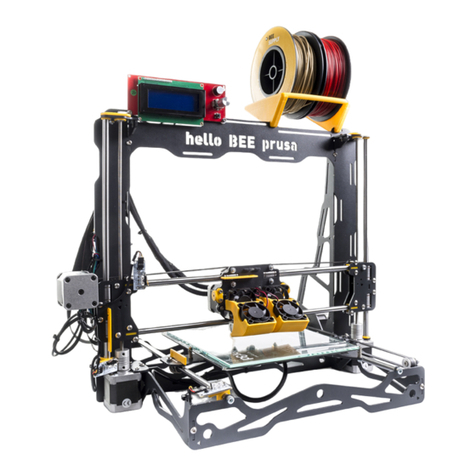

Beeverycreative B2X300 User manual

ASSEMBLY MANUAL

DIY 3D PRINTER KIT

B2X300

VERSION DATE DESCRIPTION PART NUMBERS

V1.20180503 03th May 2018 Beta-tester version 1212200001 to 1212200008

V2.20181107 7th November 2018 First release version 1212300001 to ------------

VERSIONS

1

NEEDED TOOLS

Before you start to build your B2X300 3D printer, check if you have the necessary tools

to do it. You will need the following:

You will need a set of hex key for

the assembly.

There is a 1.5mm hex key

supplied with the kit.

Sometimes you might need to use

some extra strengh assembling

the printer.

You will need it towards the end. Always a helpful tool. You will also need to remove

some strands from the

printed vparts with a cutter.

Take great care not to cut

yourself when doing this.

There is a Double Ring Spanner

included in the Structure Frame,

which can make the screw task

easier and quicker.

SET OF HEX KEYS SOFT FACE HAMMER

FLATHEAD SCREWDRIVER REGULAR PLIERS BOX CUTTER

DOUBLE RING SPANNER

There is also a nozzle changing

tool in the Structure Frame, wich

will be usefull on a future

changing nozzle process.

NOZZLE CHANGER

You need a marker to write on the

labels, for better guidance

while building B2X300.

MARKER

2

WHAT COMES WITH THE PACKAGE

BOX 3

BOX 0

Main Metal Frame

of your B2X300, guides

and Threaded Rods.

BOX 2

BOX 0

BOX 2

BOX 1

BOX 4

BOX 5

BOX 6

BOX 1

All the motors needed

are inside this box.

BOX 2

Inside this box you have

the glass, heated bed

and its cabling, and

the Printed Parts too.

BOX 4

Behold the Motherboard, the

Display and some of the

Electronic components.

BOX 5

The Extruder and

Auto-Calibration

Module is in this box.

BOX 3

Mechanic Parts

you need are right here.

BOX 6

In this box you have the

Power Supply.

To make recognizing each type of component easier, we’ve assigned a shape and colour to each type.

This way, we tried to divide all the components in boxes, just to make it easy for you.

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

3

HOW TO READ THIS MANUAL

We have divided the manual into 6 chapters, from A to F, with each chapter describing

a part of the assembly process. Within each one, we’ve numbered every step.

This way, we will have the following chapters:

A– Assembling the structure.......................................................................................p.7

B– Assembling the build plate structure.....................................................................p.19

C– Assembling the X-Axis............................................................................................p.25

D– Assembling the X-Axis to the structure.................................................................p.33

E– Assembling the Extruder........................................................................................p.40

F– Assembling the Electronics....................................................................................p.51

We aim to make it simple for you, so we have created areas in this manual to help you

build your B2X300 3D printer as well and as easily as you can.

