Benassi BL 6000 User manual

SpA

INSTRUCTION MANUAL

TILLER

BL6000

19/04/2011

SpABL6000

2

INDEX

INTRODUCTION…………………………………………………………………....2

SAFETYRULES............................................................................2

KEYTOMACHINEPARTS...........................................................3

IDENTIFICATIONSANDTECHNICALSPECIFICATIONS ...............3

CEMARK .................................................................................3

TILLINGUNITS ........................................................................3

DIMENSIONS ..........................................................................4

PACKINGANDTRANSPORT…………………………………………………...4

STICKERSFORINSTRUCTIONANDSAFETY ...............................4

STARTINGANDSTOPPING..................................................... 5

USEANDADJUSTMENT......................................................... 6

SPURADJUSTMENT ............................................................... 6

TRANSFERWHEELADJUSTMENT........................................... 6

SERVICING................................................................................. 7

CLUTCHBELT ......................................................................... 7

WARRANTY............................................................................... 8

INTRODUCTION

•Dearuser,wethankyouforpreferringaBENASSIproduct.

•Weareconfidentthatthetopperformanceandtheeasyuseofourmachinewillsatisfyyou.

•Thismachineistheresultofalongexperienceworkingatthetopqualitystandardandusingfirstqualitymaterial.

•Carefullyusingandservicingthismachine,youwillcertainlygetsatisfactoryperformancesforalongtime.

•Pleasereadverycarefullythisbookletbeforeusingyourtiller.

•Payspecialattentiontotheinstructionsmarkedoutbythefollowingsign:

ATTENTION

•Failuretocomplywiththeseinstructionscancausefatalinjury(TRANSLATEDFROMTHEORIGINALMANUAL).

SAFETYRULES

WARNING:Please,readverycarefullythisbookletbeforeusingyourmachine.Carefullyusingand

servicingthismachine,youwillcertainlygetsatisfactoryperformancesforalongtime.

FailuretocomplywiththeseinstructionsmayCAUSEfatalinjuryTOTHEOPERATORORDAMAGETO

THEMACHINE.

•Pleasereadcarefullytheoperationandmaintenancemanualsuppliedwiththemachine.

•Theuseofthemachineisforbiddentopersonsyoungerthan16years.

•Theoperatorisresponsibleofanypossibledamageandheshouldalwaysdrivethemachine

carefullyandsafely.

•Anypersonunfamiliarwiththemachinewhohasneveruseditisobligedtoreadfirstthe

instructionmanual.

•Beforecarryingthemachinealwaysemptythefueltank.

•Beforeleavingthemachinebesurethatitisfullystopped.

•Neverusethemachinebarefootorwearingsandals,alwayswearheavyshoesandlongtrousers.

Alwaysinspecttheareawhereyouwanttoworktakingoffstones,branches,wiresandanyother

thingwhichcouldbedangerous.

•Beforestartworking,makesurethataradiusofminimum5mt.iscompletelyfree.

•Cleananypossibleleakageoffuel.

•Alwaysfillupthetankwhentheengineisoffinanopenspacefarfromfiresoranyheatingsource

anddon’tsmokeduringthisoperation.

•Beforestartingthemachinemakesurethatyoucanquicklystoptheengineandthatyouare

familiarwiththecontrollevers.

•Neverallowtheenginetoruninenclosedspaceswherethehighlytoxiccarbonmonoxidecould

notevacuate.

•Neverstartorusethemachineifnotcompletelyassembledandequippedwiththesafetydevices.Neverworkwithoutthetiller

protectionguards.

•Neverfixorcleanthetillerbladesoranyothertoolswhentheengineisrunning.

•Attention!Don’tworkonslopesexceeding30%.

•Foraccidentscausedbyfailureoftheseruleswewillnotbeheldliable.

SpABL6000

3

KEYTOMACHINEPARTS

1‐Transportwheel

2‐Engineoilcap

3‐Tillers

4‐Tillerprotection

5‐Brakingspur

6‐Beltcover

7‐Gearlever

8‐Clutchlever

9‐Throttlelever

10‐Handlebaradjustment

11‐Fueltankcap

12‐Handle

13‐Recoilstarter

14‐Chokelever

15‐Aircleaner

IDENTIFICATIONANDTECHNICALSPECIFICATIONS

ATTENTION:FORTHEENGINETECHNICALSPECIFICATIONS,SEETHEENCLOSEDOWNER’SMANUALOFTHEENGINE.

