Page 2 © BEKA 2018 All rights reserved!

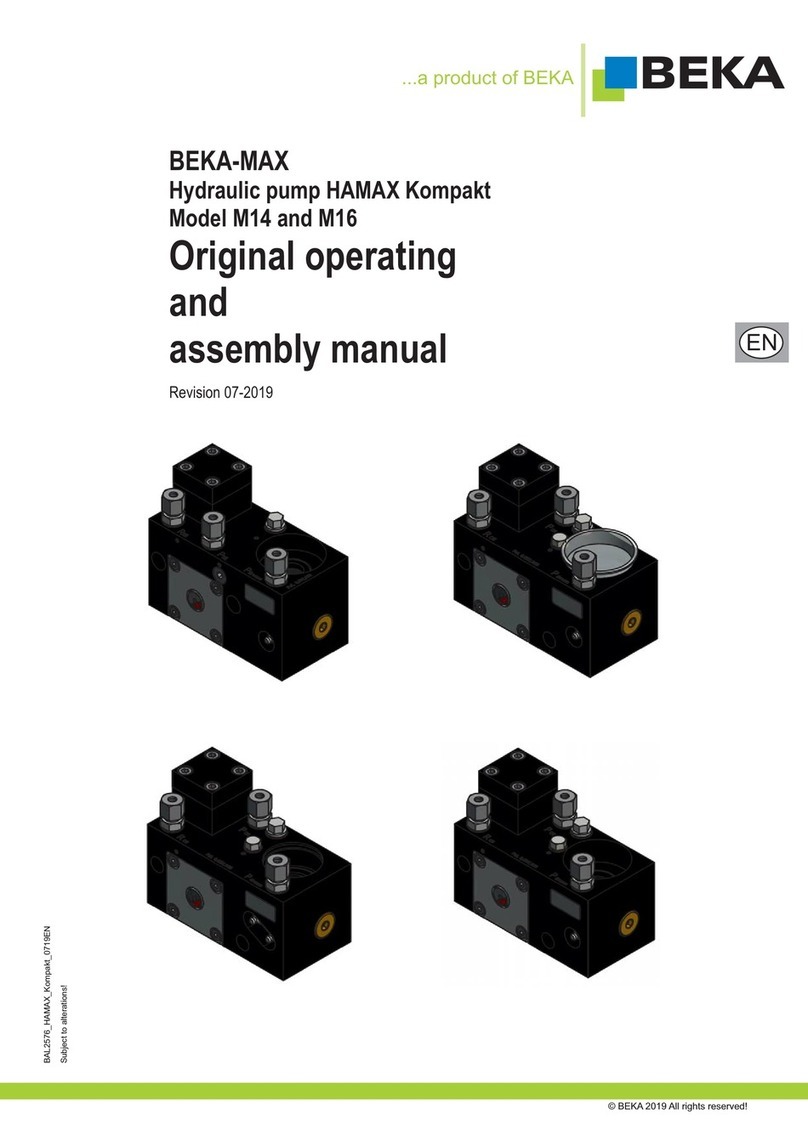

...a product of

Table of contents

1.Technical data ................................................................................................................................................................................3

