BEINAT RGX1002 User manual

CONFORMITY

230 VA

230 VAC

Guide

use and installation

Please read these installation and use instructions

carefully and keep them for future reference. The

manufacturer reserves the right to introduce all the

technical and constructive changes it deems necessar

EN 50194

CEI 216-3

EN 50270

Di Installazione EN 60079-29-2

Report rilasciati da TUV Italia

The appliance assembly / maintenance operations must be carried out in the absence of mains voltage.

HouseholdMethaneorLPGgasdetector RGX1002

BUILT ACCORDING TO REGULATIONS EN 50194-1 - EN 50270

Belonging to

The elegance and the prestige, that have always made BEINAT S.r.l stand out from its competitors, together with the

concept of home fitness comes the household gas detector RGX1002detects through the catalytic sensor , the

presence of explosive gas such as: Methane or LPG.

Gas detection

The detector is tested and calibrated to 10% of L.E.L.

Through the built-in relay, the RGX1002can activate: solenoid valves, sirens, and any other device alarm.

A series of technical features make this gas detector extremely versatile, reliable, accurate, and safe.

through an internal jumper it is possible to select the relay impulse functioning, to connect manual reset solenoid

valves, or the continuous functioning, to activate class “A” solenoid valves and sirens.

The relay, free of voltage, allows installation of multiple detectors on a single solenoid valve ensuring control of

multiple dangerous environments.

The detector is complete with a special circuit that controls the catalytic sensor’s efficiency level, and signals

any possible fault.

The enclosure with IP42 degree of protection can be installed either on the wall or on a 503 flush-mounted box.

Important: Assembly / maintenance of the appliance must be carried out by qualified personnel and in

accordance with applicable laws and regulations.

The manufacturer assumes no responsibility for the use of products that have to comply with particular

environmental and / or installation standards.

Important note

Before connecting the equipment, it is recommended that you read the instruction manual carefully and

keep it for future reference. It is also recommended to perform the electrical connections correctly as

per enclosed drawings, observing the instructions and the Standards.

N.B. Refer to the documentation in all cases where the symbol is on the side

Channel: Beinat gas solutions

Electric connections alsoavailable on

TO PROTECT YOUR FAMILY

Page 2

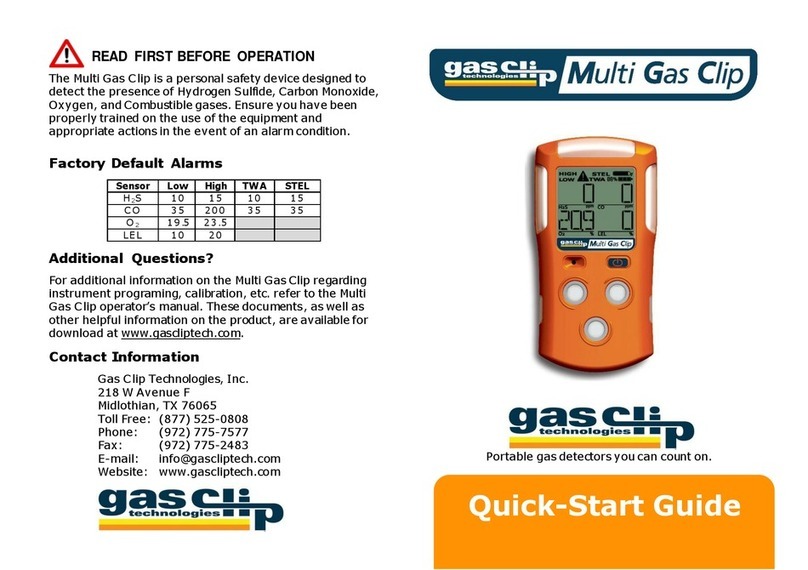

Power supply .......................................................................................... 230/240 VAC 50/60 Hz +/- 10%

Power consumption ......................................................................................................................3,1 W

Range of relay contact switching free of voltage ............................................................. 10A 250V resistive

Insulation ........................................................................................................................... Class II

Types of gas detected ................................................................................. Natural Gas - for Natural gas

LPG- for LPG model

Detection sensor ....................................................................................................................... Catalytic

Alarm sensitivity ......................................................................................................... At 10% of L.E.L.

