1. Introduction

A. Maxwell®16 MDx Purification Procedure

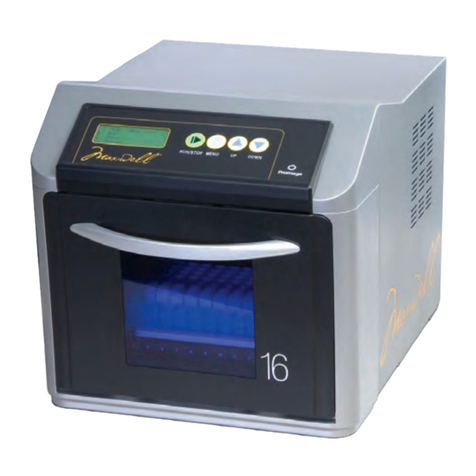

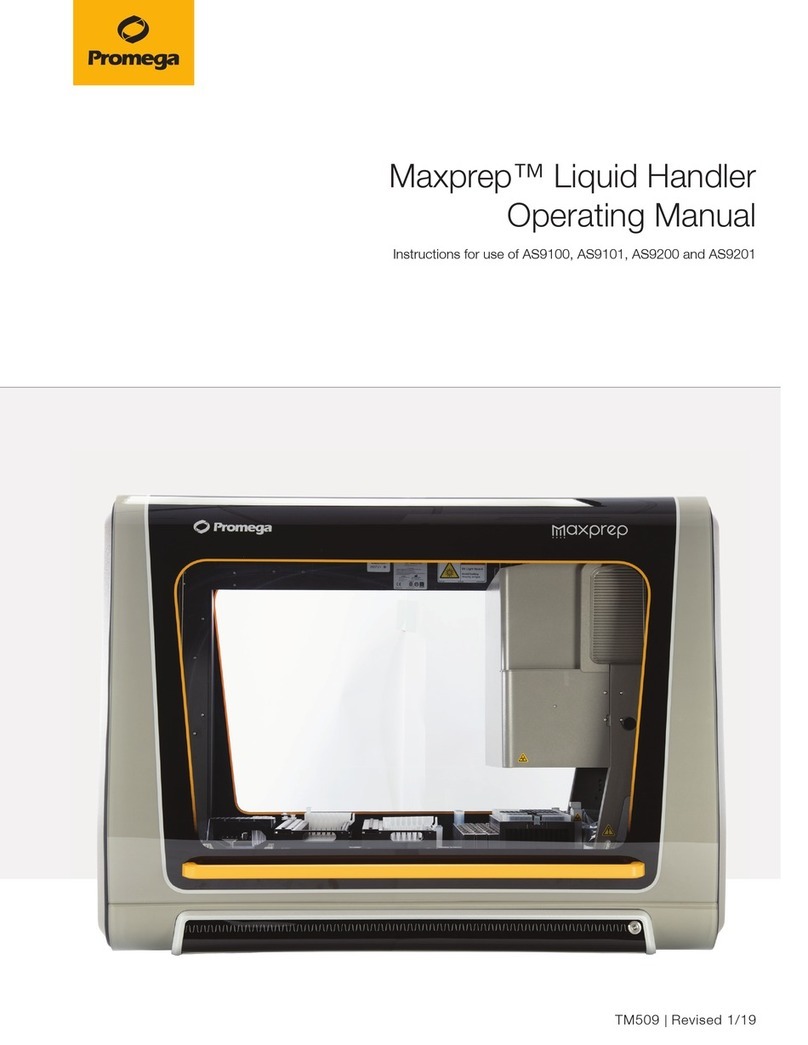

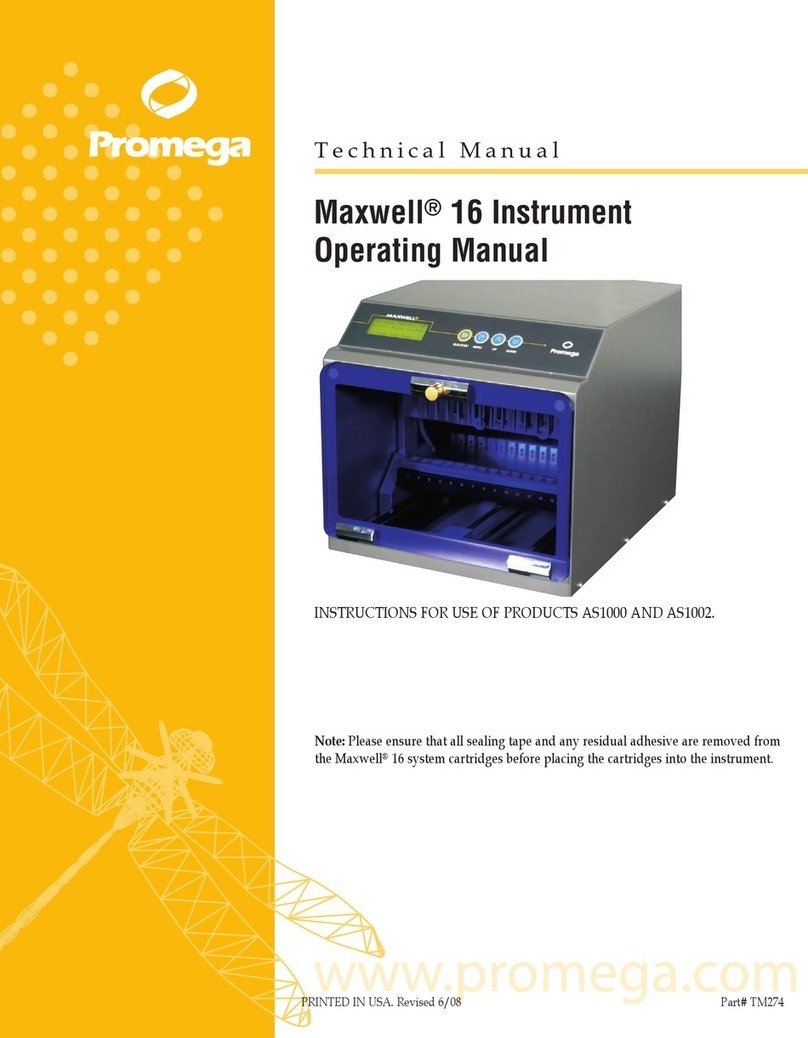

The Maxwell®16 MDx Instrument(a) provides automated

nucleic acid purification methods for multiple analytes.

The methods use sample lysis and binding to paramagnetic

particles as the primary separation principle. It has two

modes for different elution volumes. The Standard Elution

Volume (SEV) mode allows elution in a volume of up to

400μl. The Low Elution Volume (LEV) mode allows elution

in as little as 25μl. Up to 16 samples can be prepared in a

single run.

The automated steps performed by the Maxwell®16 MDx

Instrument include:

• Sample lysis in the presence of a chaotropic agent,

detergent and/or alcohol

• Binding of nucleic acids or proteins to paramagnetic

particles

• Washing of the target molecules bound to the particles

away from other cellular components

• Elution of the product

The instrument contains a touch screen for navigating,

programming and running the instrument. It has a UV

lamp to aid with decontamination. The Maxwell®16 MDx

Instrument, in association with the Maxwell®Sample Track

software, has the ability to record and provide run data. It

has a USB port that can be used to attach a bar code reader

allowing sample and reagent information to be entered

using bar codes. The Maxwell®16 MDx Instrument can

report the data gathered for each run, and the report can

be sent to a serial printer or to a computer.

The user selects the protocol to be run, collects the selected

bar code information (optional) and places the samples into

the reagent cartridges. The cartridges are placed into the

machine and the door shut to start the run, which

automatically performs the protocol.

The temperature of the samples is regulated by a heating

system that is controlled by the protocol.

Maxwell®Sample Track is a communications program that

allows downloading and printing of the run data (see

Technical Manual #TM314).

Maxwell®16 MDx Instrument Features

• Easy-to-use and easy-to-maintain system operation that

