Belanger DuraFlo User manual

1MANUL375

REV 0

Belanger, Inc.®

P.O. Box 5470

Northville, MI 48167-5470

ustomer Service Phone (248) 349-7010

Fax (248) 380-9681

www.Belangerinc.com

18 GPM

18 GPM18 GPM

18 GPM

Pumping Stations

Pumping StationsPumping Stations

Pumping Stations

DuraFlo™

DuraFlo™DuraFlo™

DuraFlo™

Belanger® Equipment Owners Manual

DuraFlo™ 18 GPM Pumping Stations

Copyright 2013

Belanger, Inc®

This manual and the accompanying equipment are protected by United States trademark, copyright, and patent laws. You

may make one copy of this manual. Do not make additional copies of this manual or electronically transmit it in any form

whatsoever, in whole or in part, without the prior written permission of Belanger, Inc.®

The registered trademarks used in this document are the property of their respective owners. The use of such trademarks is

for reference purposes only and does not imply sponsorship or approval of Belanger, Inc.®by these companies or any

companies affiliated with their respective owners.

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

1

Table of Contents

Belanger Incorporated® Limited Warranty.......................................................3

Operational Warning...........................................................................................4

Important Safety Information .............................................................................5

Safety Symbols and Signal Words.............................................................................................5

IMPORTANT Safety Information – MUST READ ......................................................................6

Safety Warnings.........................................................................................................................7

Introduction.........................................................................................................8

Specifications......................................................................................................9

Requirements.............................................................................................................................9

Operating Envelope Dimensions..............................................................................................10

Connections Overview .....................................................................................11

Assembly...........................................................................................................12

Installation.........................................................................................................14

Initial Startup ............................................................................................................................14

Plumbing Overview...........................................................................................15

Pipe System Overview.............................................................................................................15

DURAFLO™ 18 GPM PUMPING STATIONS

2

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Table of Contents

Maintenance ......................................................................................................18

Routine Procedures.................................................................................................................18

Powder Coating Maintenance..................................................................................................19

Trouble Shooting Guide...........................................................................................................22

Drive Belt Replacement and Tightening..................................................................................23

Pumping Station Float Valve Seal Replacement Kit (#105884) ..............................................26

Replacement Parts ..................................................................................................................36

Hydra-Cell™ Industrial Pump Manual .............................................................39

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

3

Belanger Incorporated® Limited Warranty

LIMITED WARRANTY: Equipment: Seller warrants to the original purchaser that the goods sold hereunder, which are

fabricated by Seller, shall be free from defects in workmanship and material under normal use and service for a period of 1 year

plus 30 days from the date of invoice - CAT

Pumps will be warranted for 2 years from the date of invoice. All

warranties, express, implied, or statutory, pertaining to Seller’s machinery, parts, and equipment are fully set forth

herein. This limited warranty applies to the original purchaser only and is not transferable. No addition to or

modification of any of the provisions of this stated Limited Warranty shall be binding upon the Seller, unless made in

writing and signed by a duly authorized employee of Seller. This warranty is subject to the following limitations: (1)

This warranty shall be void if the factory specifications for operation and maintenance, found in original equipment

manuals, and component manuals, are not followed, or if other than factory authorized erection, alterations or

modifications are made to any parts or equipment; (2) Defective parts are warranted to the Purchaser for repair or

replacement through an authorized distributor of Seller or direct with Seller for a period of 13 months from the date

of invoice. Parts warranty excludes all claims for failure resulting from normal wear and tear to the depreciable parts,

improper installation, omission of factory specified preventative maintenance, misuse, abuse, negligence, third party

damages, or acts of God. Purchaser agrees to submit to and assist Seller or its authorized distributor in conducting

in-warranty inspections of the machinery and equipment including inspection of any part claimed to be defective by

the Purchaser; (3) Labor to repair or replace parts is warranted to Purchaser during normal business hours through

an authorized distributor of Seller or direct with Seller, for 120 days from date of invoice. Labor warranty excludes all

claims for failure resulting from normal wear and tear to the depreciable parts, improper installation, and omission of

factory specified preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God. Seller

reserves the sole right to make determinations on the above stated limitation. All labor and service provided beyond

the labor warranty period shall be subject to labor charges at the rates established by the local authorized distributor

or direct with Seller; (4) This warranty shall be void for all equipment failures and premature component wear

caused by the use of corrosive chemicals in the wash process. The following list includes some, but not all, of the

particularly corrosive chemicals that if used in conjunction with Belanger® equipment will void the warranty:

