Benassi MC 3300 User manual

REVERSIBLE TWO-WHEEL TRACTOR

MC 3300 MC 4300 SERIES

Operation and Maintenance Manual

OPERATION AND MAINTENANCE MANUAL

Page 2 of 22

Contents

General details _________________________________________________________________________________ 3

Introduction ____________________________________________________________________________________ 3

Information about the guarantee____________________________________________________________________ 3

Training_______________________________________________________________________________________ 4

Key of symbols _________________________________________________________________________________ 4

Read immediately: ______________________________________________________________________________ 5

Operation _____________________________________________________________________________________ 5

Unsafe practice_________________________________________________________________________________ 5

Machine description _____________________________________________________________________________ 6

Specifications and performance ____________________________________________________________________ 6

Implements ____________________________________________________________________________________ 7

Remark on attaching implements_________________________________________________________________ 7

Description of controls____________________________________________________________________________ 8

Version of the machine with cutters _________________________________________________________________ 9

Adjusting the tilling depth _______________________________________________________________________ 9

Reverse of the machine_____________________________________________________________________ 10

Positions and controls of levers_______________________________________________________________ 11

Working procedure _____________________________________________________________________________ 11

Adjustements_____________________________________________________________________________ 12

Starting the machine _______________________________________________________________________ 14

Operating the machine __________________________________________________________________________ 15

General warnings while working ___________________________________________________________________ 15

Filling and emptying the fuel tank __________________________________________________________________ 15

Switching the machine off ________________________________________________________________________ 16

Storage of the machine__________________________________________________________________________ 16

Residual Risk _________________________________________________________________________________ 17

Maintenance __________________________________________________________________________________ 18

General guidelines ___________________________________________________________________________ 18

Engine ____________________________________________________________________________________ 18

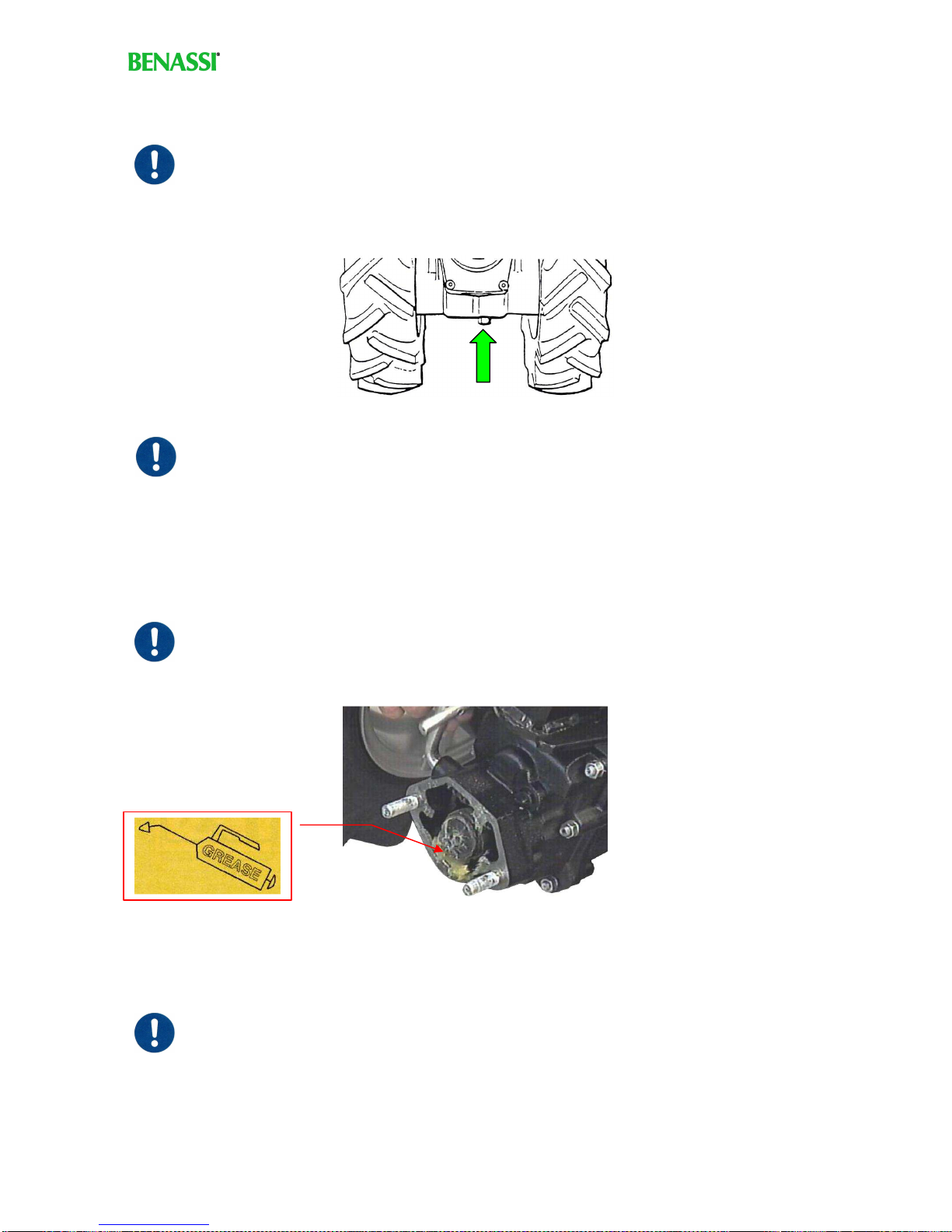

Gear: checking the oil level ____________________________________________________________________ 18

Gear: changing the oil ________________________________________________________________________ 19

Greasing power takeoff _______________________________________________________________________ 19

Periodical operations _________________________________________________________________________ 19

Cleaning _____________________________________________________________________________________ 20

General guidelines ___________________________________________________________________________ 20

Disassembly __________________________________________________________________________________ 21

CE Mark _____________________________________________________________________________________ 21

Air noise and vibrations produced by the machine _____________________________________________________ 22

Index of pictures

Picture 1 – General view__________________________________________________________________________ 6

