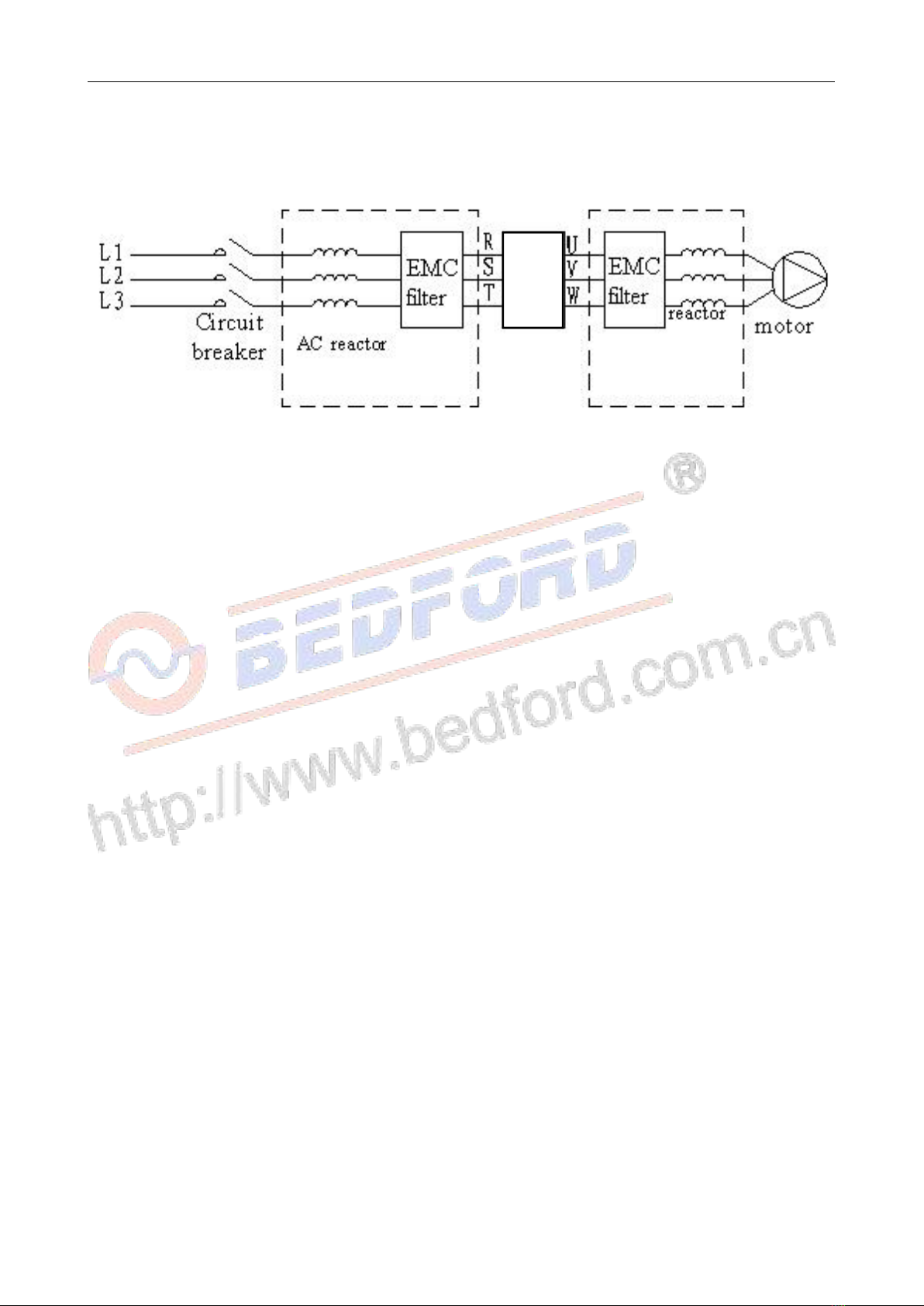

Bedford B6031I Series User manual

This manual suits for next models

47

Table of contents

Popular Inverter manuals by other brands

IOTA

IOTA IIS3P Series user manual

Phaesun

Phaesun Tre King quick guide

SCOTTEVEST

SCOTTEVEST SeV Important Instructions & Product Specifications

Sinergex

Sinergex PureWatts 1000 owner's manual

Thiele

Thiele Asian Electron PSW1500W Series instruction manual

Statpower

Statpower Portawattz 400 Installation & operation guide

Stober

Stober POSIDYN SDS 5000 Operation manual

Growatt

Growatt MOD 3000TL3-XH Installation & operation manual

