3

TABLE OF CONTENTS

SECTION 1 - INTRODUCTION ...................................................................................................... 4

1.1 USE AND FUNCTION........................................................................................................ 4

SECTION 2 - TECHNICAL SPECIFICATIONS .............................................................................. 5

2.1 TECHICAL SPECIFICATIONS TABLE............................................................................... 5

2.2 ACCESSORIES FOR NF 048 ............................................................................................ 5

2.3 GENERAL PRESENTATION............................................................................................. 6

2.4 PRECAUTIONS AND USAGE LIMITATIONS .................................................................... 6

SECTION 3 - SYMBOLS................................................................................................................ 7

SECTION 4 - INSTALLATION PROSEDURE ............................................................................... 7

4.1 LIFTING AND TRANSPORT.............................................................................................. 7

4.2 UNPACKING ..................................................................................................................... 7

4.3 POSITIONING................................................................................................................... 8

4.4 MAINS SUPPLY ................................................................................................................ 8

SECTION 5 - OPERATING PRINCIPLES ...................................................................................... 9

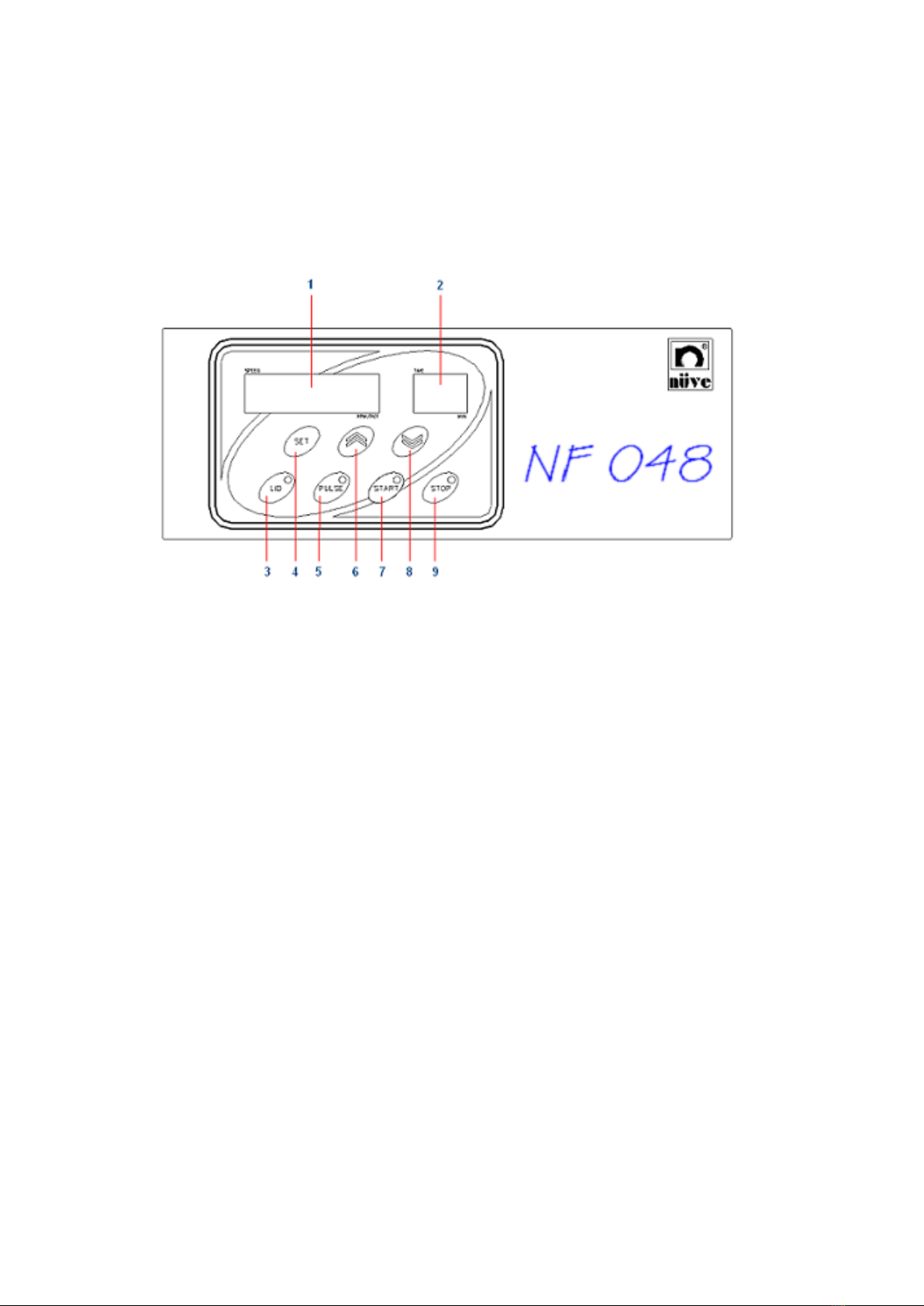

5.1 CONTROL PANEL............................................................................................................. 9

SECTION 6 - OPERATING PRINCIPLES.................................................................................... 10

6.1 LOADING ........................................................................................................................ 10

6.2 PROGRAMMING............................................................................................................. 11

6.3 MANUAL LID OPENING.................................................................................................. 11

SECTION 7 - PERIODIC MAINTENANCE, CLEANING AND STERILIZATION.......................... 11

7.1 PERIODIC MAINTENANCE............................................................................................. 12

7.2 CLEANING...................................................................................................................... 12

7.3 STERILIZATION.............................................................................................................. 13

SECTION 8 - DISPOSAL MANAGEMENT CONCEPT................................................................. 13

SECTION 9 - TROUBLESHOOTING............................................................................................ 13

SECTION 10 - ELECTRICAL CIRCUIT DIAGRAM...................................................................... 15

10.1 NF 048 ELECTRICAL CIRCUIT DIAGRAM...................................................................... 15

SECTION 11 - WARNING LABEL ............................................................................................... 16