standardizes nucleic acid or protein sample preparation

workflow

• Comprehensive technical support

• System controlled via multi-language LCD readout

• UV lamp to aid in decontamination of instrument

• Reporting functionality

•Maxwell®Sample Track Software and bar code reader

included

• Preprogrammed methods for DNA, RNA and protein

purification

• Ability to create user-defined protocols

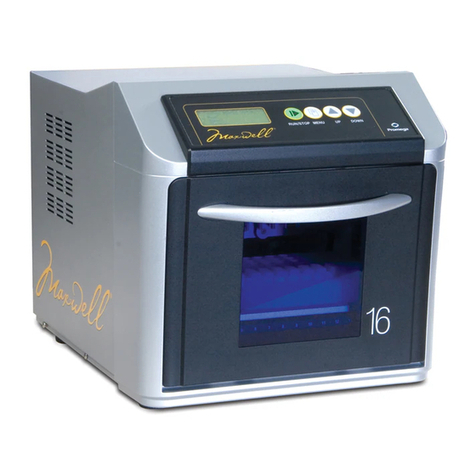

B. Maxwell®16 MDx Instrument Specifications

Processing Time: Depending upon sample type and method

used, 20–50 minutes

Number of Samples: up to 16

Weight: 42.7lb (19.4kg)

Dimensions (W × D × H): 12.8 × 17.3 × 12.9 inches (325.5 ×

438.2 × 326.5mm)

Power Requirements: 100–240VAC, 50–60Hz, 2.1A

Fuse: 3A time-lag fuse

UV Bulb: Average lifetime approx. 3000 hours, length

134.5mm, diameter 15.5mm, 4.5W, 0.17A current, 29V,

Spectral Peak 253.7, UV output 0.8W

C. Product Components

General Purpose Laboratory Equipment

AS3000 Maxwell®MDx Instruments include:

•1 Maxwell®16 MDx Instrument

• 1 power cable

• 1 UV lamp bulb*

• 1 SD card

• 1 SD card reader package (contains SD card reader and

cable)

• 1 CD containing the technical manual

• 1 Quick Start Guide

• 1 Bar Code Reader (provided in a separate box)

• 1 CD Containing Sample Track Software and manual

• 1 RS-232 Cable for communication with a computer or

printer

• 1 RS-232/USB Adaptor for data export to computer

* The UV bulb contains mercury and must be disposed of

properly. To dispose of a bulb, please follow your

institutional requirements for cleanup and disposal of

mercury.

Cat.# AS3000-SC (SEV Configuration**) includes:

• 1 cartridge rack

• 1 magnetic elution rack

Cat.# AS3000-LC (LEV Configuration**) includes:

• 1 LEV cartridge rack

**The rack(s) provided depends on the hardware mode

options that have been purchased. If both the SEV and LEV

hardware are ordered, the instrument will be provided

configured in the LEV mode with the SEV hardware

supplied separately.

Promega Corporation

2800 Woods Hollow Road • Madison, WI 53711-5399 USA part# TM320

Toll Free in USA 800-356-9526 • Phone 608-274-4330 rev. 9/09

Maxwell®16 MDx Instrument Technical Manual

1