Belimo VRP-M User manual

Product information VRP-M VAV system

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 1 / 28

Table of Contents

Overview of the system 2

System description 3

Technical data sheets

VRP-M adaptive, digital PID VAV controller

Application

Functions

System configuration

Operating data settings (with VRP-M-Tool)

Connection of the VRP-M-Tool

Bus operation

VFP-.. static differential pressure sensors for neutral to slightly aggressive gases

Fast-running damper actuator for VRP-M system solution NMQB24-SRV-ST

Damper actuator for VRP-M system solution NM24A-V-ST

7

8

9

12

13

15

16

19

21

23

Dimensions 25

Adaptive VAV control system

for sensitive working areas

MP

BUS

®

TECHNOLOGY BY BELIMO

VRP-M VAV Overview of the system

2 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Pressure sensors for

static differential pressure measurement

VFP-100 VFP-300 VFP-600

Pressure range 0 ... 100 Pa 0 ... 300 Pa 0 ... 600 Pa

Medium

– Slightly dusty air

– Very dusty air

– Corrosive gases

●

●

*

●

●

*

●

●

*

Power supply From VRP-M From VRP-M From VRP-M

VRP-M connection Ready to connect Ready to connect Ready to connect

* For a list of sensor materials that come into contact with the medium,

see «Technical data» for the VFP-.., page 19

Damper actuators

NMQB24-SRV-ST NM24A-V-ST

Torque 4 Nm 10 Nm

Speed < 5 s 110 ... 150 s

Power supply From VRP-M From VRP-M

VRP-M connection Ready to connect Ready to connect

VAV functions

Application Volumenstrom

VAV / CAV

Pressure

STP

VAV: min ... max ●

CAV: min / mid / max ●

Override functions:

Open – closed ●

Extraction systems ●

Laboratory exhaust systems ●

Bus integration ● ●

Fan optimisation ●

Modulating pressure:

Pmin … Pmax ●

Stepped pressure: Pmin / Pmax ●

Override functions OPEN / CLOSE ●

Motor stop function ●

System components

VRP-M control solution

VRP-M

VAV / CAV STP

Power supply AC/DC 24 V AC/DC 24 V

Modulating control 0 ... 10 / 2 ... 10 V 0 ... 10 / 2 ... 10 V

0 ... 20 / 4 ... 20 mA 0 ... 20 / 4 ... 20 mA

Stepped control Contacts, switches Contacts, switches

Bus function

MP

BUS

®

TECHNOLOGY BY BELIMO

MP

BUS

®

TECHNOLOGY BY BELIMO

– Optimiser COU24-A-MP ●

– LONWORKS® integration ● ●

– EIB/Konnex integration ● ●

Settings, diagnostics VRP-M-Tool VRP-M-Tool

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 3 / 28

System components

Controller VRP-M adaptive, digital PID VAV controller

for every application Pages 7 ... 18

Sensor Pressure sensors for static differential pressure measurement

– VFP-100 with 0 ... 100 Pa measuring range

– VFP-300 with 0 ... 300 Pa measuring range

– VFP-600 with 0 ... 600 Pa measuring range

Pages 19 ... 20

Actuator – NM24A-V-ST damper actuator for standard applications 1)

– NMQB24-SRV-ST damper actuator for fast-running applications 1) Pages 21 ... 24

1) Please contact your Belimo representative for other actuator solutions, e.g. spring return.

Brief description

Application This ready-to-connect system solution is an efficient control system for pressure-independent,

standard and fast-running air volume applications.

Field of application The system can be used for controlled extraction of contaminated or slightly aggressive air 1) in closed

rooms:

– Exhaust air systems for laboratory workplaces *

– Laboratories in chemical and pharmaceutical plants *

– Hospital buildings *

In combination with the NMQB24-SRV-ST fast-running actuator, this system is particularly suited to

laboratory applications *:

– Digesters *

– Extraction of contaminated air *

* Air compatibility verification essential (see «Technical data» for the VFP-... sensors, page 19).

Function The pressure differential at the static pressure sensor is converted into a volumetric flow signal with

a linear throughflow and serves as the actual value x for the adaptive PID-VAV controller. The volu-

metric flow signal (0 ... 100% nom) can be picked off at the VRP-M, controller connection U5, as a

0 ... 10 / 2 ... 10 V signal.

The actual value x is compared with the setpoint w set on the VAV controller and the connected

damper actuator is controlled according to the resulting system deviation. The VRP-M controller can

be controlled according to its function as a CAV constant controller (min /max) or a VAV controller via

the reference value input w with a modulating 0 ... 10/2 ... 10 V signal in the range from min ... max.

Control inputs with OPEN/CLOSE/mid functions are available for special applications.

The VRP-M can be integrated into an MP system via the MP-Bus connection.

Ready-to-connect system solution for

• Pressure-independent VAV and CAV

systems, e.g. in laboratories

• Fast-running VAV and CAV applica-

tions, e.g. in digesters or generally for

extracting contaminated or slightly ag-

gressive air in closed rooms

Control:

DC 2 ... 10 V / 0 ... 10 V or bus

Integration into

• DDC controller with MP interface

• EIB Konnex systems

• LONWORKS® systems

Settings and diagnostics

with VRP-M-Tool

System description VRP-M VAV system

VRP-M VFP-..

NMQB24-SRV-STNM24A-V-ST

VRP-M VAV Ready-to-connect system solution

4 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Safety notes

!

• The VRP-M system solution is not allowed be used for applications outside the specified field

of application, especially in aircraft or in any other airborne means of transport.

• Only components explicitly approved for this purpose by Belimo are allowed to be used for

the VRP-M system solution.

• The equipment configuration and settings form part of the unit manufacturer‘s system solu-

tion (OEM) and are not allowed to be modified without prior authorisation. All changes are

liable to disrupt operation and cause damage to the system or injury to persons!