Picture 2 – Attaching implements ___________________________________________________________________ 7

Picture 3 - Description of controls ___________________________________________________________________ 8

Picture 4 – Machine: version with cutters _____________________________________________________________ 9

Figura 5 – Adjusting the tilling depth_________________________________________________________________ 9

Picture 6 - Reverse of the machine_________________________________________________________________ 10

Picture 7 – Positions and controls of levers___________________________________________________________ 11

Picture 8 - Adjustment of the height of the handle______________________________________________________ 12

Picture 9 - Handle side adjustment _________________________________________________________________ 12

Picture 10 – Locking the differential ________________________________________________________________ 12

Picture 11 – Adjusting wheels with flange____________________________________________________________ 13

Picture 12 - Taking off the wheels spacers ___________________________________________________________ 13

Picture 13 – Switching the engine off _______________________________________________________________ 16

Picture 14 – Gear oil level________________________________________________________________________ 18

Picture 15 – Changing gear oil ____________________________________________________________________ 19

Picture 16 - Greasing takeoff______________________________________________________________________ 19

Picture 17 - Plate with CE Mark ________________________________________Errore. Il segnalibro non è definito.

Index of tables

Table 1 – Information and Training __________________________________________________________________ 4

Table 2 – Specifications and performance ____________________________________________________________ 6

Table 3 - Noiseness and vibrations_________________________________________________________________ 22

OPERATION AND MAINTENANCE MANUAL

Page 3 of 22

General details

Producing firm: BENASSI SpA

Via Lampedusa, 1

Tel. 0039 051 820534 Fax 0039 051 6826164

e-mail: export@benassispa.it

www.benassispa.it

This manual has been written by the Industrial Engineer Mr CIAVAGLIA Sergio

Global Service Italia Srl - 63029 Servigliano (ITALIA)

Introduction

Dear Customer,

this manual has been written thanks to the considerable experience we have acquired so far. Its purpose is

to help you in operating the machine properly during all the phases of its life.

The manual should be kept with the machine, in a safe place, accessible to all those who need to consult it.

Those who have not read, understood and learned the instructions of this manual must not operate

the machine.

Should the manual be lost or spoiled, please ask your retailer for a copy, giving him all the relevant

information about the machine

The manual and the declaration of conformity should always be kept with the machine, both when it

is sold and when it is hired, and until the hire ceases.

Information about the guarantee

We remind you that, before using this REVERSIBLE TWO-WHEEL TRACTOR, all those who will drive

it must be informed about the conditions of use and cautioned against unsafe practice. This manual

contains all such information, and through it you can obtain the best performance of the machine.

We have actually found that many of the troubles that have been reported should be mainly ascribed to the

operator’s inattention or to wrong maintenance and/or adjustments.

As a consequence, we cannot accept claims for compensation for damage caused by wrong

handlings or for loss of liabilities due to the impossibility to work when the machine is broken.

All the electrical and mechanical parts that undergo normal wear and tear are not covered by

guarantee.

DURATION OF THE GUARANTEE

The guarantee has a maximum duration of 24 months.

For mechanical parts, the guarantee only covers spare parts; it does not cover the labour nor the travelling

expenses connected to assembly.

If any faulty parts have to be repaired, they should be sent to us carriage paid. We will repair and ship them

carriage forward.

When ordering spare parts, always give the following details:

Model Number

Year of production

Model Number

The instructions, the pictures and the information contained in this manual are a technical and

reserved property of the producing firm and cannot be reproduced with any means, neither in whole nor in

part.

OPERATION AND MAINTENANCE MANUAL

Page 4 of 22

Training

If this REVERSIBLE TWO-WHEEL TRACTOR is used in a firm, we remind you that, before using it, all

those who will drive it must be informed about the conditions of use and cautioned against unsafe

practice. This manual contains all such information, and through it you can obtain the best

performance of the machine.

For a non-professional use, the retailer must train the user.

Any Information and Training should be written down in this table.

Topic Trainer Worker Date

Table 1 – Information and Training

Key of symbols

To allow you better understand this manual, we will explain here some terms and symbols:

THE COLOURS OF THE REMARKS HAVE THE FOLLOWING MEANINGS:

BLUE ALWAYS

RED NEVER

ORANGE DANGER

Benassi Spa, as the firm producing the REVERSIBLE TWO-WHEEL TRACTOR,

disclaims any responsibility for any damage that can be ascribed to an improper

use, to inattention or to the breach of safety regulations. It also disclaims any

responsibility for any damage that may occur during the transport, unpacking and

handling of the machine.

OPERATOR

QUALIFIED

TECHNICIAN

Person w

ho has the task to set

up, operate, adjust,

deal with

normal maintenance of and

clean the machine.

Person trained and qualified to solve problems with adjustment and operatio

n of the

machine, and to manage extraordinary maintenance or to repair the machine when

a

particular knowledge of the machine, of its functioning, of safety regulations and of technical

procedures is required.

Remark to be read carefully

Please read the manual before

doing anything Presence of a

danger

Something you should never do Something you should always do

OPERATION AND MAINTENANCE MANUAL

Page 5 of 22

Read immediately:

READ THE OPERATION MANUALS (MACHINE AND ENGINE)

IF THE REVERSIBLE TWO-WHEEL TRACTOR IS USED IN A FIRM, WE REMIND YOU TO HAND

IN A COPY OF THE MANUALS TO THE MAINTENANCE MANAGER. THE MAINTENANCE MANAGER

MUST HAND IN AN ABSTRACT OF THE MANUALS TO THE WORKER IN CHARGE OF THE MACHINE,

SPECIFYING THE INFORMATION ABOUT HIS TASKS.

Operation

The REVERSIBLE TWO-WHEEL TRACTOR MC3300 – MC4300 SERIES, hereinafter called machine, is

designed to be used in agriculture, farming and flower-growing.

It is a self-propelled machine with a single axle. It can work in a variety of settings, according to the

attachments used, such as:

⇒Working the ground (using hoe-shaped cutters);

⇒Mowing the grass (using a sickle bar);

⇒Transporting small volumes (using a trailer);

⇒Other uses (using ploughs, lawn mowers, snow throwers, etc.).