Hydrofluoric Acid, Ammonium Bi-flouride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen

Cyanide, Hydrochloric Acid, Sodium Hydroxide and Chlorinated Solvents. (5) Seller makes no warranty, express or

implied, with respect to the design or operation of any entire system, in which Seller’s goods sold hereunder are

mere components. (6) In no event shall Seller be liable for any incidental, special, consequential or exemplary

damages resulting from the furnishing, performance or use of any goods or services sold pursuant hereto, whether

due to a breach of contract, breach of warranty, the negligence of Seller or to otherwise; not for loss of business;

inconvenience, or property damage of any kind; not for any damages of whatever nature resulting in any way from

the purchaser’s selection and use of any chemicals not manufactured exclusively by seller but used with the

purchased goods; or for any service not expressly provided herein related to or arising from the equipment or goods

sold. This limitation of liability extends to purchaser’s use of any engineering recommendations, sales

representations, technical assistance, advice or data supplied by seller to purchaser in connection with the goods or

services supplied, other than that information contained in Belanger® manuals.

Parts: Seller warrants to the original purchaser that the Replacement Parts sold hereunder, shall be free from

defects in workmanship and material under normal use and service for a period of 30 days from the date of invoice.

This limited warranty applies to the original purchaser only and is not transferable. (1) This warranty shall be void if

the factory specifications for operation and maintenance are not followed; (2) Parts warranty excludes all claims for

failure resulting from normal wear and tear to the depreciable parts, improper installation, omission of factory

specified preventative maintenance, misuse, abuse, negligence, third party damages, or acts of God. (3) This

warranty shall be void for all replacements parts failures and premature component wear caused by the use of

corrosive chemicals in the wash process. The following list includes some, but not all, of the particularly corrosive

chemicals that if used in conjunction with Belanger® replacement parts will void the warranty: Hydrofluoric Acid,

Ammonium Bi-flouride, Bromic Acid, Muriatic Acid, Sulfonic Acid, Phosphoric Acid, Hydrogen Cyanide, Hydrochloric

Acid, Sodium Hydroxide and Chlorinated Solvents.

THIS LIMITED WARRANTY FOR EQUIPMENT AND REPLACEMENT PARTS IS EXPRESSLY IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

Copyright © 2000 by Belanger, Inc.® All rights reserved. No part of this work may be reproduced or transmitted in

any form or by any means, electronic or mechanical, including photocopying and recording, or by any information

storage or retrieval system, except as may be expressly permitted by the 1976 Copyright Act. Revised as of 8-15-

01. Belanger® reserves the right to change or modify the Belanger Inc.® Limited Warranty without notice.

DURAFLO™ 18 GPM PUMPING STATIONS

4

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Operational Warning

Formulations containing the chemicals listed below are particularly dangerous and should not be used

even at low concentrations:

•Hydrofluoric Acid

•Ammonium Bi-flouride

•Bromic Acid

•Muriatic Acid

•Sulfonic Acid

•Phosphoric Acid

•Hydrogen Cyanide

•Hydrochloric Acid

•Chlorinated Solvents

Belanger, Inc.®, does not endorse or condone the use of chemicals that are potentially dangerous to human

health, the environment or property. Belanger® recognizes that it is the right and sole decision of the end

user operators of our equipment as to the type and dilution ratio of the chemicals used in their facilities.

