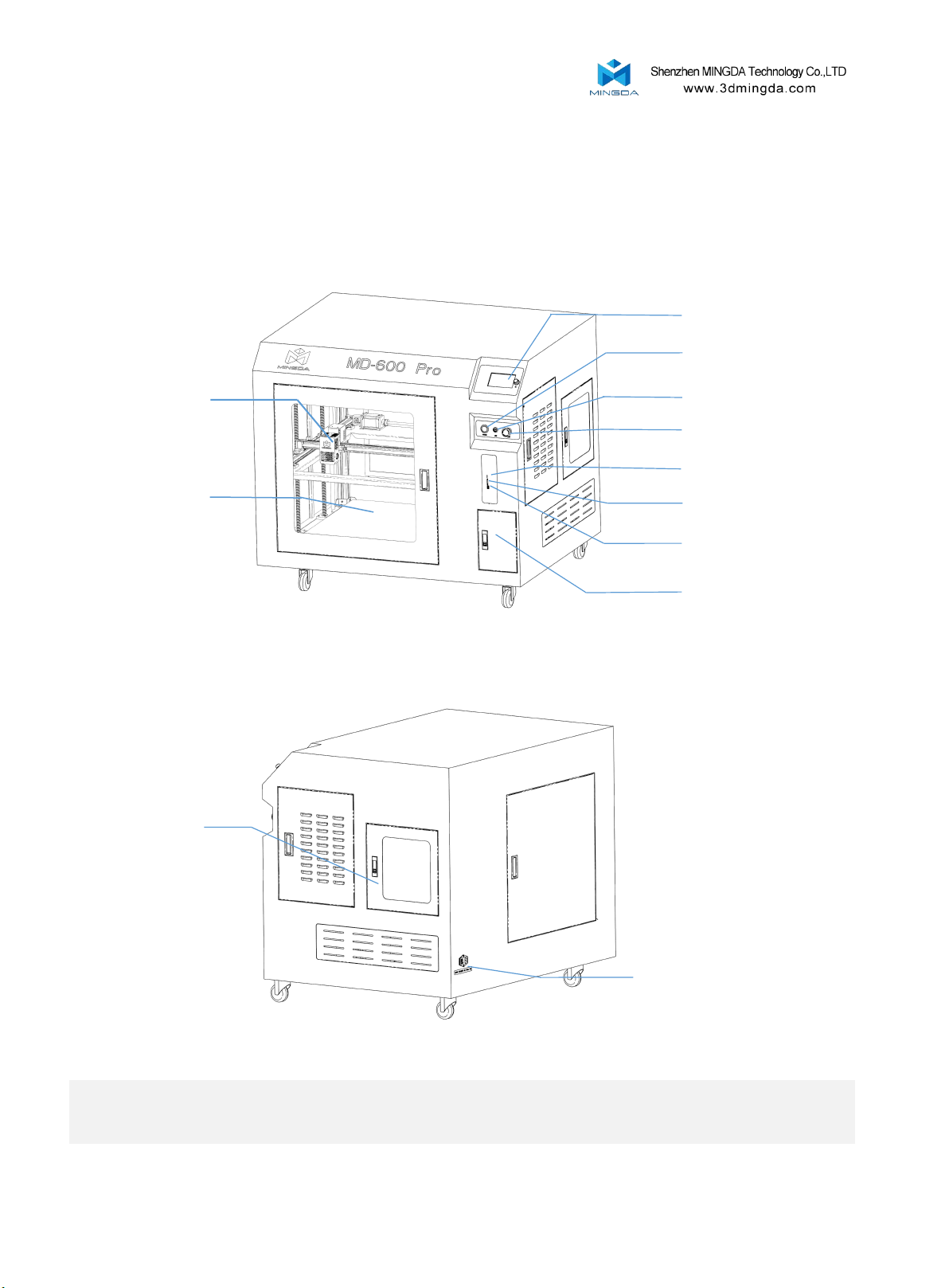

1. Brief Introduction

MD Series Industrial 3D Printers adhere to the design concept of the simple to the extreme. It can print

product quickly and easily, even if you've never used a 3D Printer.

The printer prints the model with PLA, so the products will be strong and durable. You can make drilling,

tapping, grinding and painting on the PLA models. MD Series 3D Printers combine proprietary hardware,

software and filament technologies creatively.

Welcome to a new world of 3D printing!

User-Guide Instructions

This User Guide has been carefully organized into "Installation", "Operation", "Maintenance" and

"Troubleshooting" sections for client to read and understand. Be sure to read the sections carefully to get the

best use of your 3D printer.