The machine has an internal-combustion engine.

Manuals provided by the producer explain how to change attachments.

For the machine to run, a worker is needed to control it continuously.

Unsafe practice

FOR THE RETAILER: only qualified staff should deal with all the

operations needed to set up the machine. Such procedures must follow

the instructions contained in the SETTING UP MANUAL.

Should the user make modifications to the machine, he is required

to remove the CE mark.

Everything that this manual does not treat explicitly is to be considered

forbidden.

The machine must not be used if there is danger of fire and/or explosion.

It is forbidden to drive the machine on roads.

BEFORE:

⇒HANDLING THE MACHINE;

⇒USING THE MACHINE;

⇒ADJUSTING;

⇒CLEANING;

⇒OPERATIONS OF MAINTENANCE

WARNING

OPERATION AND MAINTENANCE MANUAL

Page 6 of 22

Machine description

The two-wheel tractor is build on a metal frame where the other parts are fixed: the engine, the gear, the axle

and the steering handle, as you can see from the picture:

Picture 1 – General view

Specifications and performance

Operation Daytime

Max mass (according to the model) 90-120 kg

Size

Max forward/backward speed

Max pressure pneumatic tyres (agricultural

tread)

Min steering diameter

See tecnhical tables

Engine specifications See engine manual

Table 2 – Specifications and performance

TILLING VERSION MOWING VERSION

Attachment:

cutters with

protective case

Bonnet

EngineSteering handle

Self-winding

starter rope

Wheels

Clutch and motor-stop controls

Differential

lock controls

Hand

throttle

control Gear levers control

OPERATION AND MAINTENANCE MANUAL

Page 7 of 22

Implements

The machine can be operated as well with the following implements:

SICKLE BAR, PLOUGH, MOWER, SNOW THROWER, TRAILER, SHREDDER, REVERSIBLE PLOUGH,

LEVELLING BLADE, ROTARY SWEEPER.

For other implements, please get in touch with the producing firm.

To attach and use the different implements, refer to the specific manual.

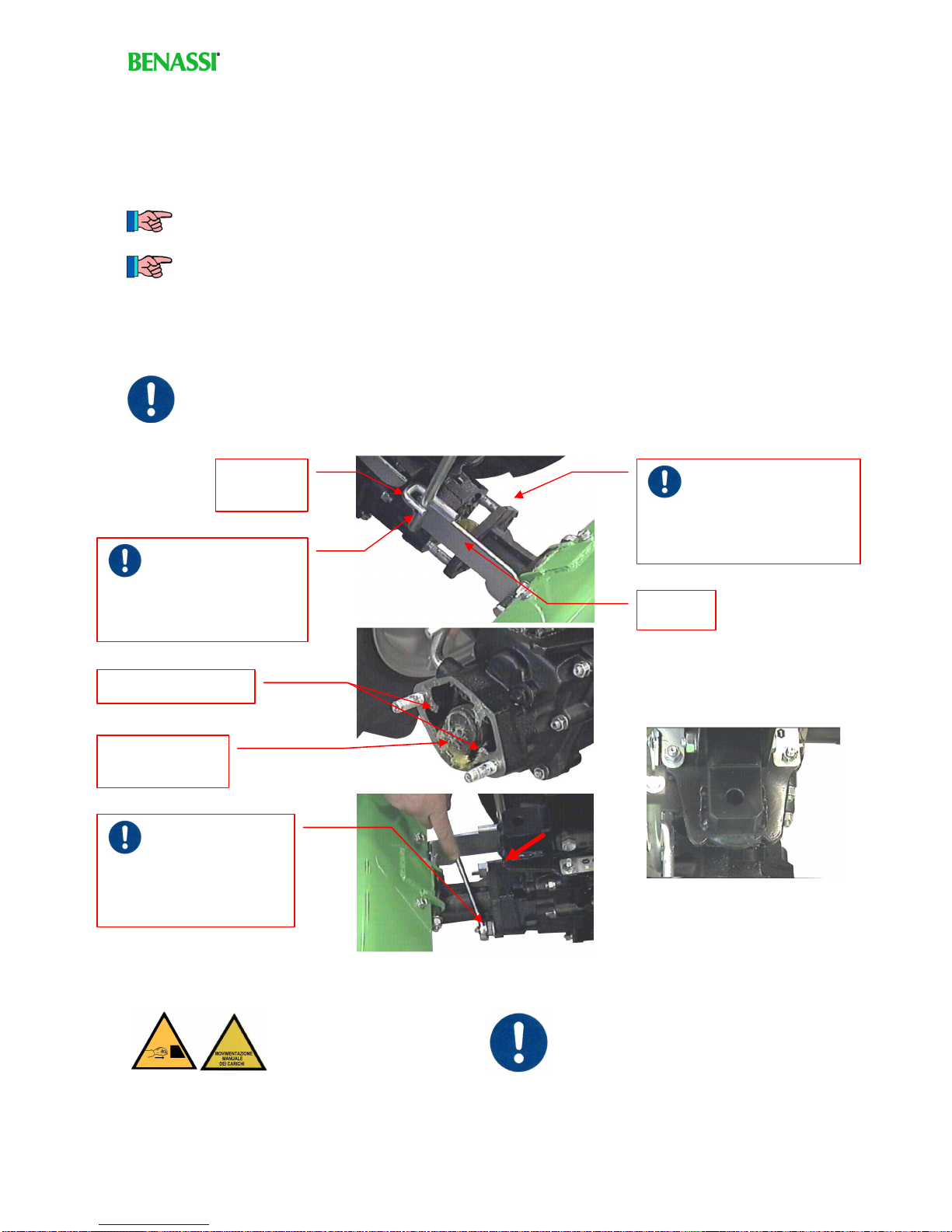

Remark on attaching implements

When attaching implements, you should follow the following instructions.

operation to be performed while the machine is switched off and well stable;

operation to be performed only by trained and informed staff;

only use implements compatible with the machine and following the instruction

provided by the producing firm;

Picture 2 – Attaching implements

put the safety plate of

the implement under the

rocker arm, on the internal

side of the lever Plate

Rocker

arm

Centring rings

Tighten the screws

with a proper spanner,

gradually and alternating

the screws.