Precision of the detector ............................................................................................................. 1% FS

Sensor’s faults detected by Fault Circuit ................................................... Interruption, short circuit, or wear

Test Phase Duration ............................................................................................................. 60 seconds

Audible and visual signal alarm by ............................................................. LED diode and buzzer 85 dB at 1 m

Selection of relay working mode ........................................................................................ through Jumper

Test buttons ........................................................................................................................... built-in

Command electrovalve ................................................................................................ class A o classe B

Functioning Temperature ............................................................................................... -10°C to +40°C

Functioning Humidity ......................................................................................... 0÷90% RH not condensed

Degree of protection ...................................................................................................................... IP42

Dimensions ......................................................................................................................... 120x80x37

CHECK the integrity of the probe after having removed it from the box.

Check that the data written on the box correspond to the type of gas used.

When doing the electrical connections, follow the drawing closely.

Any use of thedetectorforpurposesotherthantheintendedoneisconsidered improper,andas aresultofwhichBEINAT

S.r.l. therefore disclaims any responsibility for possible damages caused to people, animals or objects.

INSTALLATION

When performing the installation, please remind that if you pierce the RGX1002 container, it will lose its properties

and its conformity to REGULATIONS.

TERMS and EXPECTATIONS: The installation of the RGX1002detector, its ordinary and extraordinary maintenance,

and its out of service removal at the end of the functional life guaranteed by the manufacturer, must be carried out

by authorized and/or specialized personnel.

Do not allow it to become wet.

The detector can be seriously damaged when immersed in water.

Do not drop it.

Heavy knocks or falls during transportation or installation can damage the appliance.

Avoid abrupt temperature fluctuations.

Sudden temperature variations can cause condensation and the probe could work poorly.

Cleaning

Never clean the device with chemical products. If necessary, wash with a moist cloth.

Absolutely avoid using any cloth dipped in thinners, alcohol and chemical detergents.

Disposal of the device

Concerning the conservation, the protection and the improvement of the quality of the environment, as well as for the

protection of human health and the careful and rational use of natural resources, the device has to be the object of

aselective collection for he disposal of electronic equipmentsand can not be disposed withthecommon domestic waste.

The user thus has the obligation to separate the device of the other waste to ensure that it is recycled in a sure way

for preserving the environment For more details on the sites that are involved in the collection, contact the local

administration or the distributor of this product.

Precautions

Functional Features Of Gas Sensors

The installation of the RGX1002 detector, its ordinary and extraordinary maintenance, and its out of service

removal at the end of the functional life guaranteed by the manufacturer, must be carried out by authorized and/

or specialized personnel.

The CATALYTIC technology sensor duration is guaranteed for 6 years (in clean air).

The detector’s functioning temperature ranges from -10°C to + 40°C.

WARNING!

The CATALYTIC probe does not tolerate a gas detection exceeding 100% of L.E.L., with consequent natural

death of the sensor.

Each immediate puff of gas that exceeds 100% of L.E.L. takes away months of life from the sensor.

The detector must be tested by simulating the presence of gasby issuing it from apre-calibrated testing aerosol.

A common cigarette lighter near the sensor does not guarantee excellent functioning.