We strongly recommend that the end user does not select products containing any of the chemicals listed

above as an ingredient in the wash solutions. The chemicals listed above are potentially dangerous to

human health, and have a detrimental, deteriorating effect on the equipment and the facility. Be advised

that a portion of, or all of your warranty will be voided if you determine to use any of the chemicals listed

above as an ingredient in the wash solutions in conjunction with your Belanger® automatic car wash

equipment:

Limitation (4), of Paragraph (8), Limited Warranty, of the Belanger® Terms and Conditions of Sales

describes the potential limitation of warranty due to your chemical selection:

(4) This warranty shall be void for all equipment failures and premature component wear caused by the

use of corrosive chemicals in the wash process. The following list includes some, but not all, of the

particularly corrosive chemicals that if used in conjunction with Belanger® equipment will void the

warranty: Hydrofluoric Acid, Ammonium Bi-flouride, Bromic Acid, Muriatic Acid, Sulfonic Acid,

Phosphoric Acid, Hydrogen Cyanide, Hydrochloric Acid, and Chlorinated Solvents. The Purchaser

also agrees to accept the responsibility and liability for the selection and use of any chemicals listed

above;

However, should the end user decide to use formulations containing any of the above ingredients, the end

user should institute a comprehensive training program and implement detailed operational parameters

within their organization for the proper handling and treatment of such products to minimize the potential

dangers involved. Consult your chemical supplier for assistance in establishing operational guidelines in

the use of their products. MSDS (Material Safety Data Sheet) should be obtained from the chemical

supplier before using any chemical formulation.

During the installation process the installer is responsible for re-tightening ALL

lugs, set screws and terminals located in the electrical panels. Components may

vibrate loose during shipping.

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

5

Important Safety Information

This section introduces the hazard and safety precautions associated with installing, maintaining or servicing this product.

Before performing any task on this product, read this safety information and the applicable sections in this manual, where

additional hazards and safety precautions for your task may be found. Electrical shock could occur and cause death or

serious injury if these safe service procedures are not followed.

Safety Symbols and Signal Words

Alert Symbol

This safety alert symbol is used in this manual and on warning labels to

alert you to precautions which must be followed to prevent potential

personal safety hazards. Obey safety directives that follow this symbol to

avoid possible injury or death.

Signal Words

The signal words used in this manual and on warning labels tell you the seriousness of particular

safety hazards. The precautions that follow must be followed to prevent death, injury or damage

to the equipment.

This signal word is used to alert you to a hazard or unsafe practice which WILL RESULT IN

DEATH OR SERIOUS INJURY

This alerts you to a hazard or unsafe practice which COULD RESULT IN DEATH OR

SERIOUS INJURY

This signal word designates a hazard or unsafe practice which MAY RESULT IN MINOR

INJURY

When used by itself, CAUTION designates a hazard or unsafe practice which MAY RESULT IN

PROPERTY OR EQUIPMENT DAMAGE

Before You Begin

Only trained or authorized individuals knowledgeable in the related procedures should install,

inspect, maintain or service this equipment.

Read the Manual

Read, understand and follow this manual and any other labels or related materials supplied with

this equipment. If you do not understand the procedure, call a Belanger, Inc.® representative at

248-349-7010. It is imperative to your safety and the safety of others to understand the

procedures before beginning work.

DURAFLO™ 18 GPM PUMPING STATIONS

6

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Important Safety Information

IMPORTANT Safety Information – MUST READ

DISCONNECT THE MAIN POWER SUPPLY AND

DISSIPATE ALL POTENTIALLY HAZARDOUS

ENERGY SOURCES PRIOR TO SERVICING OR

MAINTAINING EQUIPMENT

Belanger® recommends that all workers observe the OSHA (U.S. Department of

Labor Occupational Safety & Health Administration) Lockout / Tagout procedure

prior to performing service or maintenance on machinery and equipment.

Note:

Reference the OSHA standard for the Control of Hazardous Energy (Lockout/Tagout), Title 29

Code of Federal Regulations (CFR) Part 1910.147 and the example provided in 1910.147

Appendix A for practices and procedures necessary to disable machinery or equipment, thereby

preventing the release of hazardous energy while employees perform servicing and maintenance

activities. The standard outlines measures for controlling hazardous energies – electrical,

mechanical, hydraulic, pneumatic, chemical, thermal, and other energy sources.