•AcousticpowerlevelLwA=from92dB(A)to105dB(A)

•Noiselevelatoperator’sear:LpA=from81dB(A)to90dB

(A)

•Testcondition:1,6mtatthecentreofthehandlebar

•HandlebarvibrationaccordingtoISO1033:valuefrom4,76

m/sec²to7,00m/sec²

CHARACTERISTICSOFALLTHEENGINESFITTED:

•Exhaustguard

•Recoilstarter

•ENGINELUBRICATION:seetheowner’smanualoftheengine

•Engineoilquantity:seetheowner’smanualoftheengine

•Enginefuel:unleadedpetrol

•Safetydeviceforbothforwardandbackwardgearstopping

thetiller.

•Thegearhasgottwoforwardspeedsandonereverse,abelt

joinsthetransmissiontotheengineandanoiledchainto

thetiller.

SPECIFICATIONSWITHENGINERUNNINGAT3200RPM

Iforward=82rpm

IIforward=113rpm

Reverse =61rpm

•Speedgearinoilbath

•Beltclutchwithtightener

•Tillerwithhexagonalshaftandreinforcedblades

•Guidancehandlebarscanbeadjustedinmanypositions(ver‐

ticalandsideadjustment).

•Thetilleris80cmwide.

•Thespurisadjustable

APPLICABLEACCESSORIES

•Ridgerwithattachment

•Thinironwheels(Ø320)aresuitablewhenusingtheridger

CEMARK

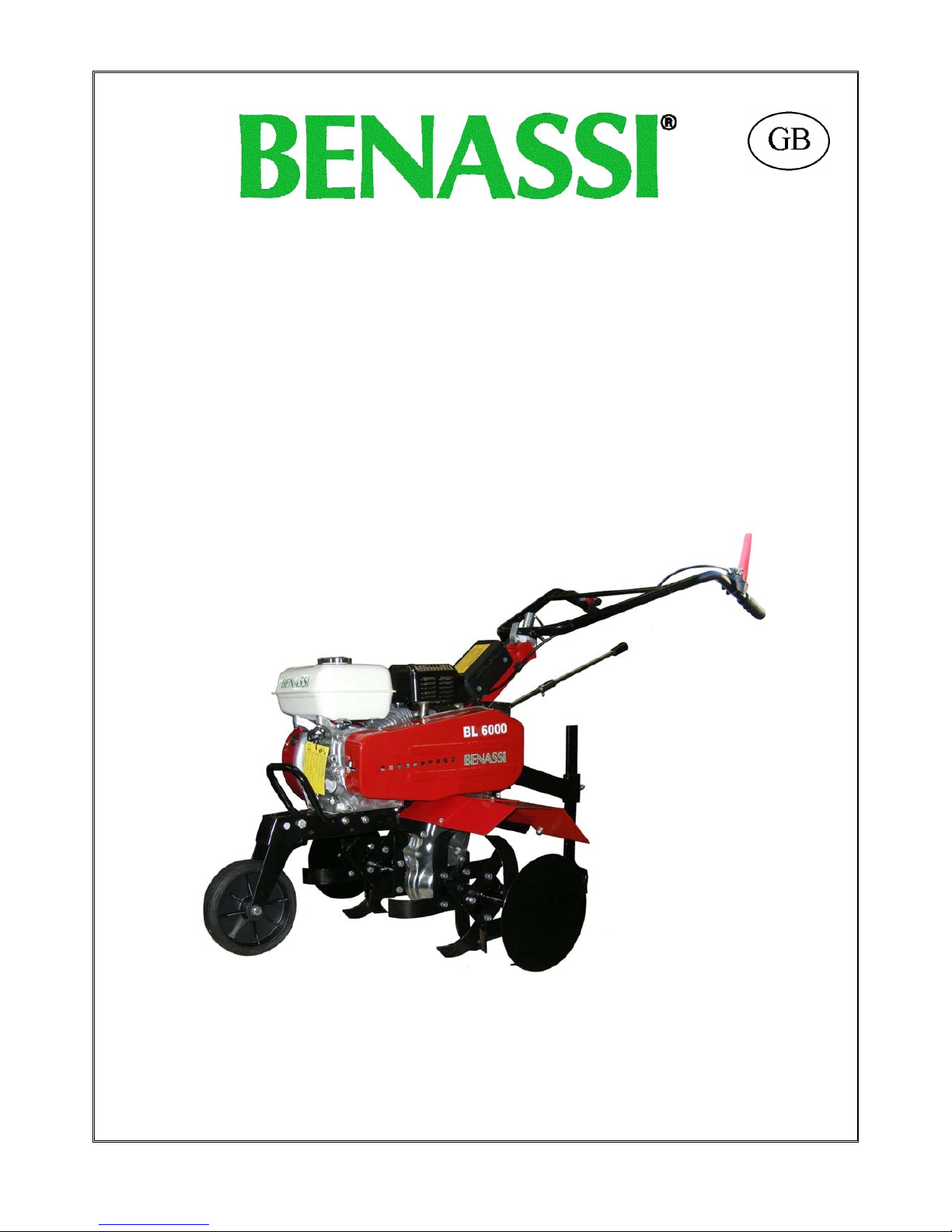

Toidentifythemachine(serialnumber,engine,weight,power)

havealookatthenumberplateputonthemachineasin(Pic‐

ture1Ref.“A”).

TILLINGUNITS:

Thebladesareadjustableandprovidedwithaprotectionmudguard.Inpicturenumber2youcanseethepossibleworkingwidth:60–

80cmwiththeextensionsandthesideplatesfitted.