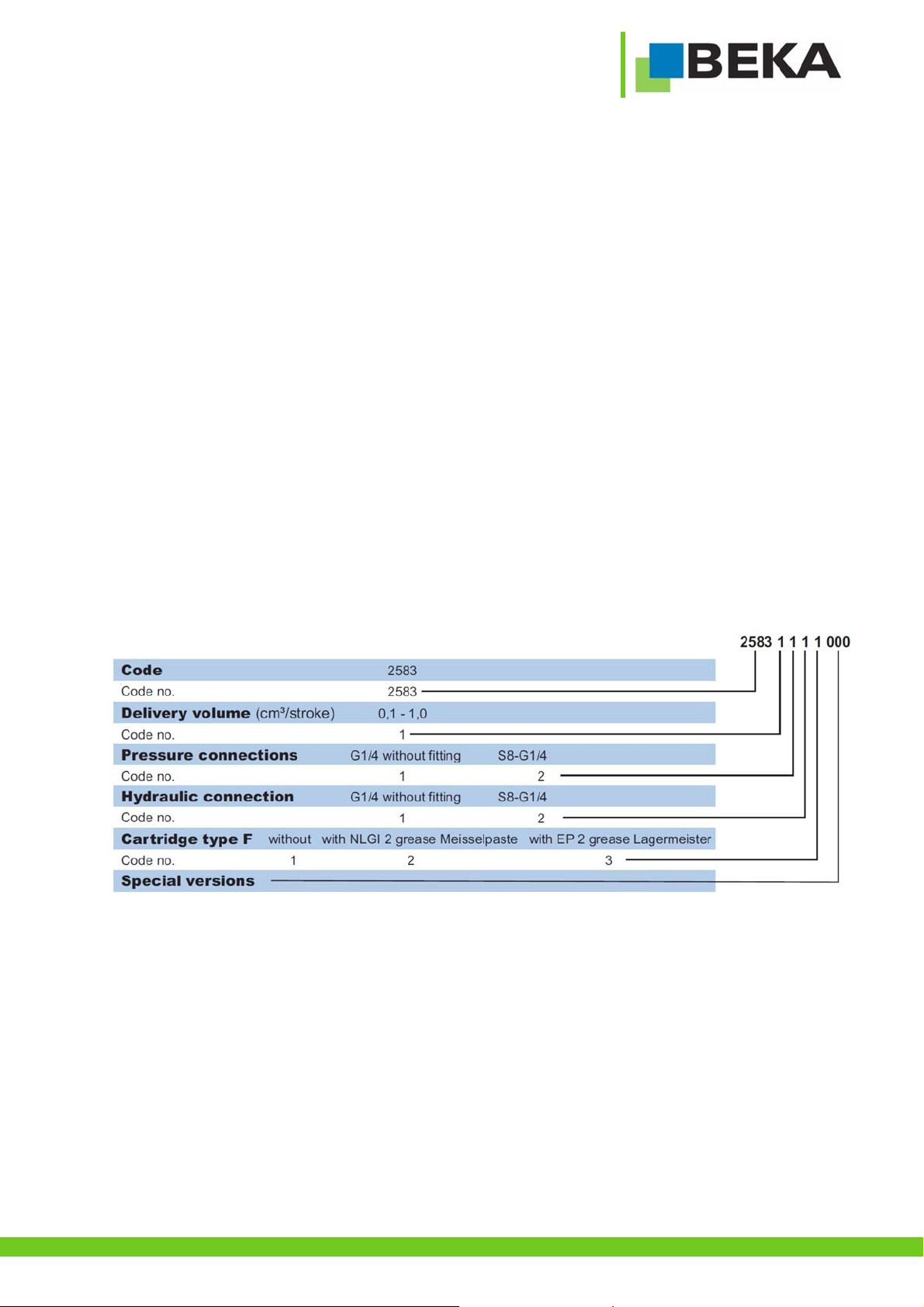

2.Code ...............................................................................................................................................................................................3

2.1Cartridges ..................................................................................................................................................................................3

3.General safety instructions .............................................................................................................................................................4

3.1Safety instructions .....................................................................................................................................................................4

3.2Qualification and training of staff ...............................................................................................................................................4

3.3Hazards in case of non-observance of the safety instructions ..................................................................................................5

3.4Obligations of the operator / user ..............................................................................................................................................5

3.5Safety instructions for maintenance, inspection and assembly .................................................................................................5

3.6Unauthorized modification and production of spare parts .........................................................................................................5

3.7Inadmissible modes of operation...............................................................................................................................................6

3.8General hazard warning – residual risk .....................................................................................................................................6

4.Intended use...................................................................................................................................................................................7

5.Scope of warranty...........................................................................................................................................................................7

6.Transport and storage ....................................................................................................................................................................7

