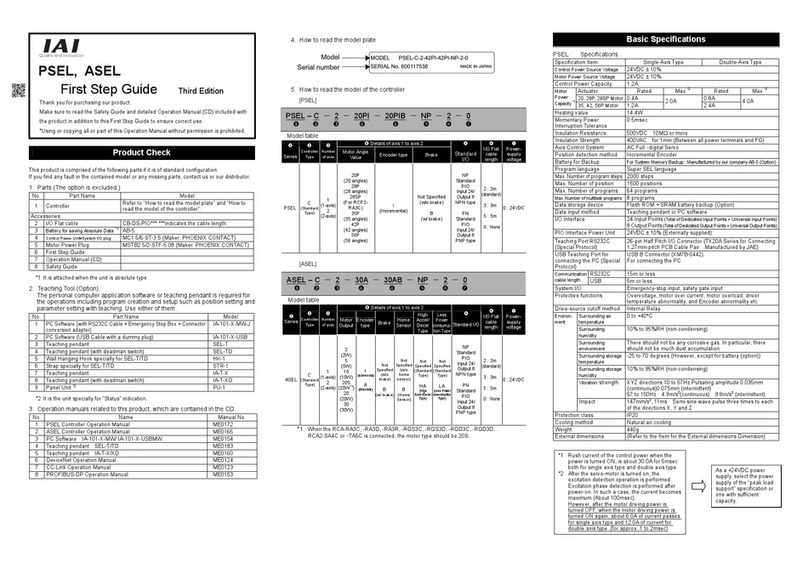

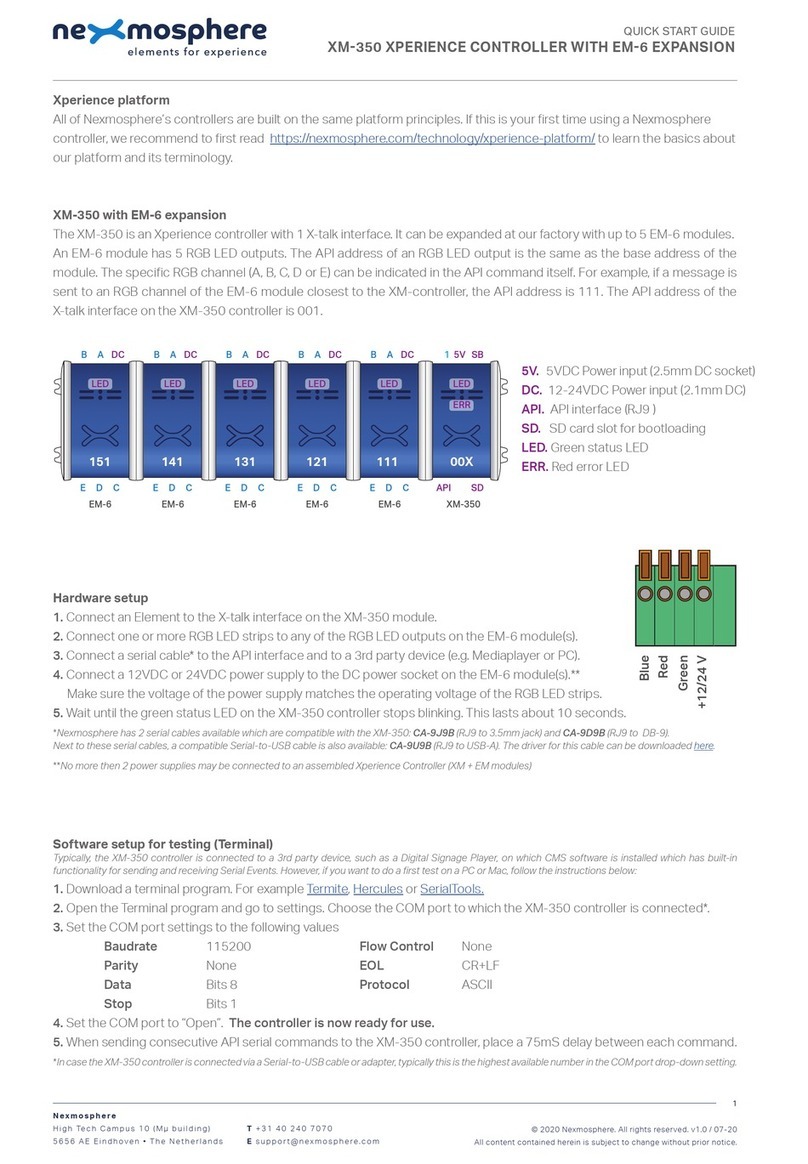

Wiring Diagram

"L" (Live wire) connects to terminal #3 for OPEN.

