Behncke UV matic A20 User manual

Installation and Operating Instructions

UV systems UV matic A 20 / A 25 / A 35 / A 48

Technical specifications subject to change without notice. Last updated 12/2016.

2

1.1.1.

UME GmbH

Alkersleber Weg 151 a

D-99334 KIRCHHEIM

Phone: + 49 036200 641 0

Fax: + 49 036200 641 20

E-Mail: [email protected]

Internet: www.umex-gmbh.de, www.abox-uv.de

Author: UME GmbH

Version: 01_2016

Datum: 07.01.2016

1.1.2.

ABO ® is a registered trademark of UME GmbH, with headquarters in Kirchheim,

Germany and protected as a trademark. (EU-Community trade mark EM 009 590 977,

ABO

®

).

All you provided information and technical data of the product are treated confidentially.

Publications may only with the consent of the manufacturer done.

Subject to technical modifications.

If you have any questions, please contact your partner, supplier or the manufacturer

directly (using the above contact details). The manufacturer can be contacted during

normal business hours, Monday to Friday.

To ensure prompt handling of your enquiry, please ensure you have your system’s serial

number (e.g. A-25-01112222) to hand. The number can be found in the following

places:

Identification plate

Delivery note

Invoice

Please read the User Manual carefully and keep it in a safe place!

3

1.1.3 Table of contents

1. Introduction

1.1.1. Communication

1.1.2. General information

1.1.3. Table of contents

1.1.4. Liability and warranty

1.1.5. General and residual risk

1.1.6. Information about this

User Manual

2. Safety

2.1.1. Explanation of symbols

2.1.2. UV light protection

2.1.3. Safety instructions

2.1.4. Hazardous situations and

safety instructions

2.1.5. Work on the electrical

subsystem

3. Intended use

3.1.1. Technical method

4. Product and ethod

ter inology

5. Technical specifications

5.1.1. Service life of main

modules/ancillary equipment

6. Design and confor ity

6.1.1. Interfaces

7. Syste description

7.1.1. UV reactor

7.1.2. Control box

7.1.3. Controller overview

7.1.4. Menu navigation

7.1.5. Switching output

7.1.6. Operation of the UV-device

8. Installation

8.1.1. Requirements for installation

at the customer

8.1.2. Reactor

8.1.3. Electrical sub system

9. Co issioning

9.1.1. Reactor

9.1.2. Switch cabinet and system

9.1.3. Power cable connection

9.1.4. Troubleshooting

10. Maintenance and service

10.1.1. General information

10.1.2. Changing the UV lamp

10.1.3. Inspecting the quartz

immersion tube

10.1.4. Cleaning the immersion tube

11. Cleaning the irradiation

cha ber

11.1.1. Cleaning with cleaning agents

12. Disposing of used e itters

13. Transportation and storage

14. Spare parts

14.1.1. List of spare parts

15. Operations log book

15.1.1. Notes

16. Declaration of Confor ity

17. Circuit diagra

4

1.1.4. Liability and warranty

For warranty claims, we are liable only to the extent permitted by the law or according

to the terms of the warranty given in agreements as concluded. Other matters are

governed by the General Terms & Conditions of your partners, suppliers or UME GmbH.

We draw your attention to the fact that the warranty is voided by damage resulting

from:

– Errors made during installation or operation

– Product usage not covered by intended use

– Modifications to the system

– Maintenance or service work not carried out to professional standards

– Removal or modification of safety mechanisms

– Failure to use original replacement parts/wear and tear

1.1.5 General and residual risk

The UV systems have been manufactured to the latest technical standards. Residual risk

in the form of material defects, mechanical breakage of the glass or other external

factors – can cause defects in individual modules. In such cases, please get in touch with

your contact person or a technical specialist. Always contact a technical specialist if

water has come into contact with the electrical modules.

1.1.6 Infor ation about this User Manual

The User Manual provides you with the basic information and guidance needed to

operate the UV system. Before starting any activity, please first read the corresponding

chapter(s) in this Manual. For your own safety, please always follow the safety

instructions that are given.

Operation of the UV system is also subject to the local accident prevention regulations

and general safety precautions applicable to its area of application.

Warning

This syste s works with UVC radiation!

UVC radiation can da age the skin and eyes!

Always wear protection when working with UVC!

5

2.1.1 Explanation of sy bols

Notice

General information.

Warning

Important information or prohibitions to avoid causing damage.

Warning

Warns the user about dangerous electrical voltage.

This sign is used for activities involving system components carrying

live current.

Warning: UVC radiation

If your eyes are not protected, looking at UVC for only a few seconds

(and at a distance of several metres) is enough to cause a painful

inflammation, similar to the “arc eye” experienced when welding, noticed

only hours later. Irradiation of the skin for just a few minutes is enough

to cause serious sunburn.

Danger

Danger to health and life if the appropriate safety precautions are not

followed.

Mandatory

Wear appropriate clothing and gloves to protect the skin.

Gloves also avoid leaving traces of grease on glass parts.

Also offers protection against cleaning agents.

Cotton gloves can be supplied as accessories.

Mandatory

Safety goggles must be worn at all times to protect the eyes. Only pure

quartz glass is UV-C-permeable. Also offers protection against cleaning

agents.

Safety goggles can be supplied as accessories.

