1SS 2, SECTION 502-323-402

TABLE A

TRANSACTION Ill

FACEPLATE ORDERING GUIDE

FACEPLATE CODE ICOLOR GUIDE I

139 A-’

LETTERING

Standard

Instruction

139 B-*

LETTERING ISUFFIX ICOLOR I

-1oo Avocado

I-108 ITeak I

I-109 \Walnut I

-111 Gold

Blank -112 Orange

!-113 IBrown I

-114 Red

I-115 Blue

I-118 IBlack ]

*Add appropriate color suffix.

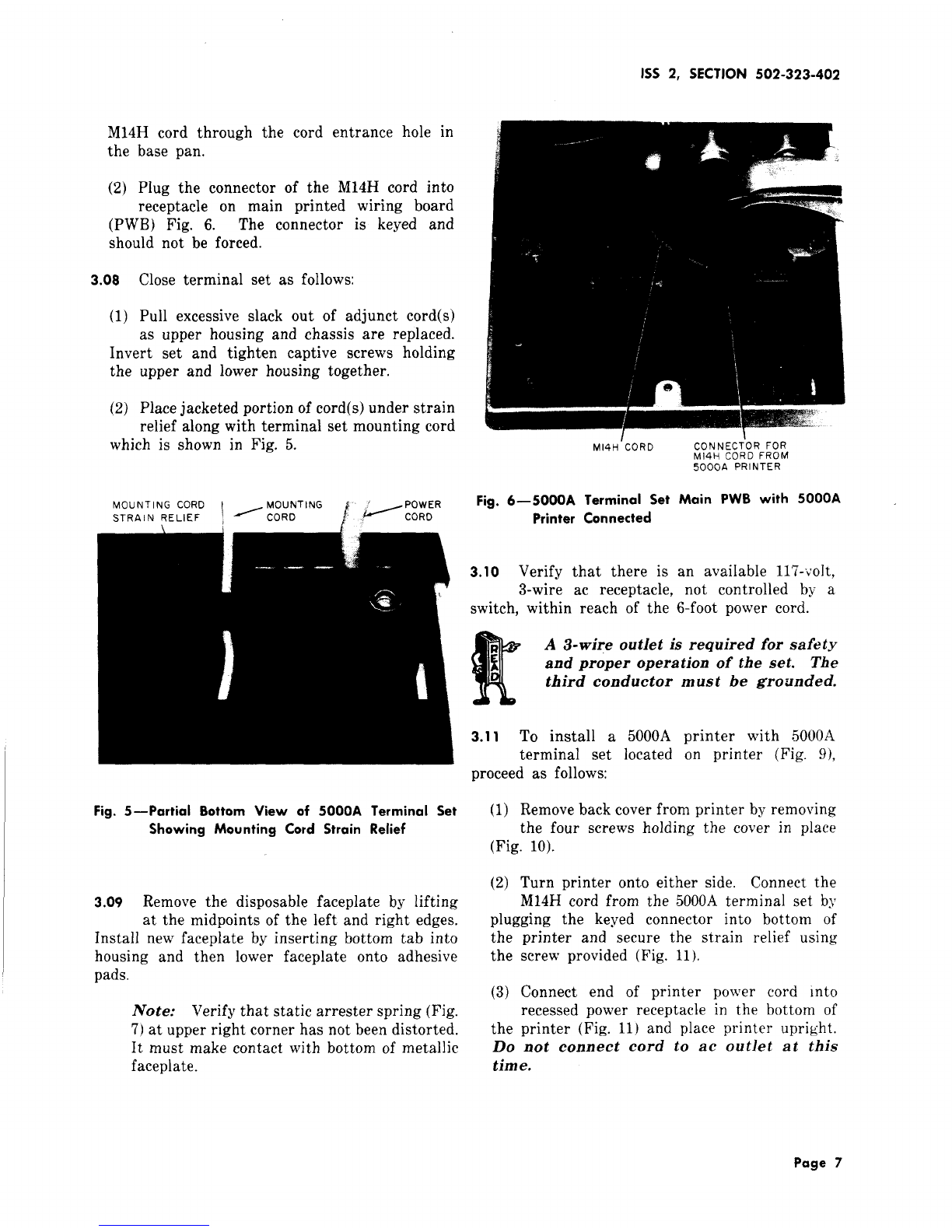

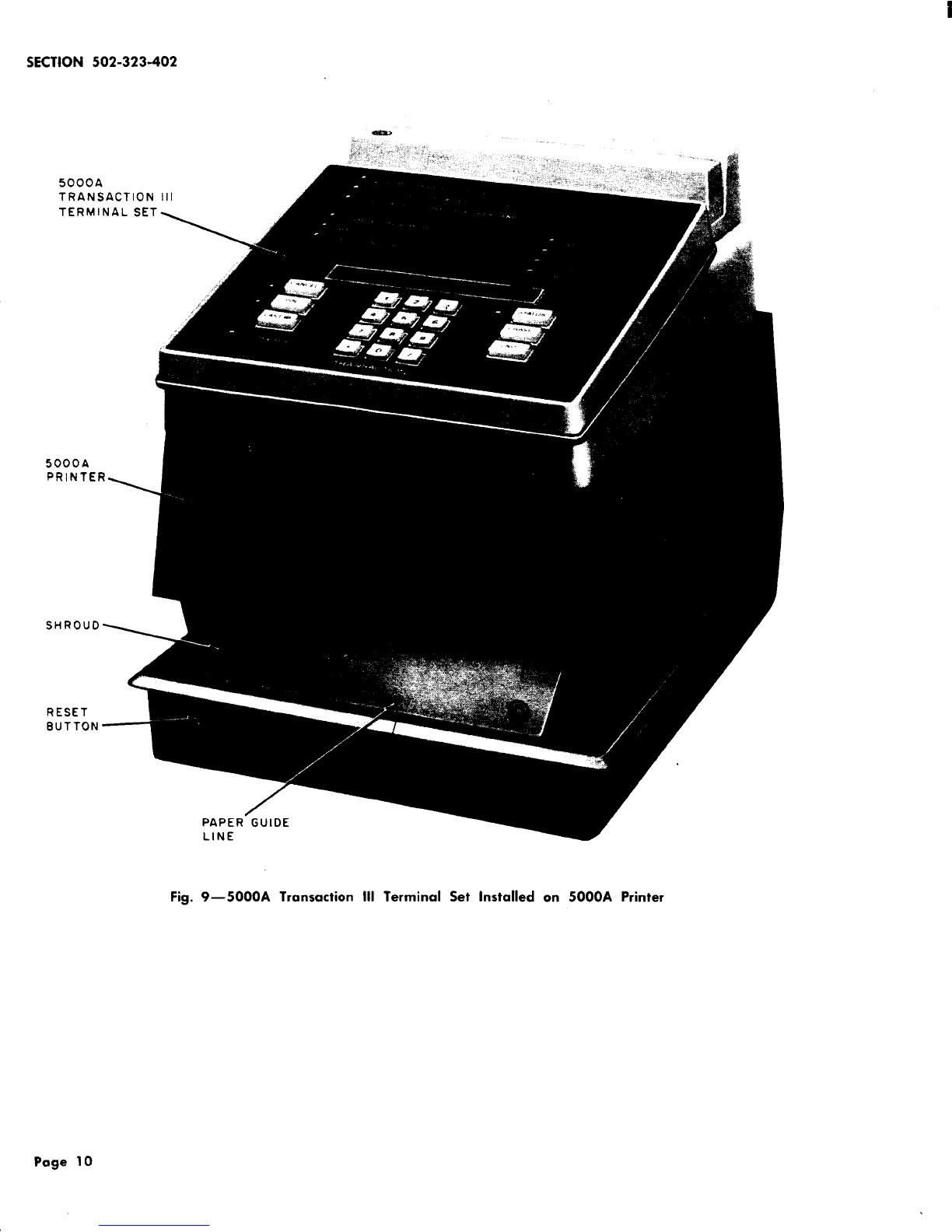

(d) If a5000A printer is to be provided, it

must be ordered separately and will be

shipped with the following items:

●Cord, M14H, to interconnect with 5000A

terminal set, (3-foot provided, 10-foot available)

●Housing Spacer, to be used when 5000A

terminal set is placed on top of printer (Fig.

10)

●Test Cards Dand E. (Test Card Dis

provided for use with the 51OOBMTransaction

set and will not be used with this terminal.)

