Soehnle Professional 3035 User manual

www.soehnle-professional.com

Manual

Terminal

3035

2

3

TABLE OF CONTENTS PAGE

1. GENERAL INFORMATION........................................................................................................... 6

1.1 Introduction.......................................................................................................................................... 6

1.2 Intended use ........................................................................................................................................ 6

1.3 Safety instructions............................................................................................................................... 7

1.4 Cleaning ............................................................................................................................................... 7

1.5 Maintenance and service .................................................................................................................... 7

1.6 Product Warranty/liability ................................................................................................................... 8

1.7 Setup instructions................................................................................................................................ 8

2. DEVICE DESCRIPTION ................................................................................................................ 9

2.1 Connection and device description .................................................................................................... 9

2.2 Technical data ..................................................................................................................................... 9

2.3 Symbols on the display ..................................................................................................................... 10

2.4 Calibration instructions..................................................................................................................... 11

2.4.1 Name plate................................................................................................................................. 11

2.4.2 Calibration counter.................................................................................................................... 11

2.5 Switching on / off .............................................................................................................................. 12

3. OPERATING CONCEPT............................................................................................................. 13

3.1 Setting mode...................................................................................................................................... 13

3.2 Program mode................................................................................................................................... 14

3.3 Function keys..................................................................................................................................... 14

4. SETTING MODE......................................................................................................................... 16

4.1 Starting the setting mode.................................................................................................................. 17

4.2 Program settings............................................................................................................................... 18

4.3 Setting mode Terminal settings ....................................................................................................... 19

4.4 Setting mode Scale settings............................................................................................................. 25

4.5 Setting Mode Communication Settings ........................................................................................... 28

4.6 Setting mode Settings Service.......................................................................................................... 39

4.7 Reset Terminal................................................................................................................................... 39

5. BASIC FUNCTIONS ................................................................................................................... 40

5.1 Switching on ...................................................................................................................................... 40

5.2 Switching off...................................................................................................................................... 40

5.3 Program selection ............................................................................................................................. 40

5.4 Zeroing ............................................................................................................................................... 40

5.5 Tare function...................................................................................................................................... 41

5.6 Gross display ..................................................................................................................................... 41

5.7 Scale switching.................................................................................................................................. 41

5.8 Tenfold display x10 ........................................................................................................................... 42

5.9 Hold function ..................................................................................................................................... 43

5.10 Secondary display ........................................................................................................................... 44

5.10.1 Second unit.............................................................................................................................. 46

5.11 Organizational data (identifier)....................................................................................................... 48

5.12 Alphanumeric input ......................................................................................................................... 51

5.13 Key lock............................................................................................................................................ 52

5.14 User Password ................................................................................................................................ 53

5.15 Login function / process start function ......................................................................................... 53

5.16 SD card data backup ....................................................................................................................... 58

5.17 Volume measurement..................................................................................................................... 59

5.18 Dynamic function keys.................................................................................................................... 61

5.18.1 Configuration commands............................................................................................................ 61

4

5.18.2 Defining a dynamic function key ................................................................................................. 61

5.18.3 Switching dynamic function keys on/off .................................................................................... 63

5.18.4 Defining the level of the dynamic function keys......................................................................... 64

5.18.5 Saving the settings of the dynamic function keys ..................................................................... 64

5.18.6 Loading the settings of the dynamic function keys ................................................................... 64

5.18.7 Printing conditions ....................................................................................................................... 65

6 APPLICATION PROGRAMS ....................................................................................................... 66

6.1 Selection of the application programs............................................................................................. 66

6.2 Function keys..................................................................................................................................... 66

6.3 Navigation in the application programs........................................................................................... 67

6.4 Custom programs.............................................................................................................................. 67

6.5 Weighing and taring........................................................................................................................... 68

6.5.1 Function keys............................................................................................................................. 68

6.5.2 Display view ............................................................................................................................... 68

6.5.3 Display information field........................................................................................................... 69

6.5.4 Weighing without taring ............................................................................................................ 70

6.5.5 Manual taring............................................................................................................................. 70

6.5.6 Taring with manual tare ............................................................................................................ 70

6.5.7 Multiplicative tare...................................................................................................................... 71

6.5.8 Additive tare............................................................................................................................... 71

6.5.9 Intermediate tare ....................................................................................................................... 72

6.5.10 Automatic tare......................................................................................................................... 72

6.5.11 Fixed tare value memory......................................................................................................... 73

6.5.12 Error messages when taring................................................................................................... 74

6.5.13 Display options with the Info key............................................................................................ 74

6.5.14 Accepting current values into the fixed memory................................................................... 75

6.5.15 Organizational data (identifier)............................................................................................... 75

6.5.16 Settings in Setting Mode......................................................................................................... 76

6.6 Totalizing and picking ....................................................................................................................... 77

6.6.1 Function keys............................................................................................................................. 77

6.6.2 Display view ............................................................................................................................... 78

6.6.3 Display information field........................................................................................................... 79

6.6.4 Tare function.............................................................................................................................. 80

6.6.5 Operating the totalizing function.............................................................................................. 80

6.6.6 Options for displaying totals..................................................................................................... 81

6.6.7 Relief factor for summation...................................................................................................... 81

6.6.8 Auto-summing / -picking........................................................................................................... 81

6.6.9 Preferred totalizing scale.......................................................................................................... 81