Mandatory

Danger of malfunctions/damage to the UV system if the appropriate

safety precautions are not followed.

2.1.2 UV light protection

During normal operation of the UV system, the UV emitters are completely enclosed and

no UV light can escape from the UV reactor. This means operating personnel cannot be

exposed to any danger from UV light.

When checking system functions, troubleshooting or performing maintenance and

servicing, it may be necessary for a live UV emitter to be less than fully enclosed. In

such cases, suitable protection for the skin and eyes – in particular – MUST be worn.

6

Safety

The installation, commissioning, operation and maintenance of the UV system must be

performed by trained and authorised personnel at all times. These appropriately qualified

personnel must have read and understood the relevant sections of this Manual, and the

safety-relevant sections in particular.

If in any doubt, please contact your specialist dealer or the head office of the

manufacturer UME GmbH. Full contact details are provided at the front of the

document.

Before opening or installing the system, ensure it is not connected to power or pressure

lines.

Before cleaning, maintenance or replacing machine parts, isolate the system from all

power sources.

Always follow the operating instructions and comply with the permissible technical

specifications that are appropriate for the specific application.

Always observe occupational safety and accident prevention regulations, and comply

with any other generally recognised health and safety at work standards.

Before commissioning the UV system, ensure that all of the safety-related requirements

have been fulfilled and that safety mechanisms are in working order.

The UV system must only be used under the operating conditions for which the system

has been specifically designed (flow rate, SAC, etc.).

The UV system must be taken offline immediately if components are damaged or are not

in proper working order. All structural or technical modifications to the UV system are

PROHIBITED.

2.1.3 Safety instructions

Potential risks for personnel and/or the UV system itself are listed, assigned to the

respective sections in this Manual and marked with these symbols.

See - “Explanation of symbols”.

Risks are assigned to one of two categories:

UV-related risks = hazard arising fro UVC radiation

Danger to health and life if the appropriate safety precautions are not

followed.

Non-UV-related risks = hazard arising fro work with electrical power or other

achine handling risks

Danger of malfunctions/damage to the UV system if the appropriate

safety precautions are not followed.

7

2.1.4 Hazardous situations and safety instructions

Situation Subsyste Hazard Action to take

Installation/removal

of UV emitter or

immersion tube

UV reactor Burn injury

UV emitters become

very hot during use.

Laceration injury

UV emitters and

immersion tubes are

fragile

(quartz glass).

Take the UV system

offline and secure the

master switch to prevent

accidental switch-on.

Depressurise and empty

the UV reactor

Functional checks

UV emitter

UV reactor UV light causes

damage to eyes and

skin

Never switch on the UV

emitter outside the UV

reactor.

Emptying the reactor UV reactor Reactor is

pressurised.

Wear personal protective

equipment (PPE).

Open the vent valve

slowly (pressure relief

valve).

Cleaning the reactor UV reactor Chemical burn

Cleaning agents

contain acids.

Take the UV system

offline and secure the

master switch to prevent

accidental switch-on.

Wear personal protective

equipment, take

appropriate precautions

concerning the handling

of acidic liquids, follow

manufacturer

instructions about the

use of cleaning agents.

Do not eat or smoke

while working.

Replacing emitters,

work on electrical

subsystem

UV system Electrical shock.

Disconnect from the

power supply and isolate

from customer input

signals as required.

Secure the UV system to

prevent accidental

switch-on.

Electrical work must be

carried out by

professionals.

8

2.1.5 Work on the electrical subsyste

For all work on the machine’s electrical subsystem, the following safety precautions

MUST be observed/followed at all times:

Warning! The voltage used to operate the machine can be dangerous

device

The system must only be opened by trained technical specialists

Isolate the machine before opening the switch box

Read the User Manual before opening the machine

3. Intended use

The ABO

®

ultraviolet systems deactivate microorganisms, like germs, viruses and

yeasts in the water. The system works efficiently only if clear free from iron and

manganese water is supplied. The function is guaranteed only within the limits of the

technical data of the device. ABO

®

UV-system UV-irradiation devices can be installed

directly into the water supply pipe. The System should be installed in the supply directly

before any ancillary distribution pipe work and possible storage reservoirs

3.1.1. Technical ethod

UV-disinfection is a process that takes place when water flows through the reactor

chamber. Microorganisms are exposed to UVC-irradiation and will be deactivated within a

few seconds. This means the cells photochemical reactions are released which inhibit

further cell division and render the microorganisms harmless.

The advantages of the procedure are

No addition of chemicals

No formation of harmful by products

Deactivation of microorganisms takes place for a few seconds

9

4. Product and ethod ter inology

Ter Explanation

UV system The UV system is the complete system, consisting of the UV

reactor, the switch cabinet and the ancillary equipment.

UV reactor Core component in a UV system, consisting of a reactor housing

plus reactor chamber, UV emitters, immersion tubes and UV

sensors with various screw fittings.

Switch cabinet Core component in a UV system, consisting of a switch cabinet

housing with ballast units to supply the UV emitters with power,

an analysis unit for the UV sensor and electrical components to

operate the UV system.

UV emitter Component in the UV reactor that generates UV light. The UV

emitter is integrated into the immersion tube.

Immersion tube Component in the UV reactor that is immersed in water. The

immersion tube contains the UV emitters.

UV sensor Component for the continuous measurement of the UV-C

irradiation strength in the irradiation chamber.