●Cord, Power, KS-14532L30, 6-foot long

Note: Power cords with right angle plugs

are available in other lengths as follows:

824013262 (P-40J326) 1-1/2 foot

824013270 (P-40J327) 2foot

824013288 (P-40J328) 4foot

824013296 (P-40J329) 6foot

824010995 (P-40J099) 12 foot

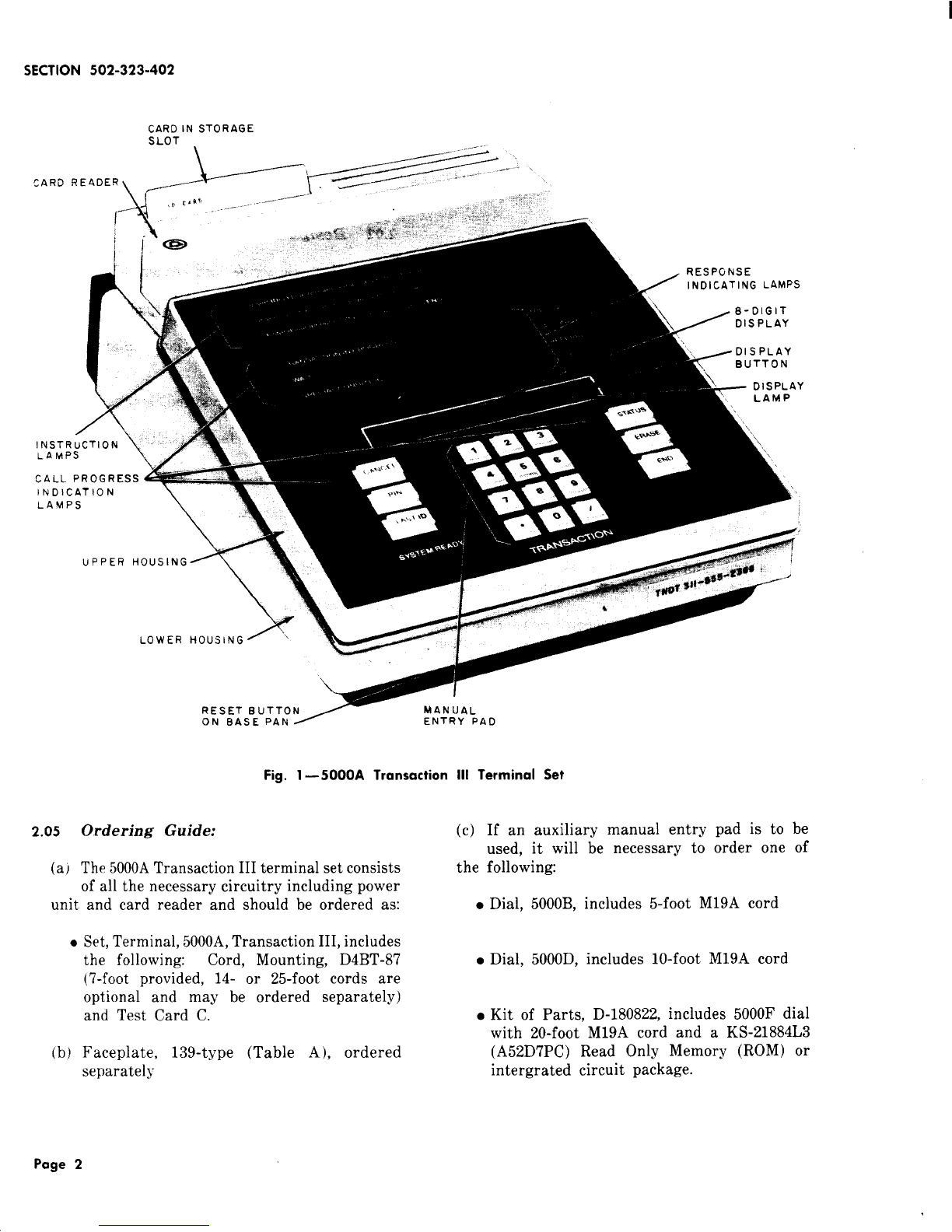

3. INSTALLATION

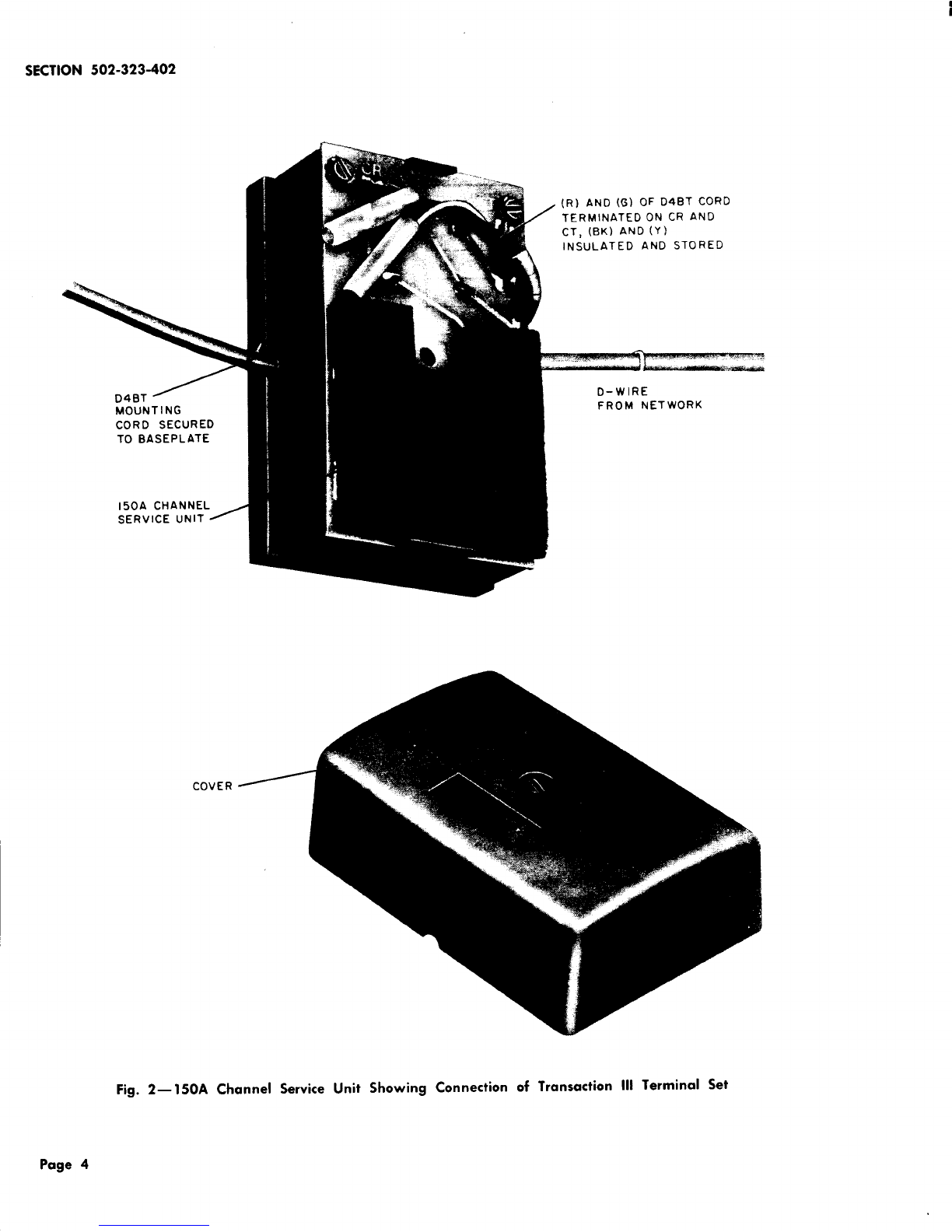

3.o1 Verify that aTransaction Network polled

access line has been installed and terminated

in a150A Channel Service Unit (CSU) Fig. 2.

IVote; The mounting cord of the 5000A

terminal set must connect directly with a

150A CSU which has been tested and the

attenuator switches set for the correct signal

level. For installation and testing of the CSU,

refer to Section 590-101-000.

3.02 Secure the J-hook (Fig. 2) of the D4BT

mounting cord into the baseplate of the

CSU and terminate as follows:

(1)

(2)

Feed end of mounting cord under printed

wiring board (PWB) to opposite side of CSU.

Terminate tip (G) and ring (R) cord conductors

to CT and CR screw terminals, respectively,

of Csu.

(3) Insulate and store the (Y) and (BK) mounting

cord leads so they will not interfere with

wiring components of the CSU.