Note:

Reference the OSHA standard 29 CFR 1910.331 to 29 CFR 1910.335 for safe work practices to

protect employees working on electrical circuits and equipment. This section requires workers to

use safe work practices, including lockout and tagging procedures. These provisions apply when

employees are exposed to electrical hazards while working on, near, or with conductors or systems

that use electrical energy.

Note:

Both referenced OSHA standards can be found at the following website: http://www.osha.gov/law-

regs.html. Browse to the General Industry tab under the Find an OSHA Standard heading, scroll

down to the link of interest and click on it.

Doing so will prevent unexpected energization, startup, or release of hazardous

energy while maintenance and servicing activities are being performed.

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

7

Important Safety Information

Safety Warnings

BE SURE TO OBSERVE OPERATING ENVELOPE.

EQUIPMENT MAY START UNEXPECTEDLY. OVERHEAD,

ROTATING AND/OR MOVING COMPONENTS COULD

RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF FOREIGN OBJECTS IN THE AREA

SURROUNDING A ROTATING PIECE OF EQUIPMENT.

OBJECTS MAY BECOME TANGLED WITH EQUIPMENT AND

COULD RESULT IN SERIOUS INJURY OR DEATH.

BE AWARE OF HAZARDS ASSOCIATED WITH

EQUIPMENT INSTALLED ON THE FLOOR

THAT MAY BE A TRIP HAZARD.

It is imperative to your safety and the safety of others to always follow safe work

procedures.

DURAFLO™ 18 GPM PUMPING STATIONS

8

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Introduction

Belanger® has developed the DuraFlo™ Pumping Station product line. It is ideal for medium and high-pressure

applications. The DuraFlo™ product line provides an assortment of pumping platforms that can be used in multiple

applications. The DuraFlo™ product line is available in an 18 GPM pumping platform with either a 10 hp or 15 hp

motor, or a 36 GPM pumping platform with either a 15 hp or 25 hp motor. These pumping station options allow the

flexibility to supply a medium-volume water application that can deliver 600 to 1100 psi.

Built for longevity, the DuraFlo™ pumping platforms are assembled with high-quality components. All frames are

powder-coated for corrosion protection. The powertrain system connecting the motor and pump is a pulley system

comprised of cast sheaves and cogged V-style belts. ompared to standard V-belts, cogged belts run cooler, last

longer, and operate with a higher efficiency. Each pulley is locked to its respective shaft with a taper-lock bushing and

torqued according to the proper specification. The powertrain is also protected with a front and back plastic guard

which provides a safe operating environment during operation. Industrial duty motors are used on all four platforms.

The construction of these motors offers superior durability. Another benefit of the industrial duty motors is the pre-

lubricated, double-shielded oversized bearings to accommodate varying belt loads and tensions. The industrial duty

motor also provides a high-efficiency energy design. This design uses class “F” copper windings that allow the motor

to operate at higher temperatures than normal and still maintain durability. The DuraFlo™ product line has the

trademark “Green and Yellow” Dura product color combination (green frame/yellow tank), which allows customers to

easily associate these pumping stations with the durability known with Belanger® Dura components.

The 18 GPM pumping platforms include a Wanner™ H-25 Hydra- ell diaphragm pump that is capable of operating

fresh water or reclaim water. The main water inlet is sized no less than 1-inch ID pipe or hose. The main water feed

connects directly to a float valve assembly, which is easily adjusted, to maintain the proper water level in the holding

tank. The float valve used on this pumping platform has a 3/4” inlet. The pump is fed with a 2-inch suction hose from

the holding tank. A low-level mechanical switch assembled inside the tank also comes standard to prevent the pump

from running without water. A pressure relief (unloader) valve is attached to the pump by a 1/2-inch hydraulic hose

assembly, and also uses a 1/2-inch hydraulic hose assembly to unload water back into the holding tank. When the

nozzle is set to the proper pressure, the valve will unload approximately 2 GPM. The distribution manifold, located

near the pump, supports a 1-inch MJI fitting and connects to a single feed spray application.