6.6.10 Assigning and deleting the sequence number ...................................................................... 82

6.6.11 Item counter ............................................................................................................................ 82

6.6.12 Keys that trigger printing......................................................................................................... 82

6.6.13 Display of current totals.......................................................................................................... 82

6.6.14 Displaying individual items ..................................................................................................... 83

6.6.15 Display options with the Info key............................................................................................ 84

6.6.16 Accepting current values into the fixed memory................................................................... 84

6.6.17 Organizational data (identifier)............................................................................................... 85

6.6.18 Settings in setting mode ......................................................................................................... 85

6.7 Counting............................................................................................................................................. 87

6.7.1 Function keys............................................................................................................................. 87

6.7.2 Display view Counting ............................................................................................................... 88

6.7.3 Display information field........................................................................................................... 89

6.7.4 Tare function.............................................................................................................................. 89

6.7.5 Counting function...................................................................................................................... 90

6.7.6 Totalizing and picking ............................................................................................................... 92

6.7.7 Reference Statistics .................................................................................................................. 96

6.7.8 Piece control.............................................................................................................................. 97

6.7.9 Counting with several weighbridges ........................................................................................ 98

5

6.7.10 Counting accuracy................................................................................................................... 99

6.7.11 Display options with the Info key..........................................................................................101

6.7.12 Accepting current values into the fixed memory.................................................................101

6.7.13 Organizational data (identifier)............................................................................................. 102

6.7.14 Settings in Setting Mode....................................................................................................... 102

6.8 Checking .......................................................................................................................................... 106

6.8.1 Function keys........................................................................................................................... 106

6.8.2 Display view ............................................................................................................................. 107

6.8.3 Display information field......................................................................................................... 108

6.8.4 Tare function............................................................................................................................ 108

6.8.5 Control functions..................................................................................................................... 108

6.8.6 Totalizing and picking .............................................................................................................111

6.8.7 Display options with the Info key............................................................................................ 115

6.8.8 Saving current values to the fixed memory ...........................................................................115

6.8.9 Organizational data (identifier)...............................................................................................116

6.8.10 Settings in Setting Mode....................................................................................................... 116

7. Error messages....................................................................................................................... 120

8. FURTHER INFORMATION....................................................................................................... 121

6

1. GENERAL INFORMATION

1.1 Introduction

Thank you for choosing the Soehnle Professional Terminal 3035.

This terminal has been developed according to the requirements of operational practice and offers you

numerous possibilities to adapt the weighing process individually to your needs in order to make your

processes rational and cost-effective.

Please read the operating instructions carefully before use.

Improper use could cause damage to you or the terminal.

If you have any questions or if problems arise on your terminal which are not covered in the operating

instructions, please contact your Soehnle Industrial Solutions service center or Soehnle Industrial Solutions

customer service.

Phone: +49 7191 3453-220

Fax: +49 7191 3453-211

E-Mail: [email protected]

Further information and documentation can be found at

https://www.soehnle-professional.com/site/documents

Please go to the customer center of our website www.soehnle-professional.com and select

the terminal 3035 under Downloads.

1.2 Intended use

The Soehnle Professional Terminal 3035 is a calibratable terminal for use in scales and weighing systems

with commercially available DMS weighing and load cells.

Up to three analogue measuring points (scales) can be simultaneously connected internally. Externally, a

total of up to 29 measuring points are possible via CAN bus. Another scale can be connected via the serial

interface, e.g. as a reference scale. Additional data can be entered via the keyboard. Various interface

options are available for the connection of printers, EDP, readers, data memory and external PC keyboard.

The Soehnle Professional Terminal 3035 has been designed for effective working even under rough

environmental conditions. It is robust, easy to clean, flexible and fast. Logical structure and user guidance

enable quick familiarization and intuitive work at the terminal. Its design adapts to your individual

requirements and supports you in your task.

7

1.3 Safety instructions

Before using the device, read the information in the user's manual carefully. They contain important

instructions for the installation, proper use and maintenance of the terminal.

The manufacturer is not liable if the following instructions are not observed:

When using electrical components under increased safety requirements, the relevant regulations must be

observed. Never perform service work on the terminal while it is live. Improper installation will void the

warranty.

> The 3035 terminal must not be used in potentially explosive atmospheres.

A special version is available for EX zones 2 and 22

> The permissible mains voltage is 100 - 240 volts. The socket must be earthed and easily

accessible.

> The terminal must only be opened by trained Soehnle Industrial Solutions service technicians.

The housing contains no user-serviceable components. Unauthorized manipulations render the

product warranty null and void.

> Repairs and the replacement or installation of parts may only be carried out by a trained

Soehnle Industrial Solutions service point.

> The terminal must be taken out of service if the power cable is damaged. Disconnect the power

supply and contact a Soehnle Industrial Solutions service location.

> The attached security labels must not be damaged if the terminal is used for functions with

calibration mandate.

Please contact your Soehnle Industrial Solutions service partner in case of problems.

1.4 Cleaning

A damp cloth and standard cleaning agents are sufficient for cleaning.

Do not use abrasive and corrosive agents.

1.5 Maintenance and service

Note:

These devices comply with the applicable EC directives 2014/31/EU, 2014/30/EU, 2014/35/EU and EN45501.

However, under extreme electrostatic as well as electromagnetic influences, e.g. when operating a radio or

mobile phone in the immediate vicinity of the devices, the scale may be affected.