Intersoft Electronics

Intersoft Electronics RTG1002 user manual

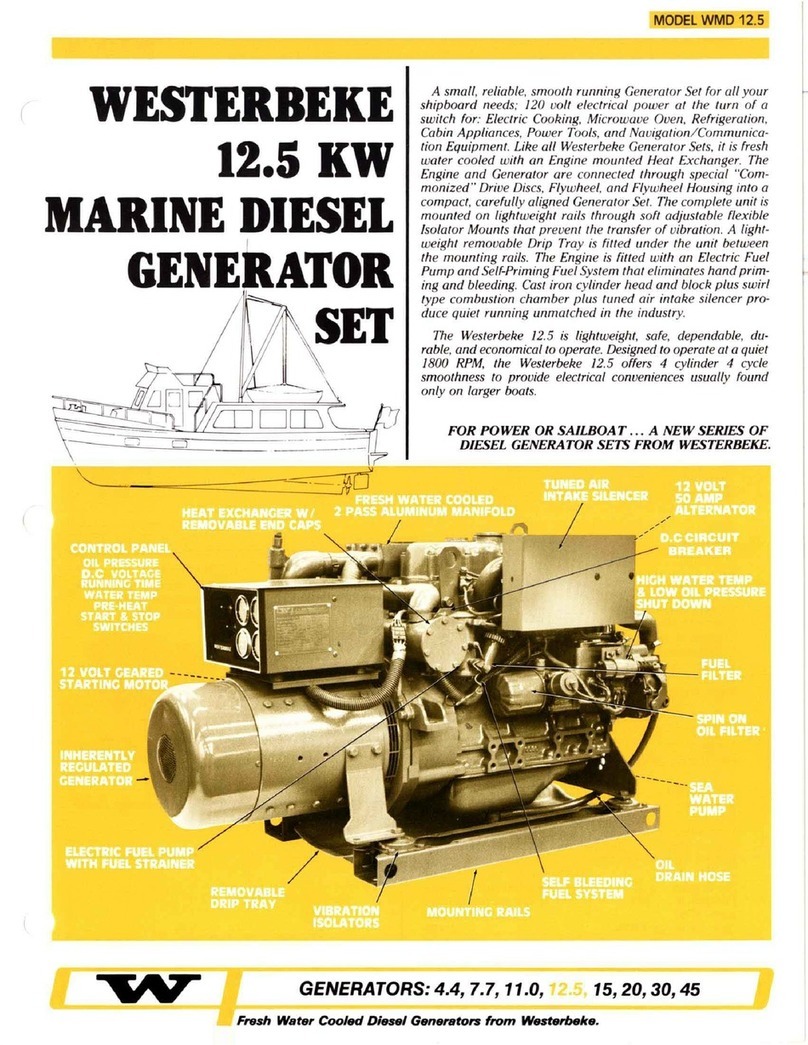

Westerbeke

Westerbeke WMD 12.5-60Hz specification

Hitachi

Hitachi L100DN DeviceNet Series Addendum Read this first

Generac Power Systems

Generac Power Systems 7kW Air-cooled owner's manual

Siemens

Siemens PM250 Hardware installation manual

Hoymiles

Hoymiles HMT-1800 Series Quick installation guide

Steca

Steca coolcept StecaGrid 3000 Installation and operating instructions

Accorroni

Accorroni HR 3.0 installation manual

Trane

Trane Sistema TVR TCONTRMUT12D manual

V-TAC

V-TAC VT-6605103 instruction manual