Technical Specifications

Page 3

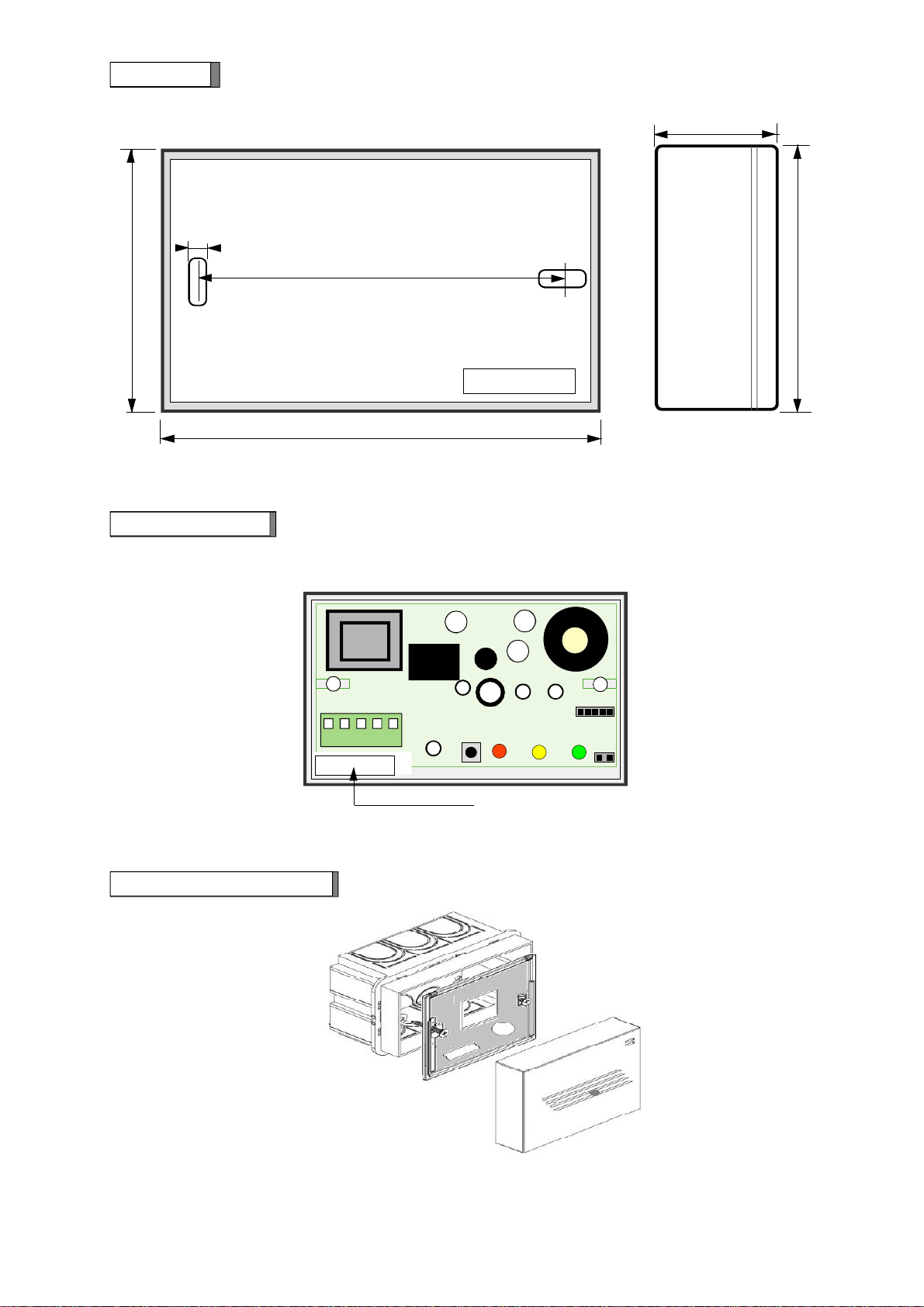

Side view

80 mm

37 mm

Dimensions

Installation on 503 box

120 mm

80 mm

83 mm

5 mm

Pass cables

Fixing holes

Rear view

Wall installation

The installation of the detector does not exempt from ... ... The compliance with all regulations concerning the

characteristics, installation and use of gas appliances. The ventilation of the spaces and the elimination of combustion

products are described in the UNI norms according to ART. 3 LAW 1083 / 71 and relevant legal provisions.