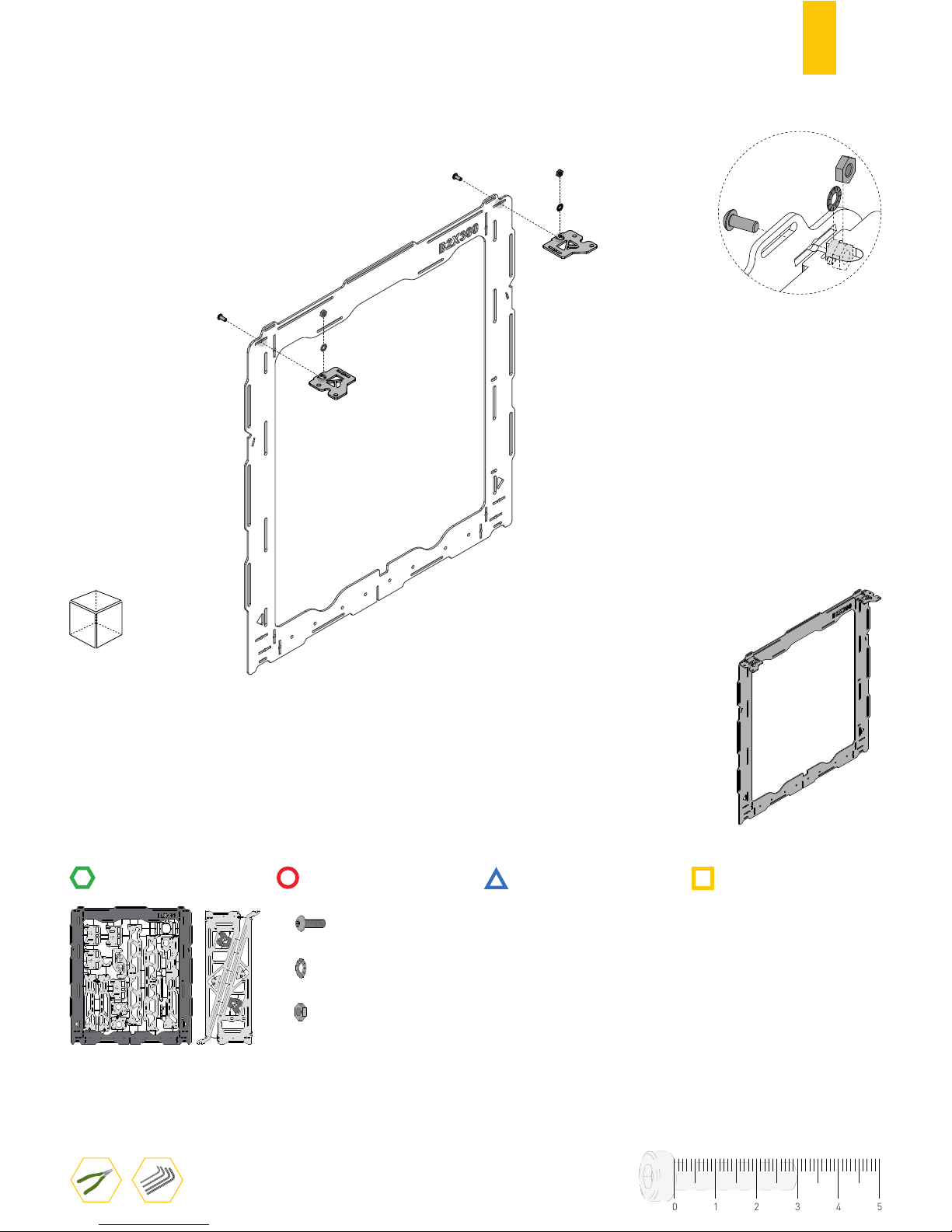

A.2

FRONT

RULER

0

1

2

3

4

5

TOOLS

BUTTON HEAD SCREW DIN7380 M4X10

2

2

2

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

This area will tell you

how to build each step

This letter and number

will help to guide your

building process.

There is a letter for each

set of steps of the assembly,

and a number for each step.

This area will tell you

from wich perspective

you are building

Which kit materials you

will use for each step

Here you will know

what tools you might

need to use

Space for some tips

and detailed instructions

What your assembly

should look like

after each step.

This ruler helps you

to measure the screws

and other mechanincs parts

0

1

2

3

4

5

4

TECHNICAL SPECIFICATIONS

LAYER RESOLUTION (user defined)

3D PRINTING TECHNOLOGY

PRINTING MATERIAL

MAX. BUILD VOLUME (up to)

HEATED BUILD PLATE

HEATED BUILD PLATE TEMPERATURE

DUAL EXTRUDER

NOZZLE DIAMETER

EXTRUDER MAX TEMPERATURE

TRINAMIC TMC 2130 DRIVERS

FILAMENT END DETECTION

MODULAR MOTHERBOARD

SENSORLESS HOMING

POWER LOSS DETECTION AND RECOVERY

EASY OFFSET CALIBRATION

STRUCTURE MATERIALS

PRINTER SIZE

WEIGHT

AMBIENT OPERATING TEMPERATURE

STORAGE TEMPERATURE

AC INPUT

POWER CONSUMPTION

CONNECTIVITY

INCLUDED ACCESSORIES

SUPPORTED FILE TYPES

AUTO BED LEVELLING

FIRMWARE

ELECTRONICS

RECOMMENDED 3D PRINTING/ SLICING SOFTWARE

SPEED

ASSEMBLY EXPERIENCE

50 - 300 microns

FFF

PLA, ABS, PETG, NYLON, Wood Composits, Metal Composits, HIPLA,

ABS-PC, HIPS, Carbon Composits

300 x 200 x 300 mm (11.81 x 7.87 x 11.81 in)

