To maximize pump performance, clean tank interior of all dirt and

foreign material before installation.

NOTE: To prevent pressure build-up and possible nozzle leak-

age, make sure the tank is vented. A vent cap rated at 1 psi

is recommended.

Priming

This pump is designed to self-prime to a minimum height of 60

inches (152 centimeters) with 10 weight oil.

If your installation requires a greater lift capacity, the pump may not

prime unless the gears are coated with oil. To coat gears, remove

the hose and squirt motor oil into the gear cavity. Replace the hose

and turn the pump on. Using this procedure, lift of up to 18 feet (5.5

meters) is possible.

On tanks over 8 feet (2.4 meters) deep, a check valve may be

required at the bottom of the suction pipe to help establish and

maintain prime.

Install the Pump

To prevent leakage, seal all connecting threads with three to four

turns of Teflon®tape during installation.

1. After sealing threads, tighten the bung adapter on the tank until

snug.

The provided suction pipe has a variable length of 22 to 40 inches

(56 to 102 centimeters). For additional length, use the Suction Pipe

Extension described in the Illustrated Parts Drawing.

An alternate suction pipe may be constructed of 1-inch pipe cut to

appropriate length. To avoid possible tank impurities which could

damage your pump, determine tank depth and cut pipe a few

inches shorter.

2. After sealing threads, tighten the suction pipe into the pump

inlet until snug. Grip on the suction pipe’s fittings.

3. Place gasket on top of bung adapter.

4. Extend the provided suction pipe to its full length and insert

carefully into the tank. The provided suction pipe will adjust to

the length needed to rest on the tank bottom.

5. Position pump on bung adapter, taking care not to displace

gasket.

6. Hold pump in position while securely tightening union ring. Do

not overtighten. Make sure union ring is not cross-threaded.

Install Hose and Nozzle

To prevent leakage, seal all connecting threads with three to four

turns of Teflon®tape.

1. If installing accessories such as meters or filters, do so now,

following manufacturer’s instructions.

CAUTION: Make sure any hose and nozzle used are compatible

with petroleum fluids.

2. After sealing threads, hand-tighten the hose into the outlet until

snug.

3. Hand-tighten nozzle to hose.

INSTALLATION

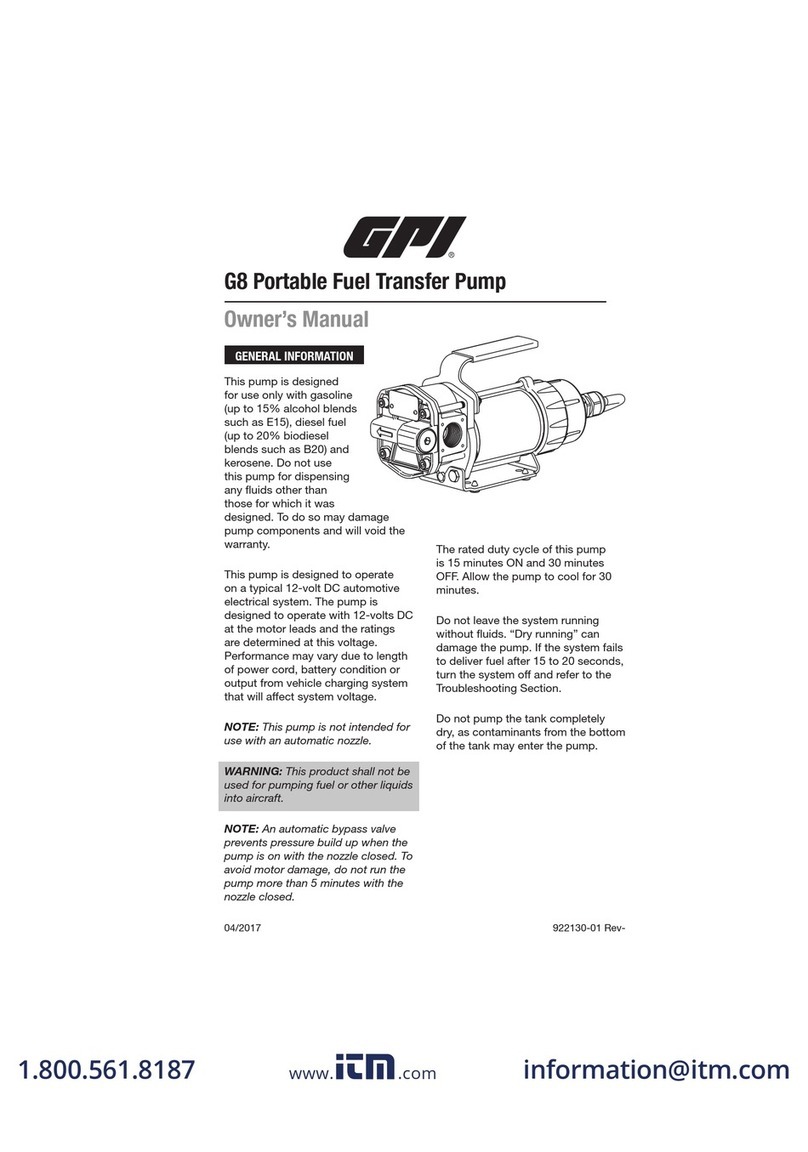

This pump was designed specifically for use with thin to medium

viscosity petroleum fluids such as 30 weight motor oil. Fluids used

with this pump should fall into NFPA listed categories for combus-

tible fluids with a flash point above 100°F (38°C). The fluids should

be clean and free of debris which might damage or impair proper

operation of internal components.

Using fluids, other than those for which the pump was designed,

could lead to serious personal injury and void the warranty.

Electrical Connections

This pump is designed for use with 115-volt power. Do not attempt to

install or operate the pump with 12-volt, 24-volt, or 230-volt power.

Use only three-pronged, grounded connectors. Do not use two-prong

connectors or adapters. Inspect power cords regularly and replace

if signs of wear are evident.

Serious electrical shock can result from operating electrical equip-

ment on wet ground.

To avoid personal injury, use a ground fault circuit interrupter

(GFCI) approved by Underwriters Laboratories Standard 943 with

this pump. If your electrical service already has GFCI outlets, you

are protected. If not, a portable GFCI is available through electrical

equipment distributors or from GPI. Contact your distributor or GPI

Customer Service for more information.

Daily Pre-Operation

Keep pump exterior clean to help identify leaks. Before each use,

inspect for leaks around seals or connections. If found, refer to the

Troubleshooting Section.

Check for leakage under the pump

housing. A small drain hole relieves

any fluid which bypasses the motor

shaftseal.Ifanyleakageisfoundhere,

replace the motor shaft seal using

instructions in the Repair Section.

Make sure hoses are in good condi-

tion and connections are tight.

Make sure the work area is dry.

Make sure the pump is connected to GFCI protected 115-volt power.

Use only three-prong, grounded connectors. Inspect the power cord

regularly and replace if signs of wear are evident.

OPERATION

▲

▲

!! ! ! WARNING ! ! !

To avoid personal injury, do not use this pump with flammable

fuels such as gasoline or alcohol. Do not use with diesel fuel,

kerosene, chemicals, or herbicides.

▲

▲

!! ! ! WARNING ! ! !

Follow standard precautions for handling combustible high

flash point fluids.

▲

▲

!! ! ! WARNING ! ! !

Serious electrical shock can result from operating electrical

equipment on wet ground.

2