"L" connects to terminal #4 for CLOSE.

Connect "L" to terminal #7 to activate the internal heater. (No

need to connect internal heating for indoor applications with

constant temperature conditions.)

1)

simultaneously

2) Relays are needed in parallel connection of

several actuators!

3) 30% duty cycle

If it is necessary to change the following settings,

only authorized and trained personnel are allowed

to do so.

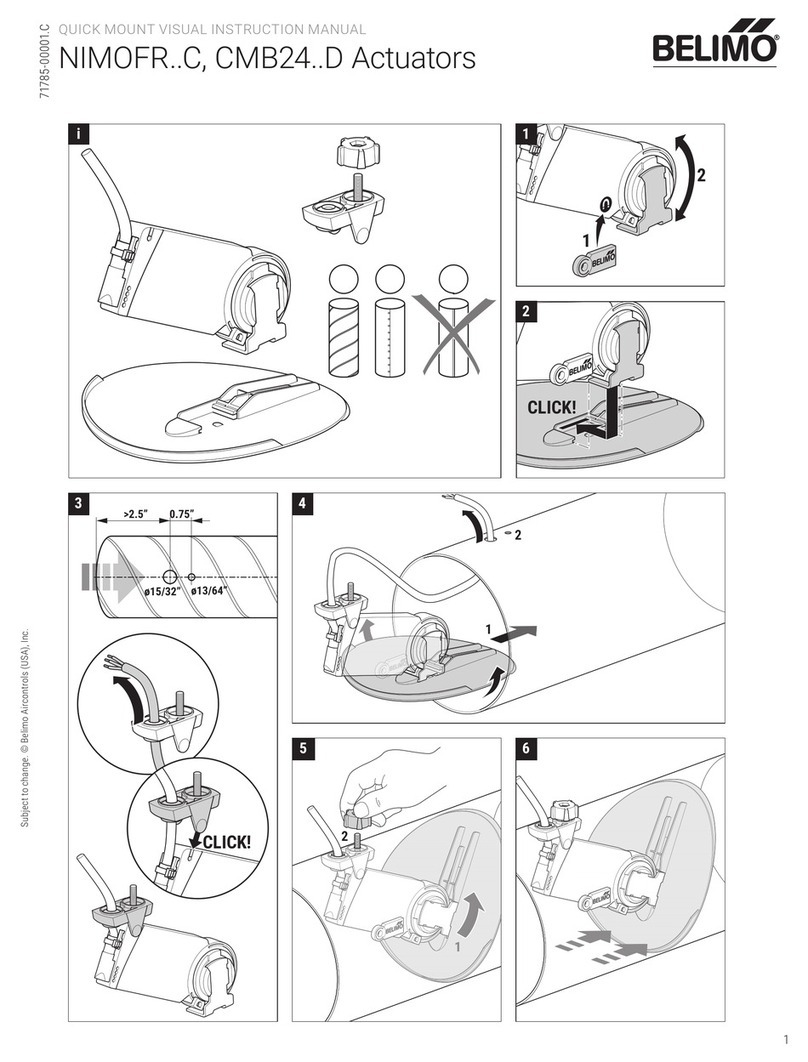

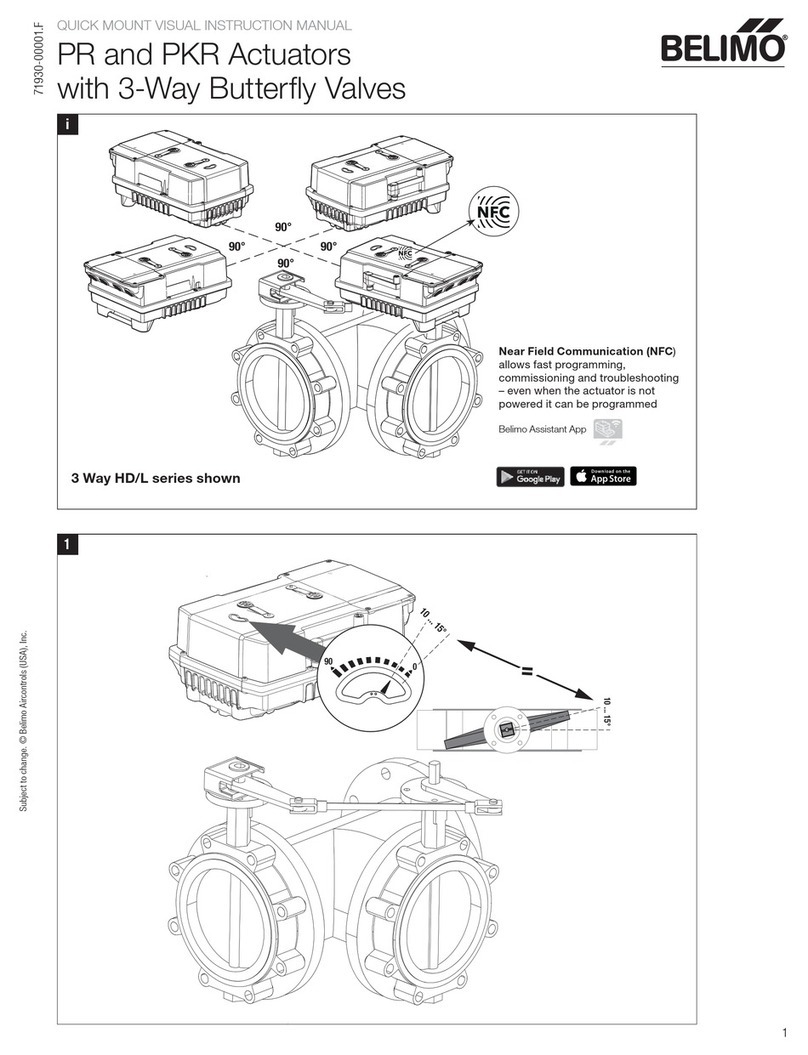

Install to butterfly valve

1)

Manual operate the actuator to the

similar open position of the valve,

which can be judged by the valve

disc.

2) Fit coupling on the top stem of the

valve.

3) Mount the actuator onto the

coupling, manual operate the

actuator to align the holes of valve

top flange and actuator bottom;

then tighten the bolts by wrench in

diagonal sequence.

4) Remove the actuator cover, wire

according to the wiring diagram.

5) Power on to test run the actuator,

check its travel angle and feedback

position, make adjustment if

necessary.

6) Put the cover on and tighten the

bolts

Limit switches LS.. with travel cams TC..

TC1 and TC2 switches are carefully calibrated at factory and

adjustment is normally not needed. Adjustment on these limit

switches must be carried out by trained personnel and wrong

adjustment could damage the system.

The TC.. cams rotate with the shaft, and trigger the LS.. limit

switches. Clockwise movement of the shaft closes the actuator,

counterclockwise movement opens the actuator.

There are 4 cams included, marked with two colors: blue for open,

silver for close; each cam can be set independently.

1. How to adjust the travel

cam

1.1. Loosen the cam to be

adjusted with a

2.5mm allen key;

1.2. By turning the key,

rotate and adjust the

cam as shown in the

diagram on the right;

Check if the valve can open and close properly

1.4. Tighten the cam after successful adjustment

2. Closed position (0%) setting

2.1. Connect power to terminal #1 and #4.

2.2. Power on. The actuator will drive CW to fully closed

position.

2.3. Adjust travel cam TC2 in the closed position.

2.4. Check whether LS2 switch trips prior to manual

operation stop. (When motor stops at fully closed

position, it should be possible to further operate the

handwheel CW ½…¾ turn. Otherwise the stop screw for

manual closed limit need to be adjusted.)

3. Adjust similarly for TC1 in open position by connecting power

to terminal #1 and #3.