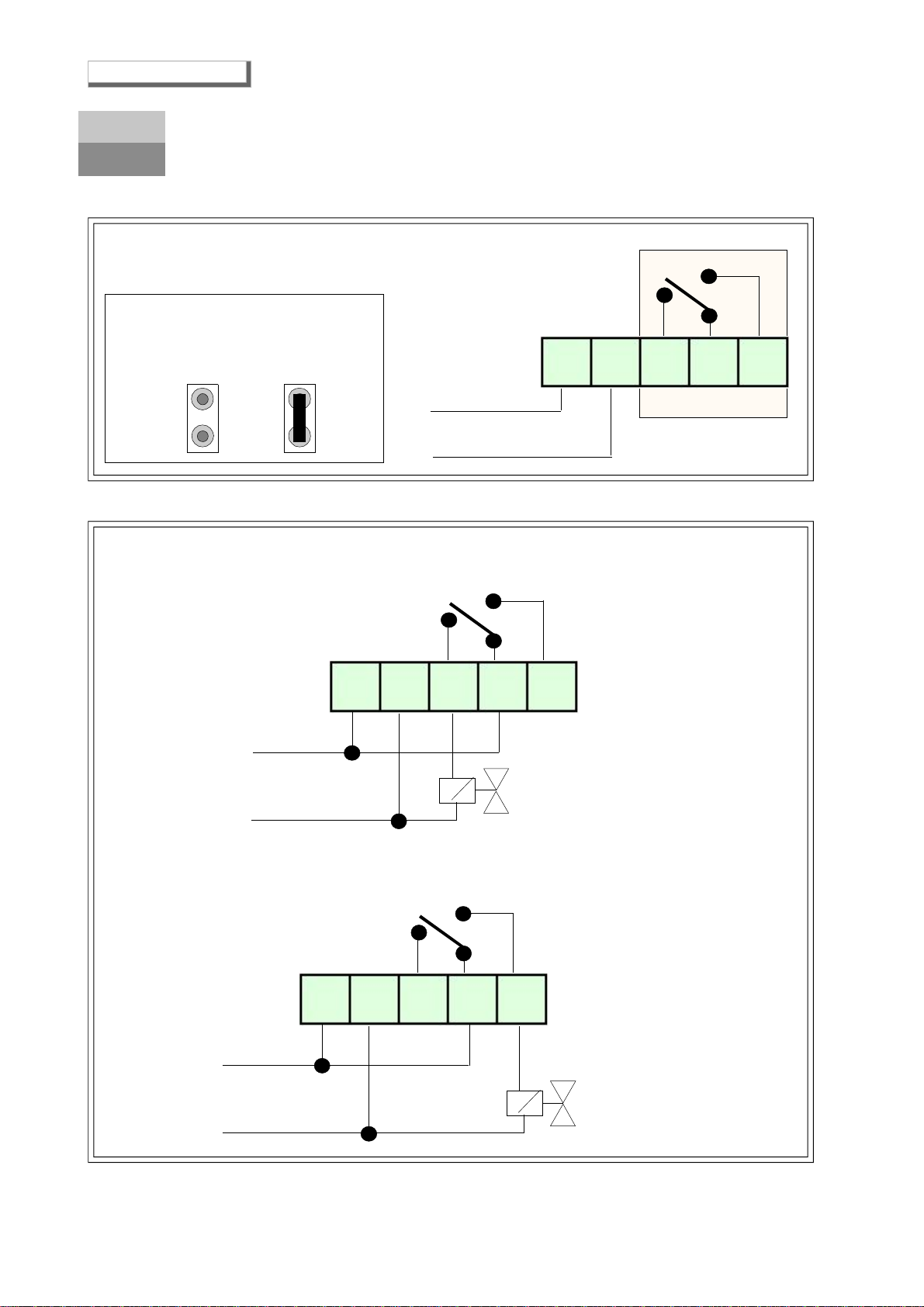

1 2 3 4 5

++

Pass cables

Pagie 4

1) MAINS connected indication LED (ON).

2) FAULT LED and decadence of the functioning period

If this LED turns on, it means that the gas detection catalytic sensor is not working efficiently and must be replaced

by an authorized service center.

3) ALARM LED. This LED turns on when the amount of gasdispersed in the environment exceeds the danger threshold,

10% of the LEL

4) TEST button. This button is used to simulate a gas leak, after installation.

BUZZER. This Buzzer sounds when the detector has exceeded the alarm threshold.

5) JUMPER to select the relay functioning mode closing the two poles, the relay will work at pulse, in the sense that

once tripped the alarm relay will close the C and NA contacts for about 90 seconds, and then will reopen them. This

is needed to prevent damaging some types of manual reset solenoid valve coils. By opening the two poles, the relay

will be set to continuous functioning.

6) Catalytic sensor for Methane or LPG explosive gas detection.

7) Identification label, registration number and manufacturing year, located under the ABS small dome.

Components and commands

1) Put out all free flames.

2) Close the main gas tap or the LPG cylinder tap.

3) Do not turn any lights on or off; do not turn on any electrical device or appliance.

4) Open windows and doors in order to increase ventilation.

If the alarm stops, its cause must be found and the relevant consequent measures taken.

If the alarm continues and the cause of gas presence cannot be found or removed, abandon the building and call

the emergency services when outside (fire department, distributors, etc.)

Warning !!

If you have the following symptoms: vomiting, sleepiness, or else, go to the closest first aid station and

inform the operators that you could have been poisoned by Gas Methane or LPG.