Danger of bruis

ing

and

manual load handling

If the implement

is too heavy, you should

perform the operations in two or using

adequate means, and following the proper

instructions

N.B.: The trailer must be

attached in a particular place

(shown in the picture above),

different from the power

takeoff

attach the implement

properly, being careful that the

centring rings join together

Point for

attachment

OPERATION AND MAINTENANCE MANUAL

Page 8 of 22

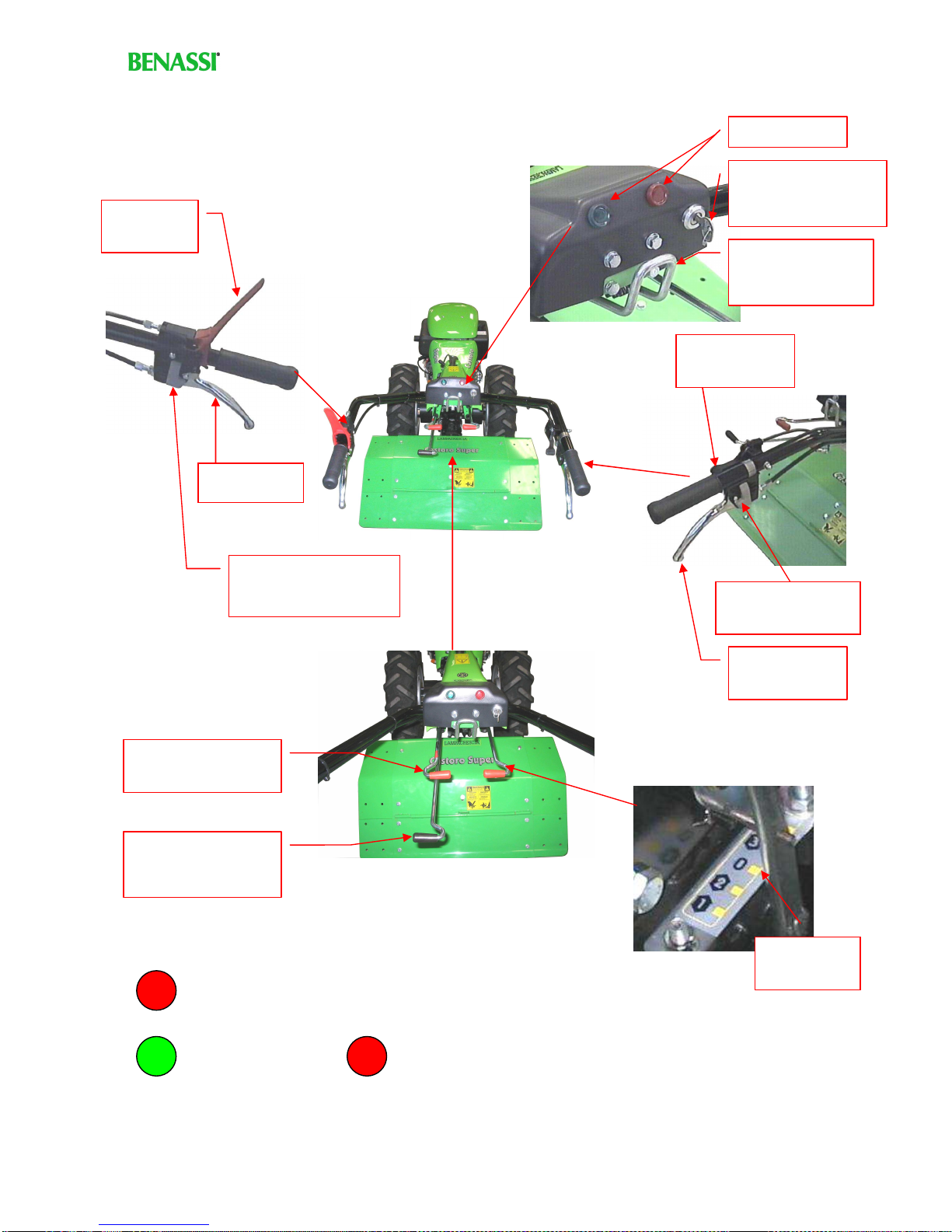

Description of controls

Functions of warning lights

Picture 3 - Description of controls

Lever to lock

differential

Motor-stop

lever

Button to lock clutch

lever and motor-stop

lever

Handle height

adjustment lever

Ignition key (for

those models who

have it)

Lever to

engage/disengage

power takeoff

Gear lever

Speed direction

lever (reverser)

Hand throttle

control

Button to lock

differential lever

Warning lights

Clutch lever

Neutral

position (0)

ALTERNATOR

OILALTERNATOR

OPERATION AND MAINTENANCE MANUAL

Page 9 of 22

LARGHEZZA (mm)

280

370

460

570

VOLPINO

360

480

630

760

CASTORO

CUTTER WIDTH (mm)