Deposit Deposition of waterborne substances in the irradiation chamber,

and esp. on measurement window and immersion tube.

Shutoff valve Used to shut off the flow of water in inlet/outlet, manually or

automatically.

Irradiation chamber Part of the UV reactor where water flows through.

Disinfection Killing off/inactivation of microorganisms, including pathogenic

microbes.

Minimum irradiation

strength

A value for measuring irradiation strength, specific to the type of

UV disinfection device and application, measured with a UV

sensor. The minimum irradiation strength and maximum flow

rate must be maintained during operation of UV disinfection

equipment to ensure the required level of disinfection is

achieved.

UV dose (fluence) Specified in J/m

2

or mJ/cm

2

. The amount of UV light that must

be applied in order to achieve a specified disinfection result. A

metric for disinfection capability.

UV transmission Relationship of emitted irradiation to incident irradiation. UV

transmission is measured in % on a layer thickness or specified

as a spectral absorption coefficient of the wavelength 254 nm

(SAC-254).

The SAC measurement encompasses both absorbent water

constituents (colour) as well as the scattering of light by

suspended particles (turbidity).

W/m² Unit of measure for UV irradiation strength.

UV-C Shortwave (200–280 nm) UV light, a part of the electromagnetic

spectrum.

UV light Light invisible to the human eye, generated by the sun or a UV

emitter.

Boot phase Time from when the UV system is switched on to “System ready

for use”.

Minimum flow rate Required to avoid overheating.

Emitter lifespan Expected usable lifespan followed by degradation of UVC 254 nm

output

HG lamps UV-C mercury lamp

HGA lamps UV-C doped mercury amalgam lamp

10

5. Technical data

Manufacturer : UME GmbH, D-Kirchheim, www.umex-gmbh.de

Type : UV-matic A, exclusive mark for BEHNCKE

Reactor : Stainless steel, 1.4571 (316)