WARNING! Actions to be taken in case of alarm

4) TEST button

5) JUMPER to select the relay

7) Serial Number Label

Serial Number

Year2019

1 2 3 4 5

Buzzer

6) Catalytic sensor

1) MAINS Led

2) FAULT LED

3) ALARM LED

Terminal Block

Page 5

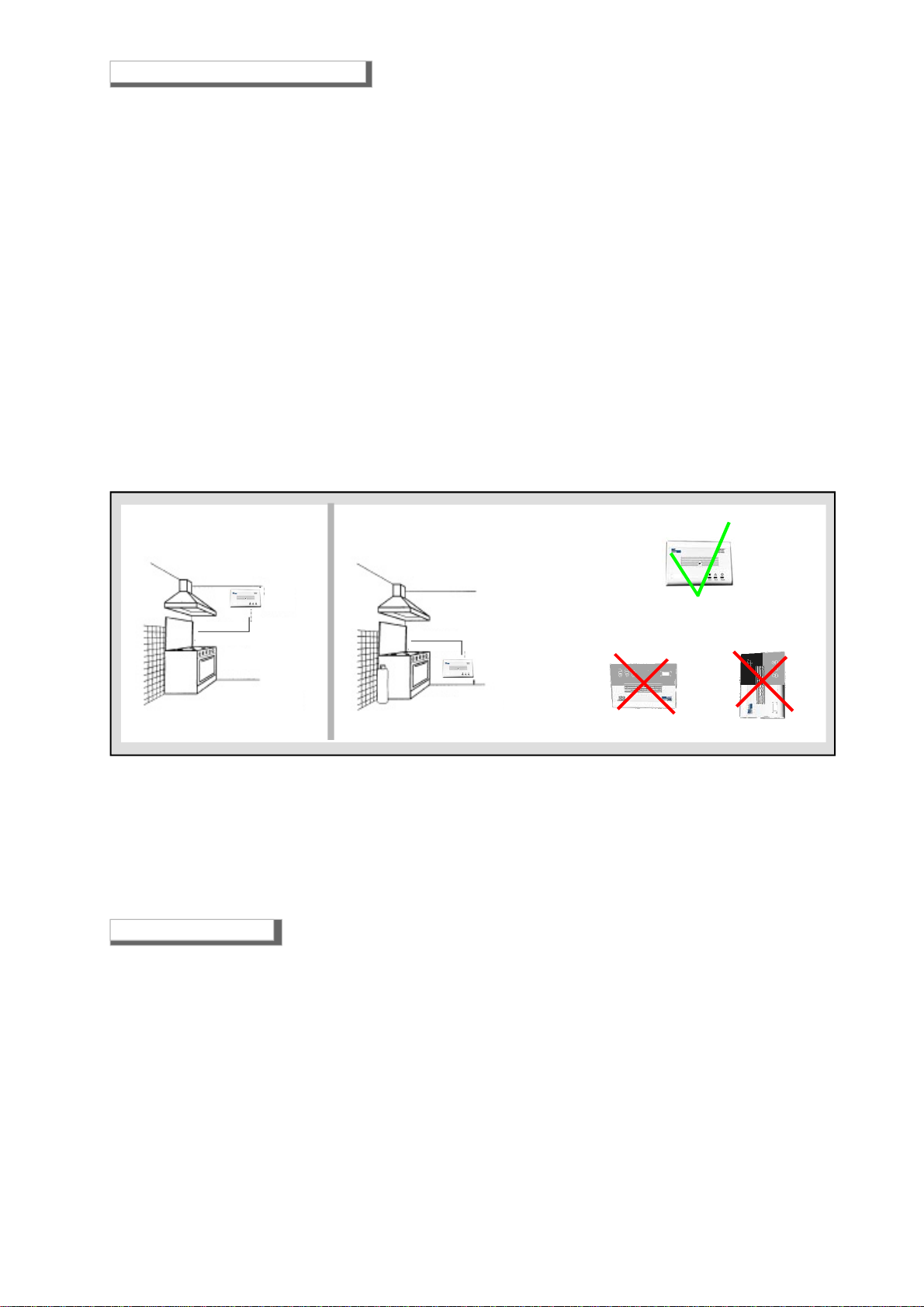

DetectorGas

LPG

30 cm

max

1- 4 m

30 cm

max

1- 4 m

Detector Gas

METHANE

NO! NO!

OK

Currently national standards enforceable in the installation country covering the installation and use of gas powered

equipment are to be respected, as are standards covering smoke dispersion and ventilation of enclosed areas, even

though gas detection equipment is installed.

Essential element for the correct functioning of the detector is its correct installation.

Following the suggestions in this section you will get a high accuracy combined with a total absence of false alarms.