Yes (with 4mm removable glass surface)

50ºC (122ºF) – 130ºC (266ºF)

Yes, with two nozzle dual extruder

0.4mm | 0.4mm (other nozzle diameters available)

300ºC (572ºF)

Print more silently, especially on stealth mode. Faster printing speeds

with reduced vibrations and improved motion precision, without compro-

mising print quality. Up to 256 microsteps.

Ability to detect absence of filament

Allows for future upgrades and customization

No limit switches required, thanks to the trinamic drivers

Possibility to resume printing after a power loss

Simple one step method, does not require mutiple test prints

High-quality powder-coated steel frame, Steel guides Removable glass

build plate,Full metal dual extruder

56 x 37.5 x 60 cm (22,04 x 14,76 x 23,62 in)

12kg (26,45 lb)

10-30ºC (50-86ºF)

5-35ºC (41º -95º F)

110-240VAC | 50-60Hz

360 W

SD Card | USB

Power cable | USB cable | Grease

.gcode

Auto Bed Levelling using a 15 point mesh, interpolated to 45 virtual

points

Marlin based

MKS Gen

Cura | Slic3r | Simplify 3D

up to 200 mm/s

+/- 6 hours

5

TECHNICAL SPECIFICATIONS

SAFETY INFORMATION

ADULT SUPERVISION

HIGH TEMPERATURES

COOL AND WELL-VENTILATED

ENVIRONMENT

MOVING PARTS

Other information you need to know

After assembling your B2X300, don’t drop/knock/damage it and don’t connect it to

zvvanything that hasn’t been previously validated by BEEVERYCREATIVE.

Make sure gases, explosive and other flammable materials aren’t kept, stored or

transported with your B2X300 3D printer or its parts.

Because we can’t stress this enough,

this 3D printer was developed to be used by adults.

Should you wish that children also use it,

you must supervise them at

all times while they do so.

You must also take great care with

small printed objects,

because children might try to swallow them,

which poses a danger of them choking.

Whenever this 3D printer is functioning,

some mechanical parts can

reach high temperatures,

which can cause serious burns if touched.

For that reason you must always

be careful not to touch it.

For better results with your 3D printer,

it is recommended you maintain an

acceptable level of air quality around the printer.

Environments with some ventilation are also

recommended so as to renew the air if you choose

to print with materials that release odors.

Whenever it’s functioning, this 3D printer

has moving parts.

For that reason, you should always

keep a safe distance

from the printer while it’s operating.

Even though the B2X300 3D printer was designed to be as safe as possible, we would

like to remind you it was conceived to be used by adults.

Still, there are safety concerns you must keep in mind:

6

WARRANTY INFORMATION

B2X300 is a DIY 3D printer assembled by the user.

Its warranty is assured for the components that are included with the KIT.

Six month warranty guaranties the replacement of defective manufactured parts.

BEEVERYCREATIVE may request the return of this part in order to improve future de-

velopments.

Warranty will be voided if:

- inappropriate handling during assembly takes place.

- the user makes incorrect connections, breaks or damages parts during assembly.

Before assembling your B2X300 you must read thoroughly the Terms and Conditions of

the BEEVERYCREATIVE Standard Warranty on our website:

www.beeverycreative.com

7

A

ASSEMBLING THE STRUCTURE

8

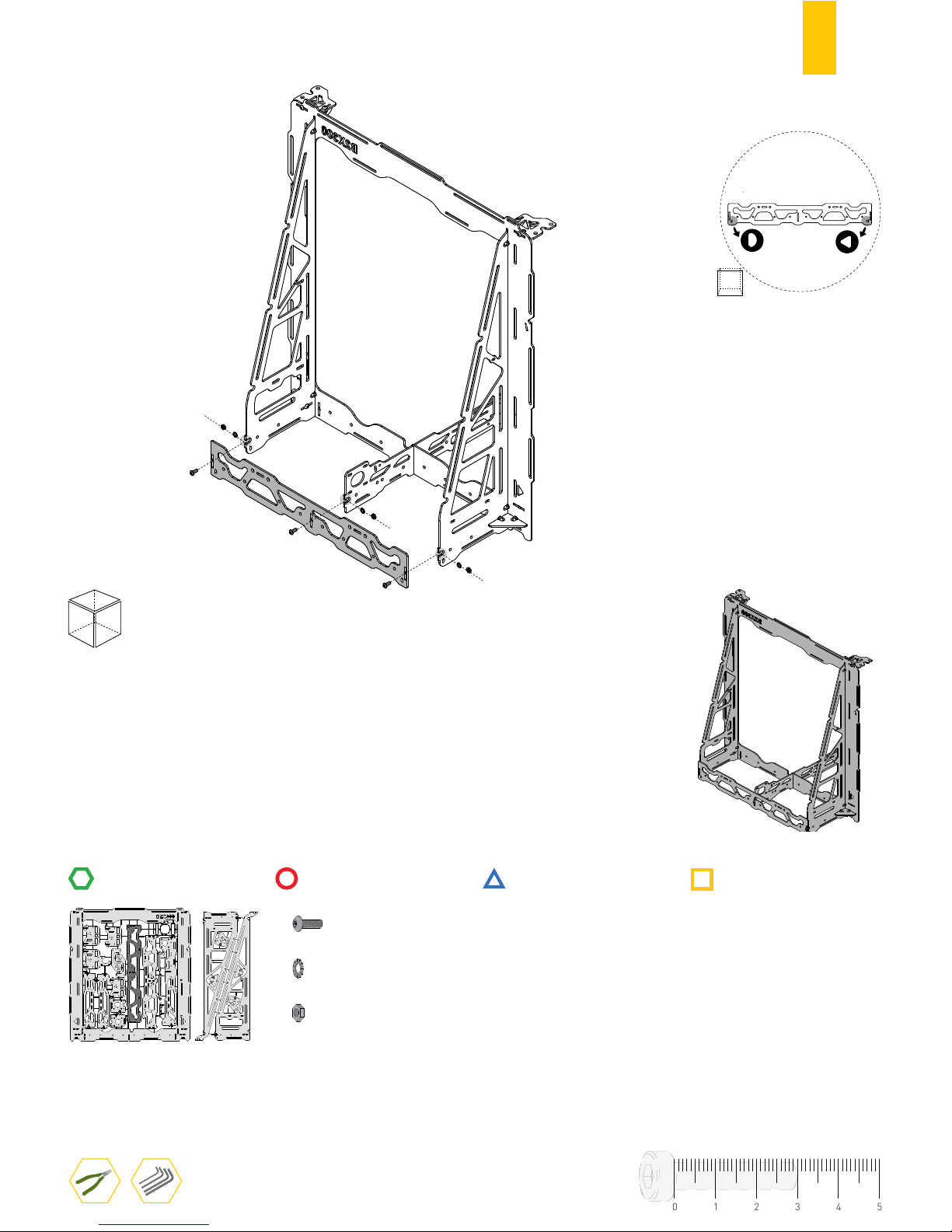

A.1

FRONT

RULER

TOOLS

BUTTON HEAD SCREW DIN7380 M4X10

2

2

2

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

0

1

2

3

4

5

Remove the pieces from the

structure with a regular pliers

⚠

9

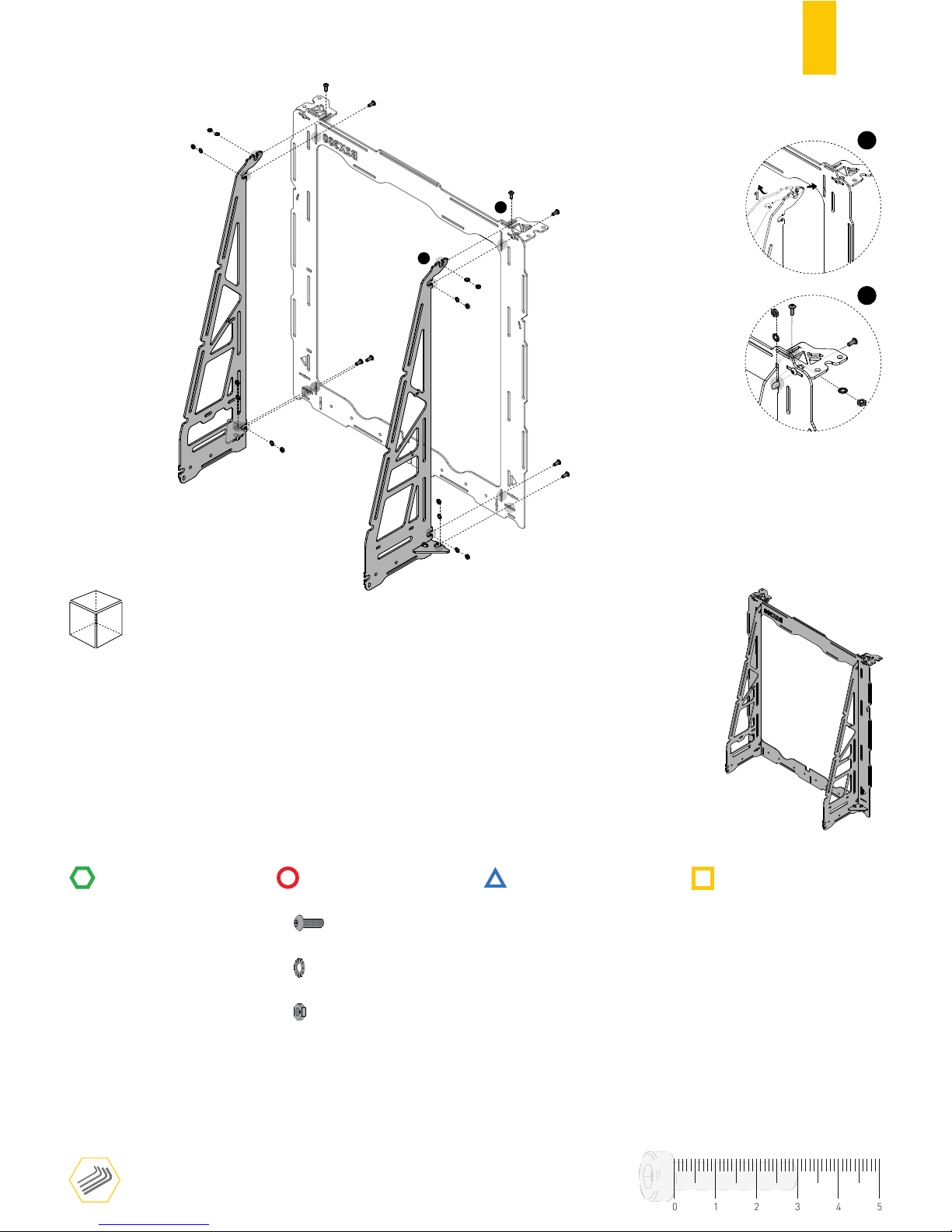

RULER

BACK

TOOLS

2

2

2

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

A.2

0

1

2

3

4

5

10

RULER

12

1

1

2

2

A.3

BACK

TOOLS

8

8

8

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

0

1

2

3

4

5

11

RULER

BACK

TOOLS

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

A.4

0

1

2

3

4

5

12

A.5

RULER

STRUCTURE

BACK

TOOLS

MECHANICS

3

3

3

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