• Attention must be paid to the following during the planning phase and before the VRP-M

system solution is operated:

– The compatibility of the VFP-.. sensor with the medium to be controlled must be verified,

– The specifications supplied by the VAV unit manufacturer (design, installation site) must

be consulted,

– All local regulations must be observed.

• Applications with fast-running actuator NMQB24-SRV-ST: The actuator moves into the

«CLOSED» position (left or right end stop, depending on the position of the direction of rota-

tion switch) when the supply voltage is switched on, in the event of a power failure >5 s or if

the pushbutton is actuated again. It then moves into the position required by the system. The

VRP-M control function is inoperative during this procedure.

• If the VRP solution is operated in a bus system, the cycle times of the MP-Bus and the

higher-level system must be taken into account.

• The manufacturer of the VAV unit (OEM) is responsible for ensuring that the VRP-M-system

solution is installed and set correctly as well as for the overall precision of the VAV unit.

If replacement devices are ordered, they are configured by the OEM at the factory according

to the installed system.

The VRP-M system solution is sold exclusively via the OEM channel for this reason.

System characteristics

Control characteristics Adaptive, digital PID VAV controller (see «System components», page 3).

Pressure measurement Static Belimo pressure sensors (see «System components», page 3).

Damper actuators Belimo VAV damper actuators (see «System components», page 3).

Optimally matched components In addition to standard VAV and CAV applications, the VRP-M system solution is also suitable for

fast-running applications such as those used in laboratories. The solution comprises optimally

matched, ready-to-connect components. These are only permitted for use in the controller-sen-

sor-actuator combinations specified by Belimo and selected by the unit manufacturer (see «Sys-

tem components», page 3).

VAV – variable air volume Variable air volume applications based on a modulating reference signal, e.g. supplied by a DDC

controller, room temperature controller, EIB Konnex or LONWORKS® system.

The reference signal for the min ... max working range can be set as follows:

DC 2 ... 10 V / DC 0 ... 10 V / adjustable DC range / bus operation

CAV – constant air volume Constant air volume applications with operating steps (relays, switching contacts).

The following operating steps are available: CLOSED / min / mid / max / OPEN / bus operation

Bus function Up to eight Belimo MP devices (VRP-M / VAV-Compact / damper actuator / valve) can be con-

nected via the MP-Bus and integrated into the following systems:

– DDC controller with integrated MP-Bus protocol

– EIB Konnex system with Belimo UK24EIB interface

– LONWORKS® system with Belimo UK24LON interface

See pages 16...18

Diagnostics tool VRP-M-Tool, plugged either directly onto the VRP-M VAV controller or via a terminal in the cont-

rol cabinet (connection 4 – PP/MP)

Version overview – VRP-M system solution

Refer to www.belimo.eu for current information about compatibility, versions and functions.

VRP-M VAV Ready-to-connect system solution

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 5 / 28

Electrical installation

Wiring diagrams: VAV operation Example 1:

With analogue reference signal

Example 2:

DC 0 ... 10 V with shut-off (CLOSED)

Conventional operation:

See pages 10 and 11 for a description of

functions such as control priority

AC 24 V

DC 24 V

~T

+

_

T

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

+DC 24 V

_

AC 24 V

DC 24 V

~T

+

_

T

Example 3:

DC 0 ... 10 V with shut-off / parallel control

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

+DC 24 V

_

AC 24 V

DC 24 V

~T

+

_

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

+DC 24 V

_

T

Example 4:

With bus control

Beispiel 5:

Typical application: MP with shut-off (CLOSED)

Bus control:

See pages 16 to 18 for a description of functions

MP

~T

+

_AC 24 V

DC 24 V

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

MP

~T

+

_AC 24 V

DC 24 V

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

Reference value input w

0 ... 10 / 2 ... 10 / adjustable

PP/MP communication

Volume flow actual value U5

0 ... 10 / 2 ... 10 / adjustable

Control input z

PP/MP communication

Volume flow actual value U5

0 ... 10 / 2 ... 10 / adjustable

CLOSED (shut-off)

ZU (Absperrung)

CLOSED (shut-off)

Reference value input w

0 ... 10

Note

– Supply via safety isolation transformer!

– We recommend routing connections 1, 2

(AC/DC 24 V) and 4 (MP signal) to accessible

terminals (floor distributor, control cabinet, etc.),

in order to simplify access with the VRP-M-Tool

for diagnostic and service work.

!

VRP-M VAV Ready-to-connect system solution

6 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Commissioning

Prerequisites – The VAV / CAV unit must be mounted

– The VRP-M system solution must have been set and calibrated for the VAV / CAV unit by the

unit manufacturer

– The electrical connection must have been made and checked

– The 24 V supply and control must be ready for operation

– The system fan must be in operation

Procedure – Check the electrical connection

– Check the zero offset of the pressure sensor

– Check the damper mobility

– Check the supply pressure (the system fan must be in operation and calibrated)

– Check the min / max settings and correct them if necessary

– Check the control signal setting and adjust it if necessary

Angle of rotation adaptation

The angle of rotation must be adapted whenever the angle of rotation limiting of the

NMQB24-SRV-ST damper actuator is adjusted.

Procedure:

– Switch on the 24 V supply

– Press the manual override pushbutton twice

The actuator moves into the CLOSED...OPEN...setpoint position

VFP-.. static pressure sensor

Zero offset

– Disconnect both (!) hose connections from the

sensor

– Remove the cover of the VFP-.. sensor

housing

– Turn the zero potentiometer inside the VFP‐..

until the LED in the VRP-M [p>0] lights up

– Turn the zero potentiometer back until the LED

goes out again

Zero potentiometer VFP-100

Note

Fast-running damper actuator NMQB24-SRV-ST

A synchronisation is performed after the power sup-

ply is switched on or after the manual disengage-

ment is actuated; this means the actuator moves to

CLOSED and returns to its nominal position.