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

9

Specifications

Requirements

Physical

Pump Type Wanner™ H-25 Hydra- ell Positive Displacement

Diaphgram

Motor Type 10 HP or 15 HP, 1765 RPM, 3-Phase 208/230/460/575 V

Unloader Type 21 GPM, 4060 psi Discharge Pressure, 1/2” NPT-F ports

Tank apacity 54 Gal apacity Max, 31 Gal Max Water Available

Maximum Flow 18 GPM

Maximum Pressure 600 psi for 10 hp motor, 1100 psi for 15 hp motor

Inlet Size 1” NPT, 100 psi Max Water Inlet Pressure

Outlet Size 18 GPM, 1” MJI

Weight With 10 hp - 545 Lb (Dry) or

With 15 hp - 685 Lb (Dry)

DISCONNECT AND LOCKOUT ELECTRICAL POWER AND DISSIPATE ANY OTHER

POTENTIALLY HAZARDOUS ENERGY SOURCES ACCORDING TO 29 CFR 1910.147

AND THE EXAMPLE PROVIDED IN 1910.147 APPENDIX ‘A’ BEFORE SERVICING ANY

EQUIPMENT!

Always wear safety glasses when performing maintenance on any equipment

It is recommended that a licensed electrician is contracted to perform all electrical

installations.

A compressed Air System should be set correctly to support 90 PSI necessary to operate

equipment, but should never be set to deliver more than 120 PSI air pressure to the Belanger®

specified equipment.

DURAFLO™ 18 GPM PUMPING STATIONS

10

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Specifications

Operating Envelope Dimensions

Note:

Be sure to leave adequate space around the DuraFlo™ pumping station to allow for service and

maintenance on the belts, pump, and motor.

21”

65”

34”

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

11

Connections Overview

Low Level Switch:

1/2” NPT-F into bulkhead

Must run in series with all other Low

Level switches, including Spot Free

Test this switch before using the wash

Pumping Station ater Inlet:

1” NPT-F into bulkhead

Max Inlet Pressure: 100 psi

Inlet Float Valve:

3/4” NPT-F Valve

50 GPM @ 60 PSI

Tank Overflow Port:

1” barbed hose fitting to drain

Pumping Station

Bypass Line

Pump Inlet

Hose:

2” ID x

2-3/8” OD

Pressure Relief

(Unloader) Valve Outlet:

1/2” Plug

Pumping Station ater Outlet:

1” MJI

Pump Inlet Hose:

2” ID x 2-3/8” OD

Pressure Relief

(Unloader) Valve Inlet:

1/2” hydraulic hose

Pump Oil Fill Port Pump Oil

Drain Cap

Pump Inlet Port

Pump Outlet Port

DURAFLO™ 18 GPM PUMPING STATIONS

12

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Assembly

1.

Install the inlet plumbing to the float valve as shown below.

Install a field supplied shut off valve in this feed line.

Install the connection to the float valve inlet (3/4” FNPT) with flexible hose.

Note:

At the fluid inlet, a minimum 1” feed to the float valve is required.

Recommended 1” barbed

hose fittings

(field supplied)

Main water feed

(typically 2”)

3/4” flexible hose required

(field supplied)

Reducer

(field supplied)

Shut off valve

(field supplied)

Recommended 1”, minimum 3/4” copper

(copper, field supplied)

Outlet

plumbing to

tank

1” Bulkhead

Fitting

Float Valve

Float Rod

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

13

Assembly

2) Install the outlet plumbing from the outlet port of the Distribution Manifold to the desired piece of

equipment. See the image below.

Note:

The outlet feed should be flexible hose from the unloader valve to any hard piping, solenoid

or tees.

Hose MUST be rated for a minimum pressure of 1500 PSI. Remember that the plumbing has

direct bearing on pressure at the nozzle (massive pressure drops are common to an incorrectly

installed system).

3) Install 3 phase wiring in accordance with any and all local and national codes (direction is

reversible).

Use caution, this machine starts automatically. Avoid contact with high pressure spray, as

serious personal injury may occur.

Outlet Port

Disribution Manifold

DURAFLO™ 18 GPM PUMPING STATIONS

14

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Installation

Initial Startup

1)

Verify the proper motor and pump rotation according to the decal on the plastic belt guard. See the image

below.

