The EU-Type Examination Certificate has an 'X' suffix indicating that the

following special conditions for safe use apply. Practical implications are

explained in later sections of this instruction sheet.

SPECIAL CONDITIONS FOR SAFE USE

The equipment has an ingress protection rating of IP66. However,

if it has been supplied without cable entry devices, then the user

shall ensure that the devices that are fitted will provide an ingress

protection that is appropriate to the environment in which it is

installed i.e. IP20 or better.

The total capacitance connected to terminals + wrt - (i.e. the

capacitance of the cable plus any other capacitance) shall not

exceed 83nF.

The equipment shall not be directly installed in any process where

its enclosure might be electro-statically charged by the rapid flow

of a non-conductive media.

The equipment shall only be supplied via Terminals + w.r.t.

Terminals - from a barrier having a maximum open circuit voltage

Uo that is < 28V and a maximum short circuit current Io that is

<93mA, where Io is resistively limited. The barrier or galvanic

isolator shall be ATEX certified by a notified body.

4.2 Zones, Gas Groups and T rating

The BR385 sounder has been certified Ex ia IIC T4 Ga. When

connected to approved Zener barriers or galvanic isolators it may be

installed in:

Zone 0 explosive gas air mixture continuously present.

Zone 1 explosive gas air mixture likely to occur in normal

operation.

Zone 2 explosive gas air mixture not likely to occur, and if it

does, it will only exist for a short time.

Warning Do not install the BR385 where it may accumulate

an electrostatic charge from a rapid flow of dry air.

Be used with gases in groups:

Group A propane

Group B ethylene

Group C hydrogen

Having a temperature classification of:

T1 450ºC

T2 300ºC

T3 200ºC

T4 135ºC

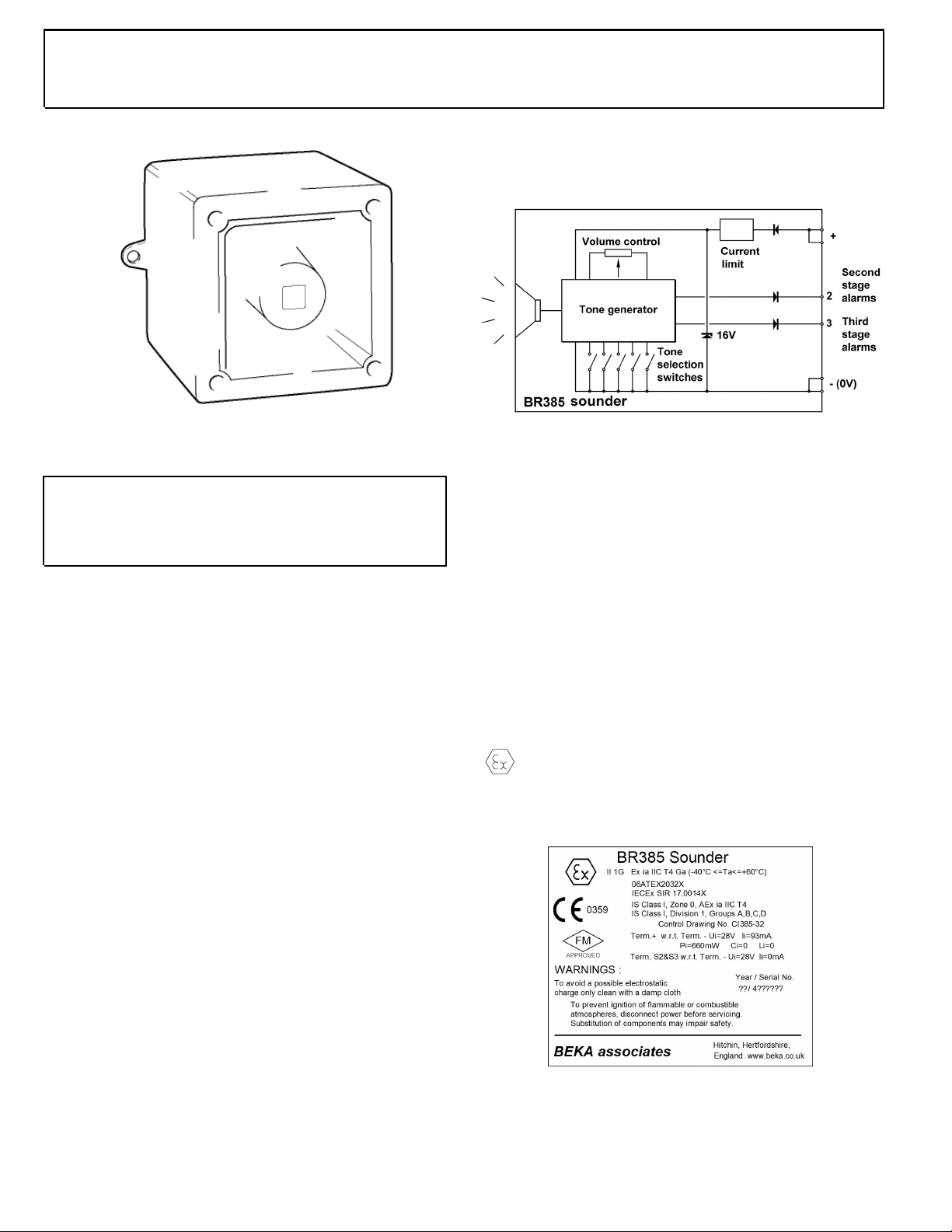

4.3 Terminals + and -

Power is supplied to the sounder via terminals + & - which have the

following maximum input safety parameters:

Ui = 28V

Ii = 93mA dc

Pi = 0.66W

BR385 sounders may be powered from any ATEX Ex ia IIC certified Zener

barrier or galvanic isolator having output parameters equal to, or less

than, these limits. e.g. a certified 28V, 93mA, 0.66W Zener barrier or

isolator may be used.

The BR385 ATEX certificate specifies that the maximum permitted total

capacitance that may be connected between the + and - terminals shall

not exceed 83nF, irrespective of the Zener barrier or galvanic isolator

powering the sounder. This total capacitance includes the cable

capacitance plus the capacitance of any other connected device. This

should not be restrictive unless the sounder and the barrier or isolator are

a long way apart. Single pair instrumentation cables have a typical

capacitance of 100pF/metre rising to 350pF/metre for multicore cables

and are unlikely to exceed 600pF/metre allowing a cable length of up to

830, 230 or 138 metres respectively.

Up to three BR385 sounders may be connected in parallel and powered

from a common barrier or isolator providing the voltage between the + and

– terminals does not fall below 8V. Connecting two sounders in parallel

will reduce the output from each sounder by about 3dB. Three sounders

should only be powered from a common supply when the maximum

supply voltage is available.

4.4 Terminals S2 and S3

When terminals S2 or S3 are connected to 0V ( - terminal) the sounder

output tone changes to the second or third stage alarm respectively. The

input safety parameters for these terminals are:

Ui = 28V

Ii = 0mA

Therefore for control from the safe area terminals S2 & S3 may only be

connected to a certified diode return barrier, or the contacts of a certified

intrinsically safe relay. For functional reasons diode return barriers with a

voltage drop of less than 0.9V must be used. The maximum permitted

cable capacitance Co will be specified on the diode return barrier ATEX

certificate, but again should not be restrictive.

For control from the hazardous area terminals S2 & S3 may be directly

connected to a mechanically operated switch in the hazardous area

complying with the requirements for simple apparatus as defined in

EN 60079-11. i.e. having IP20 protection and able to withstand a 500V

rms insulation test to earth for one minute.

5. INSTALLATION

BR385 sounders should only be installed by trained competent personnel.

5.1 Mounting

The BR385 sounder may be secured to any flat surface using the two

7mm diameter fixing holes. The enclosure provides IP66 protection and is

suitable for installation in sheltered exterior locations providing it is

positioned so that water can not collect in the horn, and the cable entry is

sealed.

2