Zero potentiometer VFP-300

VFP-600

Electrical installation (Continued)

Wiring diagrams: CAV operation Example 1: Example 2:

min – max – OPEN

See pages 10 and 11 for a description of function

Note

– Supply via safety isolation transformer!

– We recommend routing connections 1, 2

(AC/DC 24 V), 4 (MP signal) and 5 (U5 signal)

to accessible terminals (floor distributor, control

cabinet, etc.), in order to simplify access with the

VRP-M-Tool for diagnostic and service work.

!

4

3

2

1 VRP-M

MPw

~T

+

_

567

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

+DC 24 V

_

AC 24 V

DC 24 V

~T

+

_

4

3

2

1 VRP-M

MPw

~T

+

_

567

U5 z1 z2

VFP-...NM...-ST

VRP-M

Tool

+DC 24 V

_

AC 24 V

DC 24 V

~T

+

_

* Function not available with DC 24 V supply.

PP/MP communication

Volume flow actual value U5

0 ... 10 / 2 ... 10 / adjustable

CLOSED

OPEN

min

max

OPEN (damper open)

min

max

PP/MP communication

Volume flow actual value U5

0 ... 10 / 2 ... 10 / adjustable

mid *

LED ∆p>0

VRP-M

Technical data sheet VRP-M VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 7 / 28

Adaptive digital PID VAV controller

for VRP-M system solutions

• For pressure-independent VAV and

CAV systems

• Control:

DC 0 ... 10 V / 2 ... 10 V or bus

• Diagnostics socket for VRP-M-Tool

Technical data

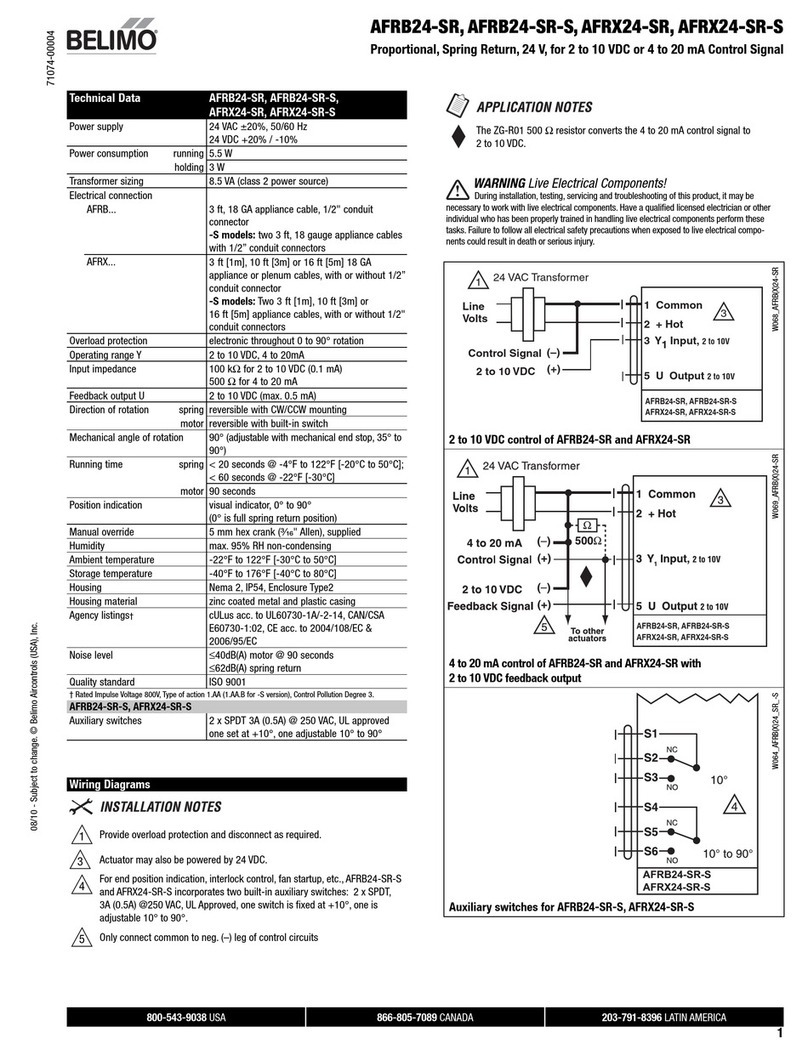

Electrical data Nominal voltage AC 24 V, 50/60 Hz

DC 24 V

Power supply range AC ±20% / DC ±10%

Power consumption In operation

For wire sizing

1.1 W (incl. VFP-.. sensor, without actuator)

2.6 VA (incl. VFP-.. sensor, without actuator)

Connection Actuator

Pressure sensor

Terminals 1 ... 7

VRP-M-Tool

Plug, 6-pin

Plug, 4-pin

Screw terminals, 7-pin, 0.5 mm2 ... 1.5 mm2

Plug, 3-pin

Functional data VAV reference signal w (terminal 3)

Range: min ... max

Input impedance >200 kΩ

– DC 0 ... 10 / 2 ... 10 V or

– 0 ... 20 / 4 ... 20 mA (with 500 Ω resistance)

Volumetric flow actual value U5 (terminal 5)

Range 0 ... 100% nom DC 0 ... 10 / 2 ... 10 V, max. 5 mA

OPEN operating step – z1 (terminal 6) OPEN, input impedance >300 kΩ

CAV operating steps z2 (terminal 7) CLOSED / min / mid / max, contact current <1 mA

Control characteristics PID, adaptive

Control tolerance ±5% of nom

Ranges nom

max

min *

mid (intermediate position) **

Nominal volumetric flow (manufacturer-specific)

