2 - SAFETY PRECAUTIONS

Safety is the primary concern in the design and manufacture of our products.

Unfortunately our efforts to provide safe equipment can be wiped out by a single

careless act of an operator.

In addition to the design and configuration of equipment, hazard control and accident

prevention are dependent upon the awareness, concern, prudence and proper training

of personnel involved in the operation, transport, maintenance and storage of

equipment. It is the operator’s responsibility to read and understand all safety and

operating instructions in the manual and to follow these.

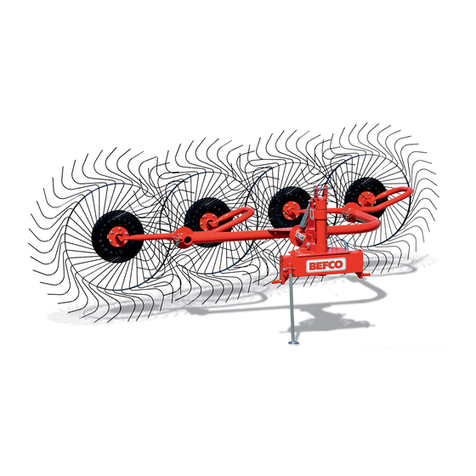

Allow only properly trained personnel to operate the windrower rake. Working with

unfamiliar equipment can lead to careless injuries. Read this manual, and the manual

for your tractor, before assembly or operation, to acquaint yourself with the machines. It

is the windrower rake owner’s responsibility, if this machine is used by any person other

than yourself, is loaned or rented, to make certain that the operator, prior to operating,

reads and understands the operator’s manuals and is instructed in safe and proper use.

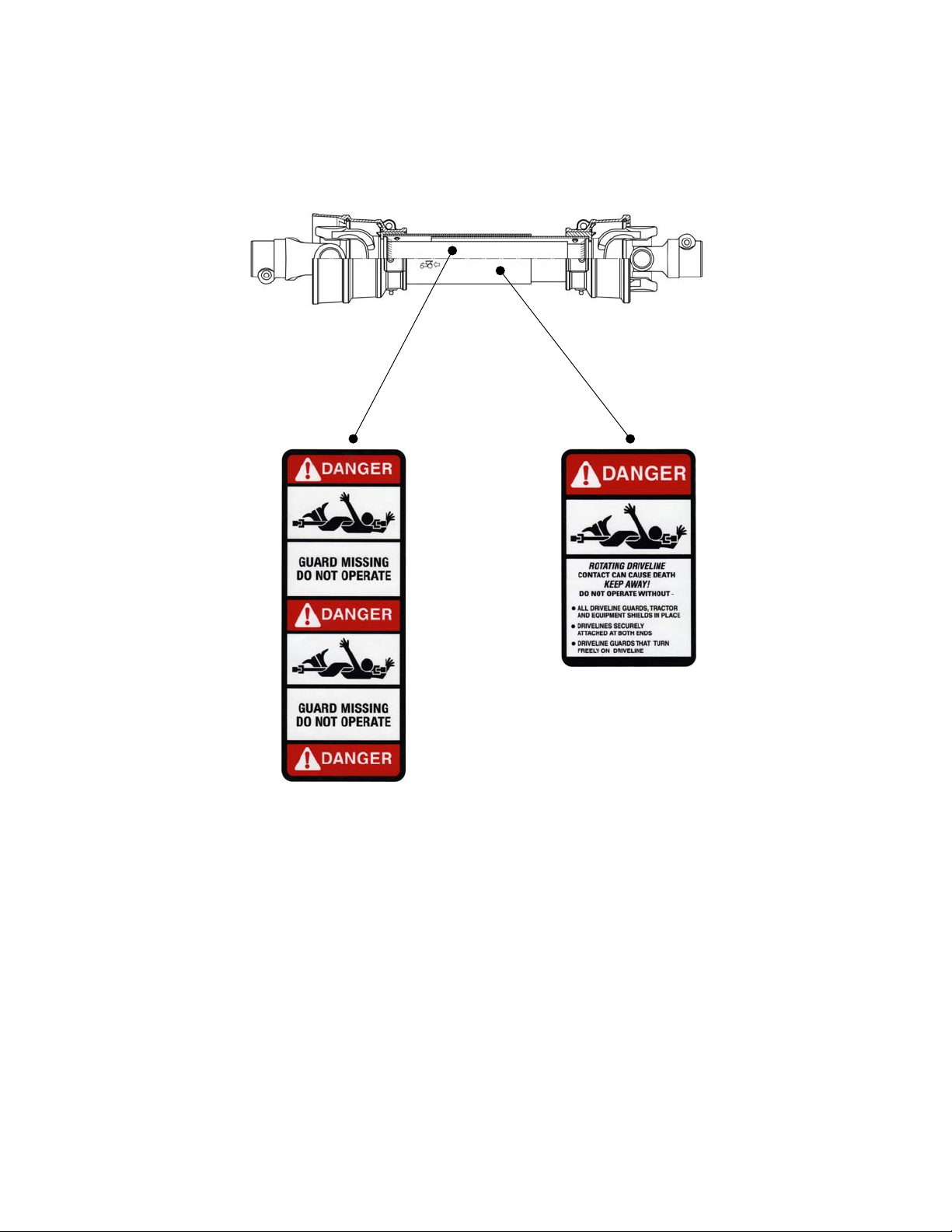

2.01 - Preparation

1. Before operating equipment read and understand the operator’s manual and the

safety signs (see fig. 2).