bath-pickled and electric-polished

Life time of lamps : 8.000 h in continuous operation

Water temperature : UV-matic A 20 and A 25 = 1 - 35 °C

UV-matic A 35 and A 48 = 2 - 55 °C

Water characteristics : no corrosive qualities, chloride level <500 mg/l,

with max. 38°C and without air entry

Ambient temperature : 2-35 ° C with maximum air humidity

of 70% at 35 ° C

Working pressure max. : 10 bar

Bezeichnung UV- atic

20

UV- atic

25

UV- atic

35

UV- atic

48

Floe rate 10 m

3

/h 15 m

3

/h 25 m

3

/h 40 m

3

/h

Capacity basin 50 m

3

75 m

3

125 m

3

200 m

3

Rate reaktor 1.000 mm 1.000 mm 1.000 mm 1.300 mm

Weight reaktor ca. 8 kg 8,5 kg 11 kg 12,5 kg

Pipe connection 1 ½“ 2“ 2“ 3“

Reaktor Ø 114 mm 114 mm 139 mm 168 mm

Length of uv lamp 880 mm 845 mm 860 mm 1.120 mm

UV- electrical power 60 W 80 W 120 W 200 W

UV-C- power 25 W 27 W 35 W 60 W

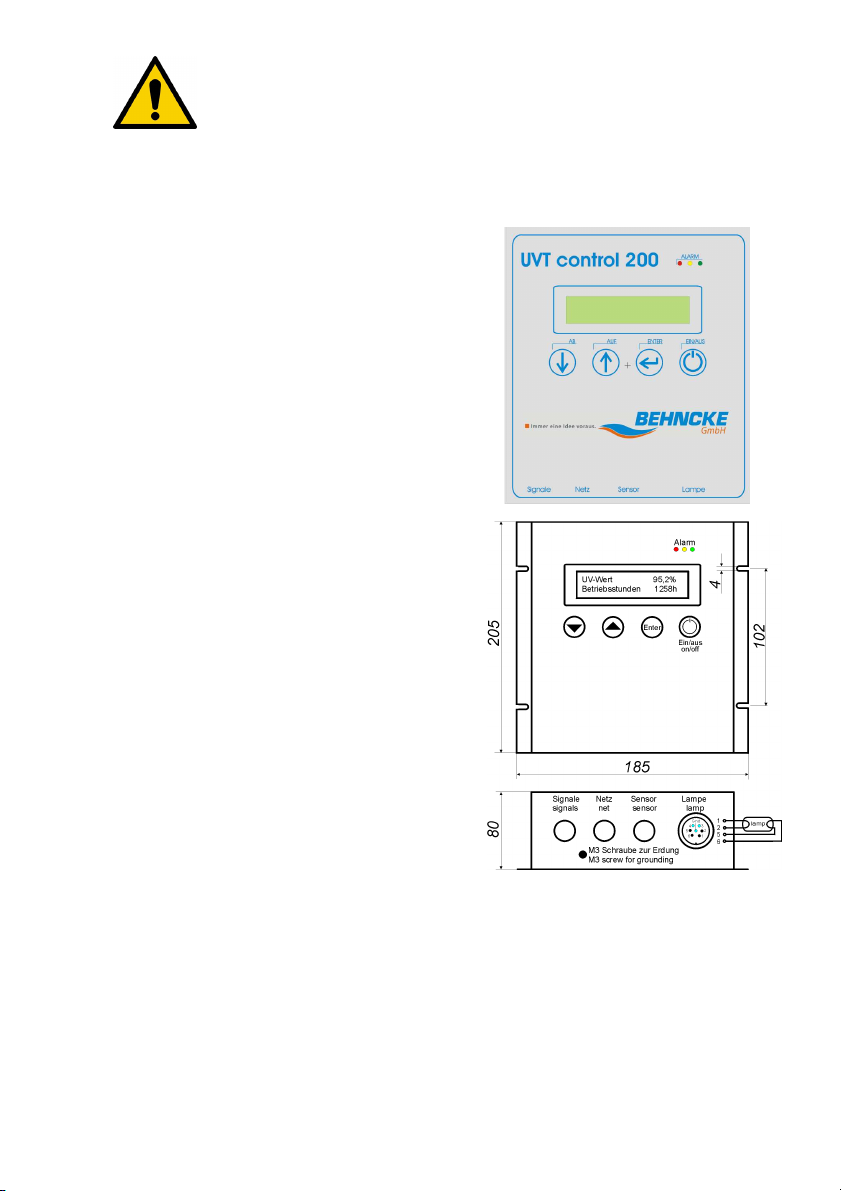

UV-unit size 185 x 205 x 80 mm HxWxD

Mains electricity

supply

230 V AC ± 10%

Artikel- Nr.: 129 200 129 250 129 350 129 480

*Arithmetic Qmax, hydraulically limited at 250 J/m

2

** In Germany, section 411.4.5 of the DIN VDE 0100-410:2007-06 standard expressly

prohibits the use of residual current devices in TN-C systems (earthing system).

11

5.1.1. Life of the ain odules / resources

Equip ent

aintenance

Intervals Testing and inspection Max. Life life

UV lamp T 8,000 h 8,000 -10 000h

Quartz immersion tube R, T 8,000 h 48 months *

Gasket Set P, T 8,000 h 12 months

UV sensor P, T P, T 48 months

Electronic Ballast(EVG) P, T 8,000 h 48 months *

Fuses P, T with Maintenance 48 months *

UV reactor R, K, T with Maintenance 120 months *

Switchbox K, P, T with Maintenance 120 months *

Stainless steel modules R, K with maintenance 120 months *

Screw connection K, T with Maintenance 24 months *

R = cleaning

T = exchange

K = control

P = Check

* Reusing after examination

Grey marked = wearing parts

6. Design and in confor ity to

Low-voltage switchgear unit combination

IEC 61439-1/-2 2011 EN 61439-1/-2 2011 VDE 0660-600 2012

Low Voltage Directive 2014/35/EU EMC Directive 2014/30/EU

DIN EN 60335-1:2005-07 safety of electrical installations both in household,

commercial, industrial and water sectors

6.1.1. Interfaces

Switch box / cabinet

terminal strip

fuse

Reactor flange UV system

Installation site

Indoor frost-free

Maximum humidity 70% at 35 ° C

Ambient temperature max. 35 ° C

water temperature

35° C HG lamps

55° C HGA lamps

Special operating conditions

Accessible to operation and maintenance

Compliance with the line length

12

7. Syste description

The UV system consists essentially of a UV reactor and the corresponding switch cabinet.

The UV system is delivered ready for installation. Connection cables for the UV emitter

and UV sensor are included in delivery.

7.1.1. UV reactor

Protective cap

Screw joist

leed valve

Outlet

UV-sensor

Quartz sleevers liner

UV-lamp

Reaktor

Drain

A

C

Lamp exchang

D

Inlet

PE

Type UV-matic A

20

UV-matic A

25

UV-matic A

35

UV-matic A

48

A 1.000 1.000 1.000 1.300

B 835 820 820 1.075

C 195 200 220 270

D 900 900 900 1.200

Reactor/stan Ø 114/175 114/175 139/200 168/230

Pipe connection 1 ½“ 2“ 2“ 3“

13

7.1.2. Switchbox the series UV atic

The UV system switch cabinets are designed for automated operation.

All UV systems have been given a 100% factory test prior to shipping. The switch boxes,

modules and terminal blocks have been tested against the applicable standards.

Complete control unit with integrated

electronic ballast, UV monitor and hour

counter in an own housing. The unit is wired

ready for connection including the sensor.

It can be combined with 4 different lamps

between 60 to 200W.

Safety check of the coded UV lamp cable

when each switching on.

Description

•for 230±10% VAC main voltage supply

•integrated electronic ballast for 60W, 80W,

120W, 200W

•safety circuitry prevent damages in case of

ground fault, short circuit, end of lifetime

and overtemperature

•control via menu in German, English,

Russian

•two line alphanumeric display is

background illuminated allows displaying

UV value and lamp working hours at the

same time

•4 switching outputs available, threshold

values programmable

•daylight blind UV-sensor SUV13.1 A1 C

optional

•calibration of the UV value via menu

possible

counter for global and lamp hours, lamp hour

resettable

14

7.1.3. Controller overview

power net

current

sensor enu

language

la p / current accessory

cable

60-200

W

max.