After the end of the disturbance, the product can be used as intended again,

If necessary, it may be necessary to switch it on again. In case of permanent electrostatic interference we

recommend grounding at the terminal housing and platform.

The terminal is a measuring instrument. Drafts, vibrations, rapid temperature changes and sunlight can affect

the weighing result. The terminal complies with protection class IP 67. Very high humidity, vapors, aggressive

liquids and heavy soiling must be avoided.

8

1.6 Product Warranty/liability

When a defect in the delivered item is attributable to Soehnle Industrial Solutions, Soehnle Industrial

Solutions is entitled at its discretion to either remedy the defect or to supply a replacement. Replaced parts

become the property of Soehnle Industrial Solutions.

The statutory regulations apply if the defect remedy or replacement delivery fails.

The product warranty period begins on the date of purchase. Please retain the invoice as proof. For service

contact your dealer or the Soehnle Industrial Solutions customer service department.

No liability is assumed, in particular for losses resulting for the following reasons:

Unsuited, inappropriate storage or use, defective assembly and/or startup by the buyer or third parties,

normal wear and tear, modifications or manipulations, deficient or careless treatment, in particular excessive

loads, chemical, electrochemical, electrical influences, or moisture, provided these are not attributable to

Soehnle Industrial Solutions.

The product warranty for the unrestricted overall function of the equipment is null and void if operational,

climatic, or other influences result in a significant change of circumstances or the condition of the material.

When Soehnle Industrial Solutions honors the product warranty on a case-by-case basis, this implies the

absence of defects on the delivered item during the product warranty period. Please keep the original

packaging for any required return shipments.

1.7 Setup instructions

Please inspect the packaging and terminal for external damage. Do not place a visibly damaged terminal into

service, but inform your dealer instead.

Please keep the packaging for any required shipping.

The terminal was designed for rough commercial operations. It is nevertheless a sensitive measurement

instrument whose performance can be influenced by unfavorable environmental conditions.

The unit should be acclimated at ambient temperature for 2 hours after unpacking or transport.

The rated ambient temperature is - 10° to + 40° C.

The setup location is a key factor for the function of your scale.

Select an appropriate setup location to protect the terminal against impact, vibration, excessive heat or cold,

temperature swings, airflow, chemicals, and moisture to ensure that the unit can work fast and reliably over

the long-term.

9

2. DEVICE DESCRIPTION

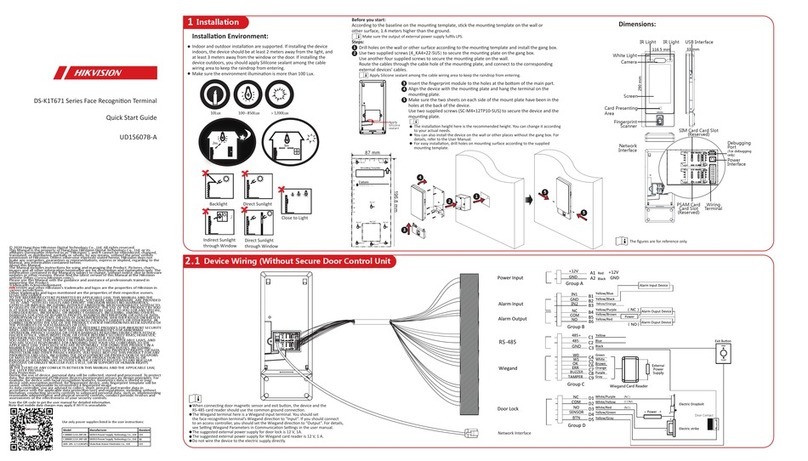

2.1 Connection and device description

2.2 Technical data

> Stainless steel housing, protection class IP 67, integrated power supply 100 - 240 V AC, 50/60 Hz

optional DC/DC-converter 12 - 60 V

> Membrane keyboard with a total of 32 keys, 6 function keys,

4 organization data keys, alphanumeric input via numeric keypad

> 10 user programs, special programs as option

> Connection possibility for external PC keyboard

> color display TFT 5.7" QVGA, dot matrix 320 x 240 pixels dimmable backlighting

> Option: Soehnle Professional Micro-SD card (high-quality SLC memory card), memory capacity:

Fixed memory for a total of 999 fixed values for all programs, alibi memory for 4 million entries

and for software update

> Interfaces: 1 x RS 232 or USB in the basic version.

> Internal with R232, USB and Ethernet, 2 additional interface slots (RS232)

> Any bus slot for bus interfaces such as Profibus, ProfiNet

> Option: IO card for 6 outputs and 4 inputs freely assignable

> Working temperature: -10° C to +40° C

> 1 measuring point in the basic version, 2 further measuring points can be connected internally, in

total up to

29 measuring points, calibratable resolution 10,000 e, internal resolution 16,000,000 d