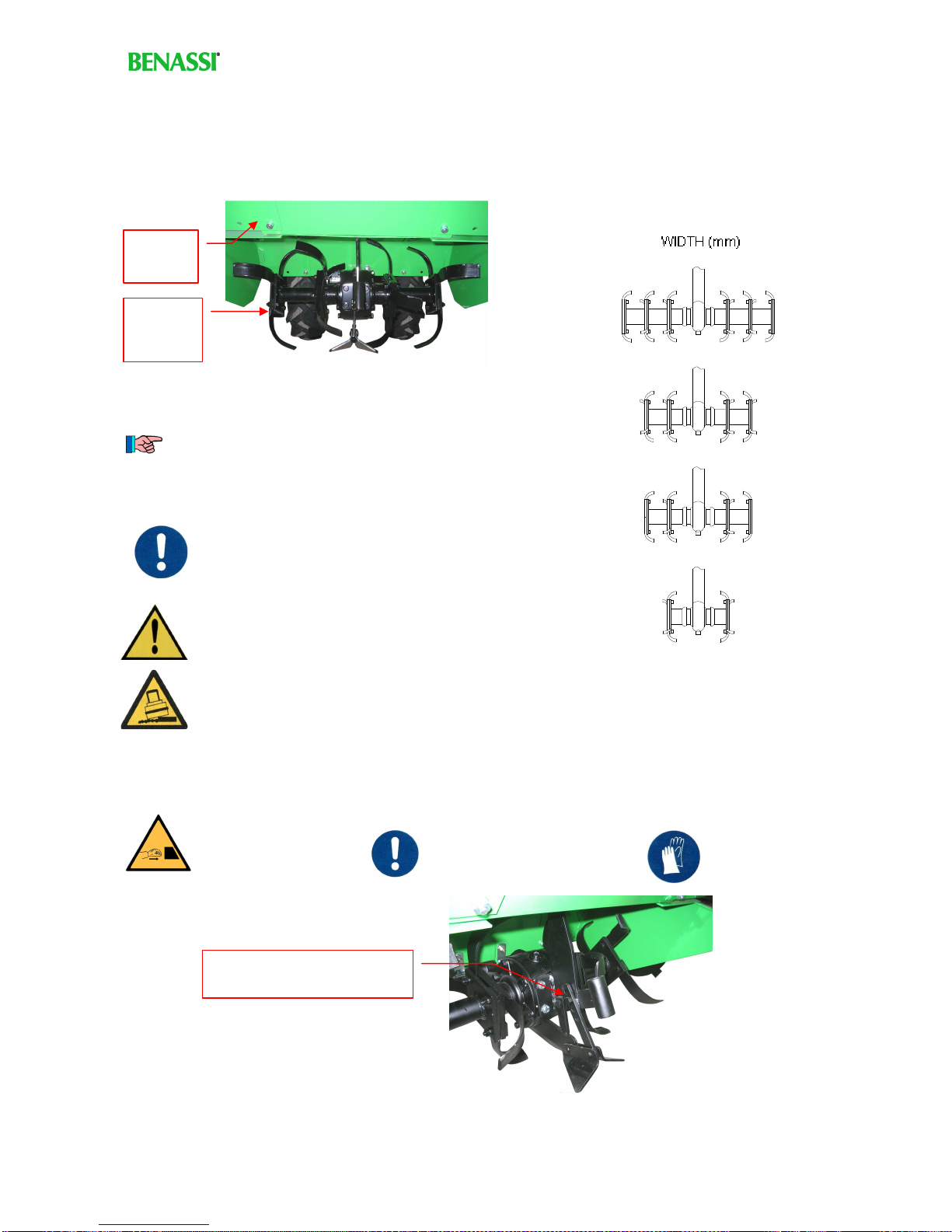

Version of the machine with cutters

In this version the machine has cutters to till the soil. The external parts of the cutters and of the protective

case can be disassembled, so you can vary the width of the machine.

The widths you can obtain are as follows.

Picture 4 – Machine: version with cutters

To assemble the implements, consult the manuals

provided by the producing firm.

Adjusting the tilling depth

The hoe-shaped cutters have a device to adjust the depth of tilling of the soil.

Figura 5 – Adjusting the tilling depth

Protecti

ve case

Hoe-

shaped

cutters

Tilling depth adjuster

OPERATIONS TO

PERFORM WHEN THE

MACHINE IS TURNED

OFF AND STABLE

DANGR OF

BRUISING AND

CRUSHING

WEAR PROPER

GLOVES

WHATEVER WIDTH YOU DESIRE, THE

CUTTERS

MUST BE SET SYMMETRICALLY

WITH THE AXE OF THE MACHINE.

DANGER OF OVERTURNING AND OF

INSTABILITY: IF THE CUTTERS ARE NOT

ASSEMBLED SY

MMETRICALLY, THE

MACHINE IS UNSTABLE, DANGEROUS

AND CAN OVERTURN.

OPERATION AND MAINTENANCE MANUAL

Page 10 of 22

Reverse of the machine

In order to attach different implements, the machine can be reversed by turning the handle 180 degrees, as it

is described in this page.

During these operation:

Before reversing the handle, you need to take away the levers that control the speed direction and the power

takeoff.

Picture 6 - Reverse of the machine

OPERATION TO PERFORM

WHEN THE MACHINE IS

TURNED OFF

DANGER OF

BRUISING AND

CRUSHING

4 – Raise completely the

lever that locks the side

adjustment of the steering

handle

1 – Take the split pins

from the levers

5 – Unlock the lever and with the

other hand rotate the steering

handle

FOR THE REVERSE, THE

HANDLE SHOULD ONLY BE

TURNED CLOCKWISE

TO GET IT TO ITS NORMAL

POSITION, ONLY

COUNTERCLOCKWISE

2 – Pull the levers out of their

places

3 – Take the levers out of the loops

6 – take the handle to the opposite

side, above the engine

7 – lock the handle by

lowering the lever

8 – put the levers back into the

loops, then in their place and

finally lock them with the split

pins

WARNING!!

In the reversed position the levers need to be inverted, so the controls as well

are

inverted.

You should refer to the paragraph “Positions and controls of levers”.

To perform maintenance of the engine in the reversed position, you need to turn the

handle to one side, otherwise the bonnet of the engine cannot be opened.

OPERATION AND MAINTENANCE MANUAL

Page 11 of 22

Positions and controls of levers

The position of motion lever and the effect obtained by using them depend on the configuration of the

machine (normal or reversed). The pictures below show the two different situations.

Picture 7 – Positions and controls of levers

Working procedure

When working on sloped surfaces, you should drive the tractor parallel with

the slope and not uphill nor downhill. Be very careful while changing direction.

Power takeoff lever

Power takeoff can be engaged only

with forward speed.

To engage takeoff, engage clutch and then

push the lever towards the machine.

To disengage it, pull the lever towards you.

Speed direction lever

To drive forward, engage clutch and then push

lever towards the machine. To drive

backwards, pull the lever towards you.

Before driving backwards, power

takeoff ought to be disengaged.

