EVCOS.p.A.|EV3143|Instructionsheetver.1.1|Code1043143E113|Page1of3|PT28/22

EV3143 Controller with two independent regulators for refrigerated milk storage

units and ice cream batch freezers

EN ENGLISH

- 230 VAC or 115 VAC power supply (according to the model)

- 2 analogue inputs (PTC/NTC)

- door switch/multi-purpose input

- main relay 16 A res. @ 250 VAC

- alarm buzzer

- TTL MODBUS slave port for EVconnect app, EPoCA remote monitoring system or for BMS

- hot or cold mode regulation.

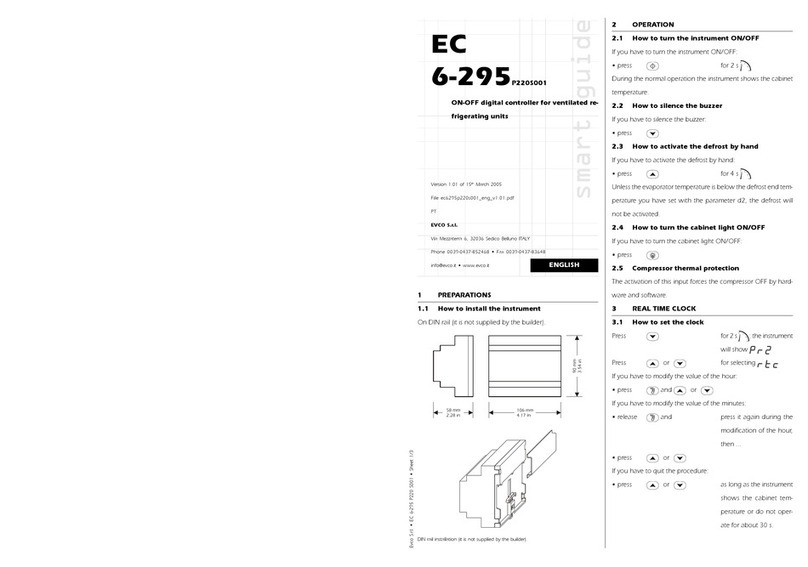

1 MEASUREMENTS AND INSTALLATION

Measurements in mm (inches). To be fitted to a panel, snap-in brackets provided.

INSTALLATION PRECAUTIONS

- the thickness of the panel must be between 0.8 and 2.0 mm (1/32 and 1/16 in)

- ensure that the working conditions are within the limits stated in the TECHNICAL SPEC-

IFICATIONS section

- do not install the device close to heat sources, equipment with a strong magnetic field,

in places subject to direct sunlight, rain, damp, excessive dust, mechanical vibrations or

shocks

- in compliance with safety regulations, the device must be installed properly to ensure

adequate protection from contact with electrical parts. All protective parts must be fixed

in such a way as to need the aid of a tool to remove them.