A

Fig.1

Fig.2

800

Ø315

1

23

4

6

5

7

89

10

11

12

HONDAKIPOR

1313 14

14

15

15

SpABL6000

4

Fig.4

A

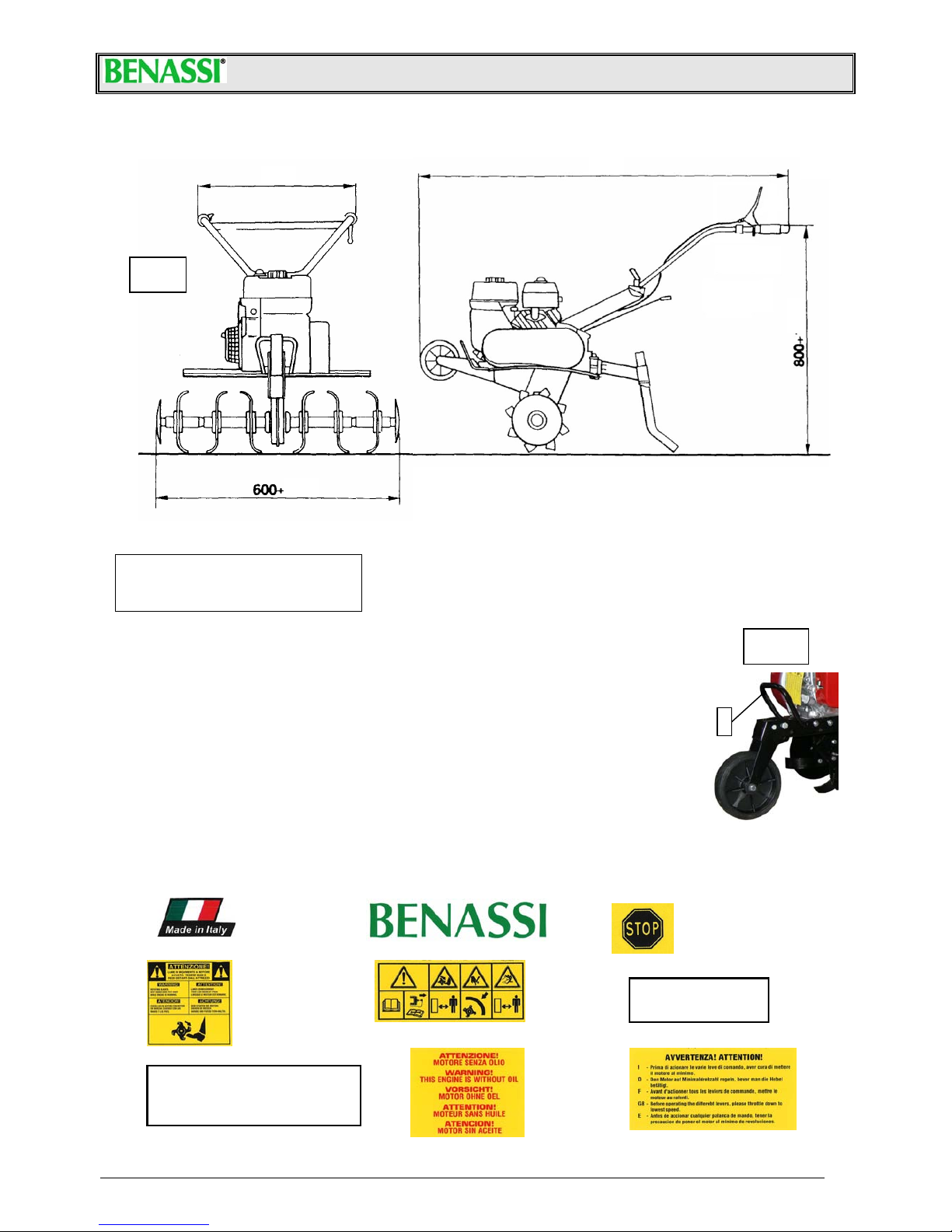

DIMENSIONS

Thedimensionsofthetillerareshowninpicture3.

PACKINGANDTRANSPORT

◊Length:80cm.

◊Width:50cm.

◊Height:70cm.

•Takethemachineoutofthecartonbox.

•Fitthetwotillingunitstothemainshaftusingthedeliveredpinsalreadyassembledonthetillingunits.

•Fitthearmwithspurinitsplaceusingthedeliveredpin.

•Fixthehandlebartothehandlebarsupportusingthepartsalreadyassembledonthehandlebarsupport

itself.

•Thesmallwheelholderisfittedtotheframebymeansofascrewnutandasplintpin.

•Fitthetwoguard‐extensionstothemaintillerprotectionsfittedonthebodyofthemachineusingthe

properscrewsandnuts.Theprotectionguardsshouldreachawidthof60cmaccordingtotheCE

requirements.

•Duringthetransportthehandlecanbeleftunassembledbymeansofthethreadedbushthatfixittothe

handlebarsupport.Thetillerisequippedwithafronthandle(seePict.4Ref.”A”)inordertobeableto

liftandtotransportthemachineeasily.

STICKERSFORINSTRUCTIONANDSAFETY

Pleasefindherebelowthestickersputonthemachine.Itisveryimportantthattheyarealwaysclearlylegibletopreventanyaccident.

Incasethestickersaredamageditisabsolutelynecessarytoreplacethembyorderingtheoriginalspareparts.

R· 2· 0· 1

BL 6000

1)2)

4)6)

7)8) 9)

3)

5)

6001660

1150

Fig.3

800

SpABL6000

5

STARTINGANDSTOPPING

Wheneveryouarestartingtheengineofthemachine,followtheseinstructionsverycarefully:

•Checktheengineoillevel:ABRANDNEWMACHINEISDELIVEREDWITHOUTOILINTHEENGINE,THEREFOREYOUSHOULDFILLIT

UPTOTHELEVELONTHEDIPSTICKOFTHEOILCUP.

•PleasereadcarefullyonthebooklettheENGINEUSEANDMAINTENANCEconcerningthe“operationsbeforestarting”.

•Starttheengineonlyinopenspaces.

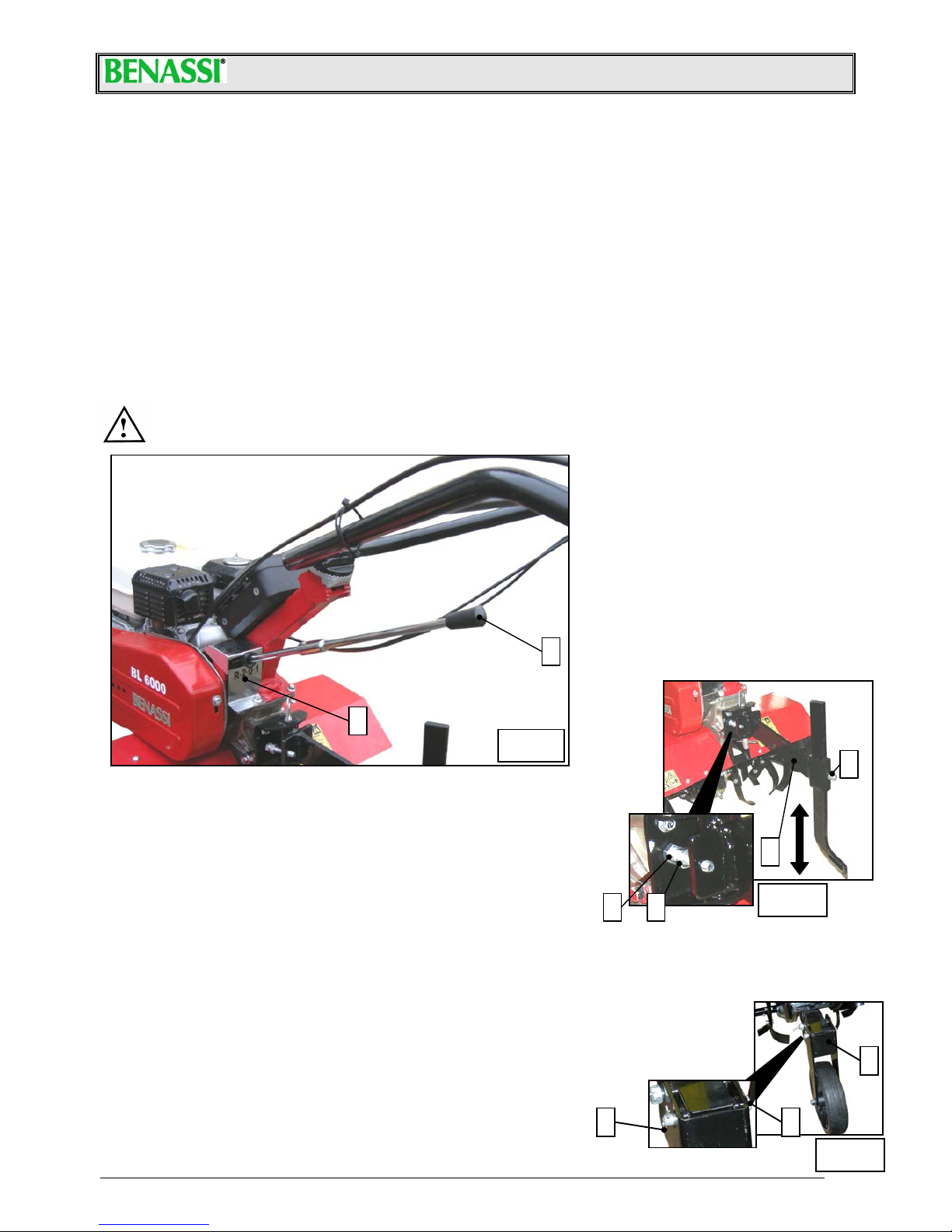

CLUTCHLEVERPROVIDEDWITHSAFETYDEVICE(seepicture6b)

•Lever(“A”)pulled:togettheleverworkingreleasethesafetydevice(“B”),nowtheclutchisengaged(thetillermovesforwardor

backwardsdependingontheengagedgear)

•Lever(“B”)released:clutchleverdisengaged(thetillerstops).

1. Pullthechokelever(Pict.5Ref.“A”).

2. Turnthethrottlelevertothe“MAX”position(Pict.6aRef.“A”).Theswitch(Ref.“A”Pict.6a)mustbe“ON”.

3. Theclutchlever(Pict.6bPosition“A”)mustbedisengaged.

4. Pullthestartingropebythehandle(Pict.5Ref.“B”),firstlysmoothlyandthenstrongly:whenyoufeelsomeresistancedon’tlea‐

vethehandlebuthelptherecoilingoftheropewithyourhand.

5. Whentheenginerunsmovethechokelevertotheinitialpositionandthethrottleleverinthemid‐position(Pict.6aRef.“B”).

6. Tostoptheenginemovetheswitchtothe“OFF”position(Fig.6aRef.”A”).

Pict.6a

A

B

Pict.6b

AB

KIPOR

A

B

HONDA

Pict.5

A

B

A

Pict.6

B

C

SpABL6000

6

Pict.8

A

B

D C

AB

C

Pict.9

USEANDADJUSTMENT

•Thetillerisequippedwithamechanicaltransmissionthatallowstwoforwardspeedsandonereverse.

•Whenthemachineisstandstilltomoveforwardsimplyengagethegearlever(Pict.7Ref.“A”)inthefirstorinthesecondspeed

(Pict.7Ref.“B”)andthenpressdowncompletelythelever(Pict.6bRef.“A”)tostartthemovement.

•Whenthemachineisstandstilltomovebackwardsengagethegearlever(Pict.7Ref.“A”)intheposition“R”(Pict.7Ref.“B”)and

thenpressdowncompletelythelever(Pict.6bRef.“A”)tostartthemovement.

•Theclutchcablemustbeadjustedinawaythatallowsthebelttobeputundertensionwhentheleverissituatedatabout1cm

fromtheknob.Tothispurposeyouhavetoregulatetheregisterofthecablenexttothelever(Ref.“B”Pict.6).

•Whenthelever(Pict.6bRef.“A”)isreleasedthemachinestopsimmediatelywhiletheengineisrunning.

•Thehandlebarcanbeadjustedbyunscrewingtheblockinglever(Pict.6Ref.“C”).Adjustthehandlebarinthedesiredpositionand

thenlockitagain.

•Thetilleris80cmwide,itiscomposedby3knives+protectionplateonbothsides.Itcanbereducedto60cmbyremovingone

bladefromeachsides(seepicture2).

•Thesharpsideofthebladesmustbeturnedtowardsthefrontsideofthemachine.

•Werecommendtousethetillerwiththesideplatesbecausetheyimprovethestabilityofthemachinewhileworking.

•Themachinecanfitanadjustableridgerwhichisanoptionalaccessorydeliveredcompletewithitsownsupportwhichshouldbe

fittedonthehandlebarholderreplacingthestandardspurandusingthesamebolt.

CAUTION:ITISADVICEDNOTTOKEEPTHEMOTORRUNNINGWHENTHEMACHINEISNOTBEINGUSEDFOR

ITSSPECIFICALPURPOSE.

SPURADJUSTMENT

Togetanoptimaltillingworkandarightadvancementofthetilleradjustthespurasshownin

picture8,thisadjustmenthastobedoneonbothsidesofthemachine:

−Adjustmentforhardsoils:loosennutandscrew(A)andliftthespurastoshiftbackthe

weightofthemachine.

−Adjustmentforsoftsoils:loosennutandscrew(A)andlowerthespurastomovethe

weightofthemachinetowardsthebladesaxle.

Toenablethetillertomoveslightlysidewaysduringthetillingwork,thespurholderarm

(B)canbeadjustedhorizontallyasfollows:

a. loosenthenut(C)andadjustthescrew(D)asdesired,thentightenthenutagain.Bytighteningthescrew(D)thespurcanmovesi‐

deways.

b. carryoutthesameadjustmentalsoontheothersideofthearm.

TRANSFERWHEELADJUSTMENT

Totransferthemachinethesmalltransferwheelhastobelowered(seepicture9).Beforeworkingremovethesplintpin

(B)andtheclampingpin(A),liftupthesmalltransferwheel(C)andinserttheclampingpin(A)againin

thelowerhole.Theclampingpinalwayshastobelockedinthedesiredpositionbymeansofthe

splintpin(B).

A

B

Pict.7

SpABL6000

7

Pict.10

A

B

SERVICING

Fortheusualengineservicing(oil,filter,sparkplugandadjustments)readtheenginemanual

deliveredwiththemachine.

•Itisnecessarytocheckperiodicallytheoillevelinthegearboxbyatleastevery50workinghours.If

necessaryaddMPSSAE80/90oil.

•Theoilhastobechangedevery200workinghours.Unscrewthecap(Ref.“B”Pict.10),drainoutall

theoillettingthecap(Ref.“A”Pict.10)open.Thenputbackthecap(Ref.“B”Pict.19)andtopup

withoil(about1,3litres).

•Theframehaswaterproofballbearings.Thetransmissionintheframeisengagedbytwonormal

grease‐lubricatedchains.

•Allthejoints,thecablesandthetightenersupportboltshouldbeoiledfromtimetotime.

•Keepthemachineandthebladesclean.Checkperiodically,atleastonceayear,thatallthescrews

andnutsarewelltied,especiallythescrewsofthetiller(alwayswearprotectiongloveswhile

workingonthetiller).

•Incaseofbreakingorwearofthebelt,youcanreplaceitaftertakingoffthesideprotectioncover

byunscrewing2knobsfixingthesideprotectioncover(Pict.11Ref.“A”).

•Takeoffthebeltfromthepulleysandinstallthenewbelt.Afterreplacingthebelt,adjustittothe

correcttensionfollowingtheinstructionsinthechapter“CLUTCHBELT”,thenreassemble

thecoveragain.

Foranytechnicalrepairespeciallyduringtheguaranteeperiod,itissuggestedtoapplytothe

specialisedworkshopsofourdealers.

CLUTCHBELT

Clutchbeltadjustment (seepicture12)

Removethecoverbyunscrewingbothfasteningscrews,asecondoperatorwillpulltheclutchlever(A).Verifythatthebelt(C)hasgot

amaxdistanceof2,7cmandifitdoesn’thappenproceedasfollows:

a. adjustthebelttensionbyregulatingtheclutchlever(A)throughtheadjustingscrew(B)onthelefthandlebar;

b. ifthebeltdistance(C)isstilloutofthementionedtolerance,loosenthefourbolts(D)clampingtheengineandshifttheengine(E)

forwardstillyougettherightvalues.

Clutchbeltreplacement(seepicture12)

a. loosentheadjustingscrew(B)onthelefthandlebarandextractthebeltfromthepulleys.

b. Installthenewbeltonthepulleysverifyingthatthemax.distanceisabout2,7cmandthattheclutchleverdoesn’thaveanyclea‐

ranceotherwisecarryouttheadjustmentdescribedbefore.

Pict.11

A

A

Pict.12

A

2,7cm

E

D

B

C

SpABL6000

8

WARRANTY

Ourmachinesandaccessoriesareguaranteedfor2yearsexcludingelectricandrubberparts.

Allthedefectivepartswillbereplacedfreeofchargeexcludingcostoflabourandtransportfeeswhichwouldbeatcustomer’scharge.

Foranyproblemregardingtheengineoranyotherpartnotofourproductionpleaserefertotheguaranteeconditionsstatedbythe

manufacturerandapplytotheirassistancecentres.

Foranykindofproblemorrepairpleaseapplytothedealerwhereyouboughtthemachine.

S.p.A.

VIALAMPEDUSA1

40017S.MATTEODELLADECIMA(BO)‐ITALY

TEL.+39/051/820511TELEFAX+39/051/6826164

e‐mail:[email protected]web:www.benassi.eu

Table of contents

Other Benassi Tiller manuals

Benassi

Benassi MC 3300 User manual

Benassi

Benassi BL 105 User guide

Benassi

Benassi BL 45 Manual

Benassi

Benassi BL 300 User guide

Benassi

Benassi BL304 Quick guide

Benassi

Benassi BL355 User manual

Benassi

Benassi BL 4000 User manual

Benassi

Benassi BL301H User manual

Benassi

Benassi BL 10 Manual

Benassi

Benassi MC 2300 REVERSO Instructions for use