The RGX1002 is an equipment adapted to be mounted externally on a wall. Installing, it is fine to use ordinary care that

requires an electronic device, and then:

- Install the detector away from sources of excessive heat.

- Avoid that liquids come into contact with the detector RGX1002, remembering that its external structure has degree

of protection IP42.

The detector should not be installed:

- in environments where the temperature drops below 10 ° C or rises above 40 ° C.

The detector isequipped todetectdifferent types of gases, and according to these, its must to be positioned at different

heights.

These heights are:

- 30 cm from the lowest point of the floor in order to detect heavy gases (LPG, etc)

- 30 cm from the highest point of the ceiling in order to detect light gase (Methane etc)

- Install detectors from 1 to 4 m from gas appliances

Installation measures and positioning

1)By providing the proper voltage with an external switch, which must be provided with safety fuses, you will see that

the POWER LED, wait 60 seconds, after this time the RGX1002 is ready to detect.

2)Pressing the TEST button, you get the simulation of a gas leak and the detector performs the following actions: The

LED ALARM will turn on and the relay will change its working state after 5 seconds. Ceased the alarm, the LED will

turn off, it will stop the buzzer sound and the connected devices will be disabled.

*To complete the general test, emit gas from a calibration bottle pre-calibrated within 20% of the LEL.

Do a test with a common cigarette lighter could cause damage to the sensor.

We recommend that you make this test at least once a year.

Turn on and testing

Pagie 6

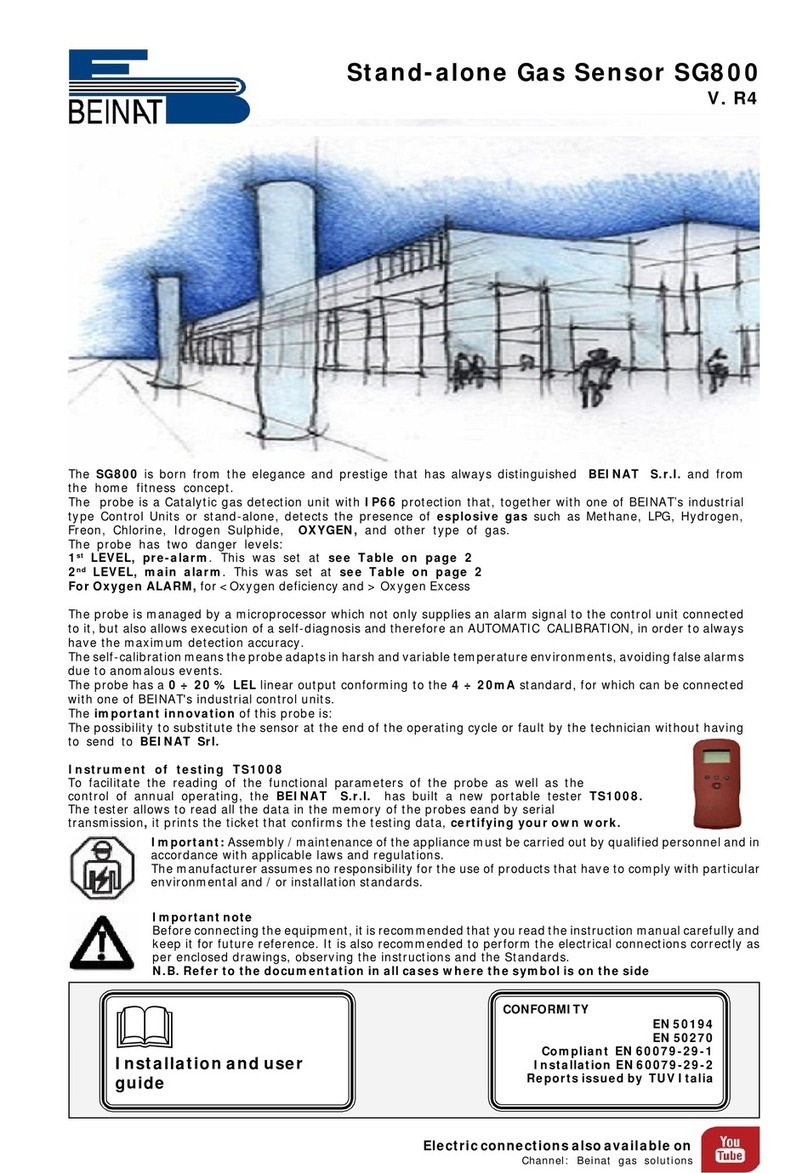

ATTENTION!