30 ... 100% of nom

0 ... 100% of nom

0 ... 100% of min ... max

LED indicator AC/DC 24 V supply

Volume too high / too low, sensor zero

MP-Bus function (terminal 4) ***

Address in bus operation

Functionality

MP 1 ... 8 (classic control: PP)

Adjustable with VRP-M-Tool and address pushbutton

Slave

Operation / service VRP-M-Tool

Safety Protection class III Safety extra-low voltage

Degree of protection IP42

EMC CE according to 89/336/EEC

Mode of operation Type 1 (to EN 60730-1)

Ambient temperature range 0 ... +50°C

Non-operating temperature –20 ... +80°C

Ambient humidity range 5 ... 95% r.H., non-condensating (EN 60730-1)

Maintenance Maintenance-free

Dimensions/weight Dimensions See «Dimensions» on page 25

Weight Approx. 250 g (without sensor)

* See «Creep flow limitation and minimum setting limit», page 9

** Not available with DC 24 V supply

*** For bus operation, see pages 16...18

VRP-M VAV Adaptive VAV controller

8 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Safety notes

!

• The controller is not allowed to be used outside the specified field of application, especially

in aircraft or in any other airborne means of transport.

• The device does not contain any parts that can be replaced or repaired by the user.

• The manufacturer of the VAV unit (OEM) is responsible for ensuring that the VRP-M-

controller is installed and set correctly as well as for the overall precision of the VAV unit. If

replacement devices are ordered, they are configured by the OEM at the factory according to

the installed system.

The VRP-M controller is sold exclusively via the OEM channel for this reason.

• The device contains electrical and electronic components and is not allowed to be disposed

of as household refuse. All locally valid regulations and requirements must be observed.

Application

Together with the VFP-.. static pressure sensor and a Belimo NM..-ST actuator, the VRP-M

forms a control system for pressure-independent variable (VAV) and constant (CAV) air volume

controls.

For more information, see «VRP-M system», pages 3 ... 6

Electrical connections

Front panel

Assignment of terminals 1 ... 7

Terminals 1 ... 7

for supply and control Tab connection for

damper actuator

Tab connection for

pressure sensor

Diagnostics socket for VRP-M-Tool

AC 24 V

DC 24 V

~T

+

_

1234567

T

~

+MPw U5 z1 z2

VAV reference signal min ... max

PP/MP signal

Volumetric flow actual value 0 ... 100% nom

OPEN operating step

CAV operating step CLOSED / min / mid / max

LED indicator and address pushbutton

PWR Green LED LED on:

– AC/DC 24 V supply OK

– Device ready

LED off:

– Supply failure

– Device defective

Blinking – If Set pushbutton pressed during MP adressing

+ Red LED LED on:

– Volumetric flow > setpoint = damper closes

or is closed

– Red LED LED on:

– Volumetric flow < setpoint = damper opens

or is open

∆p>0 Yellow LED Zero offset of VFP-.. pressure sensor

(refer to page 6 for procedure)

Set Pushbutton for assigning MP address in bus operation

(refer to page 18 for procedure)

VRP-M VAV Adaptive VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 9 / 28

Functions

Nominal volumetric flow nom nom corresponds to the maximum volumetric flow of the VAV unit at which the pressure drop

and noise are still within the permissible operating conditions. The nom values are specified and

fixed-programmed by the unit manufacturer.

The volumetric flow actual value signal U5 is always in relation to nom. Changes in the opera-

ting volumetric flow settings min and max therefore have no influence on the U5 voltage signal.

Creep flow limitation

Minimum setting limit max

Creep flow limitation (1)

This function suppresses differential pressure signals in the zero region. Undefined actuator mo-

vements in the 1 ... 6 Pa differential pressure range are prevented by this limitation. The working

range is physically limited owing to the dynamic behaviour of the differential pressure sensor and

the flow pattern of the media.

Sensor type Limitation

VFP-100 1 Pa

VFP-300 3 Pa

VFP-600 6 Pa

Unit manufacturer’s minimum setting limit (2)

Oversized VAV units can make control more difficult in the lowest differential pressure range.

A minimum volumetric flow, usually corresponding to a differential pressure of approximately

5 ... 12 Pa, is therefore specified for the units by the manufacturer. Functional restrictions in this

range can be avoided by complying with the unit manufacturer’s volumetric flow setting.

0/2 10 [V]

2

30%

0%

100% 100%

2

1

a

b

c

a

b

c

1

Start point

End point

nom

Volumetric flow [nom]

Volumetric flow actual value signal U5 [V]

Setting

[min]

Setting

[max]

Reference signal w

Optimum range

Setting with restriction

Setting with greatest

restriction

Creep flow limitation <2 Pa

Unit manufacturer’s minimum setting limit

0 ... 10 V

2 ... 10 V

adjustable

VRP-M VAV Adaptive VAV controller

10 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Functions (Continued)

Control tolerance The maximum permissible control tolerance is defined as a percentage of the nominal volumetric

flow nom. If the system deviation exceeds or undershoots this tolerance, the actuator is adjusted

so that the volumetric flow actual value corresponds to the required setpoint.

Control tolerance: ±5% of nom

The two LEDs [+p] and [-p] indicate when the maximum control tolerance is exceeded or under-

shot or when the deviation is being corrected by means of an actuator movement:

LED [+p]: Volumetric flow actual value > (setpoint + control tolerance) = damper closes

LED [-p]: Volumetric flow actual value < (setpoint + control tolerance) = damper opens

VAV operating volumetric flow

min ... max setting In variable operation, the volumetric flow is specified by means of the reference signal in the

min ... max range.

– max forms the upper limit value as a function of the nominal volumetric flow.

Range 30 ... 100% of nom.

– min forms the lower limit value as a function of nom.

Range 0 ... 100% of nom.