> Calibratable according to accuracy class III and IIII for n = 10 000 e for multi-range and

multi-partition scales

> Smallest approved input signal per calibrated value = 0.2 µV,

Load cell impedance 40 Ohms to 1,245 Ohm

> A digital reference scale can be connected via RS-232 interface

pressure

compensation

membrane

port

port 1

port 2

scale 1

scale 3

port 3 RS232 / scale 2

power supply

ground

10

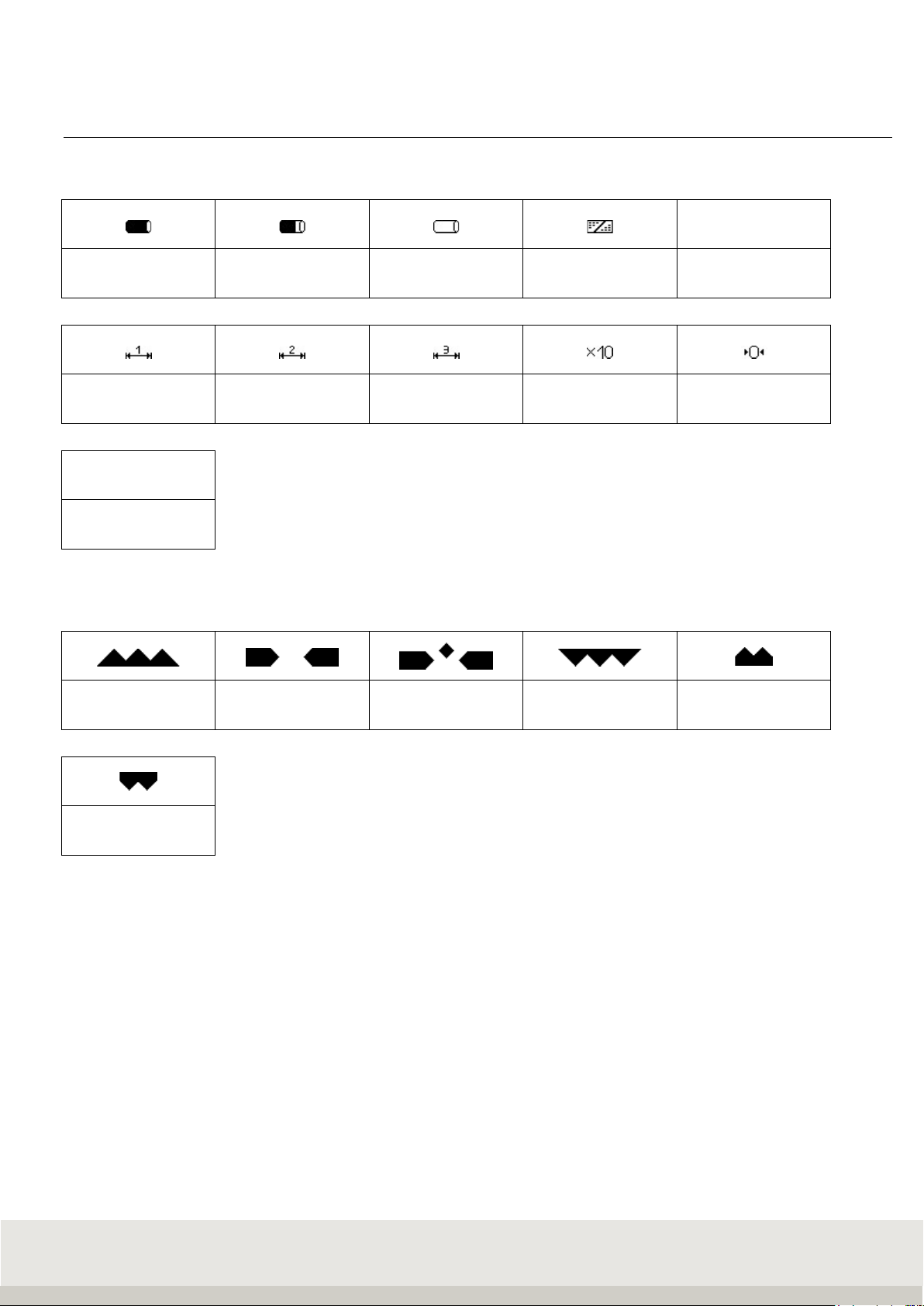

2.3 Symbols on the display

Symbols in the display toolbar

LOG

Alibi memory use

100

Alibi memory use

80

Alibi memory use

empty Keyboard lock Data logger

Multirange 1 Multirange 2 Multirange 3 Resolution X10 Zero

HLD

Hold function active

Symbols in the information field of the display

Below tolerance In tolerance Exact target

value reached Above tolerance Below minimum load

Above class 5

upper limit

Symbol for standstill

After placing the sample on the scale, the scale needs time to settle.

As long as no standstill has occurred, the dimension sign (kg, g) is hidden.

When the machine has come to a standstill and a stable value is available, this is indicated by the display of

the dimension symbol.

11

2.4 Calibration instructions

The scope of this notice is Germany. In other countries, conformity with national laws must be verified.

The Terminal 3035 is approved for custody transfer class III and IIII within the EU.

It complies with the type described in the type approval and the applicable requirements of Directives

2014/31/EU, 2014/30/EU, 2014/35/EU and EN 45501.

According to the legal regulations, approved scales must be recalibrated at regular intervals. For this

purpose, please contact a Soehnle Industrial Solutions service center or your local weights and measures

office.

Do not damage the official seals under any circumstances, as this will invalidate the calibration validity.

2.4.1 Name plate

The terminal has an electronic type plate.

Display after pressing the Info key:

2.4.2 Calibration counter

The calibration counter shows how often a scale has been calibrated. The stored counter reading must

correspond to the calibration counter reading secured by adhesive tape. The current calibration counter

reading can be displayed for each connected scale in the setting mode under Scale / Scale parameters.