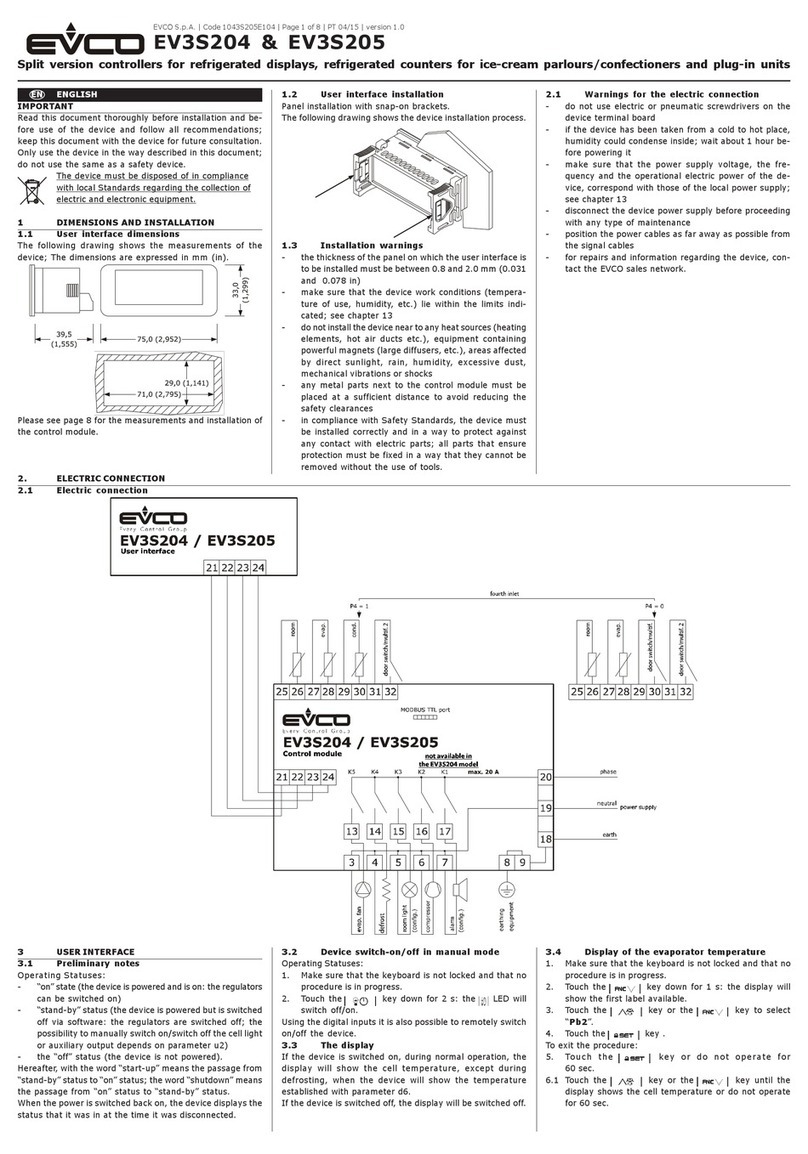

2 ELECTRICAL CONNECTION

N.B.

- use cables of an adequate section for the current running through them

- to reduce any electromagnetic interference, locate the power cables as far away as

possible from the signal cables.

The controller is operated mainly by P10 (default "controller with two independent regulators").

P10 OPERATION PROBE 1 PROBE 2 LOAD 1 LOAD 2 LOAD 3

0

controller with two inde-

pendent regulators regulator

1 regulator

2 regulator

1 regulator

2 alarm

1

controller for refrigerated

milk storage units tank

auxiliary

compres-

sor auxiliary

beater

2

controller for ice cream

batch freezers tank

plate

compres-

sor plate

heaters beater

PRECAUTIONS FOR ELECTRICAL CONNECTION

- if using an electrical or pneumatic screwdriver, adjust the tightening torque

- if the device is moved from a cold to a warm place, humidity may cause condensation

to form inside. Wait for about an hour before switching on the power

- make sure that the supply voltage, electrical frequency and power are within the set

limits. See the section TECHNICAL SPECIFICATIONS

- disconnect the power supply before carrying out any type of maintenance

- do not use the device as a safety device

- for repairs and for further information, contact the EVCO sales network.

3 FIRST-TIME USE

1. Carry out the installation following the instructions given in the section MEASUREMENTS

AND INSTALLATION.

2. Power up the device as set out in the section ELECTRICAL CONNECTION: an internal test

will start up.

The test normally takes a few seconds; when it is finished the display will switch off.

3. Configure the device as shown in the section Setting configuration parameters.

Recommended configuration parameters for first-time use:

PAR. DEF. PARAMETER MIN... MAX.

SP1 0.0 load 1 setpoint r1... r2

SP2 0.0 load 2 setpoint r12... r13

SP3 0.0 beater setpoint r16... r17

P0 1 type of probe 0 = PTC 1 = NTC

P2 0 temperature measurement unit 0 = °C 1 = °F

P10

0

operating logic

0 = controller with two independent

regulators

1 = controller for refrigerated milk

storage units

2 = controller for ice cream batch

freezers

Then check that the remaining settings are appropriate; see the section CONFIGURATION

PARAMETERS.

4. Disconnect the device from the mains.

5. Make the electrical connection as shown in the section ELECTRICAL CONNECTION, with-

out powering up the device.

6. For the connection in an RS-485 network connect the interface EVIF22TSX or

EVIF23TSX, to use the device with the EPoCA remote monitoring system, connect the

EVIF25TWX module, to use the device with the APP EVconnect connect the interface

EVIF25TBX; see the relevant instruction sheets. If EVIF22TSX or EVIF23TSX is used,

set parameter bLE to 0.