Voltage level

0,0 10

0,0 0,1 10

2,0

min

0…10 V

2…10 V

max

max

min

In mode 2 ... 10 V, it is possible to achieve shut-off mode (damper CLOSED) by lowering the

reference signal to 0.0 V.

For override control in VAV operation, for example CLOSED or OPEN, the reference signal w

(input 3) can be overridden by connecting control inputs 6 (z1) and 7 (z2).

CAV operating steps

CLOSED / min / mid / max / OPEN Five operating steps are available for step operation:

– Shut-off operation – damper CLOSED: The damper is moved into the CLOSED position in a

defined manner.

– Operating steps min / mid / max: The VRP-M adjusts the volumetric flow to the fixed selected

value.

– Flushing operation – damper OPEN: The damper can be opened for maximum ventilation, in

which case air volume control is deactivated.

The operating mode control signals are connected to inputs 6 (z1) and 7 (z2). If signals appear

at these two inputs simultaneously, input 6 (z1) for the OPEN function takes priority.

Reference signal w

[V]

nom

max

[min]

Variable operation

Volumetric flow [% nom]

Volumetric flow actual value signal U5 [V]

Example: 0 ... 10 V mode

< Modulating operation >

Start point End point

Shut-off

[max]

Mode:

CLOSED < Modulating operation >

VRP-M VAV Adaptive VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 11 / 28

Functions (Continued)

Note

mid is not available with DC 24 V supply.

100%

30 40 50 60 70 80 90

0100

10 20 30 50 60 70 80 90

43%

40

VAV override operation

CLOSED / min / mid / max / OPEN If necessary, the VAV min ... max range can be overridden by fixed operating steps in VAV ap-

plications.

The following operating steps are available:

– Shut-off operation – damper CLOSED: The damper is moved into the CLOSED position in a

defined manner.

– Operating steps min / mid / max: The VRP-M adjusts the volumetric flow to the fixed selected

value.

–

Flushing operation – damper OPEN: The damper can be opened for maximum ventilation, in

which case air volume control is deactivated.

Note

– min: All inputs (3 / 6 / 7) open.

– mid is not available with DC 24 V supply.

8

6

24

30 40

100%

30 40 50 60 70 80 90

0100

10 20 50 60 70 80 90

41%

10

0

10

2

4

6

8

Priorities for reference value input 3 (w)

and control inputs 6 (z1) / 7 (z2) If several signals appear simultaneously, they are processed acc. to the following priorities:

Terminal Priority Function

6 z1 1 OPEN

7 z2 2 CLOSED / min / mid / max

3 w 3 min … max

Reference signal w

[V]

CAV operating mode

OPEN

(depending on supply pressure)

nom

max

mid

min

CLOSED

[min]

Volumetric flow [% nom]

[max]

Volumetric flow [% nom]

[max]

ZU

OPEN

nom

max

mid

[min]

Constant operation

Variable operation

Constant operation

min

Volumetric flow actual value signal U5 [V]

Example: 2 ... 10 V mode

VRP-M VAV Adaptive VAV controller

12 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

System configuration

Unit manufacturer’s settings The system solution selected by the unit manufacturer is mounted by the latter on the VAV unit

and configured according to the system requirements (as stated in the order). This configuration

comprises the following settings.

VRP-M Tool

Expert tab

System information

Function Volumetric flow

Sensor The pressure sensor type is specified to enable the pressure range to be adapted.

Actuator The actuator type is specified to enable the running time characteristics to be adapted.

Control – reference signal w,

volumetric flow actual value signal U5 The reference signal w and the volumetric flow actual value signal U5 are adapted to the MCR

system.

Selection: DC 0...10 V / DC 2...10 V / adjustable (sequence matching in the 0...10 V range)

Calibration – nom The nom values are specified and fixed-programmed by the unit manufacturer.

Each VRP-M system solution is optimally adapted to the VAV unit by means of the nom setting.

nom corresponds to the maximum volumetric flow of the VAV unit at which the pressure drop

and noise are still within the permissible operating conditions. The nom setting is specified by

the unit manufacturer.

0

10

2

4

6

8

NW...

NW...

NW100 NW...

Replacement orders If replacement devices are ordered, they must be parameterised beforehand by the OEM at the

factory according to the installed system. The VRP-M is sold exclusively via the OEM channel for

this reason.

Note

The equipment configuration and settings form part

of the unit manufacturer’s system solution (OEM)

and are not allowed to be modified without prior

authorisation. All changes are liable to disrupt opera-

tion and cause damage to the system or injury to

persons!

Volumetric flow

actual value signal U5

[V]

Volumetric flow [nom]

nom

Smallest

nominal width

Largest

nominal width

OEM unit range

VRP-M VAV Adaptive VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 13 / 28

VRP-M Tool – Operating data settings

Adjustments on the system with VRP-M-Tool The VRP-M-Tool can be used to adjust the operating data (min, mid, max settings) and the

reference signals (mode setting – voltage range) directly on the system if necessary. The VRP-

M-Tool adapter must be connected to the diagnostics socket on the VRP-M or to the MP connec-

tion routed to the terminals for this purpose (see Note on page 15).

VRP-M-Tool

Service tab

1 Identification

2 Operating volumetric flow settings

3 System designation entry

4 Volumetric flow

5 Operational test:

Reference signal

Differential pressure [pascal]

Setpoint / actual value [m3/h, l/s]

Selected operating mode:

– AUTO / CLOSED / OPEN

– min / mid / max / nom

– Variable setpoint (min ... max)

Operating volumetric flow settings These parameters are used to set the VAV unit to the air volumes required for each application.