2)

Refer to the Wanner™ Hydra- ell section in this manual for the initial startup procedures for the pump.

3)

Verify that the water inlet valve flow rate is set correctly and does not exceed 100 psi.

4)

Verify that all hose fittings and clamps are tight.

5)

Flush out the component that is connected to the DuraFlo™ pumping station before installing any nozzles.

Note:

Check the drive belt tension after the first 8 hours of service. Refer to the Belt Tension chart in

this manual for the proper tension rating.

DURAFLO™ 18 GPM PUMPING STATIONS

1MANUL375

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470* Ph (248) 349-7010 * Fax (248) 380-9681

15

Plumbing Overview

Pipe System Overview

Type M Copper

1/2"

(13 mm)

3/4"

(19 mm)

1"

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

2"

(50.8 mm)

5 GPM

(18.9 LPM) 1.43/0.099

6.3/1.92

10 GPM

(37.8 LPM) 4.9/0.34

12.6/3.84

0.89/0.061

6.2/1.89

15 GPM

(56.8 LPM) 10.65/0.73

19.9/6.066

1.85/0.128

9.3/2.84

0.52/.036

5.5/1.68

20 GPM

(75.7 LPM)

2.92/.2

12.5/3.81

0.87/.06

7.3/2.23

25 GPM

(94.6 LPM)

4.32/.298

15.6/4.76

1.33/.092

9.2/2.8

0.49/.034

6.1/1.86

30 GPM

(113.5 LPM)

1.81/.125

1.0/.31

0.68/.047

7.3/2.23

40 GPM

(151.4 LPM)

3.04/.21

14.7/4.48

1.15/.079

9.8/2.99

0.51/.035

7.0/2.13

Note:

Velocity should not exceed 15 feet (4.6 meters) per second in a correctly installed

system

1/2"

(13 mm)

3/4"

(19 mm)

1"

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

2"

(50.8 mm)

Tee side 4 / 1.2 5 / 1.5 6 / 1.8 7 / 2.1 8 / 2.4 12 / 3.7

90

o

F Ell

(23

o

C Ell) 1-1/2 / .5 2 / .6 2-3/4 / .8 4 / 1.2 4 / 1.2 6 / 1.8

45oF Ell

(11

o

C Ell)

3/4 / .2 1 / .3 1-3/8 / .4 1-3/4 / .5 2 / .6 2-1/2 / .8

Male/Female

Adapter 1 / .3 1-1/2 / .5 2 / .6 2-3/4 / .8 3-1/2 / 1.1 4-1/2 / 1.4

Pressure loss, fittings (feet of pipe / meters of pipe)

Note:

All values calculated with clean water @ 60

o

F / 15

o

C

Example

4.16/.287

10.6/3.2

PSI per 10 foot of pipe / BAR per 3 meters of pipe

Velocity in feet per second / Velocity in meters per second

DURAFLO™ 18 GPM PUMPING STATIONS

16

Belanger, Inc.® * PO BOX 5470 * Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL375

Plumbing Overview

Pipe System Overview

Stainless Steel Tubing (type 304 per ASTM A269)

1/2"

(13 mm)

3/4"

(19 mm)

1"

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

2"

(50.8 mm)

5 GPM

(18.9 LPM) 5.2/.359

11.0/3.35

10 GPM

(37.8 LPM) 17.61/1.21

22.1/6.74

2.43/.168

9.6/2.93

15 GPM

(56.8 LPM)

4.95/.341

14.4/4.39

1.06/.073

7.5/2.29

20 GPM

(75.7 LPM)

1.75/.121

10.0/3.05

0.63/.043

6.5/1.98

25 GPM

(94.6 LPM)

2.59/.179

12.6/3.84

0.3/.064

8.1/2.47

30 GPM

(113.5 LPM)

3.57/.246

15.1/4.6

1.27/.088

9.8/2.99

0.49/.034

6.5/1.98

40 GPM

(151.4 LPM)

2.11/.145

13.0/3.96

0.81/.056

8.8/2.68

Note:

Velocity should not exceed 15 feet (4.6 meters) per second in a correctly installed

system

1/2"

(13 mm)

3/4"

(19 mm)

1"

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

2"

(50.8 mm)

Tee side 4 / 1.2 5 / 1.5 6 / 1.8 7 / 2.1 8 / 2.4 12 / 3.7

90

o

F Ell

(23

o

C Ell) 1-1/2 / .5 2 / .6 2-3/4 / .8 4 / 1.2 4 / 1.2 6 / 1.8

45oF Ell

(11

o

C Ell)

3/4 / .2 1 / .3 1-3/8 / .4 1-3/4 / .5 2 / .6 2-1/2 / .8

Male/Female

Adapter 1 / .3 1-1/2 / .5 2 / .6 2-3/4 / .8 3-1/2 / 1.1 4-1/2 / 1.4

Pressure loss, fittings (feet of pipe / meters of pipe)

Note:

All values calculated with clean water @ 60

o

F / 15

o

C

Example

4.16/.287

10.6/3.2

PSI per 10 foot of pipe / BAR per 3 meters of pipe

Velocity in feet per second / Velocity in meters per second

Table of contents

Other Belanger Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Filabot

Filabot EX6 Operation manual

Würth

Würth HSG 5 PRO Instructions for use

Linz electric

Linz electric E1S ACCOMPANIMENT TO THE INSTALLATION, OPERATION AND MAINTENANCE MANUAL

eqss

eqss OverWatch 6253 installation manual

Nidec

Nidec LEROY-SOMER LSA 49.1 IC6 Installation and Maintenance

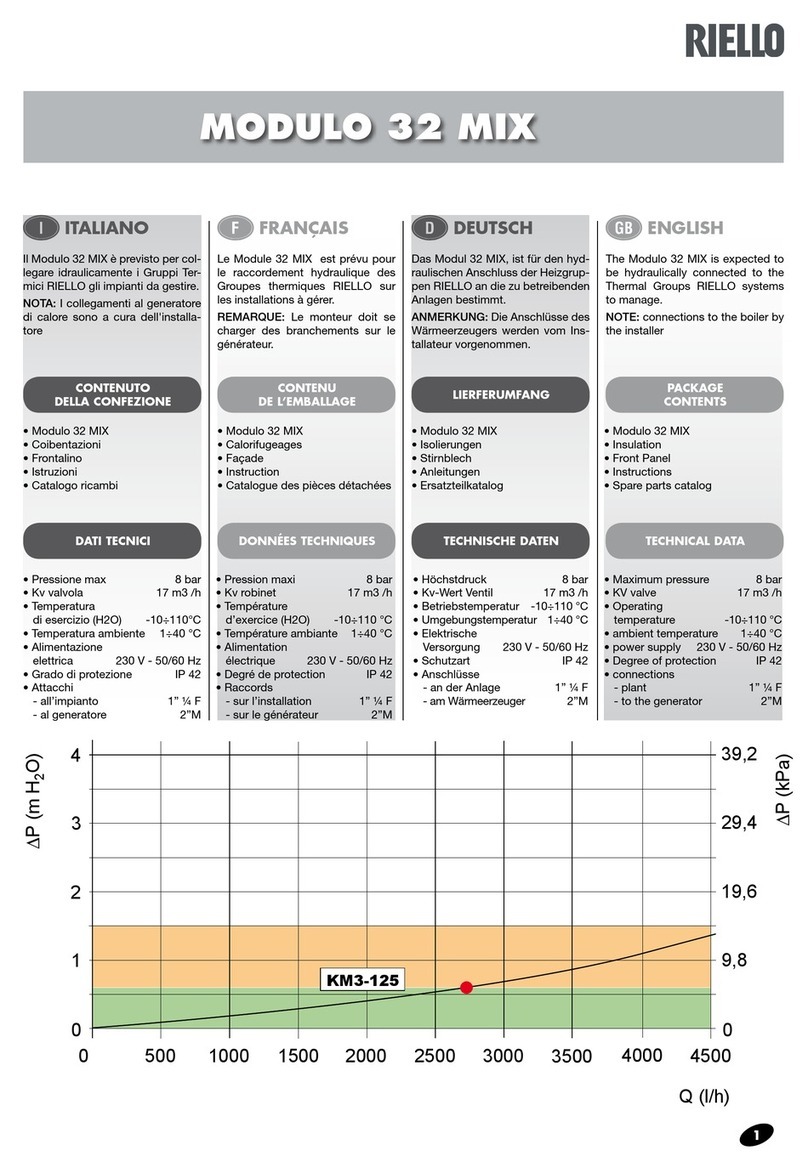

Riello

Riello MODULO 32 MIX instruction manual

Dorner

Dorner AquaPruf 7600 Series Installation, Maintenance, and Parts Manual

Siemens

Siemens 3VF 3 operating instructions

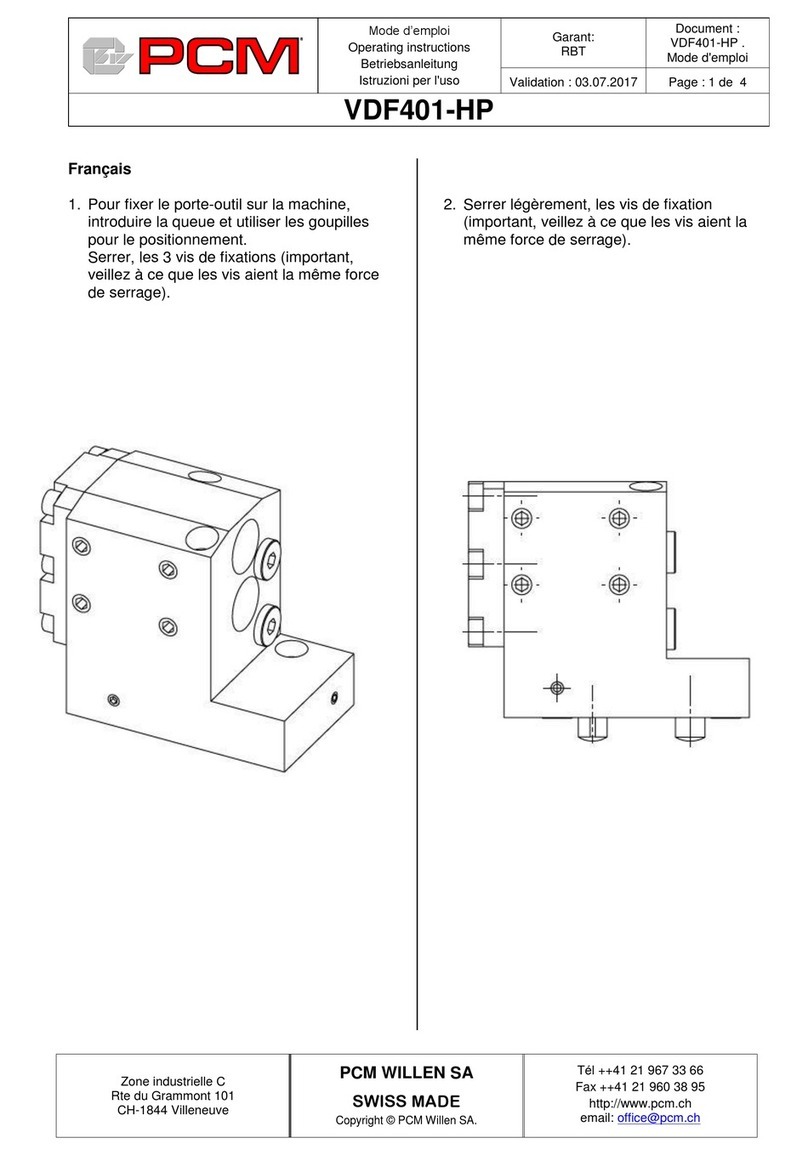

PCM

PCM VDF401-HP operating instructions

Bettersafe

Bettersafe Weight Angel Installation & user manual

Hydac

Hydac VMU Series Operating and maintenance instructions

UNI

UNI Ammeraal Beltech Plastic Modular Belt Series Assembly