12

2.5 Switching on / off

Switch on:

Press the ON/OFF key.

When switching on, the logo , terminal type 3035, filter type and the recognized measuring points are

briefly displayed during the start routine.

The scale is set to zero after the power-on process.

When the machine is switched on, the last application program used is switched back on.

Zero setting limits:

Calibratable: Zero setting range 20% of the weighing range,

Default value is -5% to +15% of the weighing range. Optional: extended range on request.

Non-verifiable: the switch-on zero setting range can be -99% to +99% of the weighing range.

If you switch on outside the switch-on zero setting range, the scale displays an error message.

Afterwards the terminal goes directly into the weighing mode if not verifiable, whereas if verifiable, it is

possible to jump to the weighing mode by pressing the zero key. The current weight value with the

previously stored zero point is then displayed. If the cause for under- or overload is removed, the scale goes

to zero without having to be switched on again and is ready for operation.

Backlight and color

Can be adjusted in the setting mode (terminal/display).

The default setting is 80% for the backlight and white for the background color.

Procedure on power failure

When power is restored, the scale returns to the previously exited state.

Switch off

Press the ON/OFF key .

If the connected measuring point is loaded, or if you have called up a menu, the scale only switches off after

pressing the ON/OFF key for 3 seconds.

It is not possible to switch off the scale while it is waiting for an input in the editing area of the setting mode.

To switch off the scale you must leave the editing area.

OFF display

In the setting mode Service (including password request) / General/OFF display, you can set whether the

word "OFF" appears on the display when the scale is switched off (medical directive).

Default setting is "with OFF display".

13

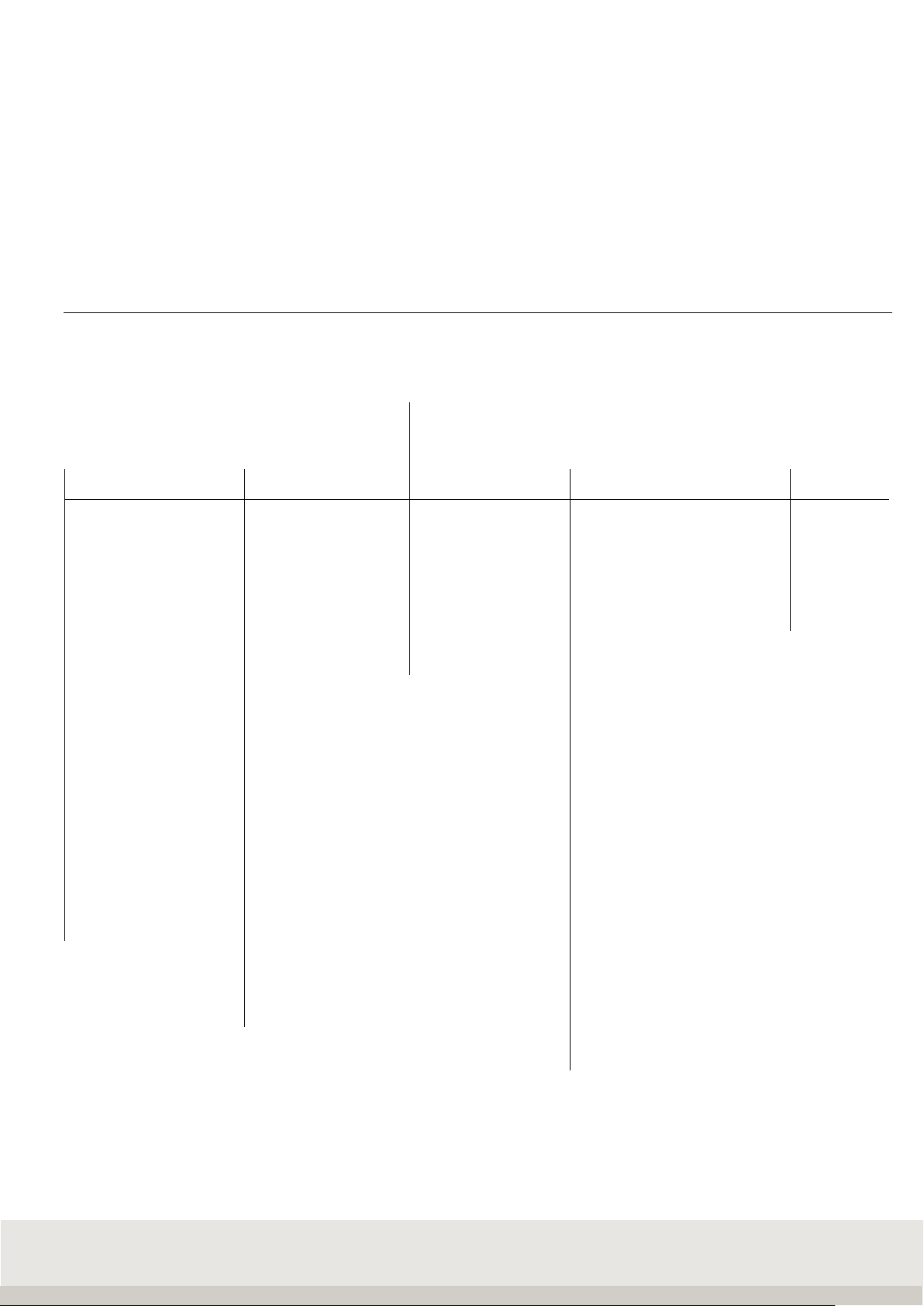

3. OPERATING CONCEPT

The operating concept is divided into two functional areas:

•Setting mode

•Program mode

3.1 Setting mode

Here you make individual settings on the terminal to optimize the scale for your needs.