The settings are based on the air volumes calculated by the planning engineer and can either be

preset by the VAV unit manufacturer or adjusted on the system using the VRP-M-Tool.

max Range 30...100% of nom

Upper volumetric flow limit

min Range 0 ...100% of nom

Control range x * ...100% of nom

Lower volumetric flow limit

Shut-off operation (CLOSED) according tomin setting

If a shut-off function is required in VAV operation, it can be achieved by setting min 0%.

mid Range 0 ...100% of min ... max

An intermediate position mid is available for constant air volume (CAV) applications to facilitate

finer steps.

* min settings lower than the control range

min values that are lower than the start value indicated in this range can be set, for example, if the

VAV unit has a shut-off function

System designation entry Input field (16 characters) for specific system designations, e.g. MCR address, system name,

item number in diagram, etc.

1

3

2

5

4

VRP-M VAV Adaptive VAV controller

14 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

VRP-M Tool – Operating data settings (Continued)

VRP-M-Tool

Expert tab

1 Mode setting

Standard 0 ... 10 / 2 ... 10 V

2 Control

System-specific settings

– Reference signal w

– Volumetric flow actual value signal U5

3 VRP-M system information

– VRP-M

Version and conductance setting

– Volumetric flow function

– Sensor type

– Actuator type

Mode setting Options: 0... 10 V / 2...10 V / system-specific

The mode setting acts on the reference signal w and the volumetric flow actual value signal U5.

Variable settings are displayed here and can also be reset by selecting 2 ... 10 / 0 ... 10 V. Vari-

able settings are entered in the «Control» field above.

Control

Variable setting It is sometimes essential to adapt the reference signal w or the volumetric flow actual value sig-

nal U5 to the MCR system directly on the control system.

The reference signal w and the volumetric flow actual value signal U5 can be set to different val-

ues (e.g. reference signal w: 2...10 V / actual value signal U5: 0...10 V).

Reference signal [w] / working range min ... max

Start point: DC 0.0 ... 8 V

Stop point: DC 2.0 ... 10 V

Volumetric flow actual value signal [U5] / display range 0...100% nom

Start point: DC 0.0 ... 8 V

Stop point: DC 2.0 ... 10 V

1

2

3

VRP-M-Tool – Availability

The current version of the VRP-M-Tool and the associated documentation can be downloaded

from www.belimo.eu.

VRP-M VAV Adaptive VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 15 / 28

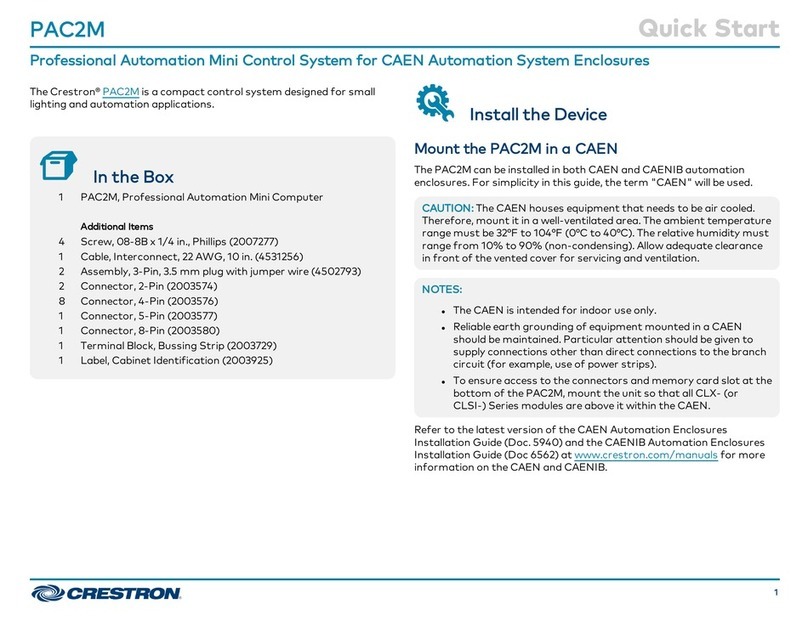

Connection of the VRP-M-Tool

The VRP-M-Tool required for settings and servicing can be connected either directly to the 3-pin service socket on the VRP-M controller or via

the MP connection (terminal 4). A level converter is required for communication, e.g.: ZIP-RS232.

Conventional operation (PP)

VRP-M runs with a locally connected reference signal (0 ... 10 V on connection 3). VRP-M detects that there is no tool connected and switches

back to the connected analogue reference signal automatically after 120 s.

VRP-M

AC 24 V

ZIP-RS232

125

OFF

Actuator

RS232

ON UPP

~T

AC 230 V

ZN230-24

VRP-M

Tool

~

T

+

_

4.21

AC/DC 24 V

VRP-M

. . .

124

ZIP-RS232

125

OFF

Actuator

RS232

ON UPP

~T

AC 230 V

ZN230-24

VRP-M

Tool

24 VAC

MP-Bus mode

VRP-M runs in the MP system, which means it obtains its reference signal via the connected MP master, e.g. UK24LON.

The VRP-M-Tool can only be connected via the bus master in MP mode, otherwise there would be two MP masters connected to the MP-Bus.

This means the local connection to the VRP-M cannot be operating at the same time as the MP master.

MP 1

MP-Bus

MP ..

UK24LON

2

MP 8

MP ..

AC 24 V

ZIP-RS232

125

OFF

Actuator

RS232

ON UPP

~T

AC 230 V

ZN230-24

VRP-M

Tool

-

+

-

+

Note

• The service plug integrated in the VRP-M is not available with bus operation.

• The MP-Bus cannot be used to transmit control functions if it is also used to

connect the VRP-M-Tool.

Workaround: Disconnect the MP-Bus (terminal 4) and use the local MP plug

instead.

AC/DC

24 V Connection in control cabinetConnection via service socket

LON application with UK24LON

VRP-M VAV Adaptive VAV controller

16 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Bus operation

The VRP-M system solution can be interconnected with other Belimo MP actuators (damper

actuators, valve actuators, VAV-Compact controllers, VRP-M system solutions) thanks to the

integrated communication principle over the Belimo MP-Bus. Up to eight Belimo MP devices are

supplied with a digital control signal by the higher-level bus master and then opened to the positi-

on dictated by this signal.