The relay is voltage free

ATTENTION!

The relay is voltage free

Jumper for Relay working Mode

1) Closed the relay works in pulsed

Mode.

The pulse lasts 5 seconds

2) Opened the relay works in continuos

mode

N

Power Supply

230 VAC

Ph

NC C

NO

Alarm relay

1 2 3 4 5

Principle Schemes of the Detector

N

Power Supply

230 VAC

Ph

NC C

NO

1 2 3 4 5

Solenoid valve NC

N

Power Supply

230 VAC

Ph

NC C

NO

1 2 3 4 5

Solenoid valve NO

WARNING

Before connecting to the mains power, ensure the voltage is correct.

Carefully follow the instructions and the connections according to Regulations in force.

An automatic disconnetting switch (appropriately identified as the detector sectioning device) must be

incorporated in the electrical system, suitably located and easily accessible.

Electrical connections

Diagram of connection with a valve normally open 230VAC

Diagram of connection with a valve normally close 230VAC

Page 7

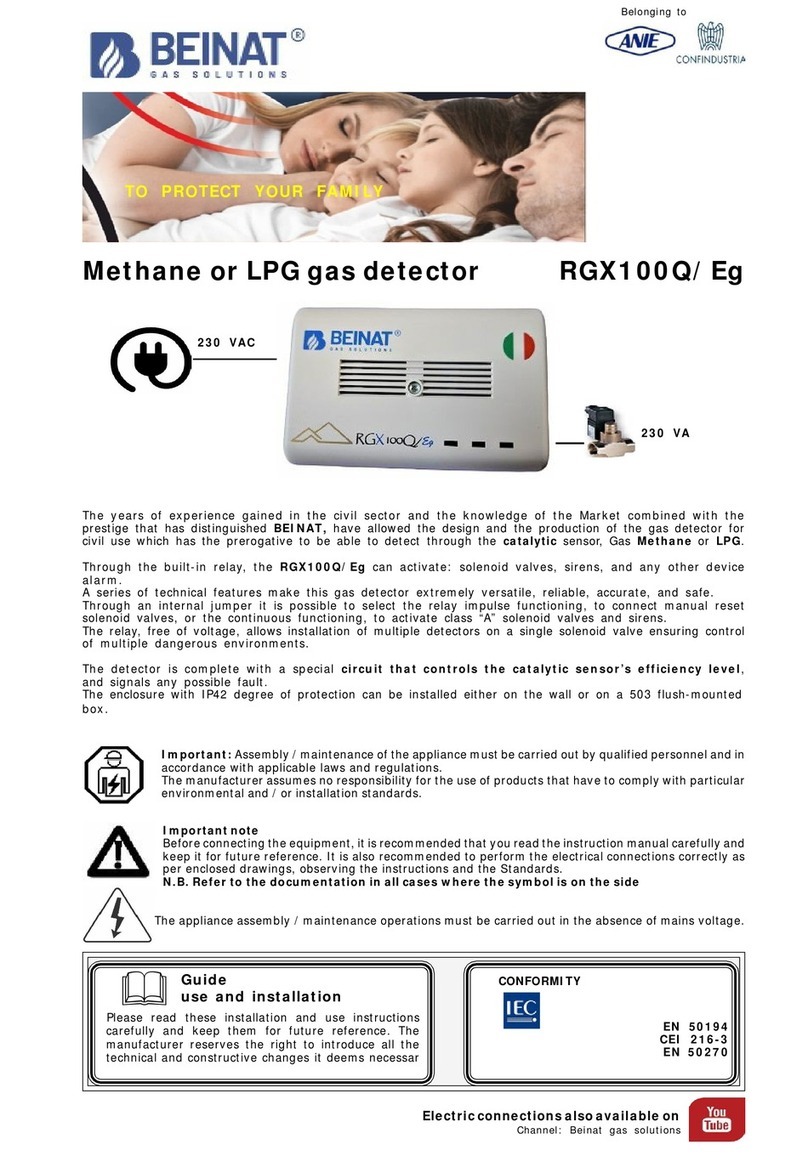

Ph

N

Power supply

230VAC

1 2 3 4 5 1 2 3 4 5

Ph

N

Power supply

230VAC

1 2 3 4 5 1 2 3 4 5

Diagram of connection with a valve normally close 230VAC

Electrical connections

One or more detectors with a valve normally open 230VAC

- If the device does not start up.

