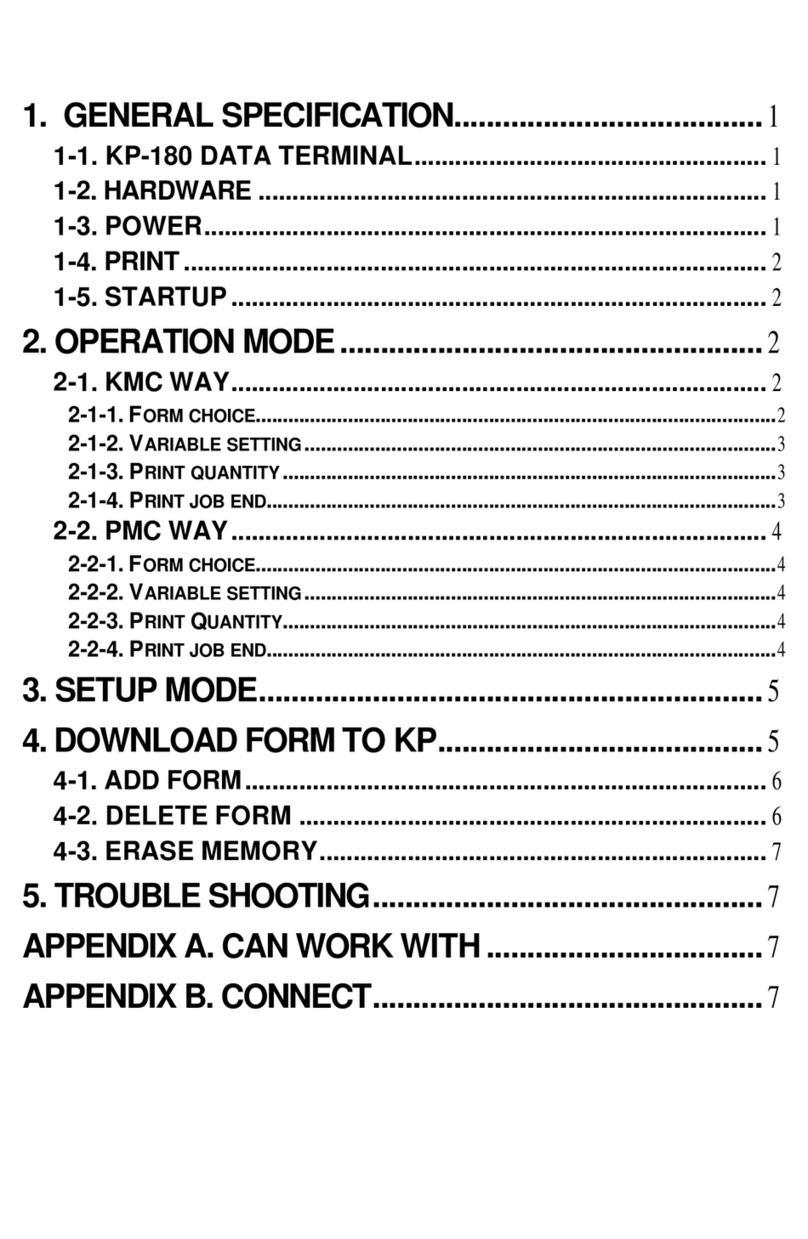

Table of Contents

1. Safety Precautions ........................................................................................ 5

1.1. General ............................................................................................ 5

1.2. Hazardous Materials ............................................................................. 5

1.3. Disposal Requirements Under WEEE Regulations ............................................ 6

1.4. UL and cUL Installation .......................................................................... 6

1.5. During Installation ................................................................................ 6

1.6. During Use ......................................................................................... 7

1.7. Service and Maintenance ........................................................................ 7

1.7.1. Cleaning the Display .................................................................... 7

1.8. Dismantling and Scrapping ...................................................................... 8

1.9. Appearance of Air in Touch Screen ............................................................ 8

2. Naming Convention ....................................................................................... 9

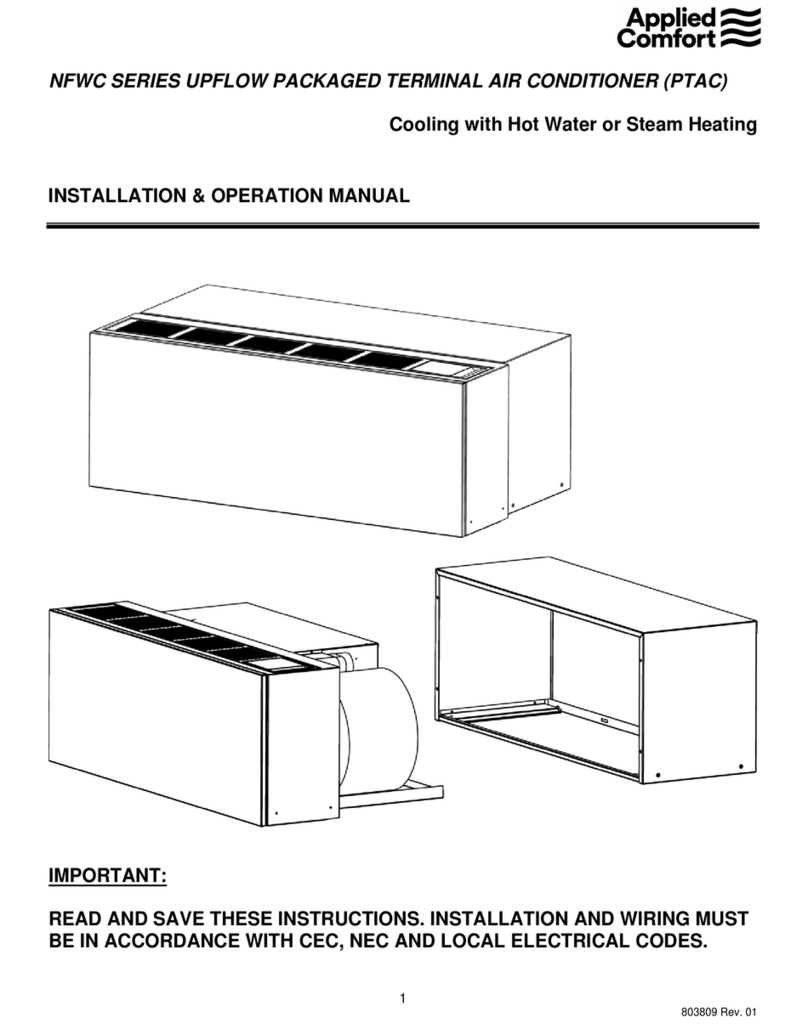

3. Installation ................................................................................................ 10

3.1. Space Requirements ............................................................................ 10

3.2. Installation Process ............................................................................. 10

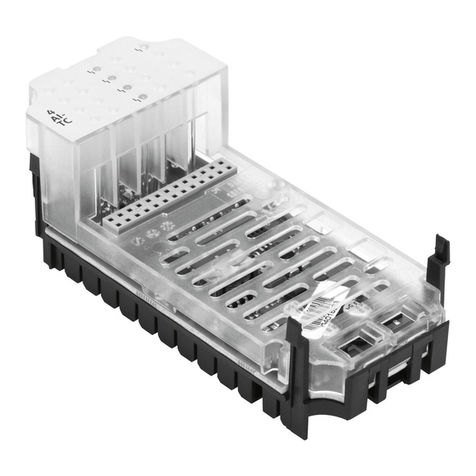

3.2.1. Connections to the Controller ........................................................ 12

3.2.2. Other Connections and Peripherals .................................................. 12

3.2.3. Open Ports ............................................................................... 13

4. Technical Data ............................................................................................ 14

5. Chemical Resistance ..................................................................................... 16

5.1. Touch Screen and Overlay Material ........................................................... 16

5.1.1. Protective Film ......................................................................... 16

5.1.2. Touch Screen Surface .................................................................. 16

5.1.3. Touch Screen Protector ................................................................ 17

6. HMI Panel Drawings ...................................................................................... 18

6.1. Connectors ....................................................................................... 18

6.2. HMI Panel Outline ............................................................................... 19

7. Additional Installation Tips ............................................................................. 21

7.1. Grounding the HMI Panel ....................................................................... 21

7.2. Ethernet Connection in the HMI Panel ....................................................... 22

7.3. To Achieve Better EMC Protection ............................................................ 23

7.4. Ambient Temperature .......................................................................... 24

7.5. Safety ............................................................................................. 25

7.6. Galvanic Isolation ............................................................................... 26

7.7. Cable and Bus Termination RS-485 ........................................................... 27

7.8. USB Flash Drive .................................................................................. 27

7.9. Image Sticking ................................................................................... 27

Beijer Electronics, MAEN333 3 2023-09