Menu structure for setup mode:

Setting mode

Program settings

Terminal

Scale Communication Service

Weighing + taring

Version

Scales Parameters Alibi memory only for

Totalizing and picking

Display

Allocation table

measuring points Interface 1 RS232(internal) Service

Counting

Keypad

Ref. points f. calib. Interface Port 2

Professionals

Checking

Date/Time

internal measuring

point Interface Port 3

Classifiying

Organization data

USB

Recipes

Error memory

Ethernet

Weight conversion

User password

Print image

Vehicle weighbridge

Login function

EDP settings

I/O port programming

Reset Terminal

Anybus

Percentage weighing

SD card

data backup

Barcode

Volume measurement

Batch processing

Dyn. function keys

IO control

IP sensors

14

3.2 Program mode

Here you select the desired weighing application program. After selecting and calling the application

program, the scale is ready to weigh.

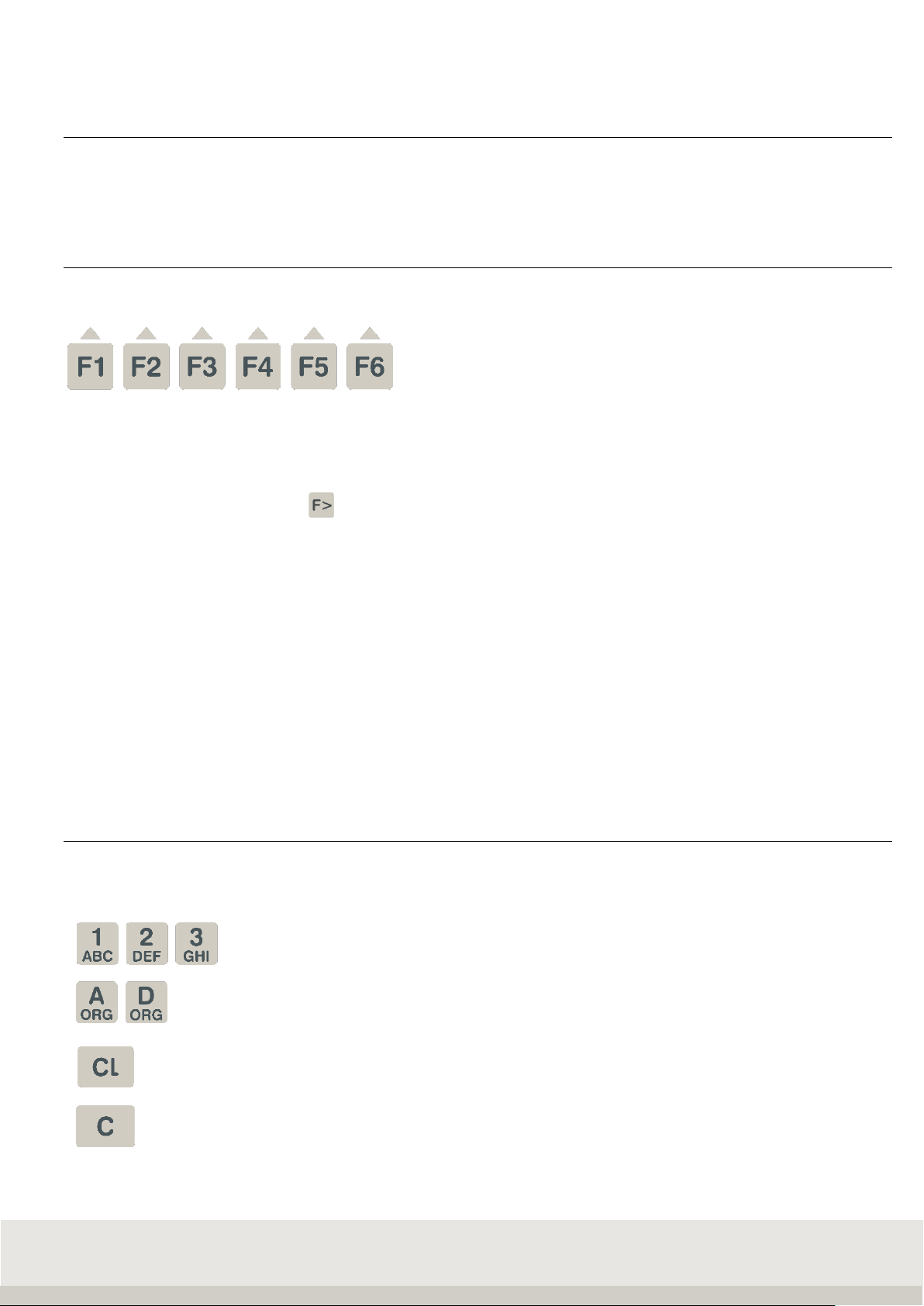

3.3 Function keys

The function keys F1 to F6 are available to call up the functions.

These take on different functions depending on the program and situation. The respective

function is shown on the display in the function bar above the key.