Speed lever

To engage gears, engage clutch and move the

lever until it stops on the number of the speed

you want, which is written on the gear.

Power takeoff lever

To engage power takeoff lever, engage clutch

and then pull the lever towards you.

To disengage it, push the lever towards the

machine.

Speed direction lever

To drive forward, engage clutch and then push

lever towards the machine. To drive

backwards, pull the lever towards you.

Speed lever

To engage gears, engage clutch and move the

lever until it stops on the number of the speed

you want, which is written on the gear.

In reverse position, 4

th

speed cannot

be used.

OPERATION AND MAINTENANCE MANUAL

Page 12 of 22

Adjustements

The machine can be adjusted in some ways, which are shown as follows.

During these operations:

You can adjust the height of the handle, in order to get a comfortable position, according to the features of

the operator.

Picture 8 - Adjustment of the height of the handle

The handle can also be adjusted to the side. This allows the operator to avoid walking on the soil that has

been just tilled, or to avoid a furrow, etc.. You can perform this adjustment with the machine both in normal

configuration and in reversed configuration.

Picture 9 - Handle side adjustment

Besides, in the version with differential (mechanical system to split the torque), it is possible to lock the

differential, so you can split the torque evenly to both wheels.

Picture 10 – Locking the differential

Handle

height

adjustment

lever

To adjust in height, keep

on pressing the lever

and with your other hand

move the handle to find

the position you want.

Once you have found

the right position, loose

the adjustment lever

Lever of lock

of handle side

adjustment

To adjust the handle to the

side, raise the lever and

with your other hand move

the handle to find the

position you want, then

loose the lever.

Grip the

lever of lock

of

differential

While gripping the lever, push

the button on the side, then

loose the lever while keeping

on pushing the button

You can unlock by gripping the lever

completely.

OPERATION TO PERFORM

WHEN THE MACHINE IS

SWITCHED OFF

DANGER OF

BRUISING AND

CRUSHING

OPERATION AND MAINTENANCE MANUAL

Page 13 of 22

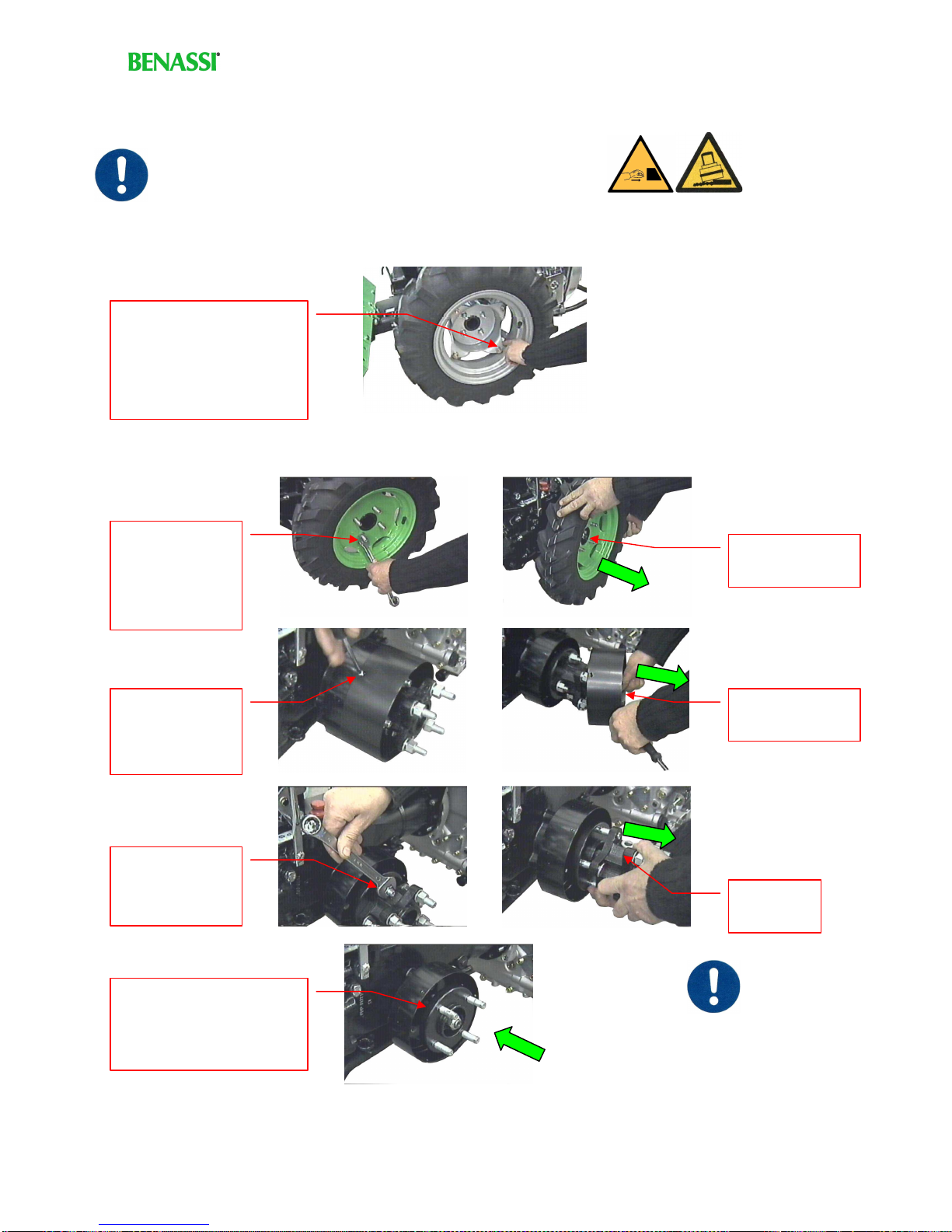

In some versions of the machine, you can adjust the track of the wheels, for example to pass more easily

through narrow places.

