Bench Power Tools WW 10039 User manual

CONGRATULATIONS

WOOD

LATHE

Yw

have

just

purchased

one

of

wr

gowing

famiry

of

Bcnch

Power

Tools.

Exh

is

cn@n

ecred

and

manufactwed

to

the

highcst

smndards

of

quality.

You

will

fine

yow

ncw

Wood

Turning

Lathe

a

very

useful

tool.

It

will

pcrfwm

htwccn

ccnlre

turning

and

fxcpbte

turning,

and

is

especbny

suitcd

lo

hi&

spccd

mndng

and

polishing

of

rmishcd

work.

This

Wood

Turning

tathe

is

a

self-contained

power

tool

mnol

rcquifing

thc

purchsc

of

a

scpcratc

motor.

INSTRUCTION

MANUAL

WI

0039

1

1

I

I3

IL

3

-

I

..-

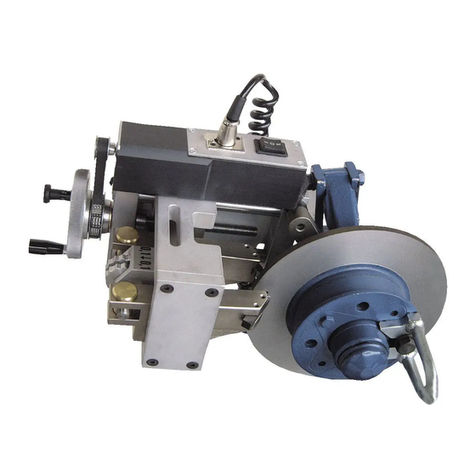

MAIN

FEATURES

I

1.

SWITCH

7.

TOOLREST

MOLDER

2.

BELT

AND

PULLEY

COVER

8.

TOOLREST

LOCKNUT

3.

FACEPLATE

9.

TAUTOCK

SPINDLE(WITH

BAIL

BEARtNG

CENTRE]

4.

MIVE

CENTRE

XI.

TAILSTOCK

SPINDLE

LOCKNUT

5.

BED

RAILS

n.TAILSTOCK

l2.

TAILSTOCK

LOCKNUT

13.

LATHE

BED

Safety

Rules

For

All

Power

Tools

I.READ

AND

BECOm

FAMILIAR

with

the

entire cpcrating manwl.

2.KEEP

GUARDS

AND

COVER

m

pkc

and

in

working

or&.

3.

ALWAYS

USE

SAFETY

GLASSES.

Also

use

face

or

&st

mask

if

cutting

apcration

is

&sty-

Everymy

cycghsscs

only

bvc

impact rcsistmt

Icnscs;

they

arc not safely

glasses,

4.

KEEP

WORK

AREA

CLEAN.

Cht-

tcrcd

arcas

and

benches

invite

xcidcnts.

5.T)ON'T

FORCE TOOL.

It

wll

db

a

bcttcr

and

safer

job

at the rate for

wkh

it

was

&signed.

work

area

well

illuminetcd.

DO

NOT

USE

in

explosive

atmocrphere(around

paint,

flammable

liquidg,

etc.

).

I8.KEEP

CATLDREN

AWAY.

All

vi-

sitors

should

be

kept

a

safc ktancc

from work

area,

espccblly

while

opn-

ntlng

unit.

X

4.

USE

TFTE

PROPER

TOOT,.

Dm'

t

force

tod

or

attachment

to

do

a

job

fw

which

it

was

not

dcsioncd.

IS.

MA

TNTATN

TOOLS

TN

TOP

CON-

nlTION.Kccp

tools

sharp

ad

clcsn

for

best

and

mfcst

pcrformancc.

Foilaw

ins

truct~ons

for

lubicating

and

changing

xccsso~cs.

6.

hVO1n

ACClnENTAL

STARTING.

1

G.

SECURE

WORK.

Use

clamps

or

a

Makc

sure

switch

is

in

"OFF"

positbn visc

to

hold

work,

whcn

pnciial.

it'

s

bcforc

plugging

in

cord.

mtcr

thn

using

your

hnd

and

prc-

vcnts

round

w

rrrcgrlarly

shaped

pic-

7.

nlSCONNECT

TOOT,S

REFORF,

ccs

from twniw.

SERVICING

and

whm

changing

acccssorics

sueh

as

Ws,

bits,

cutters.

8.

DON'T

OVERREACH.