Learn More Information

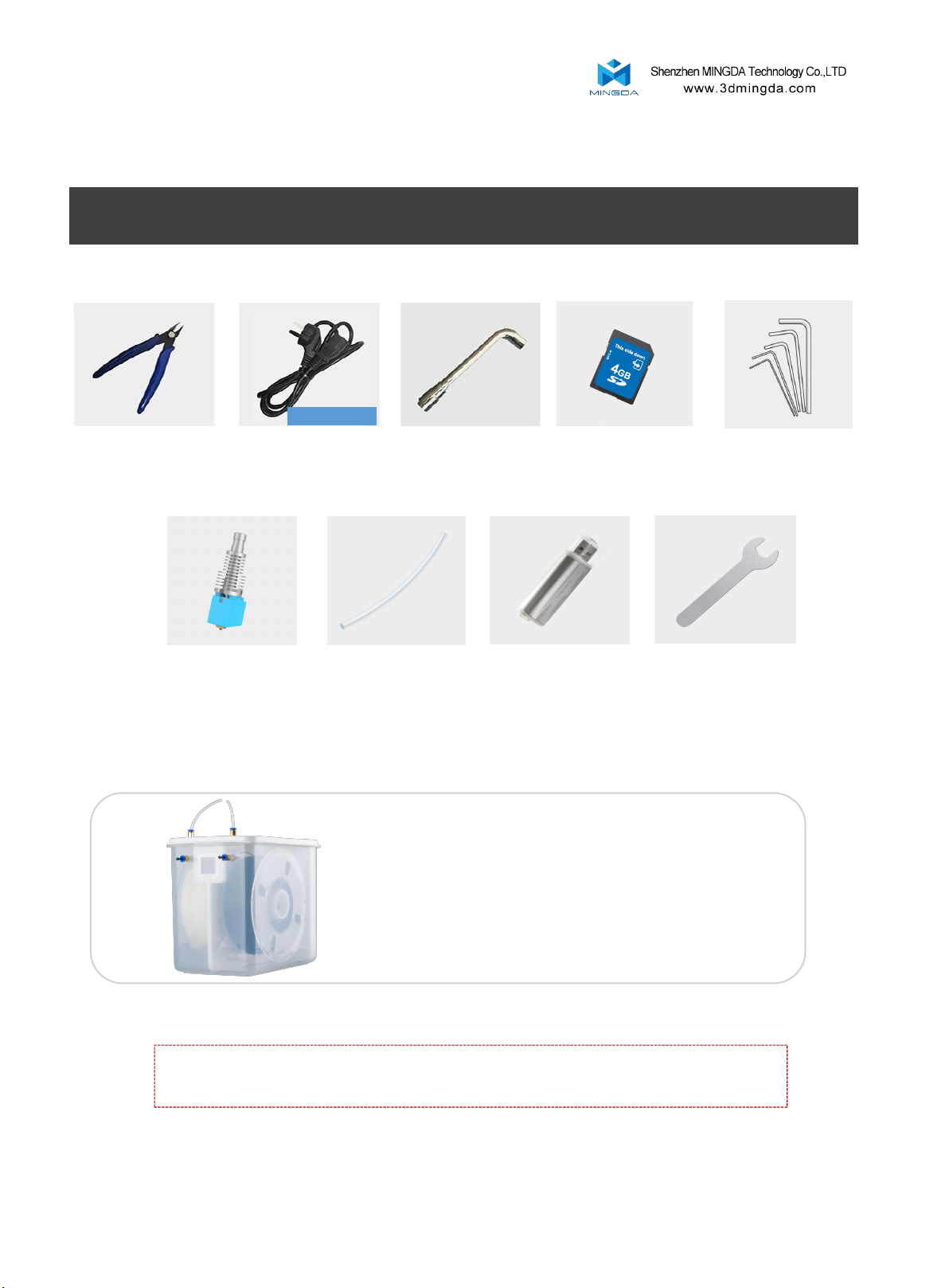

SD card provides the electronic user guide. This guide provides information as following topics:

1. Troubleshooting information

2. Important safety statements and regulatory information

3. Printing supplies related information

4. Detailed instructions for use

You can also find more information on the official website.

http://www.3dmingda.com

Safety Precautions

The following precautions ensure that the customer uses the printer correctly and protects the printer

from damage. Please always follow these precautions.