1,0 A*

SiC-sensor

SUV13.1A

German

English

Russian

HG 60/4 / 0,67 A

HG 80/4 / 0,80 A

HGA 120/4 / 1,5 A

HGA 200/4 / 2,0 A

type 1 - 60W

type 2 - 80W

type 3 - 120W

type 4 - 200W

Controller technical data:

Mains electricity supply 230 V AC ± 10%

Mains frequency 50 - 60 Hz

Operating frequency 25 - 65 kHz

Efficiency > 90%

Cos φ 0.96

Pre heating Yes

A bient te peratur 0 - 45°C

Case te perature 50°C ax.

Fault warning relays 24 VDC/230 VAC, 50 A-5A

Installation vertikal

Size (H x W x D) 205 x 185 x 80

Cable length net, la p, sensor 2.5

Degree of protection IP 65

Gewicht 2000 g

UV onitor

The relative UV-intensity is read by a sensor and shown in the display. When dropping

below the minimum alert value (e.g. 50%) „Pre-alarm“ is signalled by a yellow LED and

appropriate relay contact. When the lamp fails “Main-alarm” is signalled by the red LED

and the appropriate relay contact.

Hour counter

Total hours and lamp hours are counted continuously. The internal value will renewed

every hour. The lamp hours are shown on the display and can be reset when the lamp

will be changed.

Menu

You reach the menu by pressing the Enter button 2 seconds. With buttons / you can

browse through the menus up / down. Enter calls up the menu point for changes. Either

the changing will occur immediately or the value will called and can be changed

afterwards. With buttons / you can modify the values. With Enter the adjusted value

will be acknowledged / stored. After 10 seconds waiting an automatically return to the

basic display will take place.

15

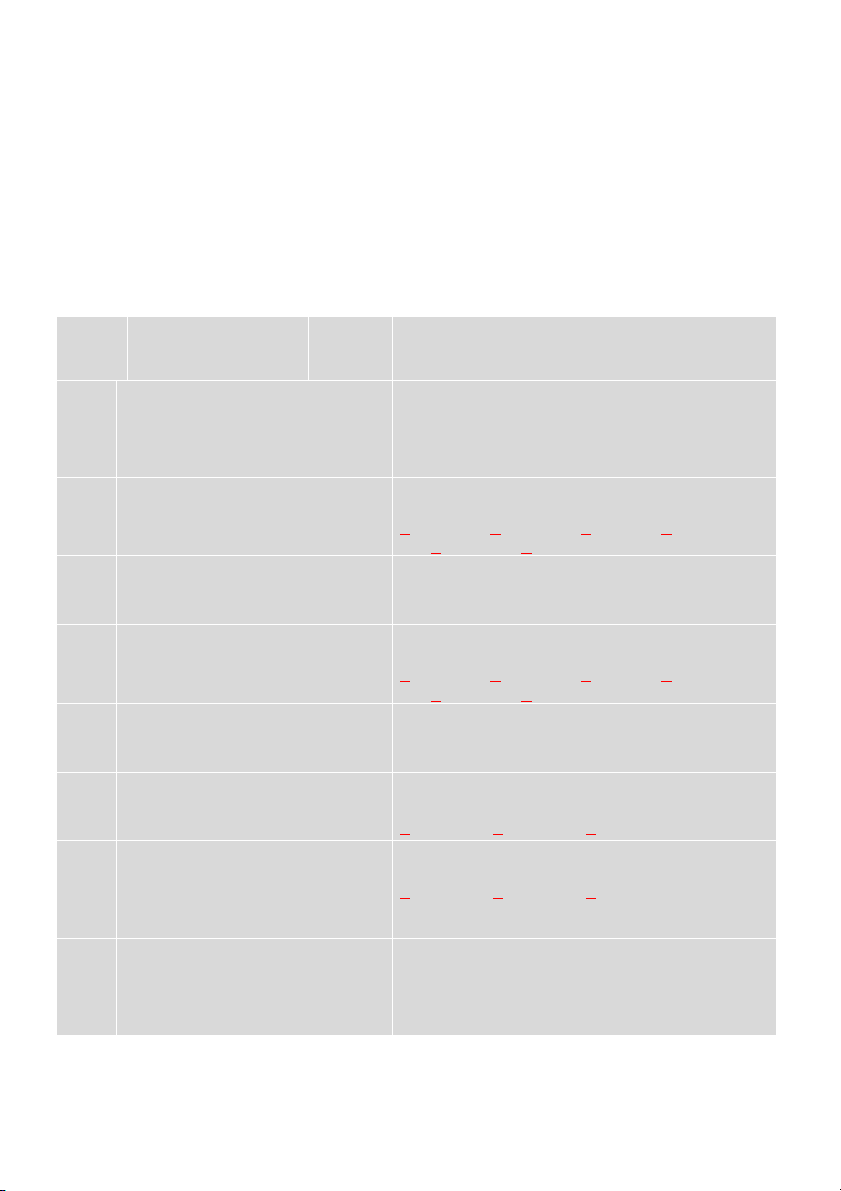

7.1.4. Menu navigation

With the first installation all menu options are served and adjusted.

Everyone turns out before the distribution is examined and adjusted as follows.

Standard setting:

1 = Language German 5 = Half

2 = 1 6 = 50%

3 = 0 7 = 110%

4 = 8.000 8 = Drinking water

enu

-

entry

display shows line 1

line 2 action with pressing ENTER

1 language

English

every ENTER will choose the next language

German English Russian German

...