You can modify the track of the wheels by inverting the wheels: take off the wheels, then assemble them

again placing outside the internal face and vice versa

Besides, you can adjust the wheels in the following ways as well:

Picture 11 – Adjusting wheels with flange

Picture 12 - Taking off the wheels spacers

ONLY TRAINED AND

INFORMED STAFF SHOULD PERMORM THESE

OPERATIONS. TURN OFF THE MACHINE AND SET IT ON A FIRM

BEARING IN ORDER TO RAISE THE WHEELS FROM THE GROUND.

DANGER OF

BRUISING AND

OVERTURNING

Loosen the

screws of the

wheels with a

suitable spanner

(one wheel at a

time)

Take the wheel

out of the hub

Adjust the position of the

flange in order to place the

wheel more to the inside

or to the outside (only

versions with adjustable

rims)

Loosen the

screws on the

side with a

screwdriver

Take out the

spacer case

Loosen the

screws of the

spacer with a

suitable spanner

Take out

the spacer

Assemble the wheel

directly on the axle,

without spacer nor case

After adjusting

the machine, all the

screws should be well tightened and

the implements stable.

Make sure that the machine is

configured symmetrically and is

perfectly stable.

OPERATION AND MAINTENANCE MANUAL

Page 14 of 22

Starting the machine

To start the machine, follow these instructions:

BEFORE STARTING THE MACHINE, MAKE SURE THAT:

- VENTILATION IS ENOUGH (YOU SHOULD GO OUTSIDE);

- ALL THE CONTROL LEVERS ARE DISENGAGED; THE SPEED LEVER MUST

BE SET ON NEUTRAL POSITION (0);

-THE FUEL TANK IS FULL ENOUGH.

FINALLY, OPEN THE FUEL TAP

1 – With your left hand, press

the red lever (motor-stop)

2 – With you left hand, while

keeping on pressing the red lever,

grip the clutch lever

3 – While keeping the two

levers, with your right hand

press the button on the side

4 – Now, loose the levers while

keeping on pressing the button

5 – Open the throttle fully

6 – Standing in front of the

machine, grip the self-winding

rope

7 – Pull the rope strongly: the

engine will start

In this way the gear is

disengaged from the engine

and the machine can be

started

6’ – Turn the key: a warning light will light up.

Then turn the key again and loose it when

the engine is running.

If the machine has manual starting,

with self-winding rope (see the

engine operating and maintenance

manual):

If the machine has ignition (see the

engine operating and maintenance

manual):

You can unlock by gripping the

clutch lever completely.

DANGER OF

BRUISING AND

CRUSHING

OPERATION AND MAINTENANCE MANUAL

Page 15 of 22

Operating the machine

Once you have chosen one of the working configurations (normal or reversed) and made the adjustments

you need (always respecting what is written in the relevant section of this manual), the machine is ready for

use.

Push the machine from storage to the place where you will start it;

Start the engine, following the instructions and warnings of the relevant section;

Once the engine is running, choose the driving direction and engage the speed you prefer;

If the operation needs it, engage the power takeoff;

Pull the clutch lever until the clutch lever lock button is released, always keeping up the motor stop

lever;

Disengage the clutch;

If the motor stop lever is lowered, the machine can move; otherwise, it remains still;

Ad just the throttle control according to the power required.

General warnings while working

While operating the machine you must:

Familiarise yourself with the controls and with how the machine moves;

Start the machine in a ventilated area, better if outdoors;

Operate the machine with good light (better if with daylight);

Check the working area and clear it of debris (sticks, stones, wires, etc.).

Wear suitable clothes and shoes; a mask as well could be needed on dusty grounds;

The operator has to walk behind the machine: maintain a suitable pace (walk, do not run) and

be careful not to stumble, especially when going backwards;

Work in conditions of stability: drive the machine parallel with the slope, trying to avoid steep

slopes, manoeuvre carefully and use caution while changing direction;

Change working direction if exhaust fumes go towards the operator;

While pushing the machine: be careful of balance, keep the implements lifted from the ground

and avoid moving the machine for too long distances or when it could require an excessive

effort.

When you are operating the machine, remember the following prohibitions:

It is severely forbidden to tamper with safety devices (as the motor stop lever), since it could

jeopardize their functioning and result in personal injuries;

Never allow children and untrained people operate the machine;

Never operate the machine near children and pets;

Never put hands or feet near the cutters or other implements of the machine when the engine

is running;

Never work on steep slopes;

Never operate the machine without the protective case;

Never operate the machine if the safety devices have been removed or are broken, faulty or

not working;

Never lift or transport the machine while the engine is running;

Never store the machine indoors if the fuel tank is not empty;

Never wear scarves, ties, loose clothing, rings, bracelets and any other such item (straps,

strings, etc.) that could get caught while working.

Filling and emptying the fuel tank

Pleas follow the instruction of the manual provided by the producer of the engine to fill and empty the

fuel tank.

DANGER

INFLAMMABLE

MATERIALS

D

ANGER

GAS AND

VAPOUR

INHALATION

Never handle fuel indoors or with poor ventilation;

Never handle fuel if the machine is

running or the

engine is still hot;

Never smoke;

Avoid fuel spillage;

Never

start the engine if some fuel has incidentally

spilled: clean the dirty parts with adequate means;

When working on steep slopes, ne

ver overfill tank, in

order to prevent fuel spillage.

OPERATION AND MAINTENANCE MANUAL

Page 16 of 22

Switching the machine off

When you want to switch the machine off, follow these instructions:

Disengage the power takeoff and set the gear on neutral position.

Finally, close the fuel tap (for more details, consult the manual provided by the producer of the engine)

Picture 13 – Switching the engine off

Storage of the machine

When you want to put the machine to storage, you should remember the following instructions:

When choosing the place where to store the machine during the periods when it is not used, you

should bear in mind its size, mass and static load. Moreover, the floor should be flat.

Take the throttle

control to the

minimum of its

stroke

.

In the versions with ignition,

remember to turn the key to

the stop position, in order to

avoid that the battery goes flat.

Loose the motor-

stop lever: the

machine will switch

off.