ELECTRONICS

PRINTED PARTS

BACK

LEFT RIGHT

0

1

2

3

4

5

13

RULER

STRUCTURE

FRONT

TOOLS

MECHANICS

2

2

2

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

ELECTRONICS

PRINTED PARTS

A.6

0

1

2

3

4

5

14

RULER

A.7

FRONT

TOOLS

4

4

4

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

0

1

2

3

4

5

15

RULER

FRONT

TOOLS

3

3

3

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

BUTTON HEAD SCREW DIN7380 M4X10

SERRATED LOCK WASHER DIN6798J M4

HEX. THIN NUT 1 DIN439 M4

A.8

FRONT

LEFT RIGHT

0

1

2

3

4

5

16

RULER

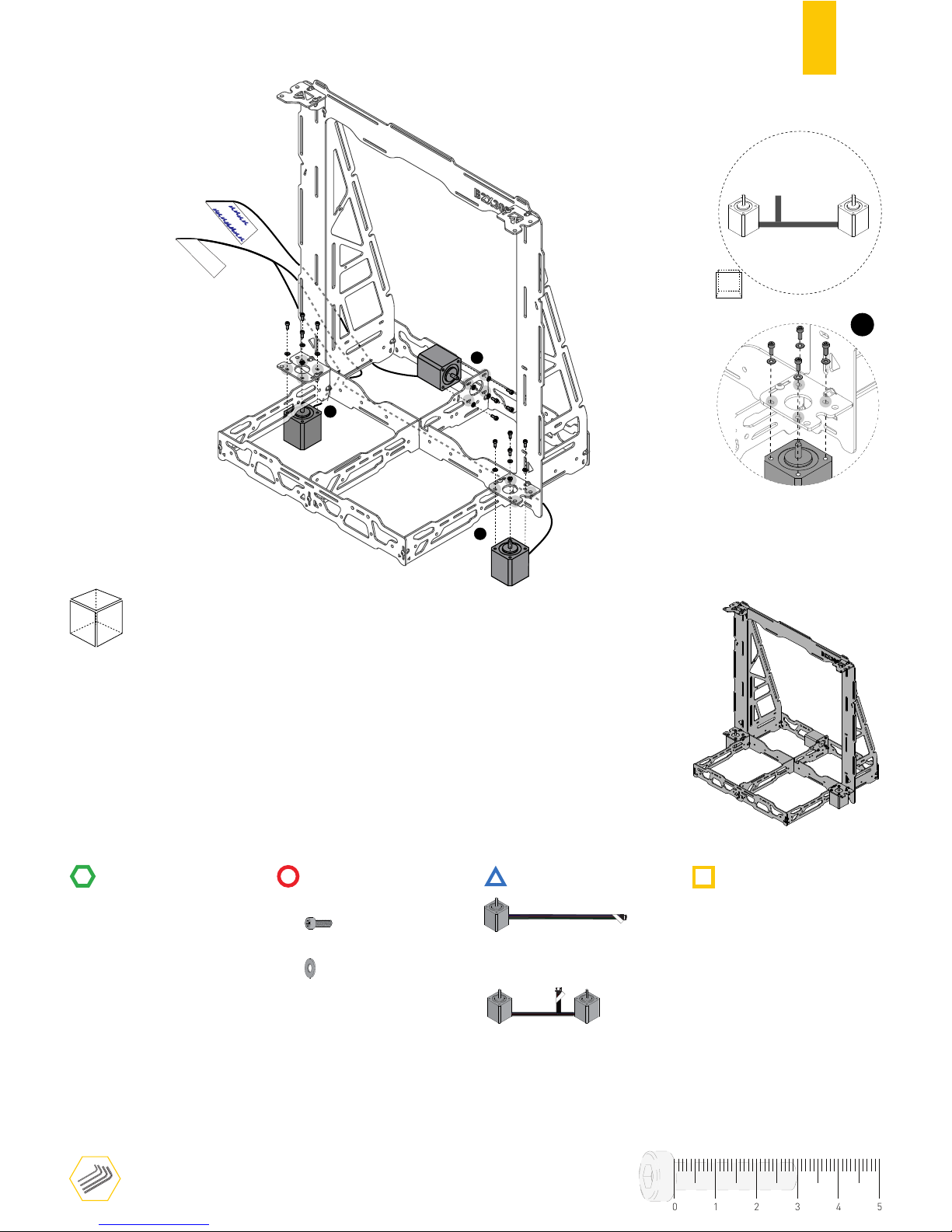

A.9

FRONT

TOOLS

CYL. HEAD SCREW DIN912 M3X6

12

12

PLAIN WASHER DIN125 M3

ΔY-AXIS

ΔZ-AXIS

NEMA17 STEPPER MOTOR Y AXIS

NEMA17 STEPPER MOTORS Z AXIS

ΔY-AXIS

ΔX-AXIS

ΔEXTRUDER E0

ΔZ-AXIS

1

1

1

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

0

1

2

3

4

5

FRONT

LEFT RIGHT

Z-AXIS

Leave Y-AXIS and Z-AXIS

motors screws slightly loose.

BACK

1

⚠

Use the marker to select

Y-AXIS motor cable label.

17

RULER

1

FRONT

FLEX COUPLING

2

TOOLS

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

A.10

1

5mm

˜

0

1

2

3

4

5

18

RULERRULER

A.11

1

2

FRONT

1

1mm

˜

1mm

2

0.5mm

˜

BUTTON HEAD SCREW DIN7380 M5X20

1

1

2

SERRATED LOCK WASHER DIN6798J M5

HEX. THIN NUT 1 DIN439 M5

FLAT BELT PULLEY

1

1

PULLEY GT2 20 TOOTH

TOOLS

STRUCTURE

MECHANICS

ELECTRONICS

PRINTED PARTS

0

1

2

3

4

5

Other manuals for B2X300

1

Table of contents

Other Beeverycreative 3D Printer manuals