The chosen language will appear on the

display immediately

2 la p hours

<nu ber of la p hours>

ENTER displace the cursor one digit, / for

value adjustment

00000 00000 00000 00000

00000 00000 back

3 overall hours

<nu ber of overall hours>

only display

example: 008023 h back

4 la p life ti e

<la p life ti e in hours>

ENTER displace the cursor one digit, / for

value adjustment

00000 00000 00000 00000

00000 00000 back

5

display contrast

<bar for contrast

adjust ent>

ENTER calls the bar, / adjustment less /

more

6

UV warning

<alar threshold value

in %>

ENTER displace the cursor one digit, / for

value adjustment

000 % 000 % 000 % back

7 calibration value

<end value in %>

ENTER displace the cursor one digit, / for

value adjustment

000 % 000 % 000 % back

Attention: maximal adjustable value is

110 %!

8 calibration

<current value in %>

ENTER an alignment to the value above will

occur

Attention: lamp must be at it working

temperature! You can check that if the value

will not change after alignment.

16

7.1.5. Switching output

The switchbox is IP 65 conformal. Around degree of protection to ensuring, a lacquer

protection is appropriate at the lower screw of the back. Attaching the reporting exits

may take place only from an experienced specialist around the operability and ensure

the tightness of the switchbox.

The accompanying picture shows the

way of the wiring which can be kept.

In the lower picture and in the table

the allocation of the relays is shown.

Opinion from the rear, cable supply right.

Fault warning relays 24 VDC/250 VAC, 50mA-5A

Configuration of the relays

Relai

s

LED Infor ation

Rel. 1 green Correct opration

Rel. 2 yello

w

Alarm theshold

overtravel

Rel. 3 red UV lamp failure

Relay configuration cut out

17

7.1.6. Operation of the UV-device

The UV systems uv matic 25 is for water temperatures 2-35 °C and the UV systems uv

matic 35 maximum 55 °C designed for continuous operation.

In addition, a continuous water flow at the specified rate is required for optimal

operation.

Please see the data sheet for your specific model.

During fluctuating operating times, please monitor the reactor temperature to avoid

damage to the equipment and associated pipe work.

The efficiency of the UV-device is determined by the UV-intensity in the reactor. This

decreases during operation by lamp ageing or deposits on the inner quartz tube. This

also applies to unstable UV-transmission turbidity values, air temperatures or lower

throughputs.

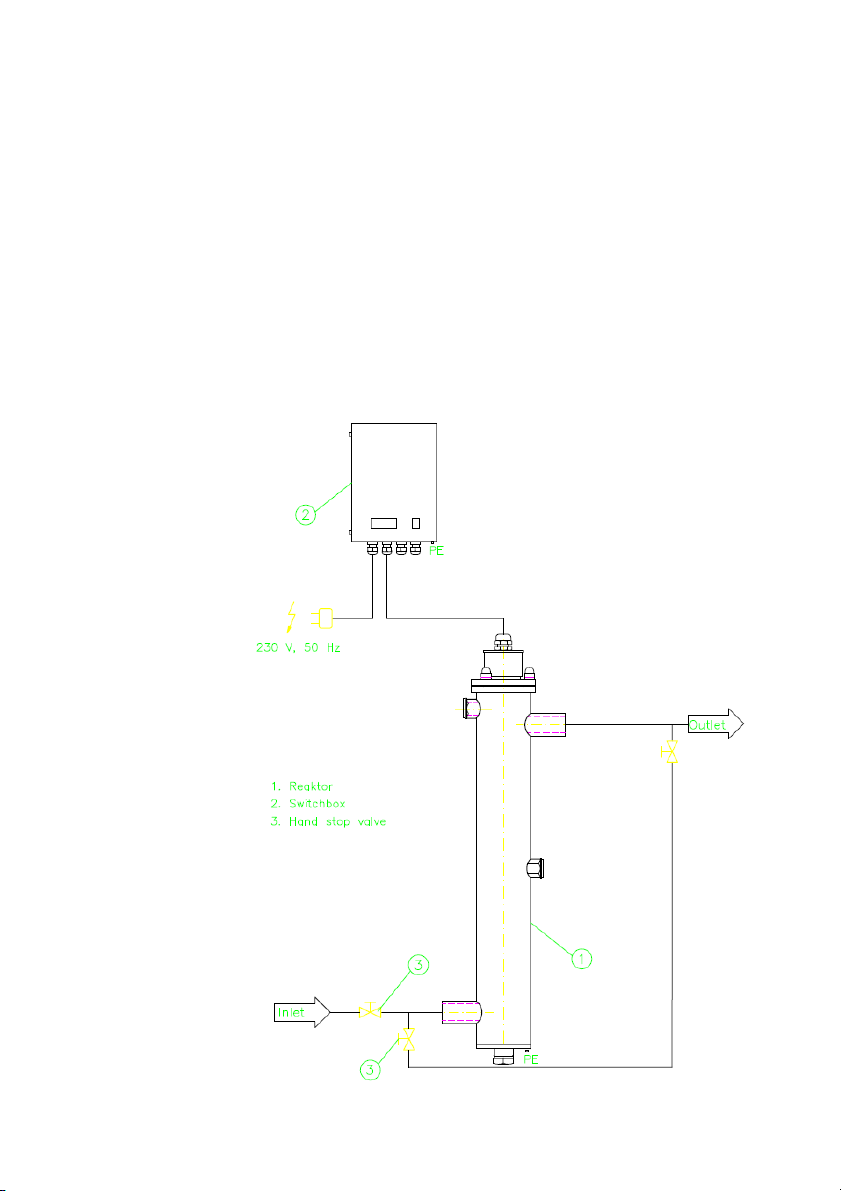

Exa ple installation sche e

18

8. Installation

The installation and commissioning of the System should only be undertaken by trained

specialists. Handling glass and UV-RADIATION requires special care. If you are in doubt,

please contact us. All contact details are on the first page.