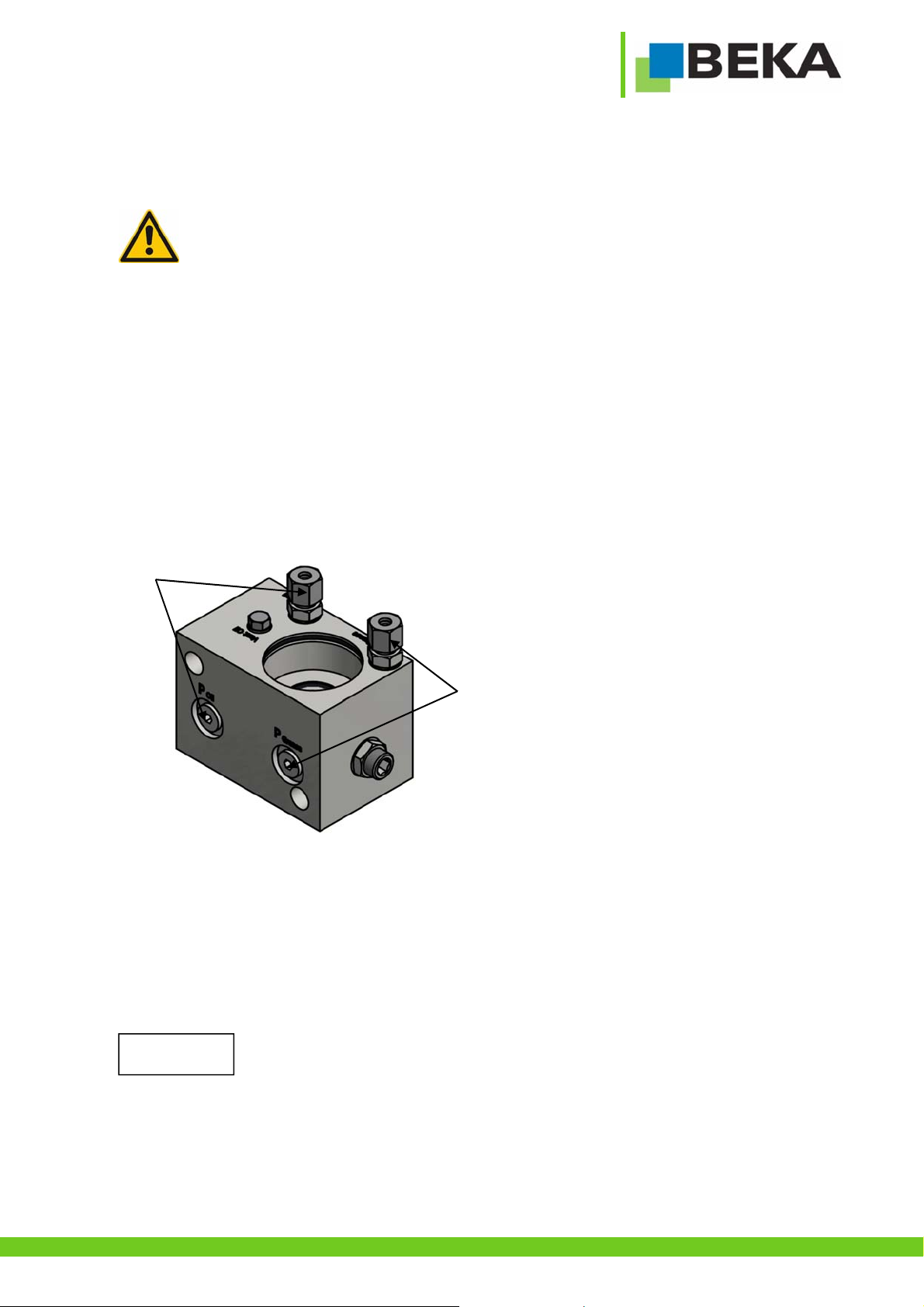

7.Assembly instructions.....................................................................................................................................................................8

7.1Connection of lines ....................................................................................................................................................................8

7.1.1Lubrication line..................................................................................................................................................................8

7.1.2Hydraulic line .................................................................................................................................................................... 8

8.Start up ...........................................................................................................................................................................................9

8.1Lubricant.................................................................................................................................................................................... 9

