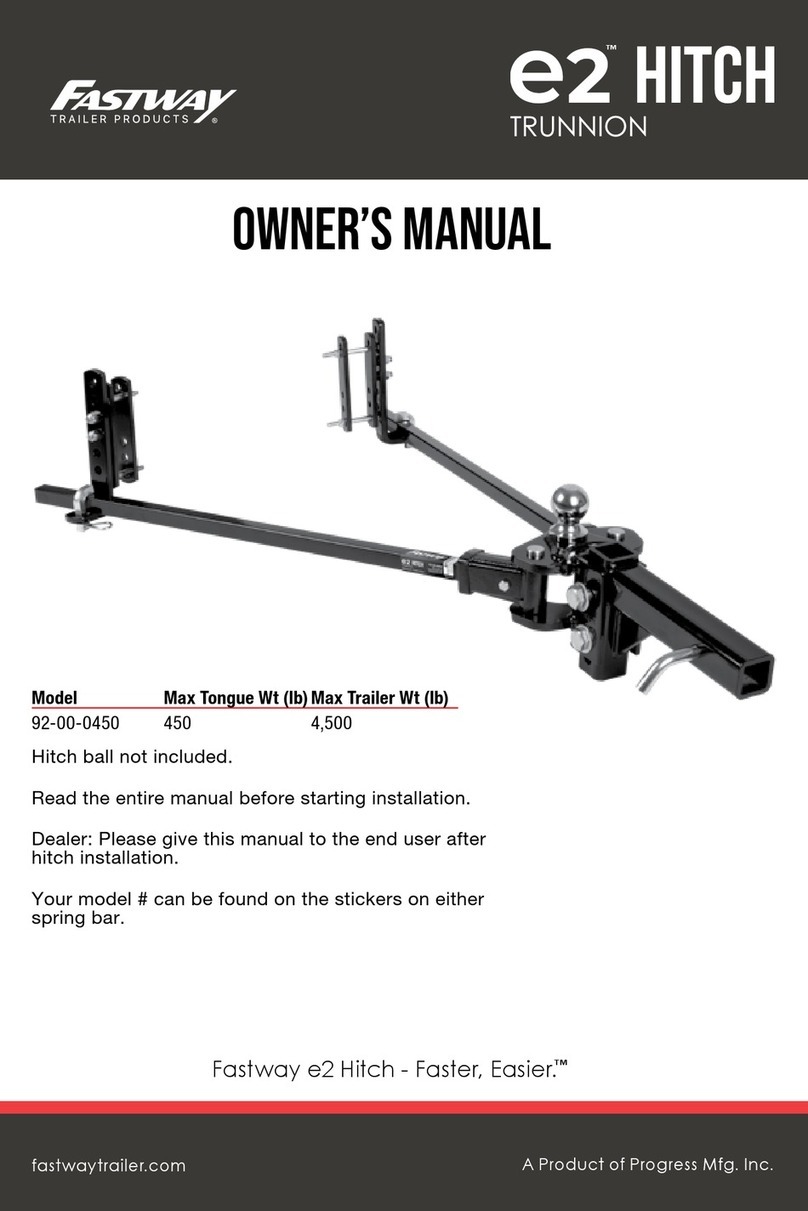

Fastway FLIP 88-00-4500 User manual

INSTALLATION AND

OPERATION INSTRUCTIONS

ID # Part # Description Qty.

1 88-01-6315 2" Spacer ring 1

2 88-01-6200 2" Stop washer 1

3 88-02-5117 3/8” flat washer zinc 2

4 88-02-5133 3/8" clevis clip zinc (R-clip) 1

588-01-4507 4” FLIP automatic jack foot 1

88-01-6600 6” FLIP automatic jack foot

6 88-02-5125 3/8” x 2-3/4" clevis pin zinc 1

PARTS BREAKDOWN 1

2

3

4

5

6

Fastway FLIP - Faster, Easier.™

Maximum lift capacity: 4,000 lb with both sides of trailer chocked

and parked on a grade less than 5% or 3˚.

For models:

88-00-4500 (4")

88-00-6500 (6")

fastwaytrailer.com Page 3

WARNING

CAUTION

• Read entire instruction manual before using this product. Failure

to do so can result in serious injury or property damage.

• Never exceed maximum 4,000 lb. lift capacity.

• Do not use the FLIP foot to support a trailer parked on grades

steeper than 5% (~3°).

• Both driver and passenger sides of the trailer must be securely

chocked when using the FLIP jack foot.

• Do not support trailer with jack foot placed on sloped ground or

debris. Jack foot base plate must be in complete contact with

ground.

• Support tongue weight with jack foot in the vertical position and

only with the jack resting on the support plate.

• Replace worn or faded safety label immediately.

• Do not install 2-1/4” model on a 2” jack.

• Install only on jack with properly positioned mounting hole.

• Always use adequate personal protective equipment when

installing including safety glasses.

• Avoid pinch points between jack extension, spacer ring, jack, and trailer

frame when retracting jack.

INSTALLATION INSTRUCTIONS

STEP 1

Park the trailer on a flat level surface, such as a driveway or

parking lot. Chock both sides of the trailer, and set the tow vehicle

parking brake. Keep the trailer coupled to the tow vehicle, or place

jack stands under the trailer tongue to support the trailer without

using the tongue jack. Disconnect the trailer plug, safety chains,

and safety breakaway cable from the tow vehicle and move them

out of the way.

Never exceed maximum 4,000 lb lift capacity.

Do not install the 2-1/4" model on a 2” jack (1-3/4" inside tube).

Install FLIP jack foot with trailer parked on level ground

both side-to-side and front-to-back.

STEP 2

Extend the jack slightly.

Inspect the jack foot

attachment hole at the

bottom of the inner tube

of the jack. If it is drilled

perpendicular to the trailer,

and between 1/2” and 1-1/4”

from the bottom of the tube,

no jack modifications are

required to install your FLIP

jack foot.

If the hole is NOT oriented correctly, is too low or too high, or if you

are installing your FLIP foot on a square jack, go first to STEP 3 to

prepare the jack, then continue with the installation of the FLIP jack

foot.

Hole at right angle to trailer and 1/2" to 1-1/4"

from bottom of tube needs no modification.

fastwaytrailer.com Page 5

Slide the spacer ring up onto the jack tube, followed by the stop

washer. The rings should slide freely up and down the tube. If the

tube is bent or damaged so as to not allow this, cut the damaged

end off of the jack, and follow STEP 3 to drill a new mounting hole in

the jack, or replace the jack.

NOTE: the spacer ring and stop washer are NOT needed when

using a square jack.

Hold the rings up above the FLIP foot, and slide the foot around

the jack tube so that the mounting holes and slots are aligned, with

the Flip label facing forward, toward the tow vehicle.

Slide a 3/8” washer over the mounting pin. Insert the pin through

the foot and jack. Slide the second 3/8” washer over the pin, and

push the R-clip through the pin to secure the foot in place.

Apply a small amount of lubricant to the top surface of the FLIP

foot. Wipe away any excess.

Lubricate

here

Test the FLIP foot operation by retracting the jack. Make sure the

FLIP foot rotates the full 90˚ to a right angle and is held tightly in

place (see STEP 6). If the jack reaches the end of travel before the

foot pivots fully and is held securely in place, you may need to add

an extra stop washer(s) to make up that distance, or drill a new

mounting hole following the instructions in STEP 3.

STEP 3

If your jack did not come with a mounting hole pre-drilled, or the

hole does not meet the requirements explained in STEP 2, you need

to drill a mounting hole in the bottom of your jack.

Retract the tongue jack far enough that you can fit a wood block

and Fastway FLIP jack foot under the inner jack tube. Place the

wood block on the ground, and place the jack foot on top, face

down with the base plate toward the back of the trailer.

1

2

Push the FLIP backward (1) so that

the inner jack tube is tight to the

support plate (2).

Make sure the FLIP is placed

parallel to the trailer before

drilling the guide holes.

3/16” pilot

hole guide

With the support plate of the FLIP pushed tightly against the jack

tube, slowly extend the jack into the back of the FLIP until it rests

firmly on the jack foot and block.

The drill guide holes should be perpendicular to the centerline of

the trailer and jack tube. They should be 1-1/4” from the bottom of

the tube, and centered on the tube.

Extend the jack until the weight

resting on the FLIP jack foot holds it

securely in place so that it will not move

while the guide holes are being drilled.

Use a 3/16” bit and drill a pilot hole on

each side of the jack tube using the pilot

guide holes on the sides of the jack foot.

fastwaytrailer.com Page 7

Retract the jack to a comfortable drilling height, and remove the

FLIP jack foot and the wood block.

Use a 3/8” drill bit to enlarge each pilot hole. Once the tube wall

has been penetrated, ream out the hole slightly to de-burr it and

open it up. Pass the drill bit all the way through the inner jack tube

to make sure there is a clean path for the pin all the way through

the tube. If drilling the holes leaves a burr or lip, use a file or grinder

to smooth the edge so the FLIP will pivot smoothly.

SQUARE JACK INSTALLATION

If you are installing the FLIP jack foot on a square, 2-1/4" jack with a

2" inner tube, you cannot use the guide holes pre-drilled in the FLIP

to locate the pilot holes as you can with a round jack. The pilot hole

must be drilled free hand, or by removing the jack from the trailer

and using a drill press.

Looking at the driver’s side face of the jack, measure up from the

bottom of the inner jack tube 1” and

scratch or draw a mark.

Measure half the distance between

the front and back faces of the tube and

scratch or draw a line that crosses the

first. This should be at 1” from both the

front and back on a 2” inner jack tube.

Repeat this process for the passenger

side.

Use a center punch to make a mark at

these locations on both sides of the jack.

Drill two 3/16” pilot holes on both sides using these punch marks

as a guide to start the hole.

Use a 3/8” bit to enlarge both pilot holes. Pass the drill bit

completely through the jack to make sure the installation pin will fit

smoothly.

Return to STEP 2 to continue the FLIP installation.

C

1”

2”

2”

INSTRUCTIONS FOR USE

Do not use the FLIP foot to support a trailer parked on grades

steeper than 5% (~3°).

Both driver and passenger sides of the trailer must be securely

chocked when using the FLIP jack foot.

Do not support trailer with jack foot resting on sloped ground

or debris .

Jack foot base plate must be in complete contact with ground.

STEP 4

When uncoupling your trailer, make sure that the trailer is parked

on fairly level ground. Pay special attention to the site when dry

camping to make sure the slope is not more than a 5% grade (3˚),

either side-to-side or front-to-back.

5%

3°

Do not use FLIP with trailer parked on a slope steeper

than a 5% grade, or 3 degrees.

Also make sure that the spot where the jack foot will rest is as level

as possible, and free from debris like sticks or stones that might

keep the jack foot from being completely supported.

Chock the wheels on both sides of the trailer securely. Disconnect

trailer plug, safety chains, and breakaway cable from the tow

vehicle. Uncouple the coupler, and extend the jack to raise the

coupler off the ball.

If using a weight distributing hitch, you may use the jack foot to

raise both the tow vehicle and trailer to make it easier to disconnect

fastwaytrailer.com Page 9

the hitch. Make sure to not exceed the 4,000 lb maximum lift

capacity. Once the spring arms are disengaged, lower the trailer

and tow vehicle back to a point where the tow vehicle is supporting

the trailer’s tongue weight. Uncouple the coupler, and extend the

jack to raise the coupler off the ball.

Support tongue weight with jack foot in the vertical position

and only with the jack resting on the support plate.

STEP 5

The FLIP jack foot is designed to

straighten automatically as more

weight is applied. At times it may be

helpful to move it forward slightly with

your foot to make sure it sits directly

below and in line with the jack so the

jack tube rests correctly against the

front of the jack foot and on top of the

support plate.

If the full tongue weight is placed

on the jack with the jack foot out of

position, the inner jack tube can bend,

resulting in improper function of the jack or jack foot. It may also

damage the jack foot or trailer.

If you must drop the trailer where there is not enough ground

clearance for the FLIP to operate correctly, simply remove the pin

and remove the FLIP from the jack.

Correct Incorrect

STEP 6

To couple your trailer, back the hitch ball under the coupler.

Retract the tongue jack until the coupler rests on the hitch ball.

Lock the coupler. If you are using a weight distributing hitch, extend

the jack to make engaging the weight distribution bars easier.

Retract the jack completely until the FLIP rotates up and out

of the way for towing. If the jack does not retract far enough to

accomplish this, you may take up the difference by adding an

additional stop washer(s) between the top of the FLIP foot and

the spacer ring. Alternatively, you may cut a small amount off the

bottom of the jack, then follow STEP 3 to drill a new mounting hole.

Do not force the jack handle after the jack has reached the top of

travel. Rotate it back slightly if necessary for towing. The FLIP foot

should be perpendicular to the jack for travel.

TOP-WIND JACK CAUTION

When traveling on very rough washboard roads for an extended

period of time, the vibration could cause the jack to unwind slightly,

allowing the FLIP foot to drop out of towing position. If you must

tow for an extended period on this type of road, remove the FLIP

foot from the jack, and replace it once your destination is reached.

Correct

With jack fully retracted

Incorrect

fastwaytrailer.com Page 11

Limited one year warranty

Progress Mfg. Inc. warrants, to the original purchaser, this product

against defects in materials and workmanship for a period of one

year from date of purchase. This warranty does not cover damage

due to normal wear and tear, misuse, neglect, abuse, or product

finish. Progress Mfg. Inc. reserves the right to repair or replace the

defective part(s) at their discretion. Replacement of product or

refund constitutes the fulfillment of all liabilities of Progress Mfg.

Inc. under this warranty. For questions about warranty coverage

and warranty authorization, please call (877) 523-9103. If warranty

repair or replacement is approved, send the entire product and

proof of purchase, shipping prepaid, to: Progress Mfg. Inc., 353

South 1100 West, Provo, UT 84601

Submit your warranty registration online at fastwaytrailer.com

Other Great Fastway Products!

The Fastway Zip™breakaway

cable’s coiled design keeps

your cable from dragging!

Fastway Trailer Products

353 South 1100 West, Provo, UT 84601

877-523-9103

fastwaytrailer.com

FLIN0518

© 2018 Copyright Progress Mfg. Inc., All rights reserved. All products patent pending.

STABILIZING WHEEL CHOCK

ONESTEP

™

The safest, most

secure way to chock

your trailer

This manual suits for next models

1

Table of contents

Other Fastway Jack manuals

Popular Jack manuals by other brands

Trailer Valet

Trailer Valet JX Series operating manual

FASANO TOOLS

FASANO TOOLS FG 719/2T manual

HAUL MASTER

HAUL MASTER 57953 Owner's manual & safety instructions

Mammuth

Mammuth ES1MH Installation and operating instructions

Clarke

Clarke Strong-Arm CTJ 50 Operating & maintenance instructions

Westward

Westward 5ML68A Operating instructions & parts manual

Omega

Omega 18207 Operating instructions & parts manual

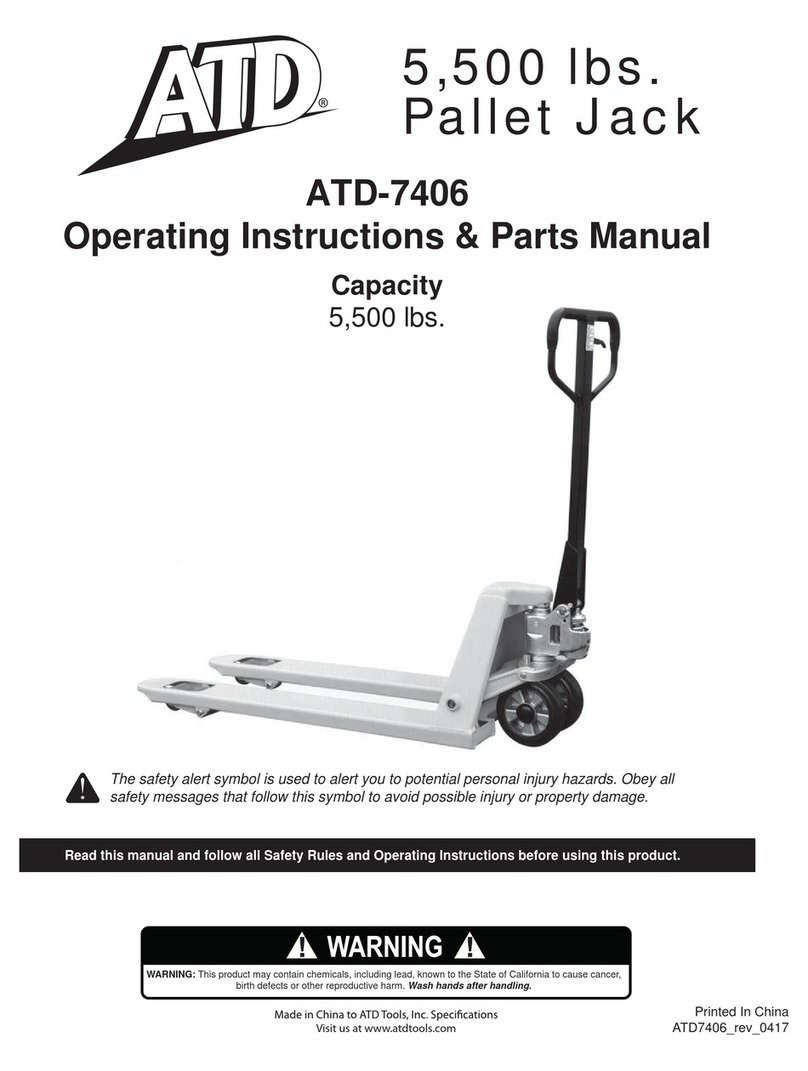

ATD Tools

ATD Tools ATD-7406 Operating instructions & parts manual

Sealey

Sealey YAJ20B.V3 instructions

OTC

OTC 1792 PARTS LIST & OPERATING INSTRUCTIONS

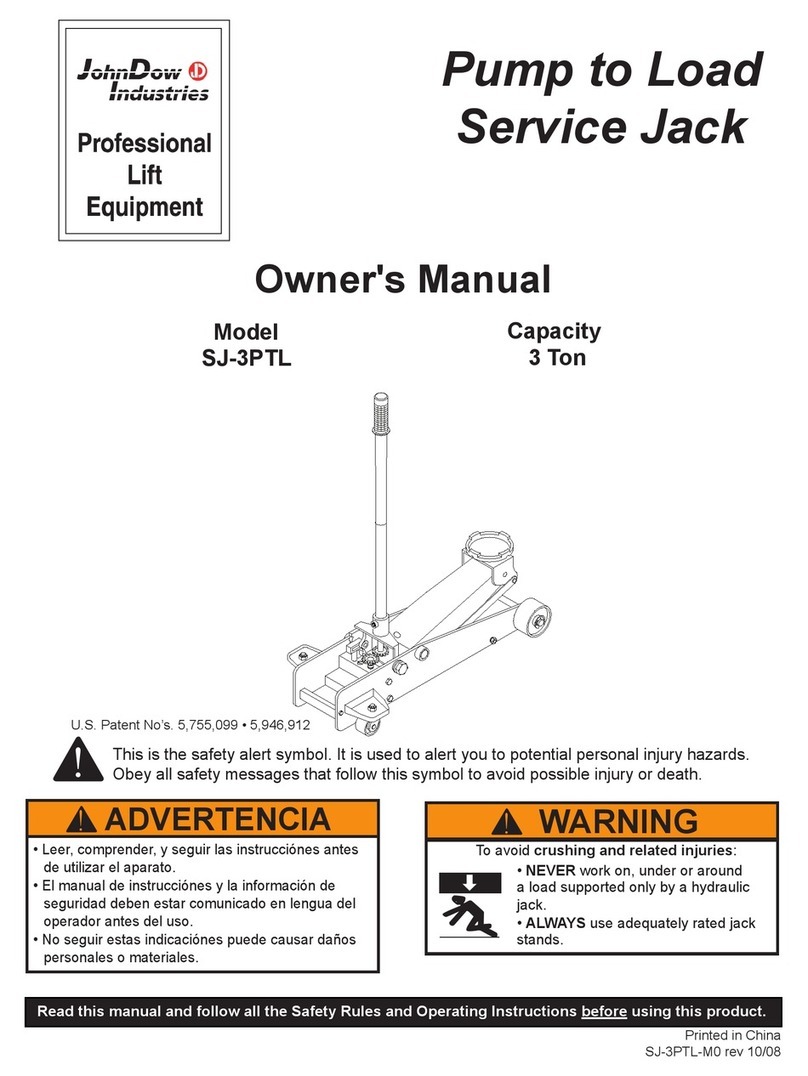

JohnDow Industries

JohnDow Industries SJ-3PTL owner's manual

Prolux

Prolux 430693 Original Operating Instruction