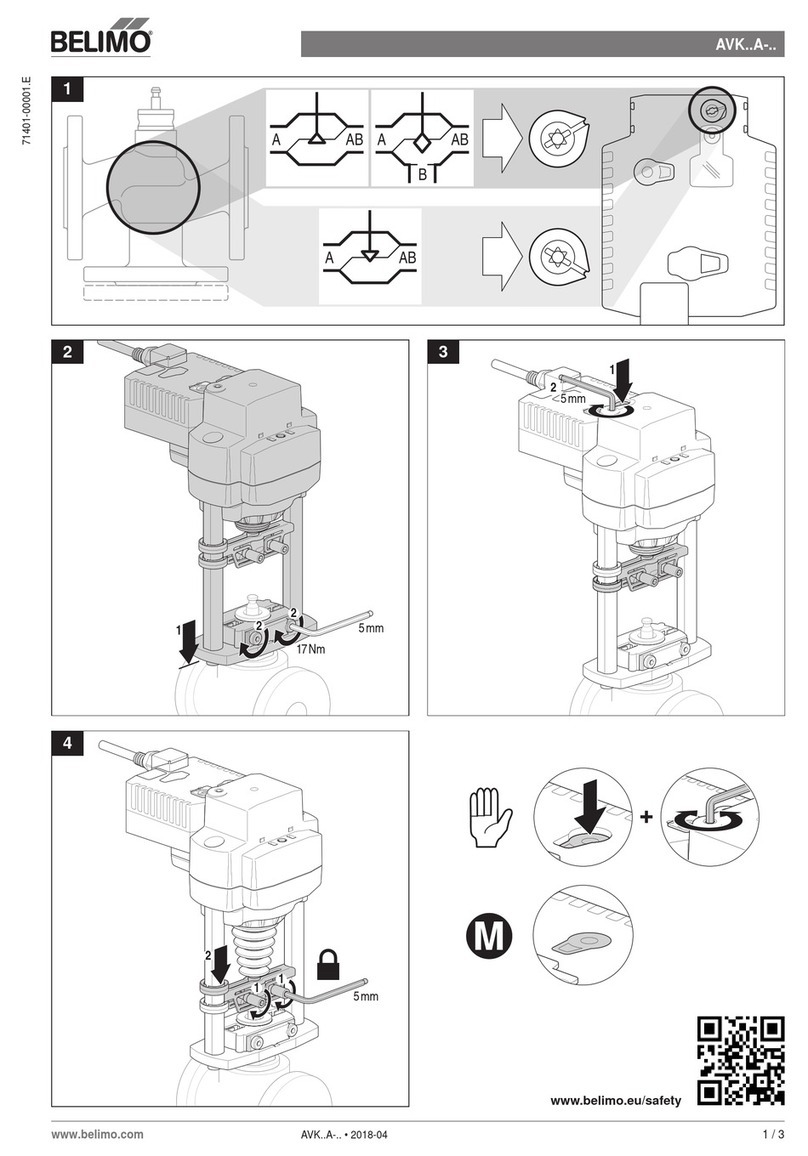

Limiting of manual rotation with top screws

Note: Top screws for manual OPEN and CLOSE limit are carefully

calibrated at factory and adjustment is normally not needed.

Adjustment on these screws must be carried out by trained

personnel and wrong adjustment could damage the system.

SY quarter-turn actuator is provided with a limiting of manual

rotation device to avoid over-travel with the handwheel going

beyond the ¼-turn rotation.

The actuator is supplied and tested for 90⁰ electrical operation, and

-2⁰…92⁰ limiting of manual rotation.

The limiting of manual rotation is realized by the stop screws 1 and

2 (max. ±2⁰ which corresponding to 1 turn of the stop screw).

The top screws must be secured

with the lock nut after any

adjustment. (by both an allen key

and a wrench)

The 90⁰ travel must always be

limited by the travel limit

switches so they must be set to

trip just BEFORE contacting the

Stop screws.

To achieve this, loose stop screws by 2½ turns. After travel limit

switch setting is completed, operate the actuator electrically to

closed position. (See paragraph Limit switches LS.. with travel

cams TC..) Now rotate the stop screw 2 to closed position, re-

loosen 1 turn, and secure by lock nut. Proceed in the same way for

stop screw 1 in open position. The limiting of manual rotation

device is only a design feature to prevent over-travel when the

actuator is being operated manually, it is not a safety function to

prevent over-travel in the event of travel limit switch failure.

Overload protection

This actuator is equipped with a torque switch that breaks the

power when an overload condition appears. An alarm switch will

be triggered when the torque limit switch activates.

TS3: When the torque value is overloaded, terminal #8 will loop to

terminal #9 when actuator turns counterclockwise.

TS4: When the torque value is overloaded, terminal #11 will loop to

terminal #12 when actuator turns clockwise.

Auxiliary switch for closed (factory setting 3⁰)

Auxiliary switch for open (factory setting 87⁰)

Closed switch (factory setting 0⁰)

Open switch (factory setting 90⁰)

!

2105-00001.B

!

SY..-3-T-TS actuators for 3-point control or open/close control

1- Stop screw for manual OPEN limit

2- Stop screw for manual CLOSED limit

3- Handwheel connection