The opening and installation of the device is only permitted when there is no water

pressure and no connection to electrical power. Before cleaning, maintenance or the

exchange of parts the system should be safely isolated from the electricity supply.

1. When installing, please consider free space for lamp change and general

maintenance.

See System description 7.

2. Protect against direct solar irradiation and against frost.

For general installation of the UV equipment, please see drawing, 7. For horizontal

installation must be ensured the ventilation in the UV reactor. In addition, the UV sensor

should not stand up, only horizontally or downwards to be installed in the water ring.

3. Installation of the UV-device should be completed with appropriate rubber lined

clamps or other suitable means (PVC-type).

4. Earthing/Grounding of the reactor and Switch Cabinet should be completed

according to local Regulations.

5. Fastening connections to the input/output (and to sampling valve).

6. Test for hydraulic pressure integrity in the reactor water. (Outlet key in the

accessories).

7. Install the switch cabinet in a suitable place. Please consider Cable lengths for

plug and la p cable.

8. Attach the lamp connector to the socket. Caution this can only be connected in

one orientation. Do not force the connection. Please ensure a good, snug fit.

9. The sensor and measuring window are screwed into the sensor connection in the

middle of the reactor. When installing the sensor screw connection, please note the

groove and notch arrangement. When the screw connection is secured, the installation

conforms to IP 65.

10. Optional! Cable connection for safety devices produce! For this purpose

11. Either ‘hard wire’ or use a plug and socket to connect to the mains depending on

your local regulations.

19

8.1.1. Require ents for installing the UV syste at the custo er

8.1.2. Reactor

Action to take Purpose

Installation indoors

Frost-free operation, protection against

direct solar radiation

Avoids damage to the system

Inspection of installation for

machine/method integration

System check

Check the working pressure, ambient

temperature and supply voltage

Protects the UV system

Ensure that sufficient clearance is available

in accordance with the installation

dimensions

Maintenance and service work

Ensure that pressure surges are avoided

– Charging and venting the reactor

– Slow ramping up of the pump (frequency

converter)

– Slow opening of the valves

(valve control system)

- Vented supply lines

Avoids damage to the UV reactor

Ensure that the reactor mounts (external to

the machine) are designed to support the

corresponding weight.

Ensures safe installation and protects the

system

Keep an eye on rinse processes and install

an external inlet/outlet system with

solenoid valves if required.

Keep Qmax n mind in this context.

Protects the UV system from overheating

Automatic operation of the system

Ensure that appropriate precautionary

measures are taken during installation so

as to prevent the distribution of untreated

water.

Ensures process safety

8.1.3. Electrical subsyste

Action to take Purpose

Ensure the supply of the necessary

operating voltage

Avoids malfunctions

Damage to the system

Check current-limiting fuses and protective

mechanisms (RCDs)

Avoids malfunctions

Ensures safe installation and protects the

system

Inspect the location chosen for wall

mounting. Double-check cable lengths.

Avoids malfunctions

Ensure that ambient temperatures do not

exceed 35 °C and the location is suitable

for a protection class of IP 54

Avoids overheating

Ensure professional installation of

connection cables and signal loads

Avoids malfunctions

20

9. Introduction

Warning

Important information or prohibitions to avoid causing damage.

Warning

Warns the user about dangerous electrical voltage.

This sign is used for activities involving system components carrying live

current.

Warning: UVC radiation

If your eyes are not protected, looking at UVC for only a few

seconds (and at a distance of several metres) is enough to cause a

painful inflammation, similar to the “arc eye” experienced when

welding, noticed only hours later. Irradiation of the skin for just a

few minutes is enough to cause serious sunburn.

Danger

Danger to health and life if the appropriate safety precautions are

not followed.

9.1.1. Reactor

Requirements

Water pipes are ready for the installation.

The correct water pressure is available.

Electrical connections are ready to be energised at the switch.

9.1.2. Cabinet and syste

Switchgear cabinet is mounted and electrical connections ready.

UV lamp is correctly installed.

ONLY OPERATE THE UNIT WITH THE CORRECT UV LAMP.

9.1.3.

Power cable connector

The system is switched on via the On / Off switch.