Depending on the program, the function keys are assigned to up to 4 levels, and you can scroll through the

levels with the function change key.

Navigation with the function keys

↑Move the marker up in the list

↓Move the marker down in the list

End Exiting the setting mode

Continue Call up the marked menu item

Back Return to higher level

AbortReturn without accepting a change

Delete Deleting a position with return

ApplyAcceptance of an entry or change

→Cursor to the right

←Cursor to the left

3.4 Input and control keys

The following additional keys are available for input and control:

Numeric keys for entering numerical values,

Multiple assignment of the numeric keys for entering letters

Call up organizational data

Deleting the complete input or resetting the functions

Deleting the last digit

15

Info key, electronic type plate with calibration data,

Calling up information on the application programs

Function change key

Scale change key

Tare key

Reset key / Delete tare

Enter key

Print key

On / Off

Display:

The display shows different views depending on the situation.

It is divided into the following display fields:

FUNKTIONSLEISTE

ANZEIGEFELD

INFORMATIONSFELD

SYMBOLLEISTE

NEBENANZEIGE

BEREICHSANZEIGE

Auxiliary display:

Displays further additional information and can be set individually under Terminal / Display.

Can be switched on and off with the F3 key.

Toolbar:

Shows information on the status of the connected measuring point

Information field:

Shows situation-dependent or individual settings Organizational data, totals when totalizing, special control

characters, classes when classifying, operator guidance, switching points

Display field:

Shows weight value, number of pieces, dimension indicator

Area display:

Displays the current weighing range with Max / Min / e (d).

Function bar:

Functions of the 6 situation-dependent function keys

Aux. display

toolbar

informationfiel

display

range indicator

functionba

16

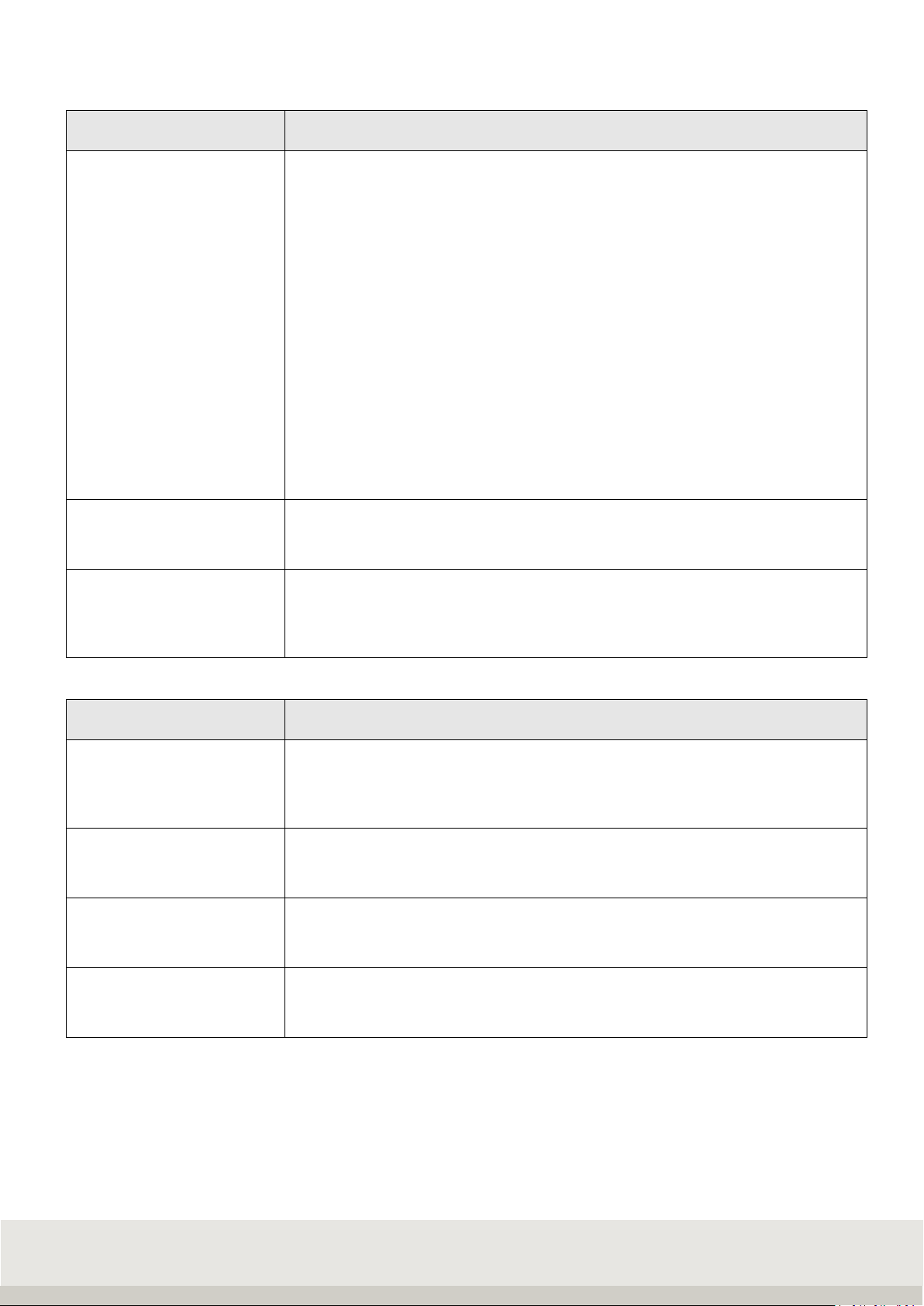

4. SETTING MODE

In the setting mode, program and weighing parameters are stored, which can be called up and individually set

up.