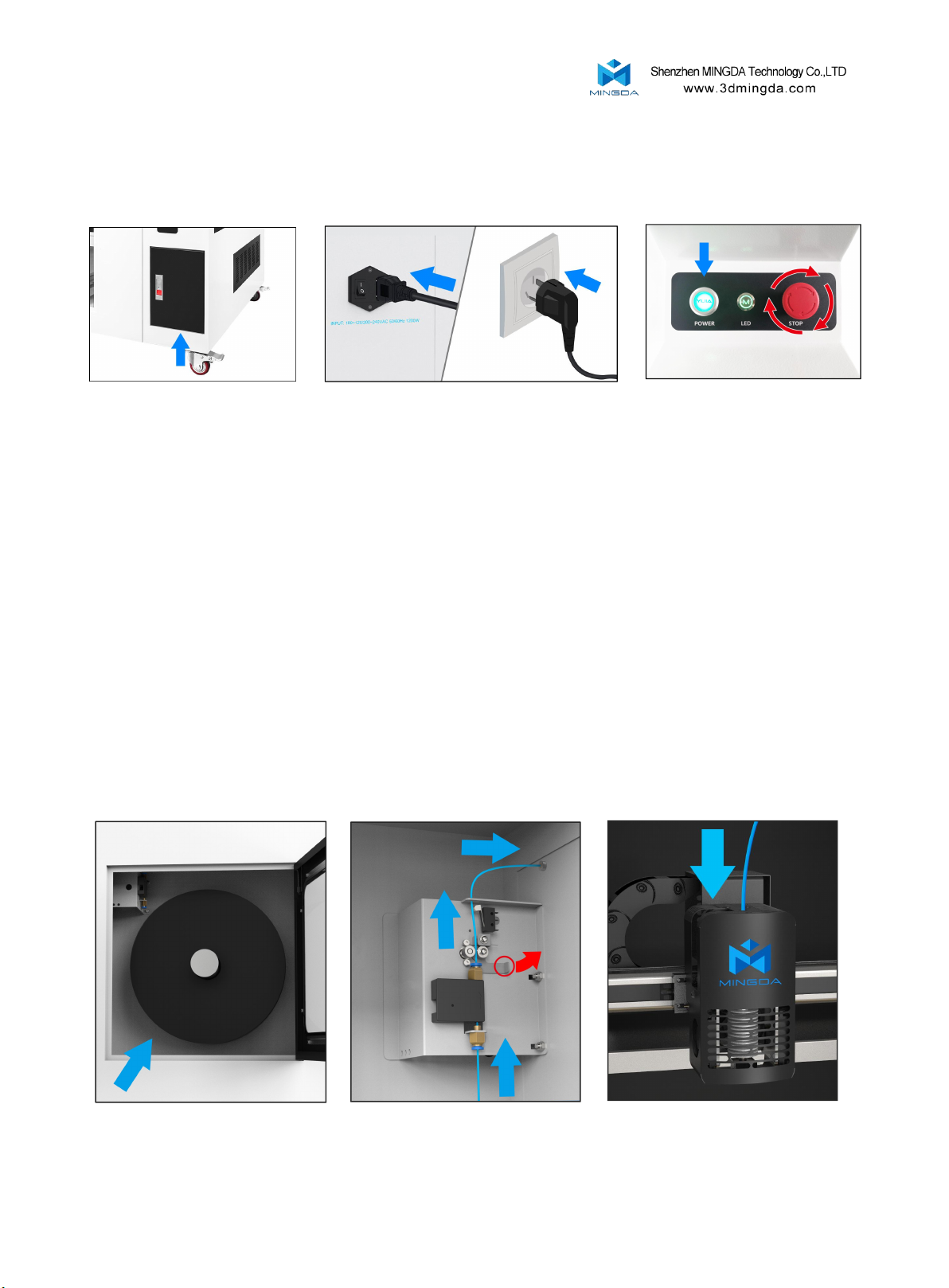

1. Use the specified power supply voltage. Do not connect multiple devices to the printer's power outlet

to avoid overload.

2. Make sure the printer is properly grounded, Or it may cause electric shock, fire or electromagnetic

interference.

3. Contact your after-sales or local service before disassembling or repairing the printer by yourself.

Check the "Support" section in the User Guide.

4. It is recommended to use the power cord that came with the printer. Do not damage, cut or repair

the power cord. Damaged power cords present a risk of fire or electric shock. Please replace the damaged

power cord with a quality-certified power cord. Do not allow metal or liquid to come into the printer and

contact with the internal parts of the printer. It may cause fire, electric shock or other serious accident.

5. Turn off the printer and unplug the power cord from the electrical outlet under the following

conditions:

1) The printer emits smoke or emits an abnormal smell.

2) The printer emits abnormal noise that has never occurred during normal operation.

3) Metal or liquid (not required for cleaning or routine maintenance) come into the printer.

4) Thunderstorm weather.

5) Power off

This guide contains the following categories.

Note: potentially dangerous situation, if not avoided, may result in minor or moderate injury.

Warning: potentially dangerous situation, if not avoided, may result in serious injury.

High temperature surface: The high temperature surface symbol indicates the presence of high

temperature equipment. When working near hot parts, be careful and wear safety gloves.

Gloves: When performing some maintenance procedures, the machine may be hot, so need to use

gloves to avoid burns.

Safety glasses: Please wear safety glasses to avoid eye injury.

Lifting hazard: Two or more people should cooperate when lifting, so as not to cause serious injury.

Recovery: Use the correct method for recovering materials and packaging materials.

ESD: Use standard electrostatic discharge (ESD) precautions when working with or near electronic

components.

3