This manual suits for next models

3

Table of contents

Popular Laboratory Equipment manuals by other brands

Omega Engineering

Omega Engineering TJ-USB user guide

W&H

W&H Lisa VA131-17 Instructions for use

Wavelength Electronics

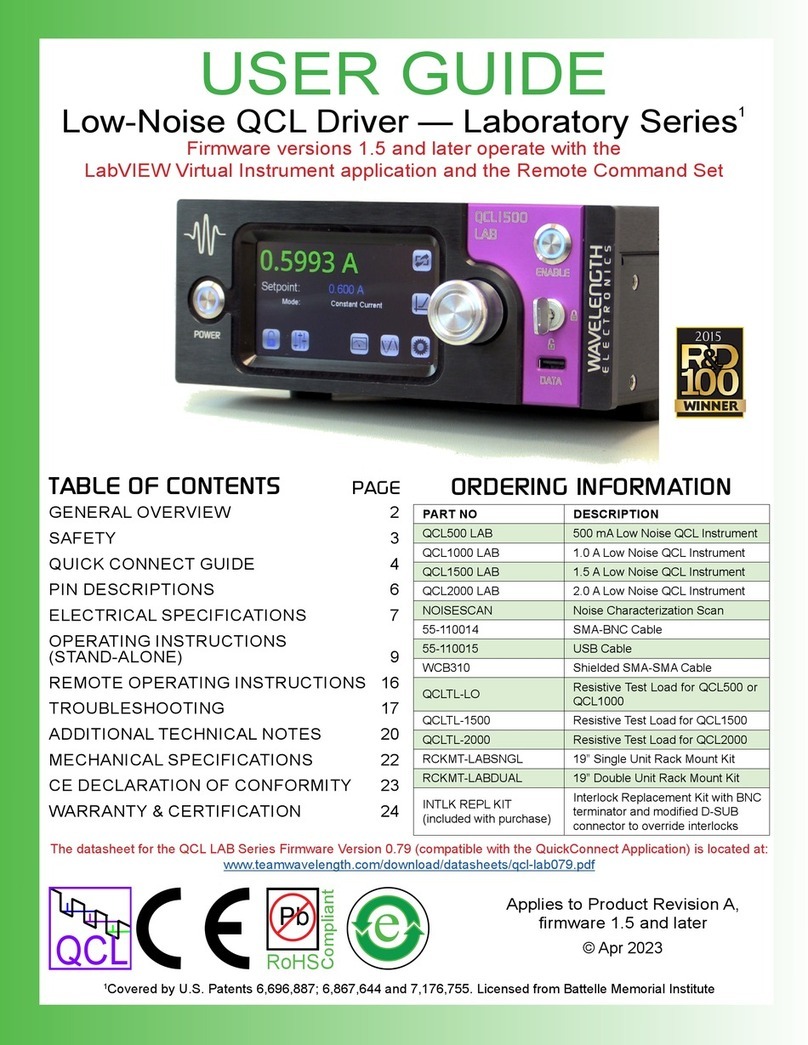

Wavelength Electronics QCL500 LAB user guide

89 North

89 North PhotoFluor II operating manual

Thermo Scientific

Thermo Scientific Gibco CTS Rotea user guide

Helmer Scientific

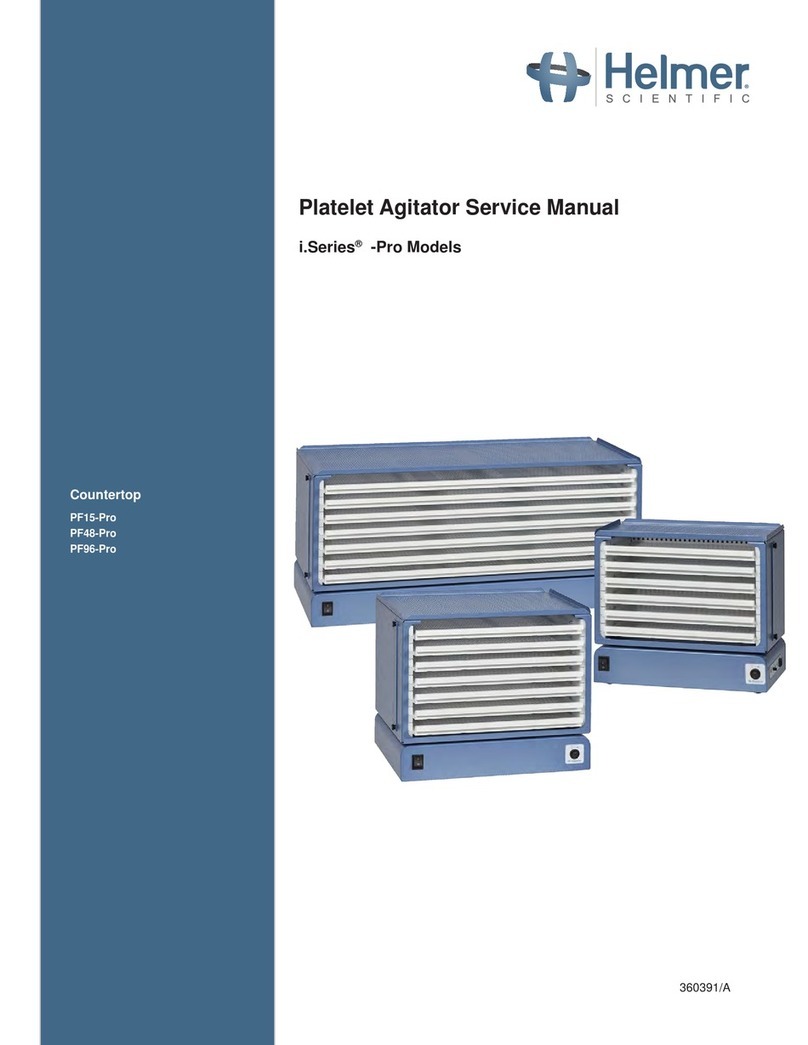

Helmer Scientific i.Series Pro Series Service manual