The adjustment is done by data input or selection from predefined parameters.

The individual parameters are stored in logical groups within a multi-level family tree structure.

Info: The modification options may be restricted in legal metrology.

Menu structure of Setting mode:

Setting mode

Program settings

Terminal

Scale Communication Service

Weighing + taring

Version

Scales Parameters Alibi memory only for

Totalizing and picking

Display

Allocation table

measuring points Interface 1 RS232(internal) Service

Counting

Keypad

Ref. points f. calib. Interface Port 2

Professionals

Checking

Date/Time

internal measuring

point Interface Port 3

Classifiying

Organization data

USB

Recipes

Error memory

Ethernet

Weight conversion

User password

Print image

Vehicle weighbridge

Login function

EDP settings

I/O port programming

Reset Terminal

Anybus

Percentage weighing

SD card

data backup

Barcode

Volume measurement

Batch processing

Dyn. function keys

IO control

IP sensors

17

4.1 Starting the setting mode

Switch on the terminal.

After the switch-on routine, the terminal automatically starts the last activated application program. To call

up the setting mode, switch to the setting functions level with the function change key.

Function keys:

Level Setting functions

Gross x 10 Secondary

display

Prog

ram

Setup

mode

F 1

F 2

F 3

F 4

F 5

F 6

Press the F6 Setting mode key.

You are now in the selection menu Setting mode.

Navigation in setting mode:

The function keys F1 to F6 are available to control the functions.

These take on different functions depending on the program and situation.

The respective function is shown on the display in the function bar.

Meaning of the function keys:

↑Move the marker up in the list

↓Move the marker down in the list

End Exiting the setting mode

Continue Call up the marked menu item

Back Return to higher level

AbortReturn without accepting a change

Delete Deleting a position with return

ApplyAcceptance of an entry or change

→Cursor to the right

←Cursor to the left

18

Entries in setting mode:

In most cases you make a selection from the various settings offered.

For editable values, numeric or alphanumeric input is possible via the keyboard.

Service area:

The service area is secured by a password.

The included parameters can only be maintained by trained service personnel.

Please contact your Soehnle Industrial Solutions service centre.

4.2 Program settings

In the Program Settings setting mode, you can adapt the user programs of your scale to your specific

requirements. The activation of the user programs and their typical use are described in part 6 Application

programs.

1 Weighing and taring

For settings and parameters see chapter 6.5.16

2 Totalizing + picking

For settings and parameters see chapter 6.6.18

3 Counting

For settings and parameters see chapter 6.7.14

4 Controlling

For settings and parameters see chapter 6.8.10

5 Classifying

For settings and parameters see chapter 6.9.10

6 Recipe

For settings and parameters see chapter 6.10.9

7 Neutral measurement

For settings and parameters see chapter 6.11.12

8 Vehicle scale

For settings and parameters see chapter 6.12.9

19

9 Dynamic switching

For settings and parameters see chapter 6.13.11

10 Percentage weighing

For settings and parameters see chapter 6.14.9

4.3 Setting mode Terminal settings

In setting mode under Terminal, you will find the following query or setting options

1 Version

Boot loader software

Software status query

LRS Software AZG

Software status query

Application software AZG

Query software status and filter type

Serial number central board

Requesting the factory-set serial number

Character set

Query character set (in later version as selection):

- Latin 1

Output parameters uni.

Output of all setting parameters of the terminal including the currently connected

measuring point via the interface with the use "EDV 2 (unidirectional)".

2 Display

Backlighting

Input

Luminosity setting, input in percent via numeric keypad

30% is darker, 100% is full brightness

factory setting: 80%

Background colour

Selection

Setting background colour

> green

> white

> light blue

> yellow

> blue

> magenta

> red

Factory setting: white

Language

Selection

1st language German (factory setting)

2nd language English or other languages

can be adapted via the Soehnle Professional service program.

20

2 Display

Secondary display

Selection

> Second unit

> tare value

> x10 resolution

> Gross/net

> Current weight

> reference quantity

> reference weight

> setpoint value

> Difference to setpoint

> Specific weight

> Car registration number

> Weight first/individual weighing

> Traffic light display

> volume

> Sensor connection status

> Last determined. Quantity

Factory setting: Second unit

Decimal Separation

Selection

comma, dot or none

Factory setting: comma

Thousand separator piece

Selection

for separators only for count quantity display

comma, dot or none

Factory setting: None

3 Keyboard

Keypad lock

On the keyboard, you can lock individual, multiple or all keys.

By pressing the key to be locked, you can change the status of the key from open

to locked and vice versa.

Press the Enter key for 3 seconds to save and exit.

Key beep

Selection from or on

Keyboard confirmation beep

Factory setting: off

Receipt beep

Selection from or on

Acknowledgement beep (e.g. error message or acceptance)

Factory setting: off

Keyboard layout

Choice of German or French

Layout for PC - Keyboard layout and keyboard looping via the USB interface

Factory setting: German

Table of contents

Other Soehnle Professional Touch Terminal manuals