7. Power up the device again.

4 USER INTERFACE AND MAIN FUNCTIONS

4.1 Switching the device on/off

1. If POF = 1 (default), touch the ON/STAND-BY key for 4 s.

If the device is switched on, the display will show the P5 value ("probe 1 temperature" default);

if the display shows an alarm code, see the section ALARMS.

LED ON OFF FLASHING

compressor on

compressor off

- compressor protection in pro-

gress

- setpoint being set

plate heaters on

plate heaters off

setpoint being set

OUT1

regulator 1 on

regulator 1 off

- load 1 protection in progress

- setpoint being set

defrost active

-

-

beater on

beater off

setpoint being set

alarm active and si-

lenced -

alarm active and not silenced

°C/°F

temperature displayed

-

-

OUT2

regulator 2 on

regulator 2 off

- load 2 protection in progress

- setpoint being set

device off

device on

device being switched on/off

When 30 s have elapsed without the keys being pressed, the display will show the “Loc” label

and the keypad will automatically lock.

4.2 Unlocking the keypad

Touch a key for 1 s: the display will show the label “UnL”.

4.3 Quick setting:

- of setpoints (if P9 = 1 or 3)

- beater switch on/off times (if P9 = 2 or 3)

Check that the keypad is not locked.

1. Touch the SET key: the display will show the label “SP1”.

2. Touch the UP or DOWN key within 15 s to set the load 1 setpoint

value within the limits r1 and r2 (default “-50... 50”).

3. Touch the SET key: the display will show the label “SP2”.

4. Touch the UP or DOWN key within 15 s to set the load 2 setpoint

value within the limits r12 and r13 (default “-50... 50”).

5. Touch the SET key: the display will show the label “SP3”.

6. Touch the UP or DOWN key within 15 s to set the beater setpoint

value within the limits r16 and r17 (default “-50... 50”).

7. Touch the SET key: the display will show the label “t0”.

8. Touch the UP or DOWN key within 15 s to set the time the beater

is switched off within the limits 0... 240 min.

9. Touch the SET key: the display will show the label “t1”.

10. Touch the UP or DOWN key within 15 s to set the time the beater

is switched on within the limits 0... 240 min.

11. Touch the SET key (or take no action for 15 s).

Settings are temporary: when the device is switched back on (and after a power failure), it resets

the values SP1, SP2, SP3, t0 and t1.

4.4 Starting up/interrupting batch freezing (if P10 = 2)

Check that the keypad is not locked.

1. Touch the ON/STAND-BY key.

4.5 Manually switching on the beater (if P10 = 1)

Check that the keypad is not locked.

1. Touch the DOWN key for 4 s.

The beater is switched on for time t1.

4.6 Activating manual defrost (if r5 and/or r19 = 0, default)

Check that the keypad is not locked.

1. Touch the UP key for 4 s.

4.7 Silencing the buzzer (if Pbu = 2 or 3)

Touch a key.

If u4 = 1, the alarm output is also deactivated.

5 OPERATION

5.1 Controller with two independent regulators (P10 = 0, default)

Cold mode regulation regulator 1 (r5 = 0).

Hot mode regulation regulator 1 (r5 = 1).

Cold mode regulation regulator 2 (r10 = 0).

Hot mode regulation regulator 2 (r10 = 1).

5.2 Controller for refrigerated milk storage units (P10 = 1)

Compressor operation.

Beater operation set to t0 and t1 (r14 = 0).

Beater operation set to r19, t0 and t1 if beater setpoint is not reached (r14 = 1).

Cold mode regulation beater (r19 = 0)

Beater operation set to r19, t0 and t1 if beater setpoint is not reached (r14 = 1).

Hot mode regulation (r19 = 1).

5.3 Controller for ice cream batch freezers (P10 = 2)

The batch freezing cycle consists of 4 phases:

- heating

- cooking

- cooling

- conservation.

5.3.1 Heating

The compressor remains off.

Plate heaters operation.

Beater operation.

End of phase.

At the end of the phase the buzzer emits 10 beeps 1 s long.

If there is a power failure during the phase, it starts back up again from the beginning.

5.3.2 Cooking

The compressor remains off.

Plate heaters operation.