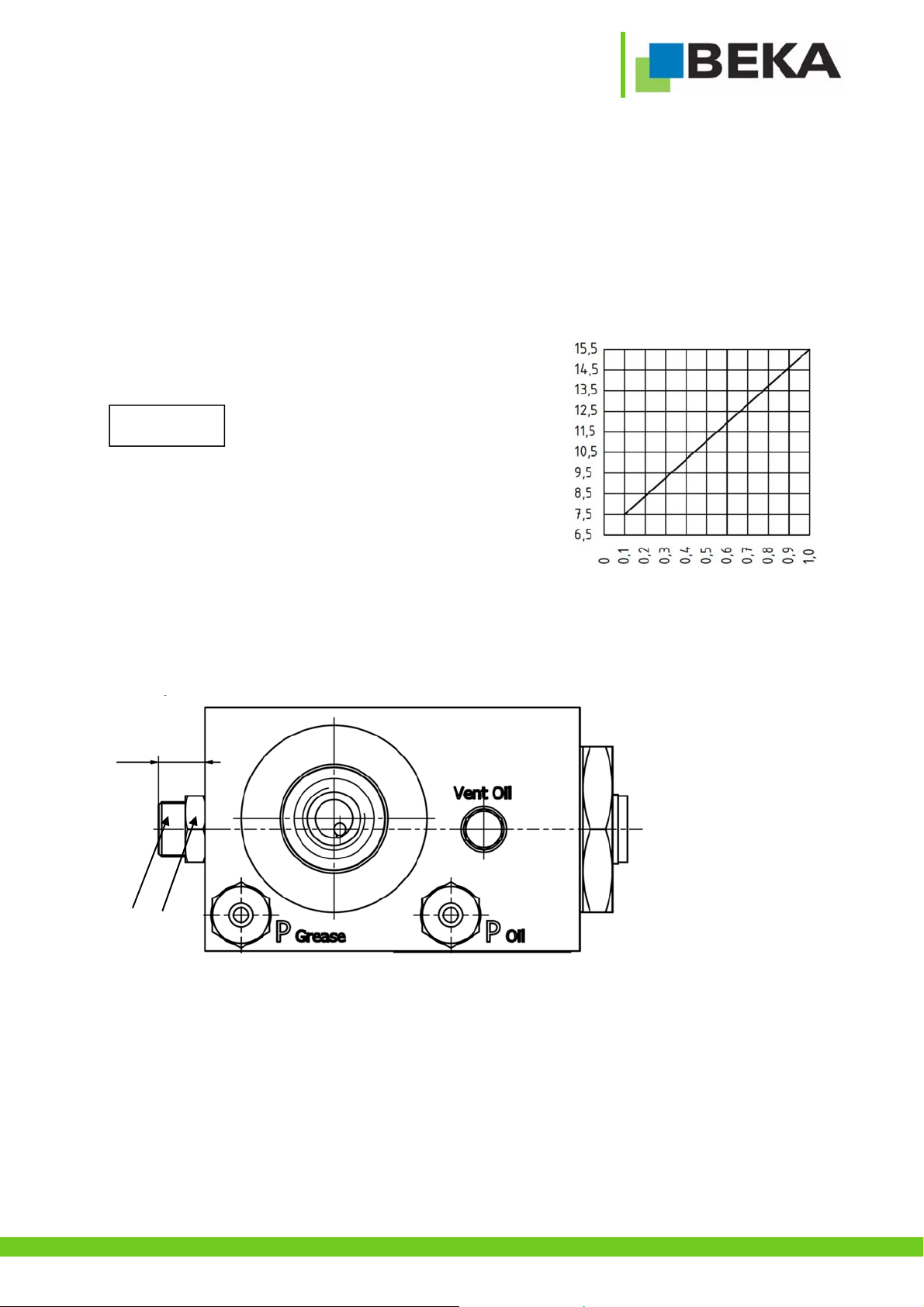

8.2Setting the delivery rate............................................................................................................................................................. 9

8.3Replacement of grease cartridge.............................................................................................................................................10

8.4Ventilation (grease area) .........................................................................................................................................................11

8.5Ventilation (oil area)................................................................................................................................................................. 11

9.Functional description................................................................................................................................................................... 12

9.1General.................................................................................................................................................................................... 12

9.2Function................................................................................................................................................................................... 12

9.3Hydraulic scheme ....................................................................................................................................................................12

9.4Pressure transmission .............................................................................................................................................................13

10.Maintenance .................................................................................................................................................................................14

10.1General maintenance ..............................................................................................................................................................14

10.2Lubricant change .....................................................................................................................................................................14

11.Shutdown......................................................................................................................................................................................14

12.Disposal........................................................................................................................................................................................14

13.Troubleshooting............................................................................................................................................................................15

14.Spare part list and drawing...........................................................................................................................................................15

15.Dimensional drawing AZ300548...................................................................................................................................................16

16.Details of the manufacturer...........................................................................................................................................................17