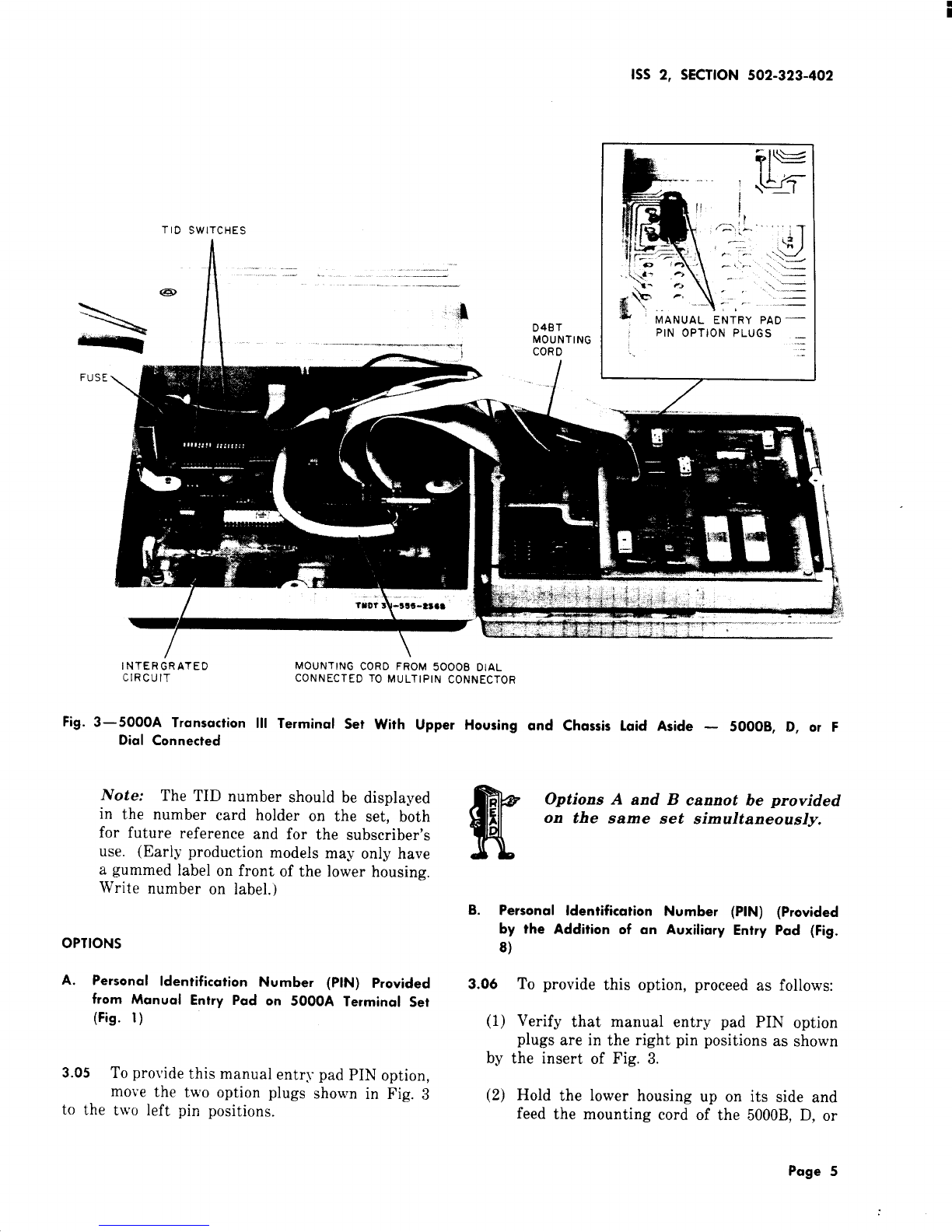

3.03

(1)

(2)

To open the 5000A terminal set, proceed as

follows:

Invert set and loosen the two captive screws

holding the upper housing and chassis.

Lay the upper housing and chassis to the

right, as shown by Fig. 3without disconnecting

any cables.

3.o4 The Terminal Identification (TID) for the

terminal being installed (number is on the

service order) should now be set on the terminal

identification switches (Fig. 3). The 4digits of

the TID are set by closing the appropriate

rocker-switches in each digit group which have

values of 1, 2, 4, and 8counting from left to right.

If front side of rocker switch is depressed, the

switch will close and the horizontal mark across

the bar is not visible. If rear side of rocker switch

is depressed, the switch will open and the horizontal

mark across the bar is visible. Only closed switches

produce a1, 2, 4, or 8(counting left to right) or

acombination thereof. See Fig. 4for example of

switches coded for TID No. 5874.

Page 3