The switch-over from conventional to bus operation is automatic as soon as the MP actuator is

assigned an MP address (1...8).

Belimo MP devices can be integrated into the following systems:

– LONWORKS®: The variables of Functional Profile 8110 can be used in conjunction with the

Belimo UK24LON interface.

– EIB Konnex: Can be used with the Belimo UK24EIB interface

– DDC controller with an integrated MP-Bus protocol: Available from several manufacturers

Damper position (From VRP-M version V3.x)

(nvoAbsAngle - absolute actuator position in angular degrees (°))

The feedback signal, i.e. the network variable nvoAbsAngle, is not available for applications with

NM24-V-ST actuators (old actuator generation).

MP-Bus cycle time

The MP-Bus cycle time must be noted when integrating setpoints and actual values. It is typically

2...8 s, depending on the number of connected bus users and integrated sensors.

The local VRP-M control function is not affected by the cycle time. The cycle time of the MP-Bus

must always be taken into account, however, when selecting setpoints via the MP-Bus.

Mode of operation

Sensor integration (From VRP-M version V3.x)

The VRP-M can be connected to an additional active 0 ... 10 V signal in MP-Bus mode inde-

pendently of the VAV control loop. The sensor signal is connected to the reference value input

that is not used in MP-Bus mode (connection 3).

The VRP-M then acts as an analogue/digital converter for transmitting the sensor signal to the

higher-level system. This system must know the physical address (which sensor is connected to

which MP device) and be capable of interpreting the corresponding sensor signal.

Active sensor connection

MP

4321 VRP-M

PPw

~T

+

_

5 6 7

U5 y z

~T

T

+

_

0 … 10 V

DC 24 V

Active 0 ... 10 V sensors for open and closed-loop control functions in the higher-level system,

such as moisture or CO2 sensors. The cycle time must be taken into account in the implementation!

Reference signal w setting if an active sensor is connected: 0 ... 10 V

Integration of switches,

passive resistance sensors The VRP-M only supports active sensors with a 0 ... 10 V output; i.e. no switches or passive

sensors (resistance elements) can be integrated.

Principle of VRP-M in bus operation In bus operation, the VRP-M controller receives its reference signal from the higher-level control

system and adjusts the volumetric flow to the fixed selected value in the min ... max range.

If necessary, the VAV min ... max range can be overridden by fixed operating steps (control

inputs z1 and z2) in bus operation.

The following operating modes are available:

– Shut-off operation – damper CLOSED: The damper is moved into the CLOSED position in a

defined manner.

– Operating steps mid / min: The VRP-M adjusts the volumetric flow to the fixed selected value.

– Flushing operation – damper OPEN: The damper can be opened for maximum ventilation, in

which case air volume control is deactivated.

Sensor

VRP-M VAV Adaptive VAV controller

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 17 / 28

Bus operation (Continued)

Note

mid not available with DC 24 V supply.

Operating volumetric flow setting min / max The setpoint selected over the MP-Bus is resolved by means of the min and max settings on

the VRP-M.

Function Volumetric flow Range

nom Nominal OEM-specific value, depending on the application and the VAV unit type

max Maximum 30 ... 100% of nom

min Minimum 0 * ... 100% of nom

* The minimum volumetric flow setting min varies according to the type of VAV unit and is also influenced

by the creep flow limitation function (see «Creep flow limitation / minimum setting limit»).

Open operating volumetric flow setting The min-/max setting can be left open if necessary, i.e. min 0% / max 100%. In this case, the

volumetric flow must be limited in the higher-level system.

This operating setting allows the limitation of the volumetric flow to be adjusted without altering

the parameters on the VAV controller.

Responsibility for the limiting function passes from the unit manufacturer to the system supplier

or integrator.

Priorities for bus signal (MP setpoint)

and control inputs 6 (z1) / 7 (z2)

Note

Note the speed of the MP-Bus!

If several signals appear simultaneously, they are processed according to the following table of

priorities.

Terminal Priority Function

6 z1 1 OPEN

7 z2 2 CLOSED / min / mid / max

3 MP override function

1 OPEN

2 CLOSED

3 max

4 min

5 mid

6 –

7 nom

4 MP setpoint 0 ... 100% = min ... max

Last setpoint

Bus fail function

The VRP-M saves the current setpoint, i.e. the last setpoint to have been received from a bus

master (VRP-M-Tool, UK24LON). If the MP network fails, the connected VRP-M detects this and

retains this setpoint until it receives a new one from the MP master.

Initial setpoint after power failure The VRP-M starts with its MP initial status (setpoint 0%, corresponding to min setting) if a power

failure occurs in the intervening period.

Reference signal

(e.g. UK24LON nviRelStpt)

[%]

[max]

CLOSED

OPEN

nom

max

mid

[min]

min

Volumetric flow actual value signal

(e.g. UK24LON nvcActualValue)

Volumetric flow [% nom]

Reference signal

(e.g. UK24LON nviRelStpt)

VRP-M VAV Adaptive VAV controller

18 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

MP-Bus

Topology The cables of up to eight actuators can be laid in a freely definable topology. The following topol-

ogies are permitted: Star-shaped, ring-shaped, tree-shaped or mixed forms.

Connection The network consists of a 3-pin connection (MP communication and 24 V supply). Neither

special cables nor terminating resistors are required. Power can be supplied either over the bus

cable or from a local power supply.

MP

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

4321 VRP-M

MPw

~T

+

_

5 6 7

U5 z1 z2

~T

+

_

AC 24

V

DC 24 V

Network Up to eight MP actuators can be connected in a network (VAV-Compact, VRP-M etc.).