Check that the 230/240 VAC power is correctly connected.

When the fault LED lights up

Check the capsule detector, the RGX1002 may have failed.

It may be exhausted: after 5/6 years should be replaced.

If the detector goes into alarm repeatedly.

Check that there are no gas leaks. Check that together with the alarm does not turn on even the led FAULT, in this

case, proceed with the inspection of the capsule detector.

If the detector goes into alarm and closes the connected equipment.

Check thatconnections are correct and that the jumperwhich leads tothecommon voltage of the relay has been carried

out, all the relays are voltage free.

Check the scheme of connection

If RGX1002 is connected to a Solenoid valves 12V.cc and does not work.

To RGX1002you can not connect directly solenoid valves, sirens in 12V DC. It must always to use to an external supply.

Do not tamper with the detector

In order not to cause decalibration of the device and electric shock.

If other problems arise, it is necessary to call a specialised and/or authorised technician and/or the Distributor of

BEINAT S.r.l. should be contacted directly.

Before calling a technician ...

IP42 Madein Italy

BEINAT S.r.l.

Via Fatebenefratelli 122/C 10077, S. Maurizio C/se (TO) - ITALY

Tel. 011.921.04.84 - Fax 011.921.14.77

http:// www.beinat.com

Lo styling è della b & b design

Dealer Stamp

Purchase Date:

Registration Number :

Beinat S.r.l. following the targhet to improve its products, reserves the right to modify the technical features, aesthetic and functional any time

without prior notice..

Detector RGX1002

INSURANCE. This device is insured by the SOCIETÀ REALE MUTUA for the PRODUCT'S GENERAL LIABILITY up to a

maximum of 1,500,000.00 EURO against damages caused by the device in case of failures in functioning.

WARRANTY. The warranty term is 3 years from manufacturing date, in agreement with the following conditions. The

components acknowledged as faulty will be replaced free of charge, excluding the replacement of plastic oraluminium

cases, bags, packing, batteries and technical reports.

The device must arrive free of shipment charges to BEINAT S.r.l.

Defects caused by unauthorized personneltampering, incorrect installation and negligence resulting from phenomena

outside normal functioning shall be excluded from the warranty.

BEINAT S.r.l. is not liable for possible damage, direct or indirect, to people, animals, or things; fromproduct faultsand

from its enforced suspension of use.

DISPOSAL OF OLD ELECTRICAL & ELECTRONIC EQUIPMENT.

This symbol on the product or its packaging to indicates that this product shall not be treated as household waste. Instead, it shall be handed over to

the applicable collection point for the recycling of electrical and electronic equipment, such as for example:

- sales points, in case you buy a new and similar product

- local collection points (waste collection center, local recycling center, etc...).

By ensuring this product is disposed of correctly, you will help prevent potential negative consequence for the environment and human health, which could

otherwise be caused by inappropriate waste handing of this product. The recycling of materials willhelp to conserve natural resources. For more detailed

information about recycling of this product, please contact your local city office, your household waste disposal service or the shop where you purchased

theproduct.

Attention: in some countries of the European Union, the product is not included in the field of application of the National Law that applies the European

Directive 2002/96/EC and therefore these countries have no obligation to carry out a separate collection at the “end of life” of the product.

Business - info@beinat.com

HelpDesk-laboratorio@beinat.com

RGX100 V3 4619

Table of contents

Other BEINAT Gas Detector manuals

BEINAT

BEINAT CHCO User manual

BEINAT

BEINAT RGX100 User manual

BEINAT

BEINAT SG800 User manual

BEINAT

BEINAT GS911K User manual

BEINAT

BEINAT CHECKER-24 User manual

BEINAT

BEINAT SGM595/A User manual

BEINAT

BEINAT RGX100Q/Eg User manual

BEINAT

BEINAT GS920 User manual

BEINAT

BEINAT GSH900 User manual

BEINAT

BEINAT GS913- V.6 User manual

BEINAT

BEINAT GSH246 Series User manual

BEINAT

BEINAT SGM595-H2CH User manual

BEINAT

BEINAT NASE25 User manual

BEINAT

BEINAT NASE25/K Instruction manual

BEINAT

BEINAT NASE25/S User manual

BEINAT

BEINAT GS920 User manual

BEINAT

BEINAT SG850 User manual

BEINAT

BEINAT SG895 User manual

BEINAT

BEINAT CHCO User manual

BEINAT

BEINAT CHCO User manual