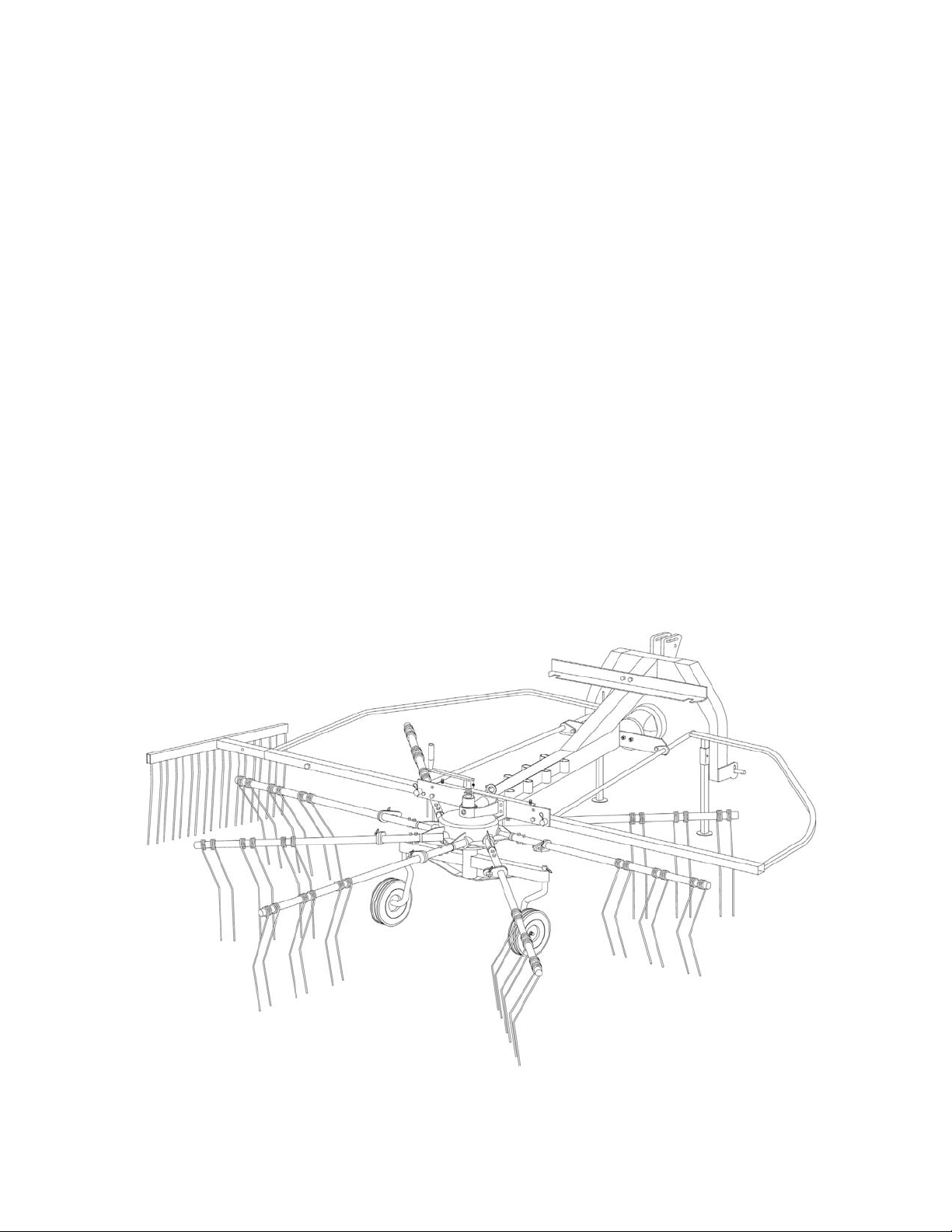

2. Thoroughly inspect the implement before initial operation to assure that all

packaging materials, i.e. wires, bands, and tape have been removed.

3. Personal protection equipment including hard hat, safety glasses, safety shoes, and

gloves are recommended during assembly, installation, operation, adjustment,

maintaining and/or repairing the implement.

4. Operate the windrower rake only with a tractor equipped with an approved

Roll-Over-Protective-System (ROPS). Always wear your seat belt. Serious injury or

even death could result from falling off the tractor.

5. Clear area of stones, branches or other debris that might be thrown, causing injury

or damage.

6. Operate only in daylight or good artificial light.

7. Ensure rake is properly mounted, adjusted and in good operating condition.

8. Ensure that all safety shielding and safety signs are properly installed and in good

condition.

SAFETY PRECAUTIONS 6BEFCO

WINDROWER RAKES OPERATOR’SMANUAL