Supply with AC or DC voltage

Nominal voltage AC 24 V, 50/60 Hz DC 24 V

Power supply range AC 19.2...28.8 V DC 21.6...26.4 V

Wire sizing See «Technical data», page 7

Length of MP-Bus cable

The cable lengths are limited:

– By the sum of the performance data of the connected devices, VAV controllers and actuators

– By the type of supply (AC 24 V or DC 24 V)

– By the cable cross-section

For more information about planning and installation, see www.belimo.com

– VAV-Compact NMV-D2-MP Product Information

– Bus and communication systems section

Addressing If the VRP-M system solution is integrated in a bus system, each connected VRP-M must be

assigned an MP address in the range 1 ... 8.

Procedure

– Start the addressing procedure on the MP-Bus master with the VRP-M-Tool, UK24LON, etc.

– Refer to the bus master documentation for further details

– Procedure with VRP-M-Tool:

a) Select the address by means of the serial number

Enter the serial number of the VRP-M (sticker on VRP-M, displayed in VRP-M-Tool)

b) Select addressing with acknowledgement on the VRP-M

Acknowledge the selected address by pressing the Set pushbutton on the required VRP-M

The power LED (green) blinks when the Set pushbutton is pressed

Up to 8 MP-Bus users

More MP-Bus users

Technical data sheet VFP-.. sensors

www.belimo.eu Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes 19 / 28

Static differential pressures sensor

for neutral to slightly aggressive gases

VFP-100

VFP-300

VFP-600

Technical data

Electrical data Power supply

Connection

DC 15 V (from VRP-M controller)

1 m cable with 4-pin plug

(compatible with VRP-M controller)

Functional data Measuring range See «Overview of types»

Overload protection See «Overview of types»

Measuring principle Diaphragm differential pressure measurement

(inductive)

Medium Neutral to slightly aggressive gases

Parts in contact with medium Ni, Al, CuBe, PU

Linearity ±1% of final value (FS)

Hysteresis Max. 0.1% of final value

Temperature sensitivity Zero

Measuring range

See «Overview of types»

t = +10 ... 40°C (reference temperature t0 = 25°C)

Mounting position Upright (connection on bottom or side)

Position dependency Max. ±4.5 Pa

when rotated 90° about horizontal axis

Pressure port Hose connection

for hose with 4 ... 6 mm internal diameter

Safety Protection class III Safety extra-low voltage

Degree of protection IP42

EMC CE according to 89/336/EEC

Mode of operation Type 1 (to EN 60730-1)

Ambient temperature range 0 ... +50°C

Non-operating temperature –10 ... +70°C

Ambient humidity range 5 ... 95% r.H., non-condensating (EN 60730-1)

Maintenance Maintenance-free

Dimensions/weight Dimensions See «Dimensions» on page 25

Weight See «Overview of types»

Overview of types

Type Measuring ranges Overload protection Temperature sensitivity

of zero Weight

VFP-100 0 ... 100 Pa max. 500 Pa ±0.1% / K Approx. 500 g

VFP-300 0 ... 300 Pa max. 5’000 Pa ±0.05% / K Approx. 280 g

VFP-600 0 ... 600 Pa max. 3’000 Pa ±0.05% / K Approx. 280 g

Safety notes

!

• The sensors are not allowed to be used outside the specified field of application, especially in

aircraft or in any other airborne means of transport.

• They may only be installed by suitably trained personnel.

All applicable legal or institutional installation regulations must be complied with.

• The devices do not contain any parts that can be replaced or repaired by the user.

• The devices contain electrical and electronic components and are not allowed to be disposed

of as household refuse. All locally valid regulations and requirements must be observed.

VFP-.. Static differential pressure sensors

20 / 28 Product information S4-VRP-M VAV • en • v2.0 • 11.2006 • Subject to changes www.belimo.eu

Product features

Application Together with a VRP-M controller and a Belimo NM..-ST actuator, the VFP-.. static pressure

sensors form a control system for pressure-independent variable (VAV) and constant (CAV) air

volume controls.

The pressure sensors are used for static differential pressure measurement with differential

pressure pickups installed in air ducts. They are also suitable for contaminated or slightly ag-

gressive air 1). Their robust design makes them ideal for installation in laboratories, clean room

systems and industrial applications.

Mode of operation A high-quality metal diaphragm is used in the sensor. The measured pressure produces a corre-

sponding diaphragm stroke, which is detected inductively and converted to a pressure-linearised

output signal.

The measuring signal is influenced by the mounting position due to the dead weight of the dia-

phragm. The sensor is calibrated at the factory in the vertical position, but can be readjusted on

site if necessary, e.g. in order to mount it in another position.

The temperature is compensated to reduce drift to a minimum. The wear-free, inductive measu-

rement method guarantees maintenance-free operation.

1) See «Technical data», page 19

For zero offset and more information, see «System description», page 6

Electrical installation

The ready-to-connect sensor unit is connected to the VRP-M controller with the 4-pin plug.

Table of contents

Other Belimo Control System manuals

Popular Control System manuals by other brands

Microengine

Microengine XP-GT Series Programming manual

Mitsubishi Electric

Mitsubishi Electric CITY MULTI PAR-40MAA Instruction book

Mitsubishi Electric

Mitsubishi Electric MCCH1 installation manual

Speco

Speco A1 installation instructions

quiko

quiko QK-CE220RL4 user manual

Skip-Line

Skip-Line SC-12 quick start guide

Siemens

Siemens SINUMERIK 840D sl Programming manual

Whelen Engineering Company

Whelen Engineering Company PCCS9R installation guide

Pilz

Pilz PNOZ m ES Profinet operating manual

Crestron

Crestron 4 Series quick start guide

Siemens

Siemens LOK16 Series manual

Extron electronics

Extron electronics TLP 1000MV user guide