Neve

r leave the machine with some fuel in the tank;

Let the engine cool before leaving the machine indoors;

Leave the machine far from inflammable materials and from sources of fire;

Leave the machine clean;

OPERATION AND MAINTENANCE MANUAL

Page 17 of 22

Residual Risk

The machine, even when you use caution, has some residual risks for the operator:

DANGER OF THROWING MATERIALS AGAINST PERSONS, ANIMALS,

OBJETS. RESPECT AND MAKE OTHERS RESPECT THE SAFETY DISTANCE

DANGER: MOVING IMPLEMENTS

DANGER OF BRUISING AGAINST THE IMPLEMENTS OF THE MACHINE

THE CUTTERS CAN CAUSE INJURY TO HANDS WHEN THEY ARE WORKING OR

DURING OPERATIONS OF MAINTENANCE

MANUAL LOAD HANDLING WHILE (DIS)ASSEMBLING THE IMPLEMENTSO OF THE

MACHINE

DANGER OF FUEL VAPOURS AND EXHAUST GAS; NEVER OPERATE INDOORS

DANGER TO FALL OR STUMBLE WHILE OPERATING

DANGER FOR FEET BECAUSE OF CUTTERS

DANGER OF OVERTURNING ON UNEVEN SURFACES, STEEP SLOPES OR WHILE

PERFORMING ADJUSTMENTS TO THE MACHINE

DANGER OF BURNING OR FIRE BECAUSE OF HOT SURFACES

EVERY DANGER IS STRESSED BY

SPECIFIC LABELS.

PROMPTLY REPLACE SPOILED

LABELS. IF NECESSARY, ASK THE

PRODUCING FIRM.

OPERATION AND MAINTENANCE MANUAL

Page 18 of 22

Maintenance

General guidelines

Warning: only trained and informed staff should perform the maintenance operations described in

this manual.

Warning: only the producing firm or the retailer of the machine should perform specific maintenance

operations.

While performing maintenance operations, the machine should be in a stable position.

Never neglect maintenance: the life and the efficiency of the machine also depend on how it is

maintained.

Never repair the machine temporarily; always do it properly and permanently.

During those maintenance operations in which the operator may touch chemical substances, please notice

the following warnings:

We remind to those who operate the machine that when using chemical substances you should

follow the instructions shown on the safety tables, which must be provided by the producer of the

substance. Please follow the instructions shown on the packing.

Engine

For the details related to maintenance operations of the engine, please consult the

manual provided by the firm producing the engine, handed in with the machine.

Gear: checking the oil level

The machine must be switched off and placed on a flat surface.

Every 100 working hours, check the oil level through the specific gauge.

Picture 14 – Gear oil level

If the oil is down the minimum level, you need to check for spillage, then fill up the oil, using proper tools and

methods.

Plug with

level gauge Hole for

filling up

Danger of bruising

Danger: chemical substances

and hot surfaces

Use

suitable

gloves and

clothes

Danger: hot surfaces

Operations to be performed by

trained and informed staff,

when the machine is cold and

not running

OPERATION AND MAINTENANCE MANUAL

Page 19 of 22

Gear: changing the oil

The machine must be switched off and placed on a flat surface.

After the first 50 working hours, change the gear oil. Then change it every 300 working hours.

Empty the gear by taking off the plug shown in the picture. Collect the oil in a proper container. To fill up, put

the plug in its place and tighten. Then, pour oil through the hole with proper tools and methods.

Picture 15 – Changing gear oil

Waste oil should be disposed of according to law.

TO FILL UP, USE 90 W OIL

Greasing power takeoff

The machine must be switched off and placed on a flat surface.

Grease the power takeoff every 8 working hours and whenever attaching a new implement.

Picture 16 - Greasing takeoff

Periodical operations

The machine must be switched off and placed on a flat surface.

Periodically, check if screws, nuts, bolts, split pins etc. are well tightened.

OPERATION AND MAINTENANCE MANUAL

Page 20 of 22

Cleaning

General guidelines

Cleaning is ordinary maintenance. With ordinary maintenance we mean scheduled operation of basic

maintenance that do not generally require special qualifications, authorizations or tools.

To clean the machine, switch it off, let it cool and place it in a stable position.

Clean the machine:

⇒every day after every time you operate it. The life and the efficiency of the machine

also depend on how it is maintained.

⇒while operating it, if necessary.

The machine uses dangerous substances (fuel); to clean its parts, follow the instruction of the manual

provided by the firm producing the engine.

The machine does not have, as far as its functions allows it, sharp corners or rough surfaces that can cause

injuries.

WARNING

You should clean the working surfaces or other parts of the machine with proper tools, methods and

products, wearing protective garments, and respecting the environment.

To clean dust, earth, weed, etc, off the implements, wheels or other parts, use proper tools and methods (for

example a pressure washer). Remember to clean the machine only when it is not running.

If using a pressure washer, be careful not to hit delicate parts of the machine

(electrical parts, engine, etc.), or persons, animals and things nearby. Follow the

instructions of the relevant manual.

When cleaning with compressed air, only use dry compressed air.

We recommend the operator to wear a mask to protect the respiratory tract, a pair of glasses to protect the

eyes and suitable clothes.

While using compressed air, the operator should make sure that there are no people nearby.

We remind to those who operate the machine that when using chemical substances you should

follow the instructions shown on the safety tables, which must be provided by the producer of the

substance. Please follow the instructions shown on the packing.

To clean the engine, please consult the manual provided by the firm producing the

engine, handed in with the machine.

DANGER OF DAMAGING

THE MACHINE

NEVER USE JETS OF W

ATER TO

CLEAN THE ENGINE

FOLLOW THE INSTRUCTION OF

THE ENGINE MANUAL

This manual suits for next models

1

Table of contents

Other Benassi Tiller manuals

Benassi

Benassi BL 45 Manual

Benassi

Benassi BL301H User manual

Benassi

Benassi BL 10 Manual

Benassi

Benassi BL30 User guide

Benassi

Benassi BL304 Quick guide

Benassi

Benassi MC 2300 REVERSO Instructions for use

Benassi

Benassi BL 105 User guide

Benassi

Benassi BL 300 User guide

Benassi

Benassi BL 10 Series Manual

Benassi

Benassi BL 4000 User manual