Kecp

yam

prwcr

footing

and

bbncc

at

all times

For

bst

footing

wwr

rub

sofcd

fo-

otwear.

Kccp floor clear

of

oil, scrap

wood. ctc.

9.

WEAR

PROPER

APPAREL.

Loose

clothing

w jcwclry

may

gct

caught

.in

moving

parts.

Wwr

protcetlvc

hdr

cov-

ering

to

contain

long

hair.

10.

MAKE

WORKSHOP

KIDPROOF

Kccp

workshop locked or

p3dockcd

whcn

not in

usc

and

store thc

key

in

a

safc

localion.

11.

REMOVE

h

IIJUSTTNC:

KEYS

AND

CVRENCHES.

Form

habit

of

chccking

to

scc

that keys and

atlju-

sting wrcnchcs arc

rcmovcd

from

tool

bcforc

turning it

on.

1

2.

AVOln

DANGEROUS

ENVIRO-

NMENT.

Don'

t

usc

power

tools

in

hrn~

or

wct

locations.

Kccp

your

27.

CHECK

DAMAGEn

PARTS.

&f-

arc

furthcr

use

of

thc tool,

a

gurd

or

other

part

tht

is

~kmagcd

shodd

bc

chcckcd

to

ssswo

that

it

will

opcratc

pr~crly

and

pcrform

its

intcndcd

func!ion-ckk

for

alignment

of

mov-

ing

parts,

hcaka~

of

parts,

rnmting,

any

othcr

condtions

that

may

atfcct

its

operations.

A

gmcd

or othcr

part

that

is

hmgcd

should

bc

properly

rcpaicd

or

rcpbccd.

18.

USE

RECOlKMENnEn

ACCES-

SORIES-

Consult

Owner'

s

Maninl.

Use

of

improper acccssmics could

bc

bzarduus.

4

9.

NEVER

STAND

OW

TOOT,.

Injury

could

occur

from

a

tall.

20.

NEVER

IJEAVF:

TOOT,

RUNN-

TNG

ANn

UNcZTTENnEn.

21.

AI,WAYS

REMOVE

CORn

PT,UC

from

elm

triisl

outlct

whcn

sdjusting.

:hm9;ng

prts or

working

on

tool.

CHANGING

SPEEDS:

1.

Turn

the

power

off

st

the

matn

swltch.

2.

Loosen

motor

rnountlng

bolts

under

pulley

cover.

3.

Press

down

on

belt

tenslon

lever

lo

loom

the

belt.

4.

Change

belt

to

the

desIrecl

pulley

steps.

5.

Lift

belt Zenslon

lever

to

tlghten

belt.

6.

Retighten

rnotor

mounting

bolts.

Wood

Turning

Chisels

Each

Wood

Turning

Chisel

is

forged

from

hlgh

carbon

steel,

hardened

and

tampered

to

hold

a

sharp

cutting

edge.

TURNING

BETWEEN

CENTRES

Turning

between

centres

Is

the operation

ot

turning

a

long

workpisce

supported

at

one

end

by

the

dr~ving

centre,

and

by

the

tailslock

centre

at

the other.

MOVING

TA1LS"FOCK

AND

TOOL

RES'lYhe

tallstcck

and

lwlresl

are

held

lo

the

bed

with

lock

nuts

undwmeath

the

bed

ralls.

To

move

them

to

a

new

posltlon,loosen

the

nut

with

the

adjustment

spanner

.slide

the

tallstock

w

toolrest

along

the

bed

end

retighten

the

nut.

The

toolrest

Is

held

In

place

by

the

lockknob.

CHANCING FACEPLATE

AND

DRIVE

CENTRE

The

OdlUstmemt

spanner

has

laws

wh3eh

flt

across

flats

on

the

headstock sptrtdle.

Locate

the

spanner

across

the

flats

end

unsrew

the

faceplate

or

drive

centre

towards

you.

MARKING

THE

CENTKES*raw

we

hes

across

each

end

of

the

workpiece,

from

comer

to

comer.

IM

jum-

h

of

the

timi

will

ba

the

correct

centre.

NEatk

W

mWws

with

an

awl

or

a

drl.

MOUNTING

THE

WORK

BETW-

EEN

CENTR~wew

&ihg

mue

ffom

the

bthe

spin&.

Locate

tfm

point

of

the

rfrivh~

mae

in

the

hob

rnarked

at

ong

end

ol

the

timbw,and

hamner

home

with

a

wooden mallet or

sort

hammer.

POSITIONING

TOOL

REST-The

position

of

the

chisel

and

weratw

Cmt-

ort

is

me

inportant

W

the

actwl

hi

-

ght

ot

the

tool

rest.

Set it

at

cenhe

hei@t

to

be&

with

and

adlust

it

sli~htly

high

or

lower

after

trial

to

wit

the

operation.

MAKTNG

A

BACKING

PIECE-

Usa

a

pie of

1"

(25m)

thick

timber

brwr

ttran

Ihe

&rater

of

the

txepbte.

Screw

the

backing

piece

to

!he

faceplate

usM

w~rews

thr~yh

the

holes

in

the

back

of

the

fxeplete.

Mcunt

the

tacepkte

and

backing

piece mto

ths

btk

spindle

aml

caretully

hnn

dm

timber

untn

it

is

cowle-

tely

circular

and

sfightly

larger

m

&meter

mrm

the

taceplate.

TURNING

THE

TIMBER

TURNING

BETWEEN

CE~~

-Use

a

Owge or

rwnd

nose

chisel

to

MW

the

mbw

m

the

desired

shape.

Hold

the

drisel

turn

against

the

tool

rest.

Use

the

hand

W&mg

the

handla

of

the

chisel

Za

raise

or

lower

the

cutting

p&t,

with

fie

too!

rest

as

a

fulcwn.

when

the

rough

shapa

is

ready

use

dtb

chissls

for

t'inal

Shaping

and

decorative

groov-rn

as

required.

FACEPLATE

TURNING

-;Mount.

the

faceplate

snd

workpiece

to

the

bthe

spinde.

Start

by

turning

the

outsids

of

the

work

t'rst.

Whsnever

possible

bring

the

railstock

up

to

support

tb

workpiece.

Move

the

faitstock

well

clear

when

tumng

the

inside

of

the

work.

Extra

care

must

be

taken

that rhe

chisel

does

not

catch

on

the

work,

particularly when

the

lnslde

turning

is

lono

and

M7fOW.

AIR

EMERY

WHEEL

(NOT

SUP-

PUED)To

ti

the

hbstock

sphdle

with

wrerch

apd

Wtly

screw

the

air

emery

wheel

towarcis

yw.

nlsc

SAN~ER(

NOT

SUPPLIED)

To

fix

the

headstock

spmdle

with

wrbnth

and

tightly

screw

DISC

towards

you.

CHUCK

(NOT

SUPPLIED)

To

tix

the

headstmk

spinrHe

with

wrench

and rightly

screw

the

chuck

towards

you.

Alter

using

ym

chisels

maintain

their

fina

cutting

edge

with

an

olstme,

taking

are

to

keep the

0fic~i~1

aRgbS.

1,

Power

llne

2.

Cwd

clam

3.

Saew

4

Washw

5.

Belt pulley

6.

Locking

screw

7.

Bolt

8.

Washer

9.

Saew

10-

Washw

11.

Protecting

crust

12.

Driving belt

13.

Belt

pulley

14.

Motor

screw

IS.

Washer

16.

Locking

screw

17.

Sc~wv

18. Washer

19.

Ball

bearlng

20.

Bearlng block

21.

Nut

22.

Tml handle

23. Bearlng

blcck

24.

Ball bearing

25.

Washw

26.

Screw

27.

Maln

shaft

28.

Lathe

tlp

29.

Chuck

30.

Power

switch

31.

Washer

32.

33.

Jip

34.

Cap

screw

35.

Tool carrlage

36.

GulUetrack

37.

Tip

38.

Ball

bearlng

39.

Tallst&

40.

Nut

41.

Screw

9x1s

42.

Lodtirg screw

43.

Handwh~l

44.

Screw

d5.

Washer

46.

Brackel

47.

Screw

48.

Washer

49.

Cap

screw

50.

Washer

51.

Spring

washer

52.

Nut

53.

Guide

track plate

54-

Nut

55.

Washw

$6.

Spring

wesher

57.

hl

58.

Lathe

bed

59.

Knob

60.

Guida treck

pIak

61.M

62.

Washer

63.

Spring

washer

64,

Nut

65.

Screw

--

Switch

66.

Screw

67.

Washer

68.

Data plate

69,

Washer

70.

Spring

washer

71,

Nut

72.

Momr

73.

Washer

74.

Sprlng